Abstract

Poly(trimethylene carbonate) (PTMC) is a biodegradable polymer that is used in biomedical materials. It has been reported that its combination with hydrophilic groups such as oligo(ethylene glycol) and poly(ethylene glycol) (PEG) would offer a useful approach to vary the PTMC properties. Diblock copolymers and triblock copolymers, as well as star-shaped polymers, are most often prepared through ring-opening polymerization of hydroxyl groups in PEG at chain ends. Additional components are employed through the combination of trimethylene carbonate (TMC) and ethylene glycol units. In addition, monomer design and polymer reactions are available. These polymers, including TMC and EG units, are useful in preparing various nanostructures and, therefore, have the potential for application in biomedical materials.

Similar content being viewed by others

Introduction

Trimethylene carbonate (TMC) is a six-membered ring, and poly(TMC) (PTMC) is synthesized by ring-opening polymerization.1, 2, 3, 4 It is possible to obtain PTMC by anionic polymerization, cationic polymerization and enzyme polymerization. In 2007, Hedrick and coworkers5 reported TMC polymerization with an organic compound as a catalyst. When PTMC is to be used as a biocompatible material, a polymerization system employing organic compounds is ideal. PTMC has been used in biomedical applications because of its biodegradable properties,6, 7 which result from a hydrolysis reaction on the polymer main chain. It is noteworthy that no acidic organic compounds are generated from hydrolysis, which is suitable for biomedical applications. The softness of PTMC is due to its low glass transition temperature. Furthermore, its reaction rate is different from that of polyester, and this property is frequently used in biomedical applications. The physical properties of PTMC are also important as they enable a wide variety of biomedical uses. To vary the properties of PTMC, many approaches have been developed that involve introducing functional groups, and some relevant reviews have been published.8, 9

Combinations with ethylene glycol (EG) are also important in biomedical applications. Poly(EG) (PEG) is one of the most commonly used biomedical polymers due to its specific properties. Oligo(EG) (OEG), which has a shorter polymer main chain, is used for the same reason. The hydrophilic nature of EG and OEG and their ability to suppress the adsorption of non-specific proteins are attractive properties for biomedical applications. Monomer and polymer designs are essential to produce various biomaterials, although there are some size limitations in actual use (Figure 1). Copolymers with hydrophobic polymers form nano-sized structures, such as micelles, nanoparticles and nanofibers, by self-assembly, leading to the production of various biomaterials.

Illustration of scale difference from molecular design to biomedical application. (a) Monomer design with functional moieties and biocompatible structure. (b) Polymer structure control, including factors involving tacticity, block and random copolymers, graft polymers and star copolymers. (c) Nano structure control through polymer assembly, such as micelle and segregated films. (d) Cell experiments, such as particles for drug delivery and gene delivery. (e) Biomaterials for medical application to tissues and organs.

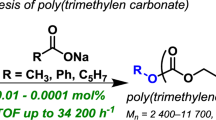

In this focused review, we analyzed PTMC derivatives possessing EG units. The use of EG as an initiator for TMC and TMC’s derivative polymerization were beyond the scope of the current review. We focused on reference papers describing biomedical applications of PTMC and EG units. Sections were created based on the polymer structure as follows: (i) diblock polymers, (ii) triblock polymers, (iii) star-shaped polymers, (iv) copolymers with more than three monomer units and (v) TMC derivatives with EG units (Figure 2). Some studies were relevant to more than one section.

Structures of PTMC derivatives with EG units, together with other monomer units. (a) Diblock polymers. (b) Triblock polymers. (c) Star-shaped polymers. (d) Copolymers including more than three monomer units. (e) TMC derivatives as a monomer. EG, ethylene glycol; PTMC, poly(trimethylene carbonate); TMC, trimethylene carbonate.

Diblock copolymers of PTMC with EG units

There are some approaches to preparing diblock copolymers of PTMC and EG units, such as the post-polymerization of TMC after epoxide polymerization10 and cationic polymerization using a PEG initiator.11 Usually, diblock copolymers of PTMC and PEG are synthesized by polymerization of TMC with one chain end protected PEG as an initiator; monomethylether-PEG (mPEG) is most commonly utilized as the initiator (Figure 3a). Diblock copolymers of PTMC and PEG possess both hydrophilic and hydrophobic moieties, and they are frequently used as nanostructured building block units and film preparations. For example, mPEG–PTMC has been used as a reflexive interface and compared with cholesterol–PTMC with selective adsorption.12 It has also been used to regulate protein immobilization and adsorption on a film surface.13

mPEG–PTMC forms micelles and nanoparticles that are incorporated into hydrophobic compounds, such as pyrene,14 dexamethasone15 and paclitaxel.16 Interestingly, thermo-sensitive transition causes the nanostructure change from a film to micelle-like nanoparticles.17

Some functional groups can be introduced into the PTMC side groups. For example, urea groups have been introduced into the TMC side group, and doxorubicin has been observed interacting through hydrogen bonding at the hydrophilic TMC moiety.18 The mPEG–PTMC derivative forms micelles with large doxorubicin loading. Similarly, benzyl groups have been introduced into TMC derivatives used to load anti-cancer drugs with micelle formation.19, 20 After the introduction of a cationic amino group and an anionic carboxylic group into TMC, micelles have been formed by polyion complexation together with the incorporation of proteins. These micelles have been applied in endosomal release applications.21

Micelles have also been used in targeted drug delivery (Figure 2c). Fang and coworkers22 introduced c(RGDyK) peptides into mPEG–PTMC for use on integrin-rich tumors (Figure 3b). They also applied micelles using paclitaxel as the anti-cancer drug in a mouse model.23, 24 In another example of the functionalization of mPEG–PTMC nanoparticles, glucose has been used for dual target delivery.25 In this manner, the biomedical application of mPEG–PTMC has been tested in vivo (Figure 2e). For example, the accumulation of micelles has been observed in mice by a near-infrared florescence technique, using a mPEG–PTMC derivative with cholesterol groups at TMC moieties.26

It is possible to create structures larger than nanoparticles and micelles. Grijpma and coworkers27 have examined the crosslinking of PEG and PTMC. mPEG–PTMC has been employed as an elastic tissue engineering scaffold created by a ultraviolet light crosslinking reaction.27 They have cultured human mesenchymal stem cells using this scaffold. In another approach, three-arm PTMC with methacrylate at the chain end has been copolymerized with mPEG methacrylate and PEG-dimethacrylates.28 mPEG–PTMC has also been applied to thermo-sensitive gelation. Jeong and coworkers29 have reported on an injectable hydrogel that takes advantage of the transition temperature to form a gel in rats. The thermosensitivity of mPEG–TMC has been investigated with cryo-TEM, revealing vesicles, spherical micelles and tubular nanostructures.30

Triblock copolymers of PTMC with EG units

Triblock copolymers have mostly been prepared by ring-opening polymerization of TMC using PEG as an initiator because TMC possesses two hydroxyl groups at both chain ends. Diethylene glycol has also been used as an initiator.31, 32 Conventional polymerization systems using Sn(Oct)2, organic compounds and cationic compounds11 as catalysts have been reported. Microwave-assisted ring-opening polymerization has been applied to prepare PTMC–PEG–PTMC using PEG as an initiator.33

Using PEG (Mn=6800) as an initiator, seven types of triblock copolymers have been prepared by changing the mole ratio of PEG and TMC during polymerization.34, 35 Thermal properties such as glass transition temperature (Tg) and melting temperature (Tm) have been recorded. Dynamic contact angles increasing from 27° to 74° when the mole fraction of TMC units in the copolymer increased from 64% to 97%, respectively, have also been reported. Endo and coworkers36 investigated the solubility of PTMC–PEG–PTMC, showing that it is soluble in CHCl3, THF and DMF (Figure 3c). It was found to be insoluble in water and hexane, and its solubility in MeOH depends on its composition. In that study, block copolymers were synthesized with TMC and PEG surfactants using Triton X, which possesses a PEG structure in the polymer backbone.

The benzyloxy group has been introduced into the side chain at PTMC moieties in PTMC–PEG–PTMC.37 An assay has revealed their low cytotoxicity and their enhanced biodegradation. Triblock copolymers have been found to produce micelles by dialysis treatment.38 Dimethyl groups have been introduced into side chains at PTMC moieties in PTMC–PEG–PTMC.39 The copolymer has been found to form nanoparticles at a range between 20 and 70 nm, and these nanoparticles are used as a drug carrier for indomethacin.

Other than the side groups, the initiating and terminating reagents have been designed.40 When a mixture of Sn(Oct)2 and PEG was used as an initiator, PTMC–PEG–PTMC was obtained and subsequent addition of trimesoyl chloride produced polymer networks that were applied in the production of drug-loading materials using 5-fluorouracil.

The behavior of core-shell type nanoparticles has been investigated with 9-chloromethyl anthracene as a fluorescence probe.41 This probe has been applied in a drug delivery system using the anti-cancer drug methotrexane.

Grijpma and coworkers42 employed PTMC–PEG–PTMC triblock copolymers for hydrogel preparation using an approach similar to the process used with diblock copolymers.27, 28 The soft hydrogel structures have been improved using a solution of methacrylate-functionalized PTMC–PEG–PTMC in colloidal dispersions of clay nanoparticles (Figure 3d). The compressive modulus and toughness values improved to 67 kPa and 200 kJ m−3, respectively, whereas the soft gels had values of <15 kPa and 25 kJ m−3, respectively, without the addition of nanoparticles. Similarly, a methacrylate-functionalized PTMC–PEG–PTMC at both chain ends has been used as a cartilage of cell cluster by photo-encapsulation.43 This hydrogel system could be used to prepare scaffolds for the repair of cartilage tissue. For strength modification, the double network of chitosan and PTMC–PEG–PTMC has been reported.44 These double network gels have shown fracture stress at 3.4 MPa under physiological conditions, whereas the single network gels have shown fracture stress at only 1.6 MPa. The ionic strength influenced the fracture stress of the double network gel. On the other hand, the use of microcavitary hydrogels for scaffold using PTMC–PEG–PTMC has been reported with gelatin as micro-spherical porogens.45 In that study, photo polymerization was used for hydrogel preparation, and it was found that the cell density in the hydrogel increased 5.6-fold after 21 days.

Waymouth and coworkers46 designed structurally dynamic hydrogels. The TMC derivative bearing pendant dithiolane was polymerized with PEG as an initiator (Figure 3e). The reversible ring opening of the pendant 1,2-dithiolanes caused dynamic crosslinking behavior, resulting in self-healing and the creation of an injectable material.

Star-shaped copolymers of PTMC with EG units

Structural design of polymers is important because it sometimes influences their properties and functionality. Branch and star-shaped PTMCs with EG units have been prepared and branched initiators have typically been used.

Matsuda et al.47 have synthesized star-shaped copolymers of CL and TMC with triol and tetraol as initiators. The chain ends of star-shaped copolymers have been conjugated with coumarin, which can be dimerized under photo irradiation, resulting in a polymer with photocuring characteristics (Figure 4a). The hydrolysis behavior of photocured biodegradable solid copolymers have been investigated under various pH conditions.48 Topological measurements have also been made by scanning electron microscopy, atomic force microscopy and observations using fluorescein staining. Coumarin end-capped copolymers have been used for customized and precision-shaped scaffolds or templates.49 The photo-cross-linkability has been improved by introducing phenylazide derivatives at the chain ends.50 When a phenylazide derivative with the RGD tripeptide sequence is used, cell adhesion increased. For this series of photocurable copolymers, the photo reactivity has also been investigated and compared with that of similarly synthesized star-shaped copolymers of CL and TMC with acrylate at the chain ends.51 Similarly, various copolymers of CL and TMC have been synthesized with methacrylate at the chain ends.28, 52, 53 These copolymers have been used in the development of high lubricity materials in biomaterials that have moving parts. Friction coefficients of relevant biomaterials have been examined in the relevant studies.

As the photoreactive moiety, fumaric acid monoethyl ester has also been used for star-shaped copolymers of TMC and CL.54, 55 The reactivity of the fumarate end groups has been observed to be sufficient to obtain gels with up to 96% reactivity as determined by ultraviolet irradiation. Such non-toxic compounds are suitable for applications in tissue engineering.

Kim and coworkers56 have reported on four-armed star-shaped copolymers composed of PEG and PTMC (Figure 4b). They studied the thermal properties and critical micelle concentration of these four-armed star-shaped copolymers of PEG and PTMC, as well as of four-armed copolymers of PEG with each of CL, 1,4-dioxan-2-one and poly(lactide-co-glycolide). These star-shaped copolymers were successfully synthesized by an activator system.57, 58, 59 The obtained micelles were effectively analyzed with nuclear magnetic resonance, dynamic light scattering, atomic force microscopy and fluorescence techniques.

Ring compounds bearing several hydroxyl groups have been employed as initiators for the polymerization and copolymerization of TMC derivatives. For example, polyoxyethylene sorbitan monolaurate (Tween 20) has been used as an initiator.60 In that study, the arms of the copolymer of CL and TMC play a role in the development of the hydrophobic properties of the star-shaped amphiphilic block copolymer, which is a property of interest in its use as an environmentally friendly surfactant. Cyclodextrin was also used as an initiating moiety for the copolymer arms of CL, TMC derivatives and EG units (Figure 4c).61 Azido groups have been introduced into the TMC side chain, where they reacted with the alkyne groups by a click reaction. Alkyne groups have been introduced into ibuprofen and the micelles from the star-shaped copolymers have been used as a prodrug material. Citric acid, tartaric acid and mucic acid have been utilized for the core of a star-shaped copolymer.62 After the amide formation of these acids with monomethyl poly(EG)amine (Mn=5000), the residual hydroxyl groups were used as initiators. When diethanolamine was used as a starting compound, the amino group was connected with acryloyl monomethyloxy-poly(EG) and the residual two hydroxyl groups were used for the polymerization of TMC,63 resulting in Y-shaped block copolymers. Critical micelle concentration and cytotoxicity have been investigated by changing the molecular weights of the PEG and PTMC moieties. Eight-armed PEG, possessing eight hydroxyl groups at the terminal end, has been used as the core of a star-shaped copolymer.64 In this case, after the eight PEG chains were connected to the core, TMC was polymerized and acryloyl groups were connected at the eight chain ends. Using ultraviolet irradiation, the nanoparticles were stabilized and then observed by SEM. This eight-armed copolymer produced hydrogels by ultraviolet irradiation at a concentration >5% w/v.

Catalyst switching systems using tri- or tetra-hydroxyl compounds as initiators have been used to produce star-shaped block copolymers with PEG and PTMC.65 In these systems, epoxides were polymerized during the first step in the presence of a strong phosphazene base promoter. Then, an excess of diphenyl phosphate was introduced for the second polymerization of TMC. Metal-free organic catalysts for ring-opening polymerization of TMC were used to prepare star-shaped amphiphilic copolymers, which were applied to achieve an efficient incorporation of the anti-cancer drug doxorubicin.66

Overall, using a star-shaped initiator is one of the most popular approaches to preparing star-shaped copolymers of TMC and EG, although many different combinations of molecular weight and ratio have been used. Some specific functional groups are introduced into star-shaped copolymers to increase the efficiency of drug incorporation because most of the studies are focused on creating efficient drug delivery systems with micelle formation.

PTMC copolymers with EG units including more than three monomers

There are many studies on copolymers with TMC and EG units using additional monomers other than those utilizing chain end-capping and TMC derivatives. It is a good approach for controlling micelle formation and the properties of the materials produced.

mPEG-(PCL/PTMC)

The random copolymers using CL and TMC as a hydrophobic moiety with mPEG as a hydrophilic moiety are known (Figure 5a). Préat and coworkers67 reported that 14C-labeled mPEG-(PCL/PTMC) was employed for the controlled drug release of risperidone after forming micelles. Similarly, mPEG-(PCL/PTMC) using PEG (Mn=550–2000) formed micelles that increased the solubility of lipophilic drugs and were designed to be applied in the oral delivery of poorly water-soluble drugs.68 The transport mechanism of mPEG-(PCL/PTMC) micelles across the intestinal barrier has been investigated.69 Using paclitaxel as an anti-cancer drug, the micelle of mPEG-(PCL/PTMC) has been evaluated by examining the viability of HeLa cells.70 As other examples, ketoprofen, furosemide71 and curcumin72 have been employed to increase the solubility of micelles in mPEG-(PCL/PTMC). The detailed structure of micelles prepared by mPEG-(PCL/PTMC) has been investigated by electron paramagnetic resonance and fluorescence.73 In addition, passive diffusion through the lipid bilayer of mPEG-(PCL/PTMC) has been examined using artificial membranes and liposomes.74 Furthermore, the safety of the micelles of mPEG-(PCL/PTMC) has been thoroughly investigated both in vitro and in vivo.75

After the copolymerization of CL and TMC derivatives with dibromomethyl groups at the TMC side chain using mPEG as an initiator, azido groups have been introduced into the block copolymer, which enables the click reaction along the entire block copolymer.76, 77, 78 Interestingly, propagyl 3,3′-ditiopropionate has been used as a cross-linker to create dual degradable nanoparticles.76

PEG–(PCL/PTMC)

When PEG is used as an initiator of the random copolymerization of CL and TMC, (PCL/PTMC)–PEG–(PCL/PTMC) is obtained (Figure 5b). For example, PEG has been used as an initiator for ring-opening polymerization of TMC and CL, followed by introduction of acryloyl groups79 or phenylazide groups80 at the chain ends. In a study using acryloyl groups,79 stereolithographic microarchitectures were prepared by a computer-aided surface photo irradiation technique. The resulting copolymers were used for in vivo drug delivery systems. Bone morphogenetic protein 6 and transforming growth factor beta-3 were also released in a controlled manner from the hydrogel matrix.81

By controlling the ratio of TMC to CL, thermogelled (PCL/PTMC)–PEG–(PCL/PTMC) has been obtained.82 TMC at 25–40% of CL has been found to create a polymer that gels in a physiologically important temperature range of 10–50 °C.

Others

Random copolymerization of TMC and lactic acid (LA) with mPEG as an initiator has been shown to produce an amphiphilic block copolymer (Figure 5c),83, 84 which has been used with micelles to incorporate the anti-cancer drug 9-Nitro-20(S)-camptothecin. Similarly, the benzoyl group has been introduced into TMC to be copolymerized with LA using mPEG as an initiator.85 The benzoyl group can be deprotected to introduce a hydroxyl group into the polymer main chain, resulting in a reaction with biotin. Applying different protection approaches, benzyl groups with two hydroxyl groups have also been reported.86 Azido groups have been introduced into the TMC side moiety in a copolymer of LA with mPEG as the initiator87 and in side groups.88 Taking advantage of the click reaction, several micelles have been prepared and confirmed by TEM, such as g-palmitate.89 Copolymers of PEG and cyclic acetal have been used as initiators of TMC polymerization where PTMC–(PEG-cyclic acetal)–PTMC was obtained, which showed pH sensitivity (Figure 5d).90 Disulfide-coupled bis-(cyclic carbonate) as a functional TMC derivative has been copolymerized with TMC using mPEG as the initiator, producing micelles used in the controlled release of doxorubicin.91

More complicated block copolymers have been synthesized as a series of flexible poly(ether carbonate urethane)ureas.92 Urethane structure has also been introduced into copolymers with TMC, EG and LA units by diisocyanate dimerization and trimerization.93, 94, 95 Multi-block copolymers of TMC and EG units using PEG and propylene glycol have been applied as thermo gelling materials for effective drug delivery.96 This composition influenced the thermal and elastic properties. Using PEG-propylene oxide-PEG (Pluronic) as an initiator,97 TMC has been polymerized followed by construction of urethane moieties using 1,4-diisocyanatobutane. This polymer was employed to facilitate cell adhesion through Arg-Gly-Asp (RGD).

It is interesting to use natural compounds possessing the molecular recognition property. For example, a peptide has been introduced into a copolymer of TMC and EG and the peptide’s function to target cellular uptake was transferred to the molecule.98 Similarly, d-glucose has been introduced into a copolymer of TMC and EG together with paclitaxel to afford controlled release properties.99

TMC derivatives with EG units

The chemical and physical properties of polymers depend on their structure. For that reason, it is possible to gain an understanding of the characteristics of polymers from their homopolymer structure. To add functionality using this approach, specific monomer design is required. We categorized these monomers into two groups: those with a reactive connection and those that are directly introduced.

Reactive units on the side chain

A vinyl sulfone group has been introduced into TMC via thioether as a carbonate monomer (Figure 6a).100 That monomer provided a vinyl sulfone functionalized biodegradable polymer, which enabled selective Michel-type conjugation. For example, PEG-SH has been made connectable, and as a result biodegradable coatings were created under aqueous conditions. Dibromo groups have been introduced into TMC, and after polymerization they were converted into azido groups (Figure 6b).101 Alkyne-modified PEG was then connected to the PTMC backbone. Micelles with a stick-shaped morphology and a spherical morphology were prepared. An alkyne group has been introduced into TMC via an ester as a TMC monomer.102 It was possible to connect azo group-modified PEG to the polymer (Figure 6c).

A carboxylic acid group has been introduced into TMC as a carbonate monomer.103 Both PEG and mPEG have been connected by ester bonding, creating hydrogels (Figure 6d), and their porous structure was analyzed by SEM. Recently, the hemocompatibility of hydrated aliphatic polymers with subtle differences in their backbone structure was evaluated, and this study included TMC (Figure 6e).104 Carboxylic acid-modified TMC can be used in crosslinking structures with the diamine compound.105, 106

Direct introduction of EG units in the side chain

OEG units have been introduced into TMC directly (Figure 6f).107 In this study, the chain length of OEG varied by one unit (TMCM-MOE1OM), three units (TMCM-MOE3OM) and four units (TMCM-MOE4OM). An aqueous solution of the homopolymers showed a lower critical solution temperature (LCST). Interestingly, the LCST of poly(TMCM-MOE3OM) (Mn=7000–11000) was 33 °C, approximately body temperature, whereas the LCST of poly(TMCM-MOE4OM) was 72 °C. TMCM-MOE1OM has been used for block copolymerization, resulting in a specific segregation film in aqueous conditions.108, 109

Conclusion

Micelle formation using block copolymers with a hydrophobic moiety for TMC units and a hydrophilic moiety for EG units has been thoroughly investigated. Among the many comonomers, CL and LA were often used in various ratios to tune the resulting properties. Thermo-sensitive properties of OEG or PEG have also been of interest because they can enable the formation of gels.

To add to the combination of TMC and EG, additional chemical functionality has also been explored, including photoresponsive, crosslinking and prodrug properties. The introduction of specific functionalities affects the overall material properties. Much of the required functionality has been achieved through copolymerization using many different chemical species.

On the other hand, variation and irregular distribution of chemical structures are unavoidable due to the nature of the polymerization procedure. The functionalized TMC derivative as a monomer can confer well-defined and homogenous properties to materials, leading to easy tuning of material properties.

References

Keul, H., Bacher, R. & Hocker, H. Anionic ring opening polymerization of 2,2-dimethyltrimethylene carbonate. Macromol. Chem. Phys. 187, 2579–2589 (1986).

Ariga, T., Takata, T. & Endo, T. Cationic ring-opening polymerization of cyclic carbonates with alkyl halides to yield polycarbonate without the ether unit by suppression of elimination of carbon dioxide. Macromolecules 30, 737–744 (1997).

Matsumura, S., Tsukada, K. & Toshima, K. Enzyme-catalyzed ring-opening polymerization of 1,3-dioxan-2-one to poly(trimethylene carbonate). Macromolecules 30, 3122–3124 (1997).

Huang, Q., Shen, Z., Zhang, Y., Shen, Y., Shen, L. & Yuan, H. Ring-opening copolymerization of Trimethylene carbonate and D,L-lactide by rare earth chloride. Polym. J. 30, 168–170 (1998).

Nederberg, F., Lohmeijer, B. G. G., Leibfarth, F., Pratt, R. C., Choi, J., Dove, A. P., Waymouth, R. M. & Hedrick, J. L. Organocatalytic ring opening polymerization of Trimethylene carbonate. Biomolecules 8, 153–160 (2007).

Ueda, H. & Tabata, Y. Polyhydroxyalkanonate derivatives in current clinical applications and trials. Adv. Drug Deliv. Rev. 55, 501–518 (2003).

Konan, S. & Haddad, E. S. A clinical review of bioabsorbable interference screws and their adverse effects in anterior cruciate ligament reconstruction surgery. Knee 16, 6–13 (2009).

Albertsson, A. C. & Liu, Y. Comparison between physical blending and copolymerization of poly(trimethylene carbonate) and poly(adipic anhydride) with special regard to compatibility, morphology and degradation. J. Macromol. Sci. 8, A34 1457–1482 (1997).

Tempelaar, S., Mespouille, L., Coulembier, O., Dubois, P. & Dove, A. P. Synthesis and post-polymerisation modifications of aliphatic poly(carbonate)s prepared by ring-opening polymerisation. Chem. Soc. Rev. 42, 1312–1336 (2013).

Zhao, J., Pahovnik, D., Gnanou, Y. & Hadjichristidis, N. A "catalyst switch" Strategy for the sequential metal-free polymerization of epoxides and cyclic Esters/Carbonate. Macromolecules 12, 3814–3822 (2014).

Hyun, H., Kim, M. S., Khang, G. & Lee, H. B. Ring-opening polymerization of trimethylene carbonate by poly (ethylene glycol) in the presence of HCl-Et2O as a monomer activator. J. Polym. Sci. A Polym. Chem. 13, 4235–4241 (2006).

Watanabe, J., Kotera, H. & Akashi, M. Reflexive interfaces of poly(trimethylene carbonate)-based polymers: Enzymatic degradation and selective adsorption. Macromolecules 24, 8731–8736 (2007).

Terao, K., Miyake, J., Watanabe, J. & Ikeda, Y. Regulation of protein loading on poly(trimethylene carbonate), poly(l- lactic acid), and their copolymer: Effect of surface enrichment by polymer crystallinity. Mater. Sci. Eng. C 4, 988–993 (2012).

Hyun, H., Lee, J. W., Cho, J. S., Kim, Y. H., Lee, C. R., Kim, M. S., Khang, G. & Lee, H. B. Polymeric nano-micelles using poly(ethylene glycol) and poly(trimethylene carbonate) diblock copolymers as a drug carrier. Colloids Surf. A Physicochem. Eng. Asp. 131–135 (2008).

Zhang, Z., Grijpma, D. W. & Feijen, J. Poly(trimethylene carbonate) and monomethoxy poly(ethylene glycol)- block-poly(trimethylene carbonate) nanoparticles for the controlled release of dexamethasone. J. Control. Release 3, 263–270 (2006).

Jiang, X., Xin, H., Sha, X., Gu, J., Jiang, Y., Law, K., Chen, Y., Chen, L., Wang, X. & Fang, X. PEGylated poly(trimethylene carbonate) nanoparticles loaded with paclitaxel for the treatment of advanced glioma: In vitro and in vivo evaluation. Int. J. Pharm. 2, 385–394 (2011).

Zhang, Z., Grijpma, D. W. & Feijen, J. Thermo-sensitive transition of monomethoxy poly(ethylene glycol)- block-poly(trimethylene carbonate) films to micellar-like nanoparticles. J. Control. Release 1, 57–63 (2006).

Kim, S. H., Tan, J. P. K., Nederberg, F., Fukushima, K., Colson, J., Yang, C., Nelson, A., Yang, Y. Y. & Hedrick, J. L. Hydrogen bonding-enhanced micelle assemblies for drug delivery. Biomaterials 31, 8063–8071 (2010).

Helou, M., Miserque, O., Brusson, J.-M., Carpentier, J.-F. & Guillaume, S. M. Organocatalysts for the controlled "immortal" ring-opening polymerization of six-membered-ring cyclic carbonates: A metal-free, green process. ChemBioChem. 46, 13805–13813 (2010).

Zeng, F., Liu, J. & Allen, C. Synthesis and characterization of biodegradable poly(ethylene glycol)- block-poly(5-benzyloxy-trimethylene carbonate) copolymers for drug delivery. Biomacromolecules 5, 1810–1817 (2004).

Li, S., Meng, F., Wang, Z., Zhong, Y., Zheng, M., Liu, H. & Zhong, Z. Biodegradable polymersomes with an ionizable membrane: Facile preparation, superior protein loading, and endosomal pH-responsive protein release. Eur. J. Pharm. Biopharm. 1, 103–111 (2012).

Jiang, X., Sha, X., Xin, H., Chen, L., Gao, X., Wang, X., Law, K., Gu, J., Chen, Y., Jiang, Y., Ren, X., Ren, Q. & Fang, X. Self-aggregated pegylated poly (trimethylene carbonate) nanoparticles decorated with c(RGDyK) peptide for targeted paclitaxel delivery to integrin- rich tumors. Biomaterials 35, 9457–9469 (2011).

Jiang, X., Xin, H., Gu, J., Xu, X., Xia, W., Chen, S., Xie, Y., Chen, L., Chen, Y., Sha, X. & Fang, X. Solid tumor penetration by integrin- mediated pegylated poly(trimethylene carbonate) nanoparticles loaded with paclitaxel. Biomaterials 6, 1739–1746 (2013).

Jiang, X., Sha, X., Xin, H., Xu, X., Gu, J., Xia, W., Chen, S., Xie, Y., Chen, L., Chen, Y. & Fang, X. Integrin-facilitated transcytosis for enhanced penetration of advanced gliomas by poly(trimethylene carbonate)-based nanoparticles encapsulating paclitaxel. Biomaterials 12, 2969–2979 (2013).

Jiang, X., Xin, H., Ren, Q., Gu, J., Zhu, L., Du, F., Feng, C., Xie, Y., Sha, X. & Fang, X. Nanoparticles of 2-deoxy-d-glucose functionalized poly(ethylene glycol)- co-poly(trimethylene carbonate) for dual-targeted drug delivery in glioma treatment. Biomaterials 1, 518–529 (2014).

Lee, A. L. Z., Venkataraman, S., Sirat, S. B. M., Gao, S., Hedrick, J. L. & Yang, Y. Y. The use of cholesterol-containing biodegradable block copolymers to exploit hydrophobic interactions for the delivery of anticancer drugs. Biomaterials 6, 1921–1928 (2012).

Bat, E., Kothman, B. H. M., Higuera, G. A., Van Blitterswijk, C. A., Feijen, J. & Grijpma, D. W. Ultraviolet light crosslinking of poly(trimethylene carbonate) for elastomeric tissue engineering scaffolds. Biomaterials 33, 8696–8705 (2010).

Van Bochove, B., Rongen, J. J., Hannink, G., Van Tienen, T. G., Buma, P. & Grijpma, D. W. Grafting a lubricious coating onto photo-crosslinked poly(trimethylene carbonate). Polym. Adv. Technol. 26, 1428–1432 (2015).

Kim, S. Y., Kim, H. J., Lee, K. E., Han, S. S., Sohn, Y. S. & Jeong, B. Reverse thermal gelling PEG - PTMC diblock copolymer aqueous solution. Macromolecules 15, 5519–5525 (2007).

Kim, S. Y., Lee, K. E., Han, S. S. & Jeong, B. Vesicle-to-spherical micelle-to-tubular nanostructure transition of monomethoxy-poly(ethylene glycol)- poly(trimethylene carbonate) diblock copolymer. J. Phys. Chem. B 25, 7420–7423 (2008).

Kim, J. H., Lee, J. H. & Chung, D. J. Synthesis and properties of triblock copolymers from L-lactide and trimethylene carbonate. Polym. J. 32, 1056–1059 (2000).

Kim, J. H. & Lee, J. H. Preparation and properties of poly(l-lactide)-block-poly(trimethylenecarbonate) as biodegradable thermoplastic elastomer. Polym. J. 34, 203–208 (2002).

Liao, L., Zhang, C. & Gong, S. Preparation of poly(trimethylene carbonate)-block-poly(ethylene glycol)-block-poly(trimethylene carbonate) triblock copolymers under microwave irradiation. React. Funct. Polym. 3, 751–758 (2008).

Wang, H., Dong, J. H. & Qiu, K. Y. Synthesis and characterization of ABA-type block copolymer of poly(trimethylene carbonate) with poly(ethylene glycol): Bioerodible copolymer. J. Polym. Sci. A Polym. Chem. 5, 695–702 (1998).

Wang, H., Dong, J. H., Qiu, A. Y. & Gu, Z. W. Studies on properties and drug delivery systems of PTMC-b-PEG-b-PTMC block copolymers. J. Macromol. Sci. Pure Appl. Chem. 5, 811–820 (1998).

Morinaga, H., Ochiai, B., Mori, H. & Endo, T. Synthesis and characterization of block copolymers by metal- And solvent-free ring-opening polymerization of cyclic carbonates initiated from PEG-based surfactants. J. Polym. Sci. A Polym. Chem. 6, 1985–1996 (2006).

Feng, J., Wang, X.-L., He, F. & Zhuo, R.-X. Non-catalyst synthesis of functionalized biodegradable polycarbonate. Macromol. Rapid Commun. 6, 754–758 (2007).

Wang, Y. X., Feng, J., He, F. & Zhuo, R. X. Metal-free synthesis of amphiphilic functional polycarbonates. Chin. Chem. Lett. 12, 158–1530 (2007).

Fan, L., Ni, X.-F. & Shen, Z.-Q. Controllable synthesis and micelles preparation of tri-block copolymers from 2,2-dimethyl-trimethylene carbonate and ethylene glycol. Colloid Polym. Sci. 3, 327–333 (2008).

Kricheldorf, H. R., Fechner, B., Shikanov, A. & Domb, A. Polylactones 57. Biodegradable networks based on A–B–A triblock segments containing poly(ethylene glycol)s—Syntheses and drug release properties. Biomacromolecules 4, 950–955 (2003).

Zhang, Y. & Zhuo, R.-X. Synthesis and drug release behavior of poly (trimethylene carbonate)-poly (ethylene glycol)-poly (trimethylene carbonate) nanoparticles. Biomaterials 14, 2089–2094 (2005).

Sharifi, S., Blanquer, S. B. G., Van Kooten, T. G. & Grijpma, D. W. Biodegradable nanocomposite hydrogel structures with enhanced mechanical properties prepared by photo- crosslinking solutions of poly(trimethylene carbonate)- poly(ethylene glycol)-poly(trimethylene carbonate) macromonomers and nanoclay particles. Acta Biomater. 12, 4233–4243 (2012).

Zhang, C., Sangaj, N., Hwang, Y., Phadke, A., Chang, C.-W. & Varghese, S. Oligo(trimethylene carbonate)-poly(ethylene glycol)-oligo(trimethylene carbonate) triblock-based hydrogels for cartilage tissue engineering. Acta Biomater. 9, 3362–3369 (2011).

Cao, Z., Yang, Q., Fan, C., Liu, L. & Liao, L. Biocompatible, ionic-strength-sensitive, double-network hydrogel based on chitosan and an oligo(trimethylene carbonate)-poly(ethylene glycol)-oligo(trimethylene carbonate) triblock copolymer. J. Appl. Polym. Sci. 35, 42459(1/7)–42459(7/7) (2015).

Fan, C. & Wang, D.-A. A biodegradable PEG-based micro-cavitary hydrogel as scaffold for cartilage tissue engineering. Eur. Polym. J. 72, 651–660 (2015).

Barcan, G. A., Zhang, X. & Waymouth, R. M. Structurally dynamic hydrogels derived from 1,2-dithiolanes. J. Am. Chem. Soc. 17, 5650–5653 (2015).

Matsuda, T., Mizutani, M. & Arnold, S. C. Molecular design of photocurable liquid biodegradable copolymers. 1. Synthesis and photocuring characteristics. Macromolecules 3, 795–800 (2000).

Mizutani, M. & Matsuda, T. Photocurable liquid biodegradable copolymers: In vitro hydrolytic degradation behaviors of photocured films of coumarin-endcapped poly(ɛ-caprolactone-co-trimethylene carbonate). Biomacromolecules 2, 249–255 (2002).

Mizutani, M. & Matsuda, T. Liquid photocurable biodegradable copolymers: In vivo degradation of photocured poly(ɛ-caprolactone-co-trimethylene carbonate). J. Biomed. Mater. Res. 1, 53–60 (2002).

Mizutani, M., Arnold, S. C. & Matsuda, T. Liquid, phenylazide-end-capped copolymers of ɛ-caprolactone and trimethylene carbonate: Preparation, photocuring characteristics, and surface layering. Biomacromolecules 3, 668–675 (2002).

Kwon, I. K. & Matsuda, T. Photo-polymerized microarchitectural constructs prepared by microstereolithography (μSL) using liquid acrylate-end-capped trimethylene carbonate-based prepolymers. Biomaterials 14, 1675–1684 (2005).

Matsuda, T., Kwon, I. K. & Kidoaki, S. Photocurable biodegradable liquid copolymers: Synthesis of acrylate-end-capped trimethylene carbonate-based prepolymers, photocuring, and hydrolysis. Biomacromolecules 2, 295–305 (2004).

Mizutani, M. & Matsuda, T. Liquid acrylate-endcapped biodegradable poly(ɛ-caprolactone-co-trimethylene carbonate). I. Preparation and visible light-induced photocuring characteristics. J. Biomed. Mater. Res. 3, 387–394 (2002).

Grijpma, D. W., Hou, Q. & Feijen, J. Preparation of biodegradable networks by photo-crosslinking lactide, ɛ-caprolactone and trimethylene carbonate-based oligomers functionalized with fumaric acid monoethyl ester. Biomaterials 16, 2795–2802 (2005).

Jansen, J., Mihov, G., Feijen, J. & Grijpma, D. W. Photo-crosslinked biodegradable hydrogels prepared from fumaric acid monoethyl ester-functionalized oligomers for protein delivery. Macromol. Biosci. 5, 692–702 (2012).

Hyun, H., Cho, J. S., Kim, B. S., Lee, J. W., Kim, M. S., Khang, G., Park, K. & Lee, H. B. Comparison of micelles formed by amphiphilic star block copolymers prepared in the presence of a nonmetallic monomer activator. J. Polym. Sci. A Polym. Chem. 6, 2084–2096 (2008).

Kim, M. S., Hyun, H., Kim, B. S., Khang, G. & Lee, H. B. Polymeric nano-micelles as drug carrier using polyethylene glycol and polytrimethylene carbonate linear and star-shaped block copolymer. Curr. Appl. Phys. 6, 646–650 (2008).

Cho, J. S., Kim, B. S., Hyun, H., Youn, J. Y., Kim, M. S., Ko, J. H., Park, Y. H., Khang, G. & Lee, H. B. Precise preparation of four-arm-poly(ethylene glycol)-block-poly(trimethylene carbonate) star block copolymers via activated monomer mechanism and examination of their solution properties. Polymer 7, 1777–1782 (2008).

Kim, B. S., Oh, J. M., Cho, J. S., Lee, S. H., Lee, B., Khang, G., Lee, H. B. & Kim, M. S. Comparison of micelles formed by amphiphilic poly(ethylene glycol)-b-poly(trimethylene carbonate) Star block copolymers. J. Polym. Sci. A Polym. Chem. 4, 1706–1712 (2009).

Morinaga, H., Ochiai, B. & Endo, T. Synthesis and properties of star-shaped polymers by the ring-opening polymerization of cyclic carbonate initiated with a trifunctional, poly(ethylene glycol)-based surfactant. J. Polym. Sci. A Polym. Chem. 22, 6633–6639 (2006).

Gou, P.-F., Zhu, W.-P. & Shen, Z.-Q. Drug-grafted seven-arm amphiphilic star poly(ɛ-caprolactone-co- carbonate)-b-poly(ethylene glycol)s based on a cyclodextrin core: Synthesis and self-assembly behavior in water. Polym. Chem. 8, 1205–1214 (2010).

Ben-Shabat, S., Kumar, N. & Domb, A. J. PEG-PLA block copolymer as potential drug carrier: preparation and characterization. Macromol. Biosci. 12, 1019–1025 (2006).

Zhang, H.-H., Huang, Z. I.-Q., Sun, B.-W., Guo, J.-X., Wang, J.-L. I. & Chen, Y.-Q. Y-shaped poly(ethylene glycol) and poly(trimethylene carbonate) amphophilic copolymer: Synthesis and for drug delivery. J. Polym. Sci. A Polym. Chem. 24, 8131–8140 (2008).

Buwalda, S. J., Perez, L. B., Teixeira, S., Calucci, L., Forte, C., Feijen, J. & Dijkstra, P. J. Self-assembly and photo-cross-linking of eight-armed PEG-PTMC star block copolymers. Biomacromolecules 7, 2746–2754 (2011).

Zhao, J., Pahovnik, D., Gnanou, Y. & Hadjichristidis, N. One-pot synthesis of linear- and three-arm star-tetrablock quarterpolymers via sequential metal-free ring-opening polymerization using a "catalyst switch" strategy. J. Polym. Sci. A Polym. Chem. 2, 304–312 (2015).

Yang, C., Liu, S. Q., Venkataraman, S., Gao, S. J., Ke, X., Chia, X. T., Hedrick, J. L. & Yang, Y. Y. Structure-directing star-shaped block copolymers: Supramolecular vesicles for the delivery of anticancer drugs. J. Control. Release 208, 93–105 (2015).

Mathot, F., Van Beijsterveldt, L., Preat, V., Brewster, M. & Arien, A. Intestinal uptake and biodistribution of novel polymeric micelles after oral administration. J. Control. Release 111, 47–55 (2006).

Ould-Ouali, L., Arien, A., Rosenblatt, J., Nathan, A., Twaddle, P., Matalenas, T., Borgia, M., Arnold, S., Leroy, D., Dinguizli, M., Rouxhet, L., Brewster, M. & Preat, V. Biodegradable self-assembling PEG-copolymer as vehicle for poorly water-soluble drugs. Pharm. Res. 9, 1581–1590 (2004).

Mathot, F., Des Rieux, A., Arien, A., Schneider, Y.-J., Brewster, M. & Preat, V. Transport mechanisms of mmePEG750P(CL-co-TMC) polymeric micelles across the intestinal barrier. J. Control. Release 3, 134–143 (2007).

Danhier, F., Magotteaux, N., Ucakar, B., Lecouturier, N., Brewster, M. & Preat, V. Novel self-assembling PEG-p-(CL-co-TMC) polymeric micelles as safe and effective delivery system for Paclitaxel. Eur. J. Pharm. Biopharm. 2, 230–238 (2009).

Latere Dwan'Isa, J.-P., Rouxhet, L., Brewster, M. E., Preat, V. & Arien, A. Spontaneously self-assembled micelles from poly(ethylene glycol)-b-poly(ɛ-caprolactone-co-trimethylene carbonate) for drug solubilization. Pharmazie 3, 235–240 (2008).

Yang, X., Li, Z., Wang, N., Li, L., Song, L., He, T., Sun, L., Wang, Z., Wu, Q., Luo, N., Yi, C. & Gong, C. Curcumin-encapsulated polymeric micelles suppress the development of colon cancer in vitro and in vivo. Sci. Rep. 5, 10322 (2015).

Beghein, N., Rouxhet, L., Dinguizli, M., Brewster, M. E., Arien, A., Preat, V., Habib, J. L. & Gallez, B. Characterization of self-assembling copolymers in aqueous solutions using Electron Paramagnetic Resonance and Fluorescence spectroscopy. J. Control. Release 2, 196–203 (2007).

Mathot, F., Schanck, A., Van Bambeke, F., Arien, A., Noppe, M., Brewster, M. & Preat, V. Passive diffusion of polymeric surfactants across lipid bilayers. J. Control. Release 120, 79–87 (2007).

Yang, X., Cao, D., Wang, N., Sun, L., Li, L., Nie, S., Wu, Q., Liu, X., Yi, C. & Gong, C. In vitro and in vivo safety evaluation of biodegradable self-assembled monomethyl poly (ethylene glycol)-poly (ɛ-caprolactone)-poly (trimethylene carbonate) micelles. J. Pharm. Sci. 1, 305–313 (2014).

Wang, Y., Du, H., Gao, L., Ni, H., Li, X., Zhu, W. & Shen, Z. Reductively and hydrolytically dual degradable nanoparticles by "click" crosslinking of a multifunctional diblock copolymer. Polym. Chem. 5, 1657–1663 (2013).

Cajot, S., Lecomte, P., Jerome, C. & Riva, R. Novel functional degradable block copolymers for the building of reactive micelles. Polym. Chem. 4, 1025–1037 (2013).

Zhu, W., Wang, Y., Cai, X., Zha, G., Luo, Q., Sun, R., Li, X. & Shen, Z. Reduction-triggered release of paclitaxel from in situ formed biodegradable core-cross-linked micelles. J. Mater. Chem. B 15, 3024–3031 (2015).

Matsuda, T. & Mizutani, M. Liquid acrylate-endcapped biodegradable poly(ɛ-caprolactone-co-trimethylene carbonate). II. Computer-aided stereolithographic microarchitectural surface photoconstructs. J. Biomed. Mater. Res. 3, 395–403 (2002).

Mizutani, M., Arnold, S. C. & Matsuda, T. Liquid, phenylazide-end-capped copolymers of ɛ-caprolactone and trimethylene carbonate: preparation, photocuring characteristics, and surface layering. Biomacromolecules 4, 668–675 (2002).

Sukarto, A. & Amsden, B. G. Low melting point amphiphilic microspheres for delivery of bone morphogenetic protein-6 and transforming growth factor-β3 in a hydrogel matrix. J. Control. Release 1, 53–62 (2012).

Hild, F., Brelot, L. & Dagorne, S. Novel N,O,N-supported tetracoordinate aluminum complexes for the highly controlled and immortal ROP of trimethylene carbonate (TMC) under mild conditions: Access to narrowly disperse poly-TMC and derived copolymers. Organometallics 20, 5457–5462 (2011).

Gao, J., Ming, J., He, B., Fan, Y., Gu, Z. & Zhang, X. Preparation and characterization of novel polymeric micelles for 9-nitro-20(S)-camptothecin delivery. Eur. J. Pharm. Sci. 34, 85–93 (2008).

Gao, J., Guo, Y., Gu, Z. & Zhang, X. Micellization and controlled release properties of methoxy poly(ethylene glycol)-b-poly(D,L-lactide-co-trimethylene carbonate). Front. Chem. China 1, 104–109 (2009).

Xie, Z., Guan, H., Lu, C., Chen, X. & Jing, X. Synthesis and characterization of novel biotinylated biodegradable poly(ethylene glycol)-b-poly(carbonate-lactic acid) copolymers. Acta Biomater. 6, 635–641 (2005).

Aguirre-Chagala, Y. E., Santos, J. L., Herrera-Najera, R. & Herrera-Alonso, M. Organocatalytic copolymerization of a cyclic carbonate bearing protected 2,2-bis(hydroxymethyl) groups and d,l-lactide. Effect of hydrophobic block chemistry on nanoparticle properties. Macromolecules 15, 5871–5881 (2013).

Hu, X., Yan, L., Xiao, H., Li, X. & Jing, X. Application of microwave-assisted click chemistry in the preparation of functionalized copolymers for drug conjugation. J. Appl. Polym. Sci. 5, 3365–3373 (2013).

Wang, Y., Yan, L., Li, B., Qi, Y., Xie, Z., Jing, X., Chen, X. & Huang, Y. Protein-resistant biodegradable amphiphilic graft copolymer vesicles as protein carriers. Macromol. Biosci. 9, 1304–1313 (2015).

Zhang, X., Zhang, Z., Zhong, Z. & Zhuo, R. Amphiphilic block-graft copolymers poly(ethylene glycol)-b-(polycarbonates- g-palmitate) prepared via the combination of ring-opening polymerization and click chemistry. J. Polym. Sci. A Polym. Chem. 13, 2687–2696 (2012).

Kaihara, S., Fisher, J. P. & Matsumura, S. Chemo-enzymatic synthesis of degradable PTMC-b-PECA-b-PTMC triblock copolymers and their micelle formation for pH-dependent controlled release. Macromol. Biosci. 6, 613–621 (2009).

Yi, X., Zhang, Q., Dong, H., Zhao, D., Xu, J.-Q., Zhuo, R. & Li, F. One-pot synthesis of crosslinked amphiphilic polycarbonates as stable but reduction-sensitive carriers for doxorubicin delivery. Nanotechnology 39, 395602 (2015).

Wang, F., Li, Z., Lannutti, J. L., Wagner, W. R. & Guan, J. Synthesis, characterization and surface modification of low moduli poly(ether carbonate urethane)ureas for soft tissue engineering. Acta Biomater. 8, 2901–2912 (2009).

Trinca, R. B. & Felisberti, M. I. Segmented polyurethanes based on poly(l-lactide), poly(ethylene glycol) and poly(trimethylene carbonate): Physico-chemical properties and morphology. Eur. Polym. J. 63, 77–86 (2015).

Trinca, R. B., Abraham, G. A. & Felisberti, M. I. Electrospun nanofibrous scaffolds of segmented polyurethanes based on PEG, PLLA and PTMC blocks: Physico-chemical properties and morphology. Mater. Sci. Eng. C 56, 511–517 (2015).

Trinca, R. B. & Felisberti, M. I. Effect of diisocyanates and chain extenders on the physicochemical properties and morphology of multicomponent segmented polyurethanes based on poly(l-lactide), poly(ethylene glycol) and poly(trimethylene carbonate). Polym. Int. 10, 1326–1335 (2015).

Loh, X. J., Guerin, W. & Guillaume, S. M. Sustained delivery of doxorubicin from thermogelling poly(PEG/PPG/PTMC urethane)s for effective eradication of cancer cells. J. Mater. Chem. 39, 21249–21256 (2012).

Tang, S., Zhao, J., Xu, S., Li, J., Teng, Y., Quan, D. & Guo, X. Bone induction through controlled release of novel BMP-2-related peptide from PTMC11-F127-PTMC11 hydrogels. Biomed. Mater. 1, 015008 (2012).

Wang, X., Yang, Y., Jia, H., Jia, W., Miller, S., Bowman, B., Feng, J. & Zhan, F. Peptide decoration of nanovehicles to achieve active targeting and pathology-responsive cellular uptake for bone metastasis chemotherapy. Biomater. Sci. 7, 961–971 (2014).

Jiang, X., Xin, H., Gu, J., Du, F., Feng, C., Xie, Y. & Fang, X. Enhanced antitumor efficacy by d-glucosamine-functionalized and paclitaxel-loaded poly(ethylene glycol)-co-poly(trimethylene carbonate) polymer nanoparticles. J. Pharm. Sci. 5, 1487–1496 (2014).

Wang, R., Chen, W., Meng, F., Cheng, R., Deng, C., Feijen, J. & Zhong, Z. Unprecedented access to functional biodegradable polymers and coatings. Macromolecules 15, 6009–6016 (2011).

Zhu, W., Wang, Y., Zhang, Q. & Shen, Z. Amphiphilic PEG-grafted poly(ester-carbonate)s: Synthesis and diverse nanostructures in water. J. Polym. Sci. A Polym. Chem. 22, 4886–4893 (2011).

Truong, V., Blakey, I. & Whittaker, A. K. Hydrophilic and amphiphilic polyethylene glycol-based hydrogels with tunable degradability prepared by "click" chemistry. Biomacromolecules 12, 4012–4021 (2012).

Nederberg, F., Trang, V., Pratt, R. C., Mason, A. F., Frank, C. W., Waymouth, R. M. & Hedrick, J. L. New ground for organic catalysis: A ring-opening polymerization approach to hydrogels. Biomacromolecules 11, 3294–3297 (2007).

Fukushima, K., Tsai, M., Ota, T., Haga, Y., Matsuzaki, K., Inoue, Y. & Tanaka, M. Evaluation of the hemocompatibility of hydrated biodegradable aliphatic carbonyl polymers with a subtle difference in a backbone structure on the basis of intermediate water concept and surface hydration. Polym. J. 47, 469–473 (2015).

Takemura, K., Ajiro, H., Fujiwara, T. & Akashi, M. Oil gels with a chemically cross-linked copolymer of a trimethylene carbonate derivative and l-lactide: Preparation and stereocomplex formation within gels. RSC Adv. 63, 33462–33465 (2014).

Takemura, K., Ajiro, H., Fujiwara, T. & Akashi, M. A Novel substrate for testosterone: biodegradable and biocompatible oil gel. Polym. J. 47, 460–463 (2015).

Ajiro, H., Takahashi, Y. & Akashi, M. Thermosensitive biodegradable homopolymer of trimethylene carbonate derivative at body temperature. Macromolecules 6, 2668–2674 (2012).

Ajiro, H., Takahashi, Y., Akashi, M. & Fujiwara, T. Polylactide block copolymers using trimethylene carbonate with methoxyethoxy side groups for dual modification of hydrophilicity and biodegradability. Macromol. Biosci. 10, 1315–1320 (2012).

Ajiro, H., Takahashi, Y., Akashi, M. & Fujiwara, T. Surface control of hydrophilicity and degradability with block copolymers composed of lactide and cyclic carbonate bearing methoxyethoxyl groups. Polymer 16, 3591–3598 (2014).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ajiro, H., Haramiishi, Y., Chanthaset, N. et al. Polymer design using trimethylene carbonate with ethylene glycol units for biomedical applications. Polym J 48, 751–760 (2016). https://doi.org/10.1038/pj.2016.35

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.35