Abstract

Alternating current bipolar electropolymerization of 3,4-ethylenedioxythiophene (EDOT) was performed in the presence of benzoquinone in 1 mM tetrabutylammonium perchlorate/acetonitrile. The obtained poly(3,4-ethylenedioxythiophene) (PEDOT) was deposited at both ends of bipolar electrode (BPE) gold wires in a linear fiber form (φ=ca. 30 μm) owing to limited accessibility of the EDOT monomer to the active site of BPEs in a micro-space. The mechanism of the fiber formation is discussed. The linear growth of the PEDOT microfibers was demonstrated to be useful for application in circuit wiring.

Similar content being viewed by others

Introduction

Conducting polymers composed of π-conjugated aromatic moieties have interesting optoelectronic properties arising from electronic communication through the polymer main chain.1, 2 Electrochemical polymerization (or electropolymerization) of aromatic monomers such as pyrrole, thiophene and their derivatives is a promising method to obtain conducting polymers as deposited films on a working electrode (anode); monomers undergo anodic oxidation to the radical cation form, followed by radical coupling and deprotonation repeadedly.3, 4 For device applications and functional surfaces, it is important to control the morphology of these conducting polymers, and thus the fabrication of micro- or nanofiber (wire) conducting polymers has been often performed using templates such as porous membranes and seeds.5, 6, 7, 8

Recently, we demonstrated the facile and template-free synthesis of conducting polymer microfibers composed of poly(3,4-ethylenedioxythiophene) (PEDOT) on bipolar electrodes (BPEs) by using oxidative electropolymerization of 3,4-ethylenedioxythiophene (EDOT) and the sacrificial reduction of benzoquinone (BQ) to hydroquinone (Figure 1a).9 In a low concentration of a supporting electrolyte, a conducting material such as a metal wire behaves as a BPE when a sufficient voltage is applied between the driving electrodes outside of the BPE.10, 11, 12 The solution potential distribution generated in the electrolyte induces a potential difference at the interface of the solution and the metal wire, which is large enough to perform anodic and cathodic reactions on both sides of the wire (Figure 1b). Thus, the termini of a gold wire are platforms for the initial deposition of PEDOT. The highly conductive PEDOT acts as part of the BPE, and subsequent propagation of PEDOT deposition occurs in a dendritic manner owing to the diffusion-limited electrolytic system. Application of alternating current (AC) voltage also contributes to successful fiber formation. Furthermore, the gold wires can be bridged with PEDOT propagated until the opposing tips connect.

(a) Schematic of the electrochemical setup for alternating current (AC)-bipolar electrolysis, including oxidative polymerization of 3,4-ethylenedioxythiophene (EDOT) and sacrificial reduction of benzoquinone (BQ) with Au wires as bipolar electrodes (BPEs) set between driving Pt electrodes. (b) Schematic illustration of the principle of bipolar electrochemistry: the potential difference at the electrode/solution interface varies across the length of BPEs according to the potential gradient applied to the solution; thus, the overpotential (ΔVBPE) can drive redox reactions at both sides. (c) Illustration of the setup for this work, using a glass cover on top of BPEs to form a micro-space.

We investigated the synthesis of linear PEDOT fibers by using a micro-space to surround BPEs to limit the monomer supply to the active sites of the BPEs (Figure 1c). The control of fiber morphology (one-dimensional growth) is of importance for applications in organic devices.

Experimental Procedures

Materials

All chemicals and dry acetonitrile were obtained from commercial sources and used without further purification unless otherwise noted. Gold (Au) wires, platinum (Pt) plates and glass plates were purchased from commercial sources.

Instruments

AC power was supplied to the driving electrodes using a NF Corporation (Yokohama, Japan) EC1000SA AC power source. Optical microscope observations were conducted using an Olympus (Tokyo, Japan) SZX10, and scanning electron microscopy observations were performed using a Shimadzu (Kyoto, Japan) SS-550.

Estimation of potential difference between anodic and cathodic poles of BPE

The minimum potential value to drive Au wires as BPEs (ΔVmin) can be estimated from the difference between the oxidation and reduction potentials of the corresponding species, Eox and Ered.13

In this system, the oxidation of EDOT and the reduction of BQ occurred at both poles of the BPE. The ΔVmin was estimated using the onset potentials as measured by linear sweep voltammetry.

The electric field transmission efficiency (θ), a ratio of electric field inside the cell (ɛeff) and the applied electric field between driving electrodes (ɛ) is defined as follows.13, 14

It follows that

and

where Um is the potential difference between two microelectrodes with distance dm, and E is the applied voltage between a pair of driving electrodes with distance dE (Figure 2). A potential value applied at both poles of the BPE (ΔVBPE) can be estimated as follows.

where dBPE is the length of the BPE. The value of ΔVBPE was stable over the time scale of the electrolysis.

Cell configuration

Au wires (φ=30 μm, length=10 mm) were placed 0.5 mm apart. To form a micro-space, a glass plate was placed on top of the Au wires, and shorter pieces of Au wire were used as spacers to control the thickness of the micro-space. The experimental configuration is shown in Figure 1c. Pt plates (20 × 20 cm2) were used as driving electrodes, and 50 mM of EDOT, 5 mM of BQ and 1 mM of tetrabutylammonium perchlorate (Bu4NClO4) in acetonitrile was used as an electrolyte.

Results and Discussion

AC-bipolar electropolymerization of EDOT in micro-space

An acetonitrile solution containing 1 mM of Bu4NClO4, 50 mM of EDOT and 5 mM of BQ was added to a bipolar electrochemical setup equipped with a pair of driving electrodes and Au wires (φ=30 μm, 10 mm length). At this low concentration of supporting electrolyte, the voltage applied between the driving electrodes generates a potential drop in the solution that can induce an interfacial potential difference between both poles of the Au wires (BPEs) that allows redox reactions at these poles. When applying 45 V between the driving electrodes under these conditions, the value of ΔVBPE on the Au wires is estimated from the equation in Figure 2 as ~6.4 V, which is above the ΔVmin. The electro-oxidative polymerization of EDOT and sacrificial reduction of BQ occurred simultaneously. An AC power supply (15 Hz) gives rise to iterative electropolymerization of EDOT from both poles of BPEs and also has a key role in the specific, fiber-like deposition of PEDOT, in combination with the effect of electrophoresis under bipolar electrochemical conditions.9

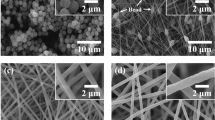

To control the propagation behavior of PEDOT fibers in this system, we designed a space around the BPEs. A glass plate (1 mm thick) was introduced to cover the BPEs with a micro-space. The space was tuned using short pieces (1 mm length) of Au wire with a diameter of 30 μm. The Au wires at the corners are not active as a BPE under the electrolytic conditions owing to their short length. Figure 3 shows optical microscope and scanning electron microscopy images of the PEDOT fibers obtained with this setup. PEDOT fibers grew from the terminals of the BPEs in a similar manner to that in previous work, but their morphology was different, that is, linear-shaped fibers bridged the 0.5 mm gap for 30 s (Figure 3a). The scanning electron microscopy images of the fibers reveal several buds on the fibers (Figure 3b), suggesting that under electrolytic conditions, fibers could potentially branch into a dendritic shape, but that this morphology is limited by the short supply of monomers around the fibers owing to the spatial limitation imposed by the cover glass.

To further understand the effect of micro-space on controlling fiber growth, we changed the thickness of the micro-space (D=30, 50, 80 and 100 μm). When the micro-space was thicker, small branches appeared on the fibers (Figure 4), indicating that monomers could approach even after formation of the main fibers. Similar behavior was observed when the concentration of EDOT monomer was increased (Figure 4). When a higher-frequency AC voltage was applied, fibers with smaller diameters were obtained. A lower-frequency condition produced fibers with larger diameters. This influence of frequency on fiber morphology was described in our previous report.9 In contrast, the number of fibers did not vary with frequency, as only one fiber grew from each BPE end in this system.

Mechanism

A proposed mechanism for the linear growth of PEDOT fibers in a micro-space is described in Figure 5. The basic principle is identical to our previous report. PEDOT clusters are formed at the edges of the BPEs, followed by the sequential deposition of clusters in a fiber-like manner owing to the electrophoretic effect of the charged (p-doped) PEDOT under the influence of the AC external electric field. The buds on the PEDOT fibers are active sites for further electropolymerization. However, in the present study, access to EDOT monomer at the active sites of the PEDOT fibers is limited owing to the micro-space around the BPEs. After the EDOT monomer is consumed during bipolar electropolymerization, the local concentration of monomer near the generated fibers is too low to allow further branching, but there is still enough EDOT surrounding the terminus of the fibers; consequently, the PEDOT fiber propagates linearly without branching in the micro-space.

After the formation of the linear PEDOT fiber from the edge of the Au wire with a micro-space, further electropolymerization was conducted without a cover glass so that monomers were accessible to the PEDOT fiber and BPE from all directions. In this situation, additional PEDOT fiber branches propagated from the buds as well as from the terminus of the trunk, resulting in a dendritic morphology (Figure 6). This result supports the fiber formation mechanism discussed above, in which the feeding (diffusion) of monomer has a key role in determining the morphology of PEDOT fibers.

Schematic illustration and optical microscope images of poly(3,4-ethylenedioxythiophene) (PEDOT) fibers prepared sequentially; (1) linear PEDOT fiber formed in a micro-space; and (2) PEDOT branches propagated after removal of the glass cover. A full color version of this figure is available at Polymer Journal online.

Circuit wiring

We have previously reported the potential use of PEDOT fibers propagated from BPE terminals for circuit wiring, namely the selective connection of Au wires along the direction of the electric field. However, dendritic fiber growth is not directly suitable for connecting BPEs. In this context, linear fiber growth using a micro-space was applied to circuit wiring. The setup for this experiment was prepared as shown in Figure 7, and the external electric field was applied to BPEs from different directions. The linear PEDOT fibers propagated only from the terminals of the activated BPEs, resulting in the successful connection of W1 and W2 (Figure 7a). For the conventional dendritic fibers, the tips of the fibers from W1 reached to W3 and W4 when the gaps of the BPEs were maintained at 0.5 mm. The finely controlled line of the PEDOT fibers connecting the desired BPEs has advantages for circuit wiring applications. When the external electric field was applied from the opposite direction, connection of W1/W3 and W2/W4 was achieved with the linear PEDOT fibers (Figure 7b).

Conclusion

We have demonstrated that the AC-bipolar electropolymerization of EDOT in a micro-space produces PEDOT fibers with a one-dimensional morphology from both edges of the Au wires used as BPEs. In this situation, the micro-space around the BPEs and generated PEDOT fibers effectively limited access to EDOT monomer from the side of the fibers, but allowed access at the fiber terminus, leading to the formation of linear PEDOT fibers. This method can connect BPE wires with linear PEDOT fibers and control the growth direction using an external electric field, which is a more effective method than current dendritic growth methods for producing PEDOT fibers. The rapid and selective wiring of conductors with organic microfibers is of potential interest for applications in organic devices.

References

Skotheim, T. A. & Reynolds, J. R. Handbook of Conducting Polymers 3rd edn (CRC, Boca Raton, FL, 2007).

Inzelt, G. Conducting Polymers–A New Era of Electrochemistry, (Springer, Heidelberg, 2008).

Heinze, J., Frontana-Uribe, B. A. & Ludwigs, S. Electrochemistry of conducting polymers–persistent models and new concepts. Chem. Rev. 110, 4724–4771 (2010).

Beaujuge, P. M. & Reynolds, J. R. Color control in π-conjugated organic polymers for use in electrochromic devices. Chem. Rev. 110, 268–310 (2010).

Martin, C. R. Nanomaterials: a membrane-based synthetic approach. Science 266, 1961–1966 (1994).

Li, C., Bai, H. & Shi, G. Conducting polymer nanomaterials: electrosynthesis and applications. Chem. Soc. Rev. 38, 2397–2409 (2009).

Zhang, X. & Manohar, S. K. Bulk synthesis of polypyrrole nanofibers by a seeding approach. J. Am. Chem. Soc. 126, 12714–12715 (2004).

Shi, W., Liang, P., Ge, D., Wang, J. & Zhang, Q. Starch-assisted synthesis of polypyrrole nanowires by a simple electrochemical approach. Chem. Commun. 2414–2416 (2007).

Koizumi, Y., Shida, N., Ohira, M., Nishiyama, H., Tomita, I. & Inagi, S. Electropolymerization on wireless electrodes towards conducting polymer microfibre networks. Nat. Commun. 7, 10404 (2016).

Loget, G., Zigah, D., Bouffler, L., Sojic, N. & Kuhn, A. Bipolar electrochemistry: from materials science to motion and beyond. Acc. Chem. Res. 46, 2513–2523 (2013).

Fosdick, S. E., Knust, K. N., Scida, K. & Crooks, R. M. Bipolar electrochemistry. Angew. Chem. Int. Ed. 52, 10438–10456 (2013).

Inagi, S. Fabrication of gradient polymer surfaces using bipolar electrochemistry. Polym. J. 48, 39–44 (2016).

Loget, G., Roche, J. & Kuhn, A. True bulk synthesis of Janus objects by bipolar electrochemistry. Adv. Mater. 24, 5111–5116 (2012).

Koizumi, Y., Shida, N., Tomita, I. & Inagi, S. Bifunctional modification of conductive particles by iterative bipolar electrodeposition of metals. Chem. Lett. 43, 1245–1247 (2014).

Acknowledgements

This research was supported by JSPS KAKENHI (Grant Numbers JP26708013 and JP15H00724).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ohira, M., Koizumi, Y., Nishiyama, H. et al. Synthesis of linear PEDOT fibers by AC-bipolar electropolymerization in a micro-space. Polym J 49, 163–167 (2017). https://doi.org/10.1038/pj.2016.100

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.100

This article is cited by

-

Theoretical modeling of dendrite growth from conductive wire electro-polymerization

Scientific Reports (2022)

-

Growth and design strategies of organic dendritic networks

Discover Materials (2022)

-

Analog programing of conducting-polymer dendritic interconnections and control of their morphology

Nature Communications (2021)

-

Site-selective anisotropic modification of conductive objects by bipolar electropolymerization

Polymer Journal (2019)

-

Pulsed electropolymerization of PEDOT enabling controlled branching

Polymer Journal (2019)