Abstract

The androgen testosterone is less expensive than bone morphogenetic proteins and has been shown to effectively repair bone fractures. However, testosterone is lipophilic and insoluble in water, making it difficult to load into hydrogels, which are common drug carriers. In this study, we prepared a novel oil gel composed of poly(L-lactide) and a poly(trimethylene carbonate) derivative and studied the release of testosterone from the gel. Dimethyl sulfoxide and dimethyl carbonate, which are organic solvents with relatively low toxicities, were used as dispersion media. The oil gel in dimethyl sulfoxide released testosterone faster than that in dimethyl carbonate. In addition, the dimethyl carbonate oil gel was vacuum-dried to reduce the gel porosity and thus slow testosterone release. Therefore, oil gel is a promising substrate for lipophilic drugs, including testosterone.

Similar content being viewed by others

Introduction

Bone fractures due to strong impact on the body are an important medical problem. Partial bone loss is a more serious problem and can be caused by trauma, tumor removal or surgery to correct congenital deformations. Segmental defects are difficult to correct because they usually require many surgeries to regenerate the bone and regain its function. Current surgical techniques, such as autografts, allografts and distraction osteogenesis, have limited success1, 2, 3 and can have serious consequences, such as leg shortening or amputation, if they fail. Therefore, delivering therapeutic drugs to the segmental defect using substances such as hydrogels for tissue engineering has been studied.4, 5, 6, 7 Bone morphogenetic proteins (BMPs) are generally used as therapeutic drugs. For example, Lutolf and coworkers7 reported the synthesis of polyethylene glycol-based hydrogels containing pendant oligopeptide ligands for cell adhesion and substrates for matrix metalloproteinase, which served as cross-linkers. The gels were used to deliver recombinant human bone morphogenetic protein-2 (rhBMP-2) to large defect sites in rat crania.7 However, clinical applications of BMP-2 have been hindered by its high cost.6 Therefore, alternative methods to aid in fracture repair must be developed.

Testosterone is an androgen that has been reported to induce callus formation within 14 days of treatment in mice. Extrapolating from the results of the study, 8.3 μg of testosterone would be required to treat a segmental defect of similar size in humans.6 Testosterone can be obtained more easily than BMP-2 and is therefore a viable alternative. However, testosterone is lipophilic and insoluble in water and cannot be loaded into hydrogels efficiently.

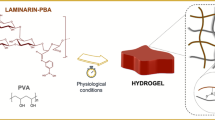

Thus, we focus on oil gel substrates. Oil gels are semi-solid systems in which an organic liquid phase is immobilized within a three-dimensional network. They are typically employed as chemomechanical materials8 and oil absorbents,9 among other uses. Because oil gels contain organic solvents, it should be possible to load testosterone into them effectively. To our knowledge, the loading of oil gels with testosterone has not been reported,10 probably because of a lack of information on the biocompatibility and toxicity of the solvents and gelators.11 In addition, physical gels might not retain testosterone effectively because of their structural instability, resulting in their collapse.12 Therefore, chemical gels composed of low-toxicity components are needed.

Polylactide (PLA) is a well-known biodegradable and biocompatible polymer that has been studied for use in biomedical material applications (for example, drug carriers,13, 14, 15 resorbable sutures16 and nanosheets17). To exploit these PLA properties in drug delivery systems, we studied nanoparticles composed of poly(γ-glutamic acid)-graft-poly(lactide) copolymers, which utilize PLA stereocomplexes.13 We also reported the rapid fabrication of PLA stereocomplexes using an inkjet printer to alternately deposit precise amounts of poly(L-lactide) and poly(D-lactide) to form LbL composites without needing to rinse them.18 This system can be employed to fabricate substrates for water-soluble drugs.19 Moreover, we described oil gels composed of a chemically cross-linked copolymer of PLLA and poly(trimethylene carbonate) derivatives.20 Poly(trimethylene carbonate) derivatives are also biodegradable and biocompatible21, 22, 23 and have been used to create cross-linking points. In addition, a compound containing oligo(ethylene glycol) groups, which resemble the biocompatible polymer polyethylene glycol, was used.24 Oil gels are assumed to be good candidates for substrates for lipophilic drugs, including testosterone, because they are composed of biocompatible polymer networks and are considered to be safe for human use. However, drug release profiles for oil gels have not been measured.

In this study, we investigated the release of testosterone from oil gels (Figures 1 and 2). Low-toxicity organic solvents (that is, dimethyl sulfoxide (DMSO) and dimethyl carbonate (DMC)) were used as the dispersion media. The oral rat LD50 of these solvents is comparable with that of ethanol, which is considered to have low toxicity (DMSO: 14 500 mg kg−1 (Material Safety Data Sheet of Tokyo Chemical Industry Co., Ltd., Japan), DMC: >5000 mg kg−1 (Material Safety Data Sheet of Ube Industries, Ltd., Japan), ethanol: 6.2–17.8 g kg−1 (Material Safety Data Sheet of Kanto Chemical Co., Inc., Japan). To the best of our knowledge, this is the first report on the medical application of a PLA chemical gel with a low-toxicity organic solvent.

Materials and methods

Materials

L-lactide (Musashino Chemical Laboratory, Ltd., Tokyo, Japan) was recrystallized from ethyl acetate. Benzyl alcohol (Wako Pure Chemical Industries, Ltd., Osaka, Japan) was distilled using 4 Å molecular sieves. Stannous 2-ethylhexanoate (Sn(Oct)2), toluene, chloroform, palladium-activated carbon (10% Pd, Pd/C), dichloromethane, testosterone, DMSO and DMC were obtained from Wako Pure Chemical Industries, Ltd. Palladium hydroxide on carbon (20% Pd(OH)2/C) was purchased from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan), and used as received. 1,2-Bis(2-aminoethoxy)ethane, ethyl chloroformate and triethylamine were purchased from Tokyo Chemical Industry Co., Ltd., and distilled before use. Phosphate-buffered saline (PBS) was prepared by dissolving the following reagents in ultrapure water: NaCl (8 mg ml−1), KCl (0.2 mg ml−1), KH2PO4 (0.2 mg ml−1), and Na2HPO4 (1.15 mg ml−1). Ultrapure water was prepared using a Millipore Academic A10 system (Merk Millipore, Darmstadt, Germany).

Measurements

The molecular weight of the polymer was determined by gel permeation chromatography. A JASCO Chem NAV system (JASCO Corporation, Tokyo, Japan) equipped with a PU-2089 pump, AS-2055 autosampler, CO-2065 column oven and RI-2031 detector was used at 40 °C. The measurements were calibrated using poly(methyl methacrylate) standards. Two commercial columns (TSKgel SuperH3000 and TSKgel SuperH7000, TOSOH CORPORATION, Tokyo, Japan) were connected in series, and DMSO was used as the eluent. 1H nuclear magnetic resonance spectra were measured with an nuclear magnetic resonance spectrometer (JEOL FX400, JEOL Ltd., Tokyo, Japan) at 400 MHz.

Oil gel preparation

Poly(2-methyl-2-carboxy trimethylene carbonate-co-L-lactide) was synthesized as a prepolymer (see Supplementary Information). The prepolymer (m:n=25:75, number-average molecular weight Mn=26 000, 0.803 mmol carboxy groups, weight-average molecular weight Mw=37 000, 300 mg) was dissolved in dichloromethane (0.68 ml). Then, ethyl chloroformate (0.11 ml, 1.16 mmol) and triethylamine (0.12 ml, 0.883 mmol) were added to the solution, which was chilled in an ice bath. After 1 h, a given amount of 1,2-bis(2-aminoethoxy)ethane was added, and the reaction mixture was heated at 40 °C for 3 h. After the reaction, excess chloroform was added to remove the unreacted compounds. More than 12 h later, an oil gel in chloroform was obtained (Scheme 1).

Testosterone release from the oil gels

Oil gels (30 mg) were immersed in DMSO or DMC containing dissolved testosterone (DMSO: 7 mg ml−1, DMC: 10 mg ml−1) for 12 h to load 180 μg of testosterone into them. The amount of loaded testosterone was determined by the absorbance of the organic solvent at 329 nm. After rinsing the gel with the organic solvent, it was immersed in 30 ml of PBS or 0.01 M aqueous NaOH at 37 °C, and the supernatants were analyzed by high-performance liquid chromatography (Shimadzu liquid chromatograph, CBM-20A system controller, LC-20AD pump, SIL-20A autosampler, SPD-20A detector, CTO-20A column oven, DGU-20A3R degassing unit, eluent: acetonitrile/water=6/4, column: Mightysil RP-18 GP Aqua 250-4.6 (Kanto Chemical Co., Inc., Tokyo, Japan), UV detector: 244 nm). The release percentages were determined and compared with the total amount of loaded testosterone. The vacuum-dried gels used in the release experiments were prepared by vacuum-drying the oil gels in DMC loaded with 180 μg of testosterone for 12 h at room temperature.

Degradation of the vacuum-dried gels

The oil gels in DMC (30 mg) were vacuum-dried for 12 h at room temperature to produce vacuum-dried gels. Then, the gels were immersed in 0.01 M aqueous NaOH or PBS (300 μl) for a certain amount of time. The gels were subsequently collected and washed with ultrapure water. After the oil gels were dried under reduced pressure for 12 h at room temperature, they were weighed, and the percent remaining was calculated based on the weight loss.

Results and Discussion

It is notable that 180 μg of testosterone could be loaded into the oil gels in DMSO and in DMC. This amount of testosterone is adequate for medical applications (8.3 μg)6. Figure 3a and b show the testosterone release profiles for the oil gels in DMSO and in DMC, respectively. The drug was released more quickly from the oil gels in DMSO than from those in DMC. For example, after 15 min, approximately 60% of the testosterone was released from the oil gels in DMSO (Figure 3a), while approximately 20% was released from those in DMC (Figure 3b). The difference in the release profiles is attributed to the different solubilities of the organic solvents in water; DMSO is soluble in water, while DMC is not (the solubility of DMC in water is 115 g l−1 at 20 °C (Material Safety Data Sheet of Ube Industries, Ltd., Japan)). When oil gels are immersed in PBS, the organic solvents tend to mix with water. Because DMSO is more soluble in water than DMC, DMSO tends to diffuse from the gels, which leads to testosterone release. However, it is desirable for testosterone to be released over a longer time period because testosterone-promoted callus formation occurs over approximately 14 days.6

It has been reported that drug diffusivity in gels decreases with decreasing gel porosity.25, 26 Thus, the release profile should be controlled by the oil gel porosity. The boiling points of DMSO and DMC are 189 °C and 90 °C, respectively. Therefore, it was assumed that DMC could be easily removed from the oil gels by vacuum-drying, which would decrease their porosity, because of its relatively low boiling point. Accordingly, vacuum-dried gels were prepared (DMC removal was evaluated based on the weight loss of the oil gels; data not shown), and their release profiles (Figure 3c) were determined. It was found that testosterone was released more slowly from the vacuum-dried gels than from the oil gels in DMC. To compare the release profiles, the time required for the oil gels to release 50% of the testosterone was determined. The release of approximately 50% of the testosterone required 6 h for the oil gels in DMSO, while it required 15 h for those in DMC.

The porosities of the gels were examined by scanning electron microscopy (Figure 4). In particular, the porosity of the vacuum-dried gels was compared with that of freeze-dried gels, which served as a reference. It was expected that the porosities of the freeze-dried gels and of the oil gels in DMC would be similar. The freeze-dried gels had pores of approximately 10 μm in diameter, indicating a porous structure.20 On the other hand, no evidence of porosity was observed on the vacuum-dried gel surfaces. On the basis of these results, it was concluded that the porosity of the oil gels in DMC can be reduced by vacuum-drying to obtain the desired slow-release profile. Moreover, vacuum-drying decreases the amount of organic solvent in the gels, resulting in a safer drug carrier.

Because the oil gels were composed of biodegradable poly(L-lactide) and poly(trimethylene carbonate) derivatives, the release profiles could also be controlled by changing their biodegradability. The degradation of the vacuum-dried gels in an alkali aqueous solution (0.01 M aqueous NaOH) and in PBS was studied. Figure 5 shows that the vacuum-dried gels were hydrolyzed in both 0.01 M aqueous NaOH and PBS. The hydrolysis occurred more readily in 0.01 M aqueous NaOH than in PBS. For example, approximately 40% of the vacuum-dried gels were hydrolyzed in 0.01 M aqueous NaOH (Figure 5a), whereas only 20% of the vacuum-dried gels were hydrolyzed in PBS (Figure 5b).

Next, the release profiles of the gels were measured in 0.01 M aqueous NaOH and in PBS. Figure 6 shows that testosterone was released more readily in 0.01 M aqueous NaOH (Figure 6a) than in PBS (Figure 6b), because the vacuum-dried gels were hydrolyzed more easily in 0.01 M aqueous NaOH than in PBS. From these results, it was concluded that the release profiles of the oil gels were related to the gel degradation. However, because the amount of testosterone released was not constant, testosterone must be released not only by the diffusion from the gel but also decomposition of the gel.27 It is assumed that testosterone release from oil gels might be affected by several factors, such as the testosterone concentration gradient, oil gel degradation or organic solvent solubility in water.

Conclusions

Testosterone release from oil gels composed of poly(L-lactide) and a PTMC derivative was investigated. Using organic solvents with low toxicity, that is, DMSO and DMC, the testosterone release profiles of the oil gels were determined. The testosterone release from the oil gels in DMSO was faster than that from the oil gels in DMC. This difference in release profiles might be due to the different solubilities of the organic solvents in water. The release time was increased by vacuum-drying the oil gels in DMC.

This system can be widely employed for many lipophilic drugs, such as indomethacin28 and hydrocortisone.29 These vacuum-dried gels are good candidates for lipophilic drug carriers.

Oil gel preparation.

References

Floerkemeier, T., Witte, F., Nellese, J., Thorey, F., Windhagen, H. & Wellmann, M. Repetitive recombinant human bone morphogenetic protein 2 injections improve the callus microarchitecture and mechanical stiffness in a sheep model of distraction osteogenesis. Orthop. Rev. 4, e13 (2012).

Miller, M. A., Ivkovic, A., Porter, R., Harris, M. B., Estok, D. M. 2nd, Smith, R. M., Evans, C. H. & Vrahas, M. S. Autologous bone grafting on steroids: preliminary clinical results. A novel treatment for nonunions and segmental bone defects. Int. Orthop. 35, 599–605 (2011).

Ridha, H., Bernard, J., Gateley, D. & Vesely, M. J. Reconstruction of large traumatic segmental defects of the femur using segmental allograft with vascularized fibula inlay. J. Reconstr. Microsurg. 27, 383–390 (2011).

Diab, T., Pritchard, E. M., Uhrig, B. A., Boerckel, J. D., Kaplan, D. L. & Guldberg, R. E. A silk hydrogel-based delivery system of bone morphogenic protein for the treatment of large bone defects. J. Mech. Behav. Biomed. Mater. 11, 123–131 (2012).

Chu, T.-M. G., Warden, S. J., Turner, C. H. & Stewart, R. L. Segmental bone regeneration using a load-bearing biodegradable carrier of bone morphogenetic protein-2. Biomaterials 28, 459–467 (2007).

Cheng, B.-H., Chu, T.-M. G., Chang, C. & Huang, K.-E. Bone morphologic protein-2 in promoting the repair of critical-size segmental defect of femoral bone in mice. PLoS ONE 8, e70234 (2013).

Lutolf, M. P., Weber, F. E., Schmoekel, H. G., Schense, J. C., Kohler, T., Müller, R. & Hubbell, J. A. Repair of bone defects using synthetic mimetics of collagenous extracellular matrices. Nat. Biotech 21, 513–518 (2003).

Gong, J., Kawakami, I. & Osada, Y. Electroconductive organogel. 4. Electrodriven chemomechanical behaviors of charge-transfer complex gel in organic solvent. Macromolecules 24, 6582–6587 (1991).

Basak, S., Nanda, J. & Banerjee, A. A new aromatic amino acid based organogel for oil spill recovery. J. Mater. Chem. 22, 11658–11664 (2012).

Zhang, C., Zhang, X., Yang, D. & Wang, P. Biodegradation of in situ-forming gel of poly(DLLA-co-CL) in vivo. J. Appl. Polym. Sci. 130, 3800–3808 (2013).

Vintiloiu, A. & Leroux, J.-C. Organogels and their use in drug delivery — A review. J. Control. Release 125, 179–192 (2008).

Tsuge, T., Hamada, Y., Watanabe, Y., Tomizawa, S., Yamamoto, T. & Abe, H. Characterization of biosynthsized P(3HB-co-3HA)s swellable in organic solvents. Polym. Degrad. Stab. 95, 1345–1348 (2010).

Zhu, Y., Akagi, T. & Akashi, M. Preparation and characterization of nanoparticles formed through stereocomplexation between enantiomeric poly(γ-glutamic acid)-graft-poly(lactide) copolymers. Polymer J 45, 560–566 (2013).

Chu, H., Ajiro, H., Takahashi, Y., Chen, M. & Akashi, M. Nanoparticle fabrication with biodegradable block copolymer composed of hydrophilic poly(trimethylene carbonate) derivative and hydrophobic polylactide. Chem. Lett. 42, 74–76 (2013).

Kondo, K., Kida, T., Ogawa, Y., Arikawa, Y. & Akashi, M. Nanotube formation through the continuous one-dimensional fusion of hollow nanocapsules composed of layer-by-layer poly(lactic acid)s stereocomplex films. J. Am. Chem. Soc. 132, 8236–8237 (2010).

Pang, X., Zhuang, X., Tang, Z. & Chen, X. Polylactic acid (PLA): Research, development and industrialization. Biotechnol. J. 5, 1125–1136 (2010).

Okamura, Y., Kabata, K., Kinoshita, M., Miyazaki, H., Saito, A., Fujie, T., Ohtsubo, S., Saitoh, D. & Takeoka, S. Fragmentation of poly(lactic acid) nanosheets and patchwork treatment for burn wounds. Adv. Mater. 25, 545–551 (2013).

Akagi, T., Fujiwara, T. & Akashi, M. Rapid Fabrication of polylactide stereocomplex using layer-by-layer deposition by inkjet printing. Angew. Chem. Int. Ed. 51, 5493–5496 (2012).

Akagi, T., Fujiwara, T. & Akashi, M. Inkjet printing of layer-by-layer assembled poly(lactide) stereocomplex with encapsulated proteins. Langmuir. 30, 1669–1676 (2014).

Takemura, K., Ajiro, H., Fujiwara, T. & Akashi, M. Oil gels with a chemically cross-linked copolymer of a trimethylene carbonate derivative and L-lactide: preparation and stereocomplex formation within gels. RSC Adv 4, 33462–33465 (2014).

Kim, S. H., Tan, J. P. K., Fukushima, K., Nederberg, F., Yang, Y. Y., Waymouth, R. M. & Hedrick, J. L. Thermoresponsive nanostructured polycarbonate block copolymers as biodegradable therapeutic delivery carriers. Biomaterials 32, 5505–5514 (2011).

Dargaville, B. L., Vaquette, C., Peng, H., Rasoul, F., Chau, Y. Q., Copper-White, J. J., Campbell, J. H. & Whittaker, A. K. Cross-Linked Poly(trimethylene carbonate-co-L-lactide) as a biodegradable, elastomeric scaffold for vascular engineering applications. Biomacromolecules 12, 3856–3869 (2011).

Ajiro, H., Takahashi, Y. & Akashi, M. Thermosensitive biodegradable homopolymer of trimethylene carbonate derivative at bodytemperature. Macromolecules 45, 2668–2674 (2012).

Fitzpatrick, S. D., Fitzpatrick, L. E., Thakur, A., Mazumder, M. A. J. & Sheardown, H. Temperature-sensitive polymers for drug delivery. Expert Rev. Med. Devices 9, 339–351 (2012).

am Ende, M. T. & Peppas, N. A. Transport of ionizable drugs and proteins in crosslinked poly(acrylic acid) and poly(acrylic acid-co-2-hydroxyethyl methacrylate) hydrogels. II. Diffusion and release studies. J. Control. Release 48, 47–56 (1997).

Ninawe, P. R. & Parulekar, S. J. Drug loading into and drug release from pH- and temperature-responsive cylindrical hydrogels. Biotechnol. Prog. 27, 1442–1454 (2011).

Kim, Y. -H., Kim, H. -K., Kim, T. -G., Lee, J. -H., Lim, Y. -K., Kim, Y. -J. & Choi, S. -Y. Sustained drug release system using porous structured poly(L-lactic acid) fabricated by solvent dispersion method. J. Porous Mater 20, 303–308 (2013).

Tokuyama, H. & Kato, Y. Preparation of thermosensitive polymeric organogels and their drug. Eur. Polym. J. 46, 277–282 (2010).

Costa, D., Valente, A. J., Miguel, M. G. & Queiroz, J. Gel network photodisruption: a new strategy for the codelivery of plasmid DNA and drugs. Langmuir 27, 13780–13789 (2011).

Acknowledgements

This work was supported by a Grant-in-Aid for Scientific Research (S) from the Ministry of Education, Culture, Sports, Science and Technology (23225004) and by the MEXT project ‘Creating Hybrid Organs of the Future’ at Osaka University. We are grateful to Drs T Kida, M Matsusaki and T Akagi for fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Takemura, K., Ajiro, H., Fujiwara, T. et al. A novel substrate for testosterone: biodegradable and biocompatible oil gel. Polym J 47, 460–463 (2015). https://doi.org/10.1038/pj.2015.17

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.17

This article is cited by

-

The electrostatic advantages of cross-linked polystyrene organogels swollen with limonene for selective adsorption and storage of hydrophobic drugs

Polymer Journal (2018)

-

Densities, Ultrasonic Velocities, Excess Properties and IR Spectra of Binary Liquid Mixtures of Organic Esters (Ethyl Lactate, Some Organic Carbonates)

Journal of Solution Chemistry (2017)

-

Polymer design using trimethylene carbonate with ethylene glycol units for biomedical applications

Polymer Journal (2016)