Abstract

Poly(L-lactide) (PLLA)–poly(ɛ-caprolactone) (PCL) multiblock copolymers (MBCs) were synthesized by the self-polycondensation of PLLA–PCL diblock copolymers. We synthesized three types of MBCs with degrees of polymerization of the lactide–caprolactone segments of 12–15 (MBC1), 24–26 (MBC2) and 49–50 (MBC3) to investigate the effect of the segment length on the properties. The strict control over the terminal functional groups of the diblock copolymers resulted in the formation of high-molecular weight MBCs (Mw=(2.4–4.9) × 105 g mol−1). Differential scanning calorimetry (DSC) measurements suggest the phase mixing of PLLA and PCL segments in amorphous region and that the MBCs contain PCL-rich regions, the extent of which is influenced by the segment length. The X-ray diffraction patterns of the MBCs contain diffraction peaks originating from lactide segment crystals. High moduli (95–43 MPa) and elongation at break (~500%) were observed for all the MBC films. The MBCs hydrolyzed slowly in comparison with PLLA, and the hydrophilic porous films of MBC2 were obtained. To estimate their potential as adhesion barrier films, the hydrophilic porous MBC films were implanted onto the abdominal side walls of rats. The MBC films effectively prevented the adhesion at the target site, but intermediate adhesion was observed at the suture site where the MBC film was fixed.

Similar content being viewed by others

Introduction

Aliphatic polyesters are important biodegradable polymers for biomedical and environmental applications.1, 2, 3, 4, 5 Poly(L-lactide) (PLLA) and its copolymers are among the most intensively investigated biodegradable polymers. PLLA is a crystalline polymer that exhibits good mechanical properties. However, the production costs for PLLA are higher than those of other commodity polymers such as polyethylenes and polypropylenes. Therefore, the application of PLLA has been focused primarily in biomedical applications. A well-known example is a copolymer of PLLA with poly(glycolide). This copolymer is used in bioabsorbable surgical sutures. One of the requirements for materials in biomedical applications is that they be soft and elastic.6, 7 The copolymerization of lactide with ɛ-caprolactone results in the formation of soft and elastic polyester copolymers because the poly(ɛ-caprolactone) (PCL) segment in the copolymer acts as a soft segment. There are numerous literature reports related to PLLA–PCL random, di- and triblock copolymers.8, 9, 10 PLLA–PCL random copolymers are a soft and flexible material. However, the good mechanical properties that originate from the crystalline PLLA components are degraded by the randomization of the structure. Di- and triblock PLLA–PCL copolymers are crystalline polymers that exhibit good mechanical properties. However, the coupling of high-molecular weight segments to obtain high-molecular weight block copolymers is often difficult. Moreover, the block copolymer films can gradually lose flexibility as the components slowly crystallize.11

The coupling of oligomers with linker molecules, such as diisocyanates, results in the formation of multiblock copolymers (MBCs).12, 13, 14 MBCs have the potential to overcome the aforementioned problems. Despite the easy synthetic procedure, the degradation products that originate from the linker molecules, such as hexamethylene diisocyanate, are potentially toxic. In 2003, Jeon et al.15 reported the synthesis of PLLA–PCL MBCs via a coupling reaction between the bischloroformates of the carboxylated PLLA and the PCL-diol in the absence of linker molecules. The resulting PLLA–PCL MBCs exhibited properties similar to those of thermoplastic elastomers because the PLLA and PCL segments act as hard and soft components, respectively. The length of each segment and the ratio between the PLLA and PCL segments affected the properties of the MBCs.

In this paper, we report the synthesis of PLLA–PCL MBCs by the self-polycondensation of PLLA–PCL diblock copolymers. Strict control over the terminal functions of the PLLA–PCL diblock copolymers makes it possible to directly adjust the 1:1 molar ratio between functional groups, which results in the easy formation of high-molecular weight polymers. The structure, thermal and crystallization behavior, and the mechanical properties of the MBCs formed were investigated. Preliminary investigations into the potential application of these PLLA–PCL MBCs as adhesion barriers were conducted by implanting the copolymer films onto the abdominal sidewall of rats.

Experimental procedure

Materials

L-Lactide was purchased from Musashino Chemical Laboratory, Ltd. (Tokyo, Japan) and was purified by sublimation before use. ɛ-Caprolactone, benzyl alcohol, tetrahydrofuran (THF), toluene and dichloromethane were purchased from Kanto Chemical Co. Inc. (Tokyo, Japan) and purified by distillation. Scandium triflate (Sc(OTf)3) and tin 2-ethylhexanoate (Sn(Oct)2) were purchased from Sigma-Aldrich Japan Inc. (Tokyo, Japan) and were used without further purification. A stock solution containing Sc(OTf)3 (50 mg) in a toluene (4 ml)/ THF (1 ml) mixture was prepared using a procedure previously described in the literature.16 Palladium on activated carbon (10 wt%) was purchased from Merck Millipore (Tokyo, Japan) and was used as received. 4-(Dimethylamino)pyridine was purchased from Kanto Chemical Co. Inc. and was used as received. N,N’-Diisopropylcarbodiimide was purchased from Kokusan Chemical Co. Ltd. (Tokyo, Japan) and was used as received. 4-Dimethylaminopyridine 4-toluenesulfonate was prepared according to a previously described procedure.17 Commercially available PLLA (Fuji Chemical Co., Ltd. (Osaka, Japan)) was used as a reference polymer. The weight average molecular weight (Mw) and molecular weight distribution (Mw/Mn) were 179 and 4.09 500 g mol−1, respectively. A random copolymer of poly(L-lactide)-co-poly(ɛ-caprolactone) (LCL) was donated by BMG, Inc. (Kyoto Japan); the Mw and Mw/Mn were 400 000 g mol−1 and 1.75, respectively. The molar ratio between the lactide and caprolactone was 52:48. All other materials were purchased from Kanto Chemical Co. Inc. and were used as received.

Synthesis of the PCL oligomer

The typical procedure used to synthesize the PCL oligomer with a target degree of polymerization of the caprolactone segment (l) of 25 is as follows. Benzyl alcohol (187 μl, 1.8 × 10−3 mol) and the Sc(OTf)3 stock solution were added to a heat-dried Schlenk flask equipped with a nitrogen inlet and stirred for 20 min under a nitrogen atmosphere. ɛ-Caprolactone (5.0 ml, 0.045 mol) was added to the Schlenk flask, and the mixture was heated at 60 °C for 24 h. After cooling to room temperature, the mixture was diluted with THF (3 ml) and subsequently poured into hexane (150 ml). The precipitate was collected by filtration and dried under vacuum at room temperature; the yield was 25%. The degree of polymerization of the caprolactone segment (l), as determined by 1H nuclear magnetic resonance (NMR) spectrometry, was 24.

Synthesis of the PLLA–PCL diblock copolymer (DBC)

The typical procedure used to synthesize the PLLA–PCL diblock macromonomer with a target degree of polymerization of the lactide segment (m) of 25 is as follows. A heat-dried Schlenk flask equipped with a nitrogen inlet was charged with the PCL oligomer (l=24, 1.5 g) and L-lactide (1.7 g, 1.2 × 10−2 mol). The Schlenk flask was evacuated and purged with nitrogen. Sn(Oct)2 (6 μl) was added to the flask, and the mixture was stirred and heated at 100 °C for 30 min and then at 130 °C for 5 h. After the mixture cooled to room temperature, chloroform (4 ml) and five drops of acetic acid were added to the mixture. The mixture was then poured into cold methanol (150 ml) to precipitate the product. The precipitate was recovered by filtration and dried under vacuum at room temperature; the yield of the benzyl-protected DBC was 89%. The degree of polymerization of the lactide segment (m) was determined to be 26 by 1H NMR analysis.

The benzyl-protected DBC (l=24, m=26, 2.5 g), palladium on activated carbon (0.25 g) and THF (100 ml) were added to a flask equipped with a three-way stopcock. The flask was evacuated twice and purged with nitrogen. The flask was then evacuated and purged with hydrogen, and the mixture stirred at room temperature for 24 h. After filtration through Celite to remove the palladium on activated carbon, the THF solution was poured into methanol. The precipitate was recovered by filtration and dried under vacuum at room temperature; the yield was 94%.

Synthesis of the PLLA–PCL MBC

The typical procedure used to synthesize the PLLA–PCL MBC from the PLLA–PCL DBC (l=24, m=26) is as follows. In a heat-dried Schlenk flask equipped with a nitrogen inlet, PLLA–PCL DBC (1.0 g) was dissolved in dichloromethane (2.5 ml). 4-Dimethylaminopyridine 4-toluenesulfonate (8.8 mg), 4-(dimethylamino)pyridine (2.2 mg) and N, N’-diisopropylcarbodiimide (46 μl) were then added to the solution. The reaction mixture was then stirred at room temperature for 48 h. After being diluted with dichloromethane (5 ml), the reaction mixture was poured into cold methanol (150 ml). The precipitate was collected by filtration and dried under vacuum at room temperature; the yield was 100%.

Preparation and alkaline hydrolysis of MBC films

The MBC films were prepared on a glass plate by casting from a chloroform solution of the MBCs. After drying at room temperature at atmospheric pressure, the film on the glass plate was dried under vacuum at room temperature for 12 h. The film was then removed from the glass plate by immersion of the plate into water. The removed film was wiped and dried under vacuum at 40 °C for 12 h. Alkaline hydrolysis of the films was conducted by immersion of the film into an aqueous NaOH solution (1 mol l−1) at 37 °C. The weight, thickness and contact angle of the films were averaged from two samples. Because one of the MBC2 films became porous and hydrophilic after 24 h, the contact angle of the other non-porous film is presented.

Adhesion barrier tests

Porous hydrophilic MBC films (l=26, m=28, ηinh=1.62 dL g−1, 12–26 μm in thickness) prepared by alkaline hydrolysis in an aqueous NaOH solution (1.0 mol l−1) were implanted onto the abdominal side walls of rats. Before the film was implanted, both sidewalls were marked with one suture of surgical silk. On one side, a square MBC film (3 × 3 cm) was sutured with nylon thread at each corner to cover the silk mark. On the other side, nylon thread was sutured around the silk mark without using the MBC film. After a week, the rat was killed, and the status of the adhesions was evaluated. Adhesion severity was scored on a scale of 0 to 3 (0=no adhesion; 1=a weak and easily removable adhesion; 2=an intermediate adhesion; 3=a strong adhesion).18

Measurements

1H and 13C NMR spectra were recorded using a JNM-ECX 500 NMR spectrometer (JEOL Ltd., Tokyo, Japan). The inherent viscosity was measured in chloroform at 40 °C at a concentration of 0.5 g dl−1. Gel permeation chromatography (GPC) measurements (Shodex KF802.5 and KF806M columns, Tokyo, Japan) were conducted using chloroform as an eluent, and the molecular weight was calculated using polystyrene standards. DSC measurements were performed on an Exster X-DSC7000 (Hitachi High-Technologies Co., Tokyo, Japan) at a heating rate of 10 °C min−1. The glass transition temperature was determined from the maximum slope at the transition. Thermogravimetric analysis measurements were conducted on a Thermoplus TG 8230 (Rigaku Co., Tokyo, Japan) at a heating rate of 10 °C min−1. Wide-angle X-ray diffraction (XRD) measurements were conducted using a Ultima IV X-ray diffractometer (Rigaku Co.). Tensile tests were performed using an Instron 5967 (Instron Japan Co. Ltd., Kanagawa, Japan) with a crosshead speed of 10 mm min−1. The tensile modulus was determined by the initial slope of the stress–strain curves. Each film was cut into test pieces (50 × 5 mm), and 10 test pieces were measured to determine the mechanical properties of each film.

Results and discussion

Synthesis of the PLLA–PCL MBC

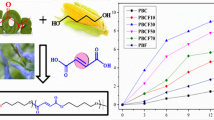

PLLA–PCL MBCs were synthesized via the self-polycondensation of PLLA–PCL DBCs, as shown in Scheme 1. These high-molecular weight polymers can be easily synthesized by self-polycondensation because the molar ratio between the carboxy and hydroxy groups is controlled to be 1:1. The terminal groups of the oligomers should be strictly controlled by the successful self-polycondensation.

First, PCL oligomers were synthesized in the presence of a Sc(OTf)3 catalyst using benzyl alcohol as an initiator according to a reported procedure.16 Figure 1a shows the 1H NMR spectrum of the prepared PCL oligomer (l=24). Peak A (7.4 ppm) and peak B (5.1 ppm) are attributed to the aromatic and benzylic methylene protons, respectively. The peak at 3.65 ppm (peak G) is attributed to the methylene protons connected to the terminal hydroxy unit. The integration ratio between peaks A:B:G was 5:2:2, which supports the formation of the PCL oligomer with the appropriate terminal groups. The other peaks are assigned to the proposed structural units. Peak F (4.1 ppm) is attributed to the methylene protons connected with the ester unit and the integration ratio between peak F and peak G allows the number-average degree of polymerization of the PCL oligomer (DPCL) to be calculated. The results for the synthesis of the PCL oligomers are summarized in Table 1. All the PCL oligomers were obtained in high yield, and their DPCLs were controlled from the concentration ratio of ɛ-caprolactone to benzyl alcohol ([M]/[I]). The integration ratio between peak B and peak G listed in Table 1 suggests that the terminal groups of the PCL oligomers are strictly controlled. The molecular weight distribution (Mw/Mn) determined by GPC using polystyrene standards was within the range 1.22–1.47, which suggests that the PCL oligomers have a narrow molecular weight distribution.

Second, the PLLA–PCL DBCs were synthesized by the ring-opening polymerization of L-lactide initiated by the PCL oligomers in the presence of a Sn(Oct)2 catalyst at 130 °C, followed by catalytic hydrogenation to remove the benzyl ester. Figure 1b shows the 1H NMR spectrum of the benzyl-protected PLLA–PCL DBC (l=24, m=26). Peak G that appeared in Figure 1a disappeared in Figure 1b. This observation indicates that the hydroxy group in the PCL oligomer is consumed as an initiator during the polymerization of L-lactide. The methine protons that originate from the lactide segments are observed at 5.2 (peak H) and 4.4 ppm (peak J). The integration ratio between peak A and J was 5:1. This result supports the formation of benzyl-protected PLLA–PCL DBCs with good control over the terminal groups. Other peaks in Figure 1b are also assigned to the proposed structure. The integration ratio between peak H and J allows the number-average degree of polymerization (DPLA) to be calculated. Table 2 summarizes the results for the synthesis of benzyl-protected PLLA–PCL DBCs. The DPLA values determined by 1H NMR analysis are comparable with the targeted DPLA values. The integration ratio between peak J and peak A suggests the formation of structurally controlled DBCs. The Mw/Mn determined by GPC using polystyrene standards are in the range 1.17–1.51, which suggests that the benzyl-protected PLLA–PCL DBCs have a narrow molecular weight distribution. Palladium-catalyzed hydrogenation of the benzyl-protected PLLA–PCL DBCs was conducted to form the PLLA–PCL DBCs bearing terminal hydroxy and carboxy groups. Figure 1c shows the 1H NMR spectrum of the PLLA–PCL DBC (l=24, m=26). The peaks attributed to the aromatic (peak A) and benzylic methylene protons (peak B) in Figure 1b disappeared in Figure 1c, which suggests that quantitative hydrogenation occurred. The PLLA–PCL DBCs were almost quantitatively recovered after the hydrogenation. In addition, the integration ratio between peak H and J were almost consistent with the PLLA–PCL DBC after hydrogenation. This observation indicates that the ester linkages in the PLLA-PCL DBC are stable under the catalytic hydrogenation conditions.

Finally, PLLA–PCL MBCs were synthesized via self-polycondensation of PLLA–PCL DBCs. The polymerization was conducted in the presence of N,N’-diisopropylcarbodiimide, 4-(dimethylamino)pyridine and 4-dimethylaminopyridine 4-toluenesulfonate at room temperature for 48 h. The polymerization mixture became highly viscous during the self-polycondensation. Figure 1d shows the 1H NMR spectrum of the PLLA–PCL MBC (l=24, m=26). The methine protons adjacent to the terminal hydroxy group in Figure 1c disappeared after the self-polycondensation (Figure 1d). The results for the synthesis of PLLA–PCL MBCs are summarized in Table 3. Three types of PLLA–PCL MBCs with different segment lengths were obtained in high yield. The high-molecular-weight MBCs (Mw=(2.4–4.9) × 105 g mol−1) were obtained by the self-polycondensation of DBCs. Strict control of the terminal functional groups of the DBCs should contribute to the achievement of higher molecular weight MBCs in comparison with a previous report.15 The inherent viscosity and molecular weight (Mw) indicate the formation of high-molecular weight PLLA–PCL MBCs. The molecular weight distribution (Mw/Mn) is in the range 2.81–4.28, and the high-molecular weight polymer (MBC2) exhibits the largest Mw/Mn.

Properties of the PLLA–PCL MBCs

The thermal properties of the MBCs and poly(L-lactide)-co-poly(ɛ-caprolactone) random copolymer (LCL) were evaluated from the second heating cycle of DSC measurements. The glass transition temperature (Tg) of PLLA and PCL are 60 and −60 °C, respectively. As shown in Figure 2, LCL showed a clear Tg at −3 °C, and no peaks attributed to crystallization or melting. Miscible copolymers or polymer blends are known to exhibit a single Tg, which can be calculated by the Fox−Flory equation (1/Tg=w1/Tg1+w2/Tg2: w1 and w2 are weight fraction of the component 1 and 2, respectively. Tg1 and Tg2 are the glass transition temperature of the component 1 and 2, respectively). The Tg of the LCL is very close to the calculated temperature of 0 °C, which implies that the PLLA and PCL segments in LCL are miscible. MBC1 exhibited a broad glass transition in the range from −42 to 24 °C, and the Tg determined from the maximum slope at this transition was 1 °C. MBC2 and MBC3 also showed broader glass transitions, and the onset of the glass transition shifted toward lower temperatures of −64 °C (MBC2) and −68 °C (MBC3). Because no glass transitions originating from the PLLA or PCL homopolymer segments were observed, and one broad glass transition was detected between the component transitions, the PLLA and PCL phases appear to mix. The broad glass transition may imply that the amorphous MBCs are composed of a distribution of PLLA and PCL segments. The PCL-rich region could lower the onset of the glass transition of the MBCs. The temperatures for the exothermic peak attributed to the crystallization of the PLLA segments in the MBCs are lower than that of PLLA. It is reported that partially miscible PCL segments enhance the crystallization rate of PLLA segments and lower the cold crystallization temperature in PLLA/PCL blends.19, 20 It seems that the same trend is observed in these PLLA-PCL MBCs. The endothermic peaks attributed to melting of the PLLA segment crystals increased as the PLLA segment length increased.

We preformed XRD experiments to better understand the crystallization behavior of the MBCs. Figure 3 shows the XRD patterns of PLLA, PCL, LCL and the MBC films prepared by casting from chloroform solutions onto glass plates. The observed XRD patterns of all the MBCs are attributed predominantly to PLLA crystals. The small diffraction peaks at approximately 21° may arise from PCL crystals. The degree of crystallization of MBC1, MBC2 and MBC3 were calculated to be 30%, 30% and 32%, respectively. The segment length apparently does not affect the degree of crystallization under the examined conditions. The crystal structure of poly(lactic acid) has been reported to depend on the crystallization temperature.21, 22, 23, 24 The most common α-form, in which two chains with a 103 helical conformation are packed into an orthorhombic unit cell, is formed at temperatures above the crystallization temperature of 120 °C. The α′-form, which has the same α-form arranged in a looser manner, is formed at temperatures below 120 °C. The 2θ values of the (200)/(100) diffractions of MBCs and PLLA are 16.1–16.2°, which suggests the formation of α′-form crystals.22, 23 Notably, no diffraction peaks associated with the poly(L-lactide-co-ɛ-caprolactone) random copolymer (LCL) were observed. The lactide block segments are required to induce the crystallization of poly(L-lactide) and poly(ɛ-caprolactone) copolymers.

We evaluated the mechanical properties of the MBC films using tensile tests; the results are summarized in Table 4. The data for linear PLLA and LCL are also listed in Table 4 for comparison. The typical stress–strain curves are available in supporting information (Supplementary Figure S1). The elongation at break of the MBC films was approximately 500%, which is considerably larger than that of linear PLLA. In thermoplastic elastomers, the microphase separation of hard and soft segments is commonly observed and contributes to their unique elastic properties. In the MBC films, PLLA and PCL segments act as hard and soft segments, respectively. The PCL segment in the MBCs has an important role in determining the elongation behavior of MBC films. The moduli of all the MBC films were more than one digit greater than that of LCL. The tensile modulus and elongation at break of MBCs were also greater than those of PLLA/PCL blends, which contain PLLA and PCL crystals.25 In MBCs, crystallized lactide and amorphous PCL segments in MBCs effectively contribute to the higher modulus and larger elongation at break, respectively. Moreover, the greatest modulus of 95.1 MPa was observed for the MBC1 film, and the moduli decreased as the segment length increased. Because the degrees of crystallinity of each MBC are almost the same, the amorphous region of the MBCs could also affect the modulus. According to the DSC measurements, MBC3 contains PCL-rich amorphous regions, which could act as softer domains in MBC3.

The degradation by hydrolysis of PLLA and related copolymers is well known to be influenced by the polymers’ structure and crystallinity. We conducted hydrolysis tests in an alkaline solution (NaOH 1.0 mol l−1) for the MBC2, LCL and PLLA films and estimated their degradation behavior on the basis of weight loss, thickness change and their contact angle (Figure 4). Figure 4a shows the residual weight and thickness of the MBC2, LCL and PLLA films. MBC2 lost weight and thickness slowly in comparison with LCL and PLLA. The hydrolytic degradation under these conditions is qualitatively ordered as MBC2<LCL<PLLA. The contact angle of all films before hydrolysis was approximately 70°, which suggests that these films are hydrophobic (Figure 4b). The contact angle decreased with increasing immersion time in the case of the MBC film. The contact angle of the MBC film decreased to 20–30° after hydrolysis for 12 h, which suggests that the MBC film became hydrophilic. After 24 h, one of the MBC films became porous, with a water droplet observed to permeate through the film, while the other film had a contact angle of 26°. Finally, the MBC film was broken into small pieces when immersed for 50 h. In the case of the PLLA film, the contact angle remained approximately 70° during the hydrolysis for 4 h, and then the PLLA film decomposed into small pieces after 5 h. The slow hydrolysis of the MBC film enables us to control the surface hydrophilicity and to prepare porous hydrophilic films. Scanning electron microscopy images of the porous hydrophilic films of MBC2 are shown in Figure 5. Isolated and interconnected pores of approximately 10 μm in diameter were observed on the film. Notably, the porous hydrophilic PLLA film could not be prepared under the same conditions because of its rapid hydrolysis. The porous hydrophilic MBC film may be advantageous in biomedical applications.

Adhesion barrier tests

Postoperative adhesions are a part of the natural healing process after surgery. However, undesired adhesions between the wound sites and the nearest organs may cause severe pain and require additional operations in some cases. Bioresorbable physical barrier films have been used to prevent undesired adhesion formation. SeprafilmTM (Genzyme Corp., Cambridge, MA, USA) is the most widely used adhesion barrier film; it is composed of sodium hyaluronate and carboxymethylcellulose.26, 27, 28, 29 Because of its hygroscopic nature, SeprafilmTM requires careful handling so that it does contact any moist areas before being placed on the target organ. Moderately hydrophilic and bioabsorbable membranes are a promising alternative to SeprafilmTM, particularly in endoscopic surgery. In this study, MBC films were subjected to preliminary tests to examine their potential as adhesion barriers in the abdominal sidewalls of rats.

To evaluate their performance as an adhesion barrier film, the porous hydrophilic MBC films (l=26, m=28) prepared by hydrolysis in aqueous NaOH (1.0 mol l−1) were implanted onto the abdominal sidewalls of rats. Before the films were implanted, both sidewalls were marked with one suture of surgical silk to accelerate the biological response to form an adhesion. On one side of the sidewall, a square MBC film (3 × 3 cm) was sutured with nylon thread at each corner to fix and cover the silk mark. On the other side, the nylon thread was sutured around the silk mark without using the MBC film. After a week, the rat was killed, and the status of the adhesions was monitored. As shown in Figure 6a, severe adhesion was observed at the silk-marked site in the control experiment, where the MBC film was not used. Weak and easily removable adhesions were also observed at the nylon thread site. However, the silk-marked site was covered with the MBC film, and no adhesion was observed at this site (Figure 6b). The MBC film clearly prevented the direct contact between the silk-marked site and the nearest organ and therefore functioned as a physical barrier for adhesion. Notably, the adhesion at the nylon thread site was intermediate, as shown in Figure 6c. Table 5 summarizes the results of the adhesion test experiments for five rats. No adhesion was observed at the silk-marked site when the MBC film was implanted. In contrast, the adhesion observed at the nylon thread site was intermediate and more severe compared with the control experiments. Unfortunately, suturing of the MBC film with nylon thread is essential to fix the film at the target site because the adhesion between the MBC film and the wet surface is not very strong. Coating with bioadhesive materials, such as collagen, may improve the adhesion between the MBC and the target site.30, 31 Figure 7 shows a cross-sectional micrograph of the abdominal sidewall of a rat after 6 days of implantation. Figure 7a clearly shows the tissue generated by the adhesion between the side wall and the nearest organ in the control experiment. In contrast, fibrous tissue was observed on the surface of the sidewall in Figure 7b. Notably, no inflammation caused by the MBC film was observed on the surface. These observations suggest that the MBC film is inactive at the implanted site and may find future application in biomedicine.

Conclusion

PLLA–PCL MBCs were synthesized by the self-polycondensation of PLLA–PCL diblock copolymers. 1H NMR analysis of the PCL oligomers and DBCs confirmed the strict control over the terminal functions. High-molecular weight MBCs (Mw=(2.4–4.9) × 105 g mol−1) were synthesized by the self-polycondensation of DBCs in the presence of condensation agents. DSC measurements suggested the phase mixing of PLLA and PCL segments in the amorphous region, and the broad glass transition implies that MBCs contain PCL-rich regions that are influenced by the segment length. XRD measurements suggested that all the MBC films contain lactide segment crystals. The presence of crystallized components in the MBCs strongly affects their mechanical properties, resulting in high moduli (95–43 MPa) MBC films. The MBC films hydrolyzed slowly in comparison with PLLA, and hydrophilic porous films of MBC2 were obtained.

To estimate their potential as an adhesion barrier film, the hydrophilic porous MBC films were implanted into the abdominal sidewalls of rats. The MBC films effectively prevented adhesion at silk-marked sites in comparison with control experiments. However, intermediate adhesion was observed at the nylon-sutured site where the MBC film was fixed. The lack of inflammation induced by the MBC film at the implanted site is encouraging for future biomedical applications of this material.

Biodegradable flexible materials have attractive properties for use in biomedical applications. The self-polycondensation of diblock copolymers allows the length and ratio between the segments to be easily controlled, which enables the fine-tuning of their properties. This study reveals that the short lactide block segment strongly influences the crystallization and mechanical properties of the MBC. Moreover, this synthetic strategy can be applied to other cyclic esters such as glycolide and δ-valerolactone. Therefore, the self-polycondensation of diblock copolymers is a useful strategy for the synthesis of various biodegradable thermoplastic elastomers.

Synthesis of a poly(L-lactide)–poly(ɛ-caprolactone) multiblock copolymer.

References

Gross, R. A. & Kalra, B. Biodegradable polymers for the environment. Science 297, 803–807 (2002).

Ikada, Y. & Tsuji, H. Biodegradable polyesters for medical and ecological applications. Macromol. Rapid Commun. 21, 117–132 (2000).

Södergård, A. & Stolt, M. Properties of lactic acid based polymers and their correlation with composition. Prog. Polym. Sci. 2002, 1123–1163 (2002).

Dorgan, J. R., Braun, B., Wegner, J. R. & Knauss, D. M. Poly(lactic acids): A brief review. ACS Symp. Series 939, 102–125 (2006).

Mülhaupt, R. Green polymer chemistry and bio-based plastics: dreams and reality. Macromol. Chem. Phys. 214, 159–174 (2013).

Shi, R., Chen, D., Liu, Q., Wu, Y., Xu, X., Zhang, L. & Tian, W. Recent advances in synthetic bioelastomers. Int. J. Mol. Sci. 10, 4223–4256 (2009).

Li, Y., Thouas, G. A. & Chen, Q.-Z. Biodegradable soft elastomers: synthesis/properties of materials and fabrication of scaffolds. RSC Advances 2, 8229–8242 (2012).

Broström, J., Boss, A. & Chronakis, I. S. Biodegradable films of partly branched poly(L-lactide)-co-poly(ɛ-caprolactone) copolymer: Modulation of phase morphology, plasticization properties and thermal depolymerization. Biomacromolecules 5, 1124–1134 (2004).

Fernández, J., Meaurio, E., Chaos, A., Etxeberria, A., Alonso-Varona, A. & Sarasua, J. R. Synthesis and characterization of poly (L-lactide/ɛ-caprolactone) statistical copolymers with well resolved chain microstructures. Polymer 54, 2621–2631 (2013).

Cohn, D. & Salomon, A. H. Designing biodegradable multiblock PCL/PLA thermoplastic elastomers. Biomaterials 26, 2297–2305 (2005).

Arimura, H. & Taira, T. Artificial dura. Japan Tokkyo Kokai 2009-131358A (2009).

Nagata, M. & Sato, Y. Synthesis and properties of photocurable biodegradable multiblock copolymers based on poly(ɛ-caprolactone) and poly(L-lactide) segments. J. Polym. Sci. Part A: Polym. Chem. 43, 2426–2439 (2005).

Zhang, J., Xu, J., Wang, H., Jin, W. & Li, J. Synthesis of multiblock thermoplastic elastomers based on biodegradable poly (lactic acid) and polycaprolactone. Mater. Sci. Eng.: C 29, 889–893 (2009).

Nakayama, Y., Okuda, S., Yasuda, H. & Shiono, T. Synthesis of multiblock poly(L-lactide)-co-poly(ɛ-caprolactone) from hydroxy-telechelic prepolymers prepared by using neodymium tetrahydroborate. React. Funct. Polym. 67, 798–806 (2007).

Jeon, O., Lee, S.-H., Kim, S. H., Lee, Y. M. & Kim, Y. H. Synthesis and characterization of poly(L-lactide)−poly(ɛ-caprolactone) multiblock copolymers. Macromolecules 36, 5585–5592 (2003).

Möller, M., KåNge, R. & Hedrick, J. L. Sn(OTf)2 and Sc(OTf)3: Efficient and versatile catalysts for the controlled polymerization of lactones. J. Polym. Sci. Part A: Polym. Chem. 38, 2067–2074 (2000).

Moore, J. S. & Stupp, S. I. Room temperature polyesterification. Macromolecules 23, 65–70 (1990).

Sakuma, K., Tanaka, Y., Watanabe, S., Yokoyama, H., Iguti, A., Ikada, Y. & Tabayasi, K. Closure of the pericardium using synthetic bioabsorbable polymers. Jpn J. Artif. Organs 29, 233–238 (2000).

Yang, J.-M., Chen, H.-L., You, J.-W. & Hwang, J. C. Miscibility and crystallization of poly(L-lactide)/poly(ethylene glycol) and Poly(L-lactide)/poly(e-caprolactone) blends. Polym. J. 29, 657–662 (1997).

López-Rodríguez, N., López-Arraiza, A., Meaurio, E. & Sarasua, J. R. Crystallization, morphology, and mechanical behavior of polylactide/poly(ɛ-caprolactone) blends. Polym. Eng. Sci. 46, 1299–1308 (2006).

Santis, P. D. & Kovacs, A. J. Molecular conformation of poly(S-lactic acid). Biopolymers 6, 299–306 (1968).

Kawai, T., Rahman, N., Matsuba, G., Nishida, K., Kanaya, T., Nakano, M., Okamoto, H., Kawada, J., Usuki, A., Honma, N., Nakajima, K. & Matsuda, M. Crystallization and melting behavior of poly (L-lactic acid). Macromolecules 40, 9463–9469 (2007).

Zhang, J., Tashiro, K., Tsuji, H. & Domb, A. J. Disorder-to-order phase transition and multiple melting behavior of poly(L-lactide) investigated by simultaneous measurements of WAXD and DSC. Macromolecules 41, 1352–1357 (2008).

Saeidlou, S., Huneault, M. A., Li, H. & Park, C. B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 37, 1657–1677 (2012).

Tsuji, H. & Ada, Y. I. Blends of aliphatic polyesters. II. Hydrolysis of solution-cast blends from poly(L-lactide) and poly(ɛ-caprolactone) in phosphate-buffered solution. J. Appl. Polym. Sci. 67, 405–415 (1998).

Diamond, M. P. Reduction of adhesions after uterine myomectomy by Seprafilm membrane (HAL-F): a blinded, prospective, randomized, multicenter clinical study. Fertil. Steril. 66, 904–910 (1996).

Burns, J. W., Colt, M. J., Burgess, L. S. & Skinner, K. C. Preclinical evaluation of SeprafilmTM bioresorbable membrane. Eur. J. Surg. 163, 40–48 (1997).

Decherney, A. H. & Dizerega, G. S. Clinical problem of intraperitoneal postsurgical adhesion formation following general surgery and the use of adhesion prevention barriers. Wound Healing 77, 671–688 (1997).

Liakakos, T., Thomakos, N., Fine, P. M., Dervenis, C. & Young, R. L. Peritoneal adhesions: Etiology, pathophysiology, and clinical significance. Dig. Surg. 18, 260–273 (2001).

Suh, H., Park, S.-N. & Kim, J. H. Evaluation of tissue adhesion preventive surface modified natural and synthetic polymeric materials. Materials Science Forum 426-432, 3255–3260 (2003).

Park, S. N., Jang, H. J., Choi, Y. S., Cha, J. M., Son, S. Y., Han, S. H., Kim, J. H., Lee, W. J. & Suh, H. Preparation and characterization of biodegradable anti-adhesive membrane for peritoneal wound healing. J. Mater. Sci. Mater. Med. 18, 475–482 (2007).

Acknowledgements

This work was partially supported by Feasibility Study of Akita prefecture, Japan. We appreciate the kind donation of a random copolymer of poly(L-lactide)-co-poly(ɛ-caprolactone) (LCL) from BMG, Inc. (Kyoto, Japan).

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Jikei, M., Takeyama, Y., Yamadoi, Y. et al. Synthesis and properties of Poly(L-lactide)-Poly(ɛ-caprolactone) multiblock copolymers by the self-polycondensation of diblock macromonomers. Polym J 47, 657–665 (2015). https://doi.org/10.1038/pj.2015.49

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.49

This article is cited by

-

Synthesis and Characterization of the Temperature Controllable Shape Memory of Polycaprolactone/Poly(ethylene terephthalate) Copolyester

Fibers and Polymers (2022)

-

Polymerization of ε-caprolactone with degraded PET for its functionalization

Journal of Polymer Research (2019)

-

Enhanced proliferation of HeLa cells on PLLA-PCL and PLGA-PCL multiblock copolymers

Polymer Journal (2017)

-

Synthesis and properties of poly(L-lactide-co-glycolide)-b-Poly(ɛ-caprolactone) multiblock copolymers formed by self-polycondensation of diblock macromonomers

Polymer Journal (2017)