Abstract

In this work, we performed molecular dynamics simulations of liquid-crystalline epoxy resins using the simulation system OCTA in combination with J-OCTA. One molecule was modeled as a diamine, the ends of which are connected to derivatives of diepoxy mesogens. The number of molecules in the system was eight for the present simulation. The molecular ends were drawn by an external force in order to generate a well-aligned initial structure. We relaxed the system after removing the external force and calculated statistical average. The results exhibited an even–odd effect of density and alignment order for the number of methylene units in the mesogenic structure. The obtained alignment order of the epoxy molecules showed a strong correlation with the experimentally obtained thermal conductivity. Finally, we proposed a protocol for using the present simulation to screen for epoxy molecules of higher thermal conductivity.

Similar content being viewed by others

Introduction

Epoxy resins are widely used because of their properties of adhesion, electronic insulation and heat and chemical resistance. The properties of resins can be adjusted by altering the chemical structures of the epoxy molecules and the curing agents. Recent developments in electronic devices have enhanced the requirement for insulating epoxy resins of high thermal conductivity, and the cooling of insulated conductors is a crucial problem for highly concentrated electronic systems.

The thermal conductivity of epoxy resins is too low for practical usage. Thus, epoxy resins are used as composites with inorganic powders.1 It is hence important to suppress the disturbance of thermal conductivity caused by the epoxy resin within the powder. If epoxy resins of higher thermal conductivity can be produced, we can obtain composites with smaller amounts of inorganic powders, thus improving the mechanical properties of thermo-conductive adhesives. The mechanical and thermal stabilities of epoxy resins result from the polymer network constructed in the curing process. Controlled alignment of the network can improve the properties of the resins.

Epoxy molecules containing liquid crystal mesogens are one of the main focuses in this field. The synthesis and thermal properties of liquid-crystalline epoxy resins have been reported,2, 3 and their alignment by mechanical and magnetic forces has been examined.4

In insulating materials, electrons do not effectively contribute to the thermal conductivity. Instead, the thermal conductivity is dominated by phonon propagation. In polymer systems, the phonon propagation differs between the direction of the molecular chain axis and that perpendicular to it. In other words, the thermal conductivity of a polymer system is controlled by the alignment of the molecules. The importance of the polymer network alignment in epoxy resins with high thermal conductivity was suggested by Akatsuka and Takezawa.5

There are various combinations of positional and alignment order that can be used to describe liquid crystal systems. The nematic phase is a liquid of aligned molecules. In the smectic phase, a positional order of molecules also appears in addition to the alignment. In the present study, we examined the alignment order of epoxy molecules via molecular dynamics (MD) simulations.

We performed MD simulations for a small system of epoxy molecules. One benefit obtained by using a small system is that the computation time is reduced. In some cases, small systems present properties that differ from bulk properties.6 However, it has been reported that the solid–liquid transition appears even for a system of only eight particles.7

In MD simulations, the thermal conductivity is usually examined by calculating the energy flow along a temperature slope or by calculating the decay in the correlation of energy flow following the regime of the Green-Kubo formula.8 When using the Green-Kubo relation in atomistic systems including angle and torsion potentials, we must start with a microscopic definition of the energy flow of three- and four-body potentials.9 Much longer simulation runs are needed to obtain an accurate correlation function. The development of a general program code for calculating the energy flow of an atomistic chemical system is a heavy task. To compensate for this, we indirectly investigate the thermal conductivity of an epoxy resin by studying the alignment order of the molecules.

Simulation Procedure

Modeling

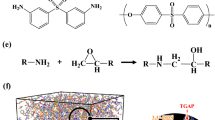

The materials for this study consist of a series of liquid-crystalline epoxy resins experimentally examined by Akatsuka and Takezawa,5 which include cured mixtures of 4,4′-diaminodiphenylmethan (DDM) and diepoxy monomers. The model molecules for the present simulation are displayed in Figures 1 and 2 and are composed of DDM molecules whose ends are replaced by derived structures from 4,4′-biphenol diglycidyl ether (BPE) and diepoxy monomers containing twin phenyl benzoate mesogens connected by a normal alkane of n carbons (TMEn). In the present study, we used n values of 3–8. As noted in Figure 1, we denote the molecules of the present study as R-DDM-R, where R is replaced by BPE or TMEn as illustrated in Figure 2. For these molecules, we set the atomistic force field GAFF10 using J-OCTA (http://www.j-octa.com/). Electrostatic interactions due to charge distributions were not considered in the present study.

The model epoxy molecule as a derivative of diaminodiphenylmethane (DDM). This structure is abbreviated as R-DDM-R with R- given in Figure 2.

End groups for R-shown in Figure 1. The n value of TMEn indicates the number of methylene units connecting twin phenyl benzoates. As described in the scheme and simulation conditions subsection, the end carbons denoted as 1 at the oxirane rings are dragged by an external force in order to align the molecules for the initial configuration.

MD simulations were performed using the MD engine COGNAC in the OCTA system (http://octa.jp). In the COGNAC input file, the units m, ɛ, and σ, respectively, for mass, energy and length were set as m=1 amu, ɛ=4.1855 kJ mol−1, and σ=1 Å. The unit of time τ is given by τ=σ(m NA/ɛ)1/2, where NA is Avogadro’s number.

Scheme and simulation conditions

We examined the alignment order of molecules in the present simulation. It is difficult to observe the spontaneous formation of uniform alignment in a short simulation run. Thus, we constructed a well-aligned structure by using an external dragging force for the initial structure and relaxed the alignment after removing the external force.

The dragging force was applied to the end carbons denoted as 1 of the oxirane rings, as shown in Figure 2. Each R-DDM-R molecule has two end dragging points. The strength of the force was 10 mστ−2 for each point. The directions of the force were opposite to each other for the two points of each molecule. This dragging was performed at the initial stage of the simulation.

The shape of a single R-DDM-R molecule was energetically optimized using a molecular mechanics calculation prepared in J-OCTA and COGNAC. The optimized single molecule was copied to obtain R-DDM-R molecules, which were then randomly placed in a cubic box with periodic boundaries. The number of molecules N in the system was eight for the present study. The distance between periodic boundaries at this stage was 100 Å, which was large enough to ensure that the molecules did not interact with each other in the initial state.

We started the simulation in this dilute condition in order to effectively align the molecules by applying the dragging force. The time step of the MD iteration was 1 fs ≈0.02 τ for the whole simulation. The temperature was controlled using a Nosé-Hoover thermostat.11 The pressure was always maintained at 1 atm.

The first simulation stage started with the dragging force. In this stage, the pressure was controlled by following the Andersen method to compress the system.12 The size of the simulation box changed, but the shape was kept cubic. Figure 3 shows a snapshot of the simulation of eight BPE-DDM-BPE molecules after equilibration at this drawing stage.

After the drawing stage, we removed the dragging force and relaxed the system for 3000 ps according to the Andersen method. For another 3000 ps, the pressure control was changed to the Parrinello-Rahman scheme, in which the cubic shape was relaxed to a general parallelepiped shape to remove inner stress.13 The density and the alignment order parameter S of the molecules were averaged for the final 1500 ps (15 × 105 time steps) at each temperature. The calculation of the alignment order parameter S is described in Appendix A. We denote the historyof simulation described here as the direct relaxation, indicating that the relaxation began at the target temperature, continuing from the initial drawing stage to the final relaxation.

In order to examine the reproducibility of the states obtained at 300 K, we examined another route to 300 K. For this purpose, we successively decreased the temperature from 450 to 400, 350 and 300 K. For example, the starting configuration at 400 K was the final state of the simulation for 450 K. At each temperature, an MD run of 3000 ps was performed in the Parrinello-Rahman scheme for pressure control. The alignment order and density were averaged for the last 1500 ps at 300 K. We denote these results as the data after cooling.

Results and discussion

Even–odd effect

In Figure 4, we show the average alignment order after direct relaxation at target temperatures of 300, 400, and 450 K. The data after cooling from 450 to 300 K are also shown. One remarkable point to note is the even–odd effect because of the number n of methylene units of TMEn. The even–odd effect is known to occur for the number of methylene units of liquid crystal molecules.14, 15 Figure 4 indicates that the alignment order for even values of n is higher than that of the adjacent odd numbers for 300 and 450 K after the direct relaxation. The appearance of the even–odd effect is dependent on the temperature and history of the simulation. Figure 4 shows that the results obtained after the direct relaxation at 400 K do not show a remarkable even–odd effect.

Alignment order S after relaxation at each temperature. The closed circles, closed triangles and closed squares represent the results of the direct relaxation, respectively, at 300, 400 and 450 K. The open circles represent data at 300 K after cooling from 450 K. The solid lines show results for TMEn-DDM-TMEn. The dotted lines are references.

In this study, the simulation started from a highly oriented structure. We expect that when the temperature decreases to 300 K, thermal agitation will not be sufficient to overcome the threshold needed to escape the local energy minimum. The effect of the number of methylene units on the correlation of end mesogens produced an even–odd effect in placing the system in the local energy minimum. At high temperatures such as 450 K, thermal agitation is sufficient to decrease the alignment order. Figure 4 shows that thermal excitement destroys the alignment more effectively for odd values of n than for even values of n at 450 K. However, for 400 K, we expect that the energy cost required to escape from the energy local minimum will increase the relaxation time in which the system reaches equilibrium. For this case, at 400 K, the system did not reach equilibrium in the present simulation time in the direct relaxation scheme.

Figure 4 also shows the alignment order at 300 K after cooling from 450 K. In this case, the alignment orders for even values of n in TMEn were the same as those of the direct relaxation at 300 K. In contrast, the alignment order for odd values of n were not. The order decreased significantly compared with the value of the direct relaxation. This result indicates that well-aligned structures of TMEn-DMM-TMEn molecules of even n are stable, as they can also be established by cooling. However, the molecules of odd n cannot overcome the disorder caused by thermal disturbance. As a result, the even–odd effect was enhanced compared with that of the direct relaxation process.

In Figure 5, we replace the vertical axis of Figure 4 with the density. As with the alignment order, the density for even values of n in TMEn-DDM-TMEn matched that of direct relaxation at 300 K when we cooled the system from 450 K, while that of odd n did not.

Density dependence on molecular structure. The closed circles, closed triangles and closed squares show data for direct relaxation at 300, 400 and 450 K, respectively. The open circles display data for 300 K after cooling from 450 K. The crosses show the experimentally obtained density values given in Table 1. The solid lines display results for TMEn-DDM-TMEn. The dotted lines are references.

Figure 5 also shows the experimentally obtained density values given in Table 1. To obtain the experimental data shown in Table 1, we produced samples by curing diepoxy monomers with a stoichiometric amount of DDM. The thermal conductivity was measured for experimental samples corresponding to TMEn-DDM-TMEn with n=3 and 5. The method for measuring the thermal conductivity was described in a previous paper,16 from which we obtained data for TMEn-DDM-TMEn of even n and BPE-DDM-BPE. The densities of the samples were measured by a densitometer (Alfa Mirage Co., Ltd., Osaka, Japan, SDL-200L).

Figure 5 shows that the experimental density for odd values of n qualitatively agrees with the simulation data; however, the results for even values of n do not. The even–odd effect of the experimental density is more obvious than that of the simulation, and the difference between the experimental and simulation density results is remarkable for even values of n.

Correlation to experimentally obtained thermal conductivity

We examined the relationship between the experimentally obtained thermal conductivity and the present simulation data, which are presented in Table 1 and Figure 6. Owing to the even–odd effect, the data are shown on the left-hand side and the right-hand side in Figure 6.

Plots depicting the data of Table 1. With the experimentally obtained thermal conductivities as the horizontal axis, the open circles indicate the alignment orders obtained by simulation for the left-hand axis and the closed circles show the densities obtained by simulation for the right-hand axis. The solid line is fitted for the alignment orders without the TME3 data. The dotted lines are references.

The data for the simulated density and experimental thermal conductivity did not show any remarkable correlations. However, the alignment shows a strong correlation with the thermal conductivity, except for TME3. The thermal conductivity and alignment order fit well to the linear solid line shown in Figure 6. The correlation between the alignment order and the thermal conductivity of the present results indicates that the thermal conductivity is strongly related to the molecular alignment.

According to Debye, the thermal conductivity K of a resin is related to the heat capacity C per unit volume, the velocity of sound v, and the mean free path l of a phonon by17

Molecular alignment decreases the mutually excluded volume between molecules. This increases the density and contributes to an increase in thermal conductivity by increasing the heat capacity. Such an alignment can also cause a difference between the mean free path of the chain direction and that of the direction perpendicular to the chain. Phonon propagation along the molecular chain results in an intramolecular energy transfer, and phonon propagation perpendicular to the chain causes intermolecular energy transfer. The alignment of molecules decreases defects that may disturb phonon propagation. In other words, alignment can improve intra- and intermolecular energy transfer, resulting in an increase in l in the system. As a result, the alignment of molecules improves the thermal conductivity of a polymer system by increasing C and l.

Conclusions

We performed MD simulations for a small system of 8 R-DDM-R molecules and found that the alignment order at 300 K depends on the type of R employed. There are various candidate epoxy molecules for thermoset resin of high thermal conductivity. Our present mesogenic structure was limited to the biphenyl type of BPE and the twin-mesogen type of TMEn. Other types of mesogens will be examined in the future. To obtain liquid-crystalline epoxy resin of higher thermal conductivity, we propose an examination using the present simulation for screening before actual synthesis.

Following our present simulation, a protocol for screening is given as follows. We perform MD simulations for a system of eight molecules of amines whose ends are connected to an epoxy structure. In the present case, the amine corresponds to DDM and the epoxy is BPE or TMEn. After drawing the molecule, we relax the system at a temperature that provides enough thermal agitation to shift the system from the strongly drawn state. Then, we cool the system to 300 K and analyze the alignment order of the system. By considering the correlation between the alignment order and the experimentally obtained thermal conductivity shown in Figure 6, we propose that the molecular structure with a higher alignment order has a higher thermal conductivity. We can ignore the structures giving low alignment orders for an initial screening of molecular structures before actual synthesis.

References

Akatsuka, M., Takezawa, Y. & Amagi, S. Influence of inorganic fillers on curing reactions of epoxy resins initiated with a boron trifluoride amine complex. Polymer 42, 3003–3007 (2001).

Barclay, G. G., Ober, C. K., Papathomas, K. I. & Wang, D. W. Liquid crystalline epoxy thermosets based on dihydroxymethylstilbene: synthesis and characterization. J. Polym. Sci., Part A: Polym. Chem. 30, 1831–1843 (1992).

Shiota, A. & Ober, C. K. Synthesis and curing of novel LC twin epoxy monomers for liquid crystal thermosets. J. Polym. Sci., Part A: Polym. Chem. 34, 1291–1303 (1996).

Barclay, G. G., McNamee, S. G., Ober, C. K., Papathomas, K. I. & Wang, D. W. The mechanical and magnetic alignment of liquid crystalline epoxy thermosets. J. Polym. Sci., Part A: Polym. Chem. 30, 1845–1853 (1992).

Akatsuka, M. & Takezawa, Y. Study of high thermal conductive epoxy resins containing controlled high-order structures. J. Appl. Polym. Sci. 89, 2464–2467 (2003).

Veerman, J. A. C. & Frenkel, D. Relative stability of columnar and crystalline phases in a system of parallel hard spherocylinders. Phys. Rev. A 43, 4334–4343 (1991).

Kegel, W. K., Reiss, H. & Lekkerkerker, H. N. W. Freezing transition in very small systems of hard spheres. Phys. Rev. Lett. 83, 5298–5301 (1999).

Schelling, P. K., Phillpot, S. R. & Keblinski, P. Comparison of atomic-level simulation methods for computing thermal conductivity. Phys. Rev. B 65 144306-1–12 (2002).

Torii, D., Nakano, T. & Ohara, T. Contribution of inter- and intramoleular energy transfers to heat conduction in liquids. J. Chem. Phys. 128 044504-1–8 (2008).

Wang, J., Wolf, R. M., Caldwell, J. W., Kollman, P. A. & Case, D. A. Development and testing of a general amber force field. J. Comput. Chem. 25, 1157–1174 (2004).

Hoover, W. G. Canonical dynamics: equilibrium phase-space distributions. Phys. Rev. A 31, 1695–1697 (1985).

Andersen, H. C. Molecular dynamics simulations at constant pressure and/or temperature. J. Chem. Phys. 72, 2384–2393 (1980).

Parrinello, M. & Rahman, A. Polymorphic transitions in single-crystals: a new molecular dynamics method. J. Appl. Phys. 52, 7182–7190 (1981).

Marčelja, S. Chain ordering in liquid crystals. I. even-odd effect. J. Chem. Phys. 60, 3599–3604 (1974).

Pines, A., Ruben, D.J. & Allison, S. Molecular ordering and even-odd effect in a homologous series of nematic liquid crystals. Phys. Rev. Lett. 33, 1002–1005 (1974).

Fukushima, K., Takahashi, H., Takezawa, Y., Kawahira, T., Itoh, M. & Kanai, J. High thermal conductive resin composites with controlled nanostructures for electric devices. IEEJ Trans. FM 126, 1167–1172 (2006).

Kittel, C. Introduction to Solid State Physics. 7th edn, 131–133 (John Wiley & Sons, Inc., New York, Chichester, Brisbane, Toronto, Singapore, 1996).

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

Calculation of the alignment order

The alignment order parameter S in this study was estimated with respect to the averaged eigenvector n of the moment of inertia tensor of the molecules. A calculation program for this purpose was already available in COGNAC.

n is a unit vector given by

where uj is the unit eigenvector of the smallest eigenvalue of the j-th molecule. When uj is an eigenvector, the opposite -uj is also an eigenvector. In calculating n, we choose uj as

in order not to cancel the length of the vector. The alignment order parameter S is given by:

Rights and permissions

About this article

Cite this article

Koda, T., Toyoshima, T., Komatsu, T. et al. Ordering simulation of high thermal conductivity epoxy resins. Polym J 45, 444–448 (2013). https://doi.org/10.1038/pj.2012.163

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.163

Keywords

This article is cited by

-

Enhanced in-plane thermal conductivity of ultrahigh molecular weight polyethylene films via a new design of a two-step biaxial stretching mode

Polymer Journal (2021)

-

Design of peptides with strong binding affinity to poly(methyl methacrylate) resin by use of molecular simulation-based materials informatics

Polymer Journal (2021)

-

Liquid Crystalline Epoxies with Lateral Substituents Showing a Low Dielectric Constant and High Thermal Conductivity

Journal of Electronic Materials (2017)

-

High thermal conductivity epoxies containing substituted biphenyl mesogenic

Journal of Materials Science: Materials in Electronics (2016)