Abstract

A chain transfer agent was immobilized onto the surface of 11-μm diameter silica particles (CPD-SiO2) for use in reversible addition-fragmentation chain transfer (RAFT)-controlled radical polymerization. pH-responsive poly(6-(acrylamido)hexanoic acid) (PAaH)-grafted silica particles (PAaH-SiO2) were prepared via RAFT-controlled radical polymerization using CPD-SiO2. Immobilization of the PAaH chains onto the surface of silica particles was confirmed by thermogravimetric analysis, attenuated total reflection-Fourier transfer infrared and scanning electron microscopy measurements. The solubility of PAaH in water is strongly dependent on the pH of the solution. PAaH-SiO2 was flocculated at pH 3 because of the hydrophobic interaction of the grafted PAaH chains with protonated carboxyl pendant groups. In contrast, PAaH-SiO2 was dispersed at pH 10 because of electrostatic repulsion between the grafted PAaH chains with pendant carboxylate ions. Millimeter-sized ‘liquid marbles’ can be prepared using the pH-responsive PAaH-SiO2 particles. The ‘liquid marble’ can be transferred intact onto the surface of a neutral or acidic water pool and exhibit long-term stability. When the pH of the water pool becomes alkaline, the ‘liquid marble’ immediately bursts on the surface of the water pool.

Similar content being viewed by others

Introduction

There has been increased interest in solid particles adsorbed to liquid–liquid, gas–liquid and gas–solid interfaces. An emulsion can be stabilized by solid particles adsorbed to an oil–water (liquid–liquid) interface, which is known as a Pickering emulsion.1, 2, 3 Such emulsions have been extensively studied over the last decade.4, 5 Furthermore, ‘liquid marbles’, which are stabilized by solid particles adsorbed at gas–liquid interfaces, have attracted increasing attention with respect to their potential applications in cosmetics, pharmaceuticals and in home and personal care products.6, 7, 8, 9 ‘Liquid marbles’ are liquid-in-gas dispersed systems prepared using relatively hydrophobic particles adsorbed onto a gas–liquid interface. It has been reported that inorganic particles such as silica,10, 11, 12, 13 graphite,14 synthetic polymer particles15, 16, 17, 18 and surface-modified lycopodium powder19 can be used as effective ‘liquid marble’ stabilizers. The ‘liquid marbles’ that are coated with hydrophobic particles can float on the water surface and remain intact on glass. One of the present authors has reported the preparation of pH-responsive ‘liquid marbles.’20, 21 In this case, particles with pH-responsive cationic polymers, such as poly(2-(diethylamino)ethyl methacrylate) or poly(2-vinylpyridine), on their surfaces were used as ‘liquid marble’ stabilizers. ‘Liquid marbles’ on the surface of the water pool immediately disintegrated upon addition of acid to the pool, because the weakly alkaline nature of the particle surface confers pH-responsive behavior. In order to widen the application range of liquid marbles, it is important to develop pH-responsive liquid marbles stabilized with anionic polymer-modified particles, which can be disrupted on addition of alkaline solution. However, there has been no study on alkaline-induced breakable liquid marbles as far as we are aware. Herein, we have investigated the stability control of ‘liquid marbles’ prepared using poly(6-(acrylamido)hexanoic acid) (PAaH)-grafted micrometer-sized silica particles (PAaH-SiO2) used as ‘liquid marble’ stabilizers, by tuning their surface hydrophobicity/hydrophilicity with external pH stimuli. Under acidic and neutral pH conditions, the surface of PAaH-SiO2 is hydrophobic, because the pendant carboxyl groups in PAaH are protonated. However, under alkaline conditions, PAaH can dissolve in water and the wettability of the surface of PAaH-SiO2 increases, because the pendant carboxyl groups are deprotonated to form carboxylate ions. It is expected that PAaH-SiO2 can stabilize ‘liquid marbles’ on the surface of an acidic or neutral water pool; however, the ‘liquid marbles’ would disintegrate upon the addition of an alkali.

Grafting a polymer to a solid surface involves polymer chains grafted to the solid substrate (grafting to), or the grafting reaction can proceed by polymerization from the surface (grafting from). In both cases a thin polymer layer can be formed on the solid surface. However, it is difficult to form a polymer layer with high density using the grafting to approach. Therefore, we performed the grafting from the method to graft PAaH onto the surface of silica particles in order to prepare a high-density polymer layer. Many researchers have studied the controlled radical polymerization at the surface of a solid particle; for example, Lattuada et al.22 reported that poly(acrylic acid) was grafted to magnetic nanoparticles via atom transfer radical polymerization. Zhao et al.23 reported that vinyl monomers such as methyl acrylate, n-butyl acrylate, N,N-dimethylacrylamide, N-isopropylacrylamide, methyl methacrylate and styrene could be grafted to silica via reversible RAFT-controlled radical polymerization.

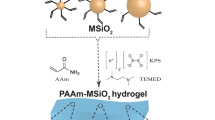

In this work, PAaH-SiO2 was prepared via the grafting from approach with a RAFT-controlled radical polymerization method (Scheme 1). The stability of pH-responsive ‘liquid marbles’ formed on a water surface using PAaH-SiO2 was studied at various pH. These PAaH-SiO2 particles are shown to be interesting novel pH-responsive particulate ‘liquid marble’ stabilizers. This study shows the first example of pH-responsive ‘liquid marbles’ that can disintegrate upon addition of alkali, rather than acid.

Experimental procedure

Materials

Silica particles (SiO2) with diameters of 11 μm (HIPRESICA, Ube-Nitto Kasei, Tokyo, Japan) were used after drying under reduced pressure at 100 °C for 3 days. 2,2′-azobis(isobutyronitrile) (98%, Wako Pure Chemical Industries, Osaka, Japan) was used after recrystallization from methanol. 4-Cyanopentanoic acid dithiobenzoate (CPD)24 and sodium 6-(acrylamido)hexanoate (AaH)25 were synthesized according to previously reported methods. Toluene, methanol and dichloromethane were dried over 4 Å molecular sieves and purified by distillation. 3-Aminopropyltriethoxysilane (APSi; 96%, Tokyo Chemical Industry, Tokyo, Japan), 1,3-dicyclohexylcarbodiimide (95%, Kishida Chemical, Osaka, Japan), 4-(dimethylamino)pyridine (99%, Toyo Gosei, Tokyo, Japan), 2-mercapto-2-thiazoline (88%, Wako Pure Chemical Industries), safranin (80%, Kanto Chemical, Tokyo, Japan) and gelatin from bovine bone (Wako Pure Chemical Industries) were used as received. Water was purified using a Millipore Milli-Q system (Millipore, Billerica, MA, USA). Other reagents were used as received.

Synthesis of amino group-immobilized silica particles (APSi-SiO2)

SiO2 particles (10.0 g) were dispersed in dry toluene (330 ml) using ultrasonication for 20 min, after which APSi (10.0 g, 55.9 mmol) was added to the solution. The solution was heated at 100 °C for 18 h with stirring. After the reaction, the silica particles were washed by centrifugation at 6000 r.p.m. for 30 min in acetone (three times) and then dried in a vacuum oven at 100 °C overnight to obtain APSi-immobilized silica particles (APSi-SiO2, 7.55 g).

Synthesis of activated CPD

CPD (10.0 g, 35.8 mmol), 2-mercapto-2-thiazoline (4.27 g, 35.8 mmol) and 4-(dimethylamino)pyridine (0.438 g, 3.59 mmol) were dissolved in distilled dichloromethane (120 ml).26, 27 1,3-Dicyclohexylcarbodiimide (9.65 g, 46.8 mmol) in distilled dichloromethane (80 ml) was added dropwise to the solution under an Ar atmosphere and the reaction mixture was then stirred at room temperature for 18 h. The solvent was removed by evaporation and purified by silica column chromatography using chloroform as an eluent. Activated CPD was obtained as a red oil (3.61 g, 24.4%). 1H NMR (500 MHz, CDCl3): δ (p.p.m.) 1.94 (s, 3 H), 2.56–3.01 (m, 4 H), 3.13 (t, 1 H), 4.58 (t, 1 H), 7.40 (m, 2 H), 7.56 (m, 1 H), 7.90 (m, 2 H).

Synthesis of CPD-immobilized silica particles (CPD-SiO2)

APSi-SiO2 (3.60 g) and activated CPD (3.61 g, 9.50 mmol) were dispersed in dry toluene (132 ml) and the reaction was carried out at room temperature for 20 h with stirring. After the reaction, the particles were washed by centrifugation at 6000 r.p.m. for 30 min in acetone (3 times) and then dried in a vacuum oven at 120 °C overnight to obtain CPD-immobilized silica particles (CPD-SiO2, 3.33 g).

Synthesis of PAaH-grafted silica particles (PAaH-SiO2)

CPD-SiO2 (1.20 g), CPD (5.1 mg, 0.0183 mmol), AaH (1.00 g, 5.41 mmol) and 2,2′-azobis(isobutyronitrile) (1.4 mg, 0.00853 mmol) were dispersed in methanol (8.63 ml). The polymerization was performed at 60 °C for 24 h with stirring under an Ar atmosphere. After polymerization, the supernatant was measured by gel-permeation chromatography, and the particles were dispersed in a pH 3 aqueous solution and then precipitated by centrifugation at 6000 r.p.m. for 30 min. The precipitated particles were washed by centrifugation at 6000 r.p.m. for 30 min in methanol (two times) and in acetone (three times). The particles were dried in a vacuum oven at 120 °C overnight to yield PAaH-grafted silica particles (PAaH-SiO2, 1.00 g).

Preparation of ‘liquid marbles’

Pure water or safranin dye-containing water was dispensed as 7 μl droplets and mixed with the dried PAaH-SiO2 particles. Under these conditions, the PAaH-SiO2 powder spontaneously coats the water droplet, which then behaves as a perfectly non-wetting ‘liquid marble’ when transferred either onto a glass slide or onto the surface of a water pool.28

Measurements

1H NMR

1H NMR spectra were obtained with a Bruker BioSpin (Billerica, MA, USA) DRX 500 FT-NMR spectrometer.

Gel-permeation chromatography

Gel-permeation chromatography was performed using a refractive index detector equipped with a Shodex 7.0 μm bead size GF-7M HQ column (exclusion limit ∼107, Showa Denko K. K., Tokyo, Japan) operated at 40 °C under a flow rate of 0.6 ml min−1. A phosphate buffer (pH 9, 50 mM) containing 10 vol% acetonitrile was used as an eluent. The values of Mn and Mw/Mn were calibrated according to standard sodium poly(styrenesulfonate) samples of different molecular weights ranging from 1.37 × 103 to 2.16 × 106.

Attenuated total reflection-Fourier transform infrared

Attenuated total reflection-Fourier transfer infrared spectra were recorded using a Jasco (Tokyo, Japan) FT/IR-4200 spectrophotometer with an ATR PRO450-S base kit and ZnSe prism. Spectra were collected over 64 scans with a spectral resolution of 1.0 cm−1.

Thermogravimetric analysis

Thermogravimetric analysis was performed using an Exstar TG/DTA 6200 apparatus (SII Nano Technology, Chiba, Japan) under nitrogen with a flow rate of 100 ml min−1 and a heating rate of 2 °C per min. The graft density of the polymer (Γ), the distance between graft sites (D) and the thickness of the grafted polymer layer (H) were estimated according to the following Equations:

where R is the radius of the silica particle (=5.5 μm), ρSiO2 and ρpolymer are the mass density of the silica particles (1.93 g cm−3) and polymer, respectively, φpolymer is the mass fraction of the polymer (obtained from TGA) and NA is the Avogadro number.29, 30

Scanning electron microscopy

Scanning electron microscopy (SEM) images were obtained using a VE-9800 (Keyence, Osaka, Japan) for all silica particle samples operating at 5 kV. SEM samples were coated with platinum using a Sanyu Electron Quick Coater SC-701 Mk-II (Sanyu Electron, Tokyo, Japan).

Percent transmittance (%T)

The %T was measured at 600 nm using a Jasco V-530 UV-Vis spectrophotometer with quartz cells having a path length of 1.0 cm. Measurements were recorded at predetermined time intervals for dispersed PAaH-SiO2 with a concentration of 4.0 g l−1 in water adjusted to pH 3 and 10 with aqueous HCl and NaOH solutions.

Optical microscopy

Optical microscopy images were obtained using a Keyence VHX-100 microscope with a VHZ-450 zoom lens. The pH of PAaH-SiO2 dispersions in water were adjusted to 3 and 10 using aqueous HCl and NaOH solutions. The water dispersion of the PAaH-SiO2 particles was placed between a glass slide and a cover glass for microscopic observation. A Keyence (Osaka, Japan) VH-Z00R zoom lens was used to record photographic images of the millimeter-sized ‘liquid marbles.’

Results and discussion

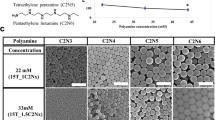

CPD-SiO2 particles can be used for the RAFT-controlled radical polymerization of AaH in methanol (Scheme 1). We have performed the polymerization of AaH in the presence of CPD-SiO2 and CPD as a free chain transfer agent.31 After the polymerization, PAaH-SiO2 was isolated from free PAaH, of which the Mn and Mw/Mn values were measured using gel-permeation chromatography (Figure 1). The Mn and Mw/Mn values for free PAaH were 3.19 × 104 and 1.07, respectively. The narrow Mw/Mn value indicated that the polymerization proceeded in accordance with a controlled/living radical polymerization mechanism. The number-average degree of polymerization was calculated from Mn to be 153. A polymer chain length similar to that of the free polymer can be grafted onto the surfaces of silica particles.23

Figure 2 shows attenuated total reflection-Fourier transfer infrared spectra of bare SiO2, PAaH-SiO2 and PAaH. In the spectrum of PAaH-SiO2 (Figure 2b), new absorption peaks at 1547 (amido, C=O), 1649 (amido, C=O), 1721 (carboxyl group, C=O) and 2937 cm−1 (C-H), which are characteristic of PAaH chains (Figure 2c), were evident. These results indicate that the grafting of PAaH onto the silica surface was successfully achieved by RAFT-controlled radical polymerization of AaH using CPD-SiO2. Attenuated total reflection-Fourier transfer infrared spectra of APSi-SiO2 and CPD-SiO2 were also measured; however, the spectra were almost the same as that of bare SiO2. The amounts of immobilized APSi and CPD on the surface of the silica particles were too small, because the specific surface area of 11 μm diameter SiO2 particles is much less than that of nanometer-sized particles.

Immobilization of the PAaH polymer chains onto the silica particles was confirmed by TGA. Figure 3 compares TGA curves for the bare-SiO2 and PAaH-SiO2 particles. The weight loss for bare SiO2 and PAaH-SiO2 was 0 and 0.78%, respectively. Exact weight loss values for APSi-SiO2 and CPD-SiO2 could not be estimated from TGA, because the amounts of APSi and CPD immobilized onto the SiO2 particle surfaces were too small. Assuming the mass density of PAaH is 1.0 g cm−3, the graft density (Γ) of PAaH on the surface of SiO2 was calculated from Equation (1) and TGA data to be 0.28 chains per nm2. The distance between graft sites (D) and the thickness of the grafted PAaH layer (H) were calculated from Equations (2) and (3) to be 1.89 and 14.8 nm, respectively. The H value for the PAaH layer of 14.8 nm, which is smaller than that expected from computer simulation of the end-to-end distance of a fully extended PAaH chain length with a degree of polymerization of 153 can be calculated to be 38.2 nm.

Figure 4 compares SEM images of untreated bare SiO2 and PAaH-SiO2. The surface of bare SiO2 is smooth and without roughness (Figures 4a and b). In contrast, the SEM images of PAaH-SiO2 show a rough surface, which suggests that the PAaH polymer chain was grafted on the surface (Figures 4c and d). The shape of PAaH-SiO2 was maintained as a fairly spherical shape after polymerization with vigorous stirring.

The pH-responsive association and dissociation behavior of PAaH-SiO2 particles in water was investigated. Figure 5a shows photographs of the dispersibility of PAaH-SiO2 in water at pH 3 and 10, immediately after vigorous shaking. The aqueous solution at pH 3 was more transparent than that at pH 10, because the PAaH-SiO2 particles were precipitated and immediately settled at pH 3. In contrast, the aqueous solution at pH 10 was turbid, because the PAaH-SiO2 particles were dispersed. Almost all bare silica particles precipitate and settle in water, because the density of the particles is 1.93 g cm−3. Figure 5b shows time-course changes in the stability of aqueous PAaH-SiO2 suspensions at pH 3 and 10. If the 11 μm diameter particles are well dispersed, then the %T value at 600 nm is small. When the particles are completely precipitated and settled, %T at 600 nm becomes 100%. The photograph shown in Figure 5a immediately after vigorous shaking corresponds to time=0 in Figure 5b. %T at pH 3 and 10 at time=0 was 46.3 and 17.9%, respectively. %T at pH 3 and 10 increased with increasing time and reached a maximum of 97.9 and 89.2%, respectively, at time=180 s. It is apparent that the PAaH-SiO2 particles are stably dispersed in water at pH 10 compared with those at pH 3. At pH 3, the PAaH graft chains cannot dissolve in water, because the pendant hexanoic acid groups are protonated. Therefore, the PAaH-SiO2 particles at pH 3 tend to associate because of the hydrophobic interaction between the PAaH graft chains on the particle surfaces. At pH 10, the PAaH graft chains can dissolve in water, because the pendant hexanoate groups are ionized because of deprotonation. The PAaH-SiO2 particles at pH 10 tend to disperse because of an increase in surface wettability of the particles and the electrostatic repulsion of the pendant deprotonated carboxylate ions in the PAaH graft chains.

The pH-induced flocculation and dispersion behavior of PAaH-SiO2 suspensions in water was studied using optical microscopy. At pH 3, flocculation of the particles was observed because of the hydrophobic interaction between protonated PAaH chains (Figure 6a). The pendant hexanoic acid groups in PAaH are hydrophobic, and the wettability of the PAaH-SiO2 particle surface is decreased at pH 3. NaOH aqueous solution was added to the aqueous suspension of PAaH-SiO2 to change the pH from 3 to 10, and the suspension was mixed with a vortex mixer for 1 min (Figure 6b). The particles were dispersed separately because of the electrostatic repulsion between the pendant negatively charged hexanoate groups in the PAaH graft chains. At pH 10, the PAaH graft chains become hydrophilic polyanions, because the pendant hexanoate groups are deprotonated. HCl aqueous solution was added to the aqueous suspension to change the pH from 10 to 3 and the suspension was mixed with a vortex mixer for 1 min (Figure 6c). Flocculation of the particles was again observed at pH 3. Furthermore, NaOH aqueous solution was added to the aqueous suspension to change the pH from 3 to 10 and the suspension was mixed with a vortex mixer for 1 min (Figure 6d), which again resulted in a dispersion of particles. These observations indicate that the surface wettability of PAaH-SiO2 can be reversibly controlled by changing the pH of the solution.

Optical microscope images of the reversible association and dissociation behavior of PAaH-SiO2 particles in water (a) at pH 3, (b) at pH 10 after addition of NaOH aqueous solution to a, (c) at pH 3 after addition of HCl aqueous solution to b and (d) at pH 10 after addition of NaOH aqueous solution to c. A full color version of this figure is available at Polymer Journal online.

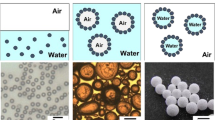

Individual ‘liquid marbles’ were prepared by rolling a 7 μl droplet of pure water over the dried PAaH-SiO2 particles. The particles immediately coated and armored the water droplet and rendered it hydrophobic. These ‘liquid marbles’ clearly have significant surface roughness, which suggests that they are coated with particle multilayers rather than just a monolayer (Figure 7c). We performed SEM measurements for the ‘liquid marbles’ that were prepared using the PAaH-SiO2 particles and an aqueous solution of gelatin to fix the structure. The SEM observation of the surface fine structure (Supplementary Figure S1) indicates that the PAaH-SiO2 particles are accumulated at the surface of the ‘liquid marbles.’ The ‘liquid marbles’ can be transferred intact onto a hydrophilic substrate such as glass and even the planar surface of a water pool within a Petri dish, where they become highly mobile. Figures 7a and b shows ‘liquid marbles’ with a radius of 1 mm, which are made of pure water, placed on a glass plate and pure water pool surface, respectively. In control experiments, no liquid marbles could be formed using bare SiO2 particles, because their surfaces can be well wetted by water. This control experiment indicated that the PAaH graft chains on the silica surface have a crucial role in the formation of ‘liquid marbles.’

‘Liquid marbles’ were prepared by rolling a 7 μl droplet of aqueous safranin dye solution over the dried PAaH-SiO2 particles, which was then transferred to the water pool within a Petri dish. The PAaH-SiO2 particles adsorbed at the air–water surface of the ‘liquid marble’ prevents the diffusion of water between the ‘marble’ interior and the bulk liquid. The water pool was not colored when the ‘liquid marble’ was stable on the planar air–water surface (Figure 8a), but the ‘liquid marble’ eventually burst on the water surface. The destabilization time, defined as the time required for the ‘liquid marble’ to burst after transfer to the water face, was measured. Measurements were recorded more than five times and the average destabilization time below pH 4 was 7.5 min. Enhanced stabilities were achieved below pH 4, which indicates that the protonated PAaH-SiO2 particles are sufficiently hydrophobic to adsorb strongly at the air–water interface under these conditions. On the other hand, the liquid marbles were always unstable and burst above pH 9 within ∼0.5 min of transfer to the water pool surface. This is because the non-protonated PAaH chains led to spontaneous desorption of the particles, followed by disintegration of the ‘liquid marbles.’ The resulting anionic PAaH-SiO2 particles are then dispersed into the acidic bulk solution. The minimum pH required for long-term ‘liquid marble’ stability is closely correlated with the pKa value of 1-aminohexanoic acid (=4.37).

The ‘liquid marble’ consisting of aqueous safranin dye solution coated with PAaH-SiO2 particles remained stable for several minutes when placed on the water pool at neutral or acidic pH; however, it immediately burst and released safranin dye upon addition of a small amount of aqueous NaOH solution to the water pool (Figure 8b). A video of the pH-responsive behavior of the ‘liquid marble’ is provided Supplementary Video S1 in the Supplementary Information. Therefore, a ‘liquid marble’ of water coated with PAaH-SiO2 particles subsequently placed on the water pool rapidly disintegrated in response to the alkalinity of the water pool. When pure water instead of the aqueous NaOH solution was added to the water pool, the ‘liquid marble’ remained unchanged.

Conclusions

pH-responsive PAaH chains were grafted from the surface of CPD-SiO2 via RAFT-controlled radical polymerization. The graft density of PAaH and the thickness of the grafted PAaH layer on the surface of SiO2 were 0.28 chains per nm2 and 14.8 nm, respectively. The PAaH-SiO2 particles in water at pH 3 tend to associate because of the hydrophobic interaction between PAaH graft chains on the PAaH-SiO2 surface. In contrast, the PAaH-SiO2 particles tend to disperse in water at pH 10 because of an increase in surface wettability and the electrostatic repulsion of the PAaH graft chains. Finally, ‘liquid marbles’ were prepared using PAaH-SiO2 particles and the stability of the ‘liquid marbles’ was confirmed to change according to pH.

Synthetic route for pH-responsive PAaH-grafted silica particles (PAaH-SiO2) via RAFT-controlled radical polymerization.

References

Ramsden, W. Separation of solids in the surface-layers of solutions and ‘suspensions’ (observations on surface-membranes, bubbles, emulsions, and mechanical coagulation). Proc. R. Soc. London 72, 156–164 (1903).

Pickering, S. U. CXCVI.-emulsions. J. Chem. Soc. Trans. 91, 2001–2021 (1907).

Amalvy, J. I., Armes, S. P., Binks, B. P., Rodrigues, J. A. & Unali, G.- F. Use of sterically-stabilised polystyrene latex particles as a pH-responsive particulate emulsifier to prepare surfactant-free oil-in-water emulsions. Chem. Commun. 1826–1827 (2003).

Binks, B. P. & Lumsdon, S. O. Pickering emulsions stabilized by monodisperse latex particles: effects of particle size. Langmuir 17, 4540–4547 (2001).

Li, J. & Stöver, H. D. H. Doubly pH-responsive pickering emulsion. Langmuir 24, 13237–13240 (2008).

Aussilious, P. & Quere, D. Properties of liquid marbles. Proc. R. Soc. London Ser. A 426, 973–999 (2006).

Fujii, S. & Murakami, R. Microparticles as foam and liquid marble stabilizers. KONA 26, 153–166 (2008).

Binks, B. P. & Murakami, R. Phase inversion of particle-stabilized materials from foams to dry water. Nat. Mater. 5, 865–869 (2006).

Mahadevan, L. & Pomeau, Y. Rolling droplets. Phys. Fluids 11, 2449–2454 (1999).

Aussillous, P. & Quéré, D. Liquid marbles. Nature 411, 924–927 (2001).

Rao, A. V., Kulkarni, M. M. & Bhagat, S. D. Transport of liquids using superhydrophobic aerogels. J. Colloid Interface Sci. 285, 413–418 (2005).

Wang, W., Bray, C. L., Adams, D. J. & Cooper, A. I. Methane storage in dry water gas hydrates. J. Am. Chem. Soc. 130, 11608–11609 (2008).

Bhosale, P. S., Panchagnula, M. V. & Stretz, H. A. Mechanically robust nanoparticle stabilized transparent liquid marbles. Appl. Phys. Lett. 93, 034109-1-3 (2008).

Dandan, M. & Erbil, H. Y. Evaporation rate of graphite liquid marbles: comparison with water droplets. Langmuir 25, 8362–8367 (2009).

Bormashenko, E., Pogreb, R., Bormashenko, Y., Musin, A. & Stein, T. New investigations on ferrofluidics: ferrofluidic marbles and magnetic-field-driven drops on superhydrophobic surfaces. Langmuir 24, 12119–12122 (2008).

Bormashenko, E., Pogreb, R., Whyman, G., Musin, A., Bormashenko, Y. & Barkay, Z. Shape, vibrations, and effective surface tension of water marbles. Langmuir 25, 1893–1896 (2009).

Gao, L. & McCarthy, T. J. Ionic liquid marbles. Langmuir 23, 10445–10447 (2007).

Matsukuma, D., Watanabe, H., Yamaguchi, H. & Takahara, A. Preparation of low-surface-energy poly[2-(perfluorooctyl)ethyl acrylate] microparticles and its application to liquid marble formation. Langmuir 27, 1269–1274 (2011).

McHale, G., Herbertson, D. L., Elliott, S. J., Shirtcliffe, N. J. & Newton, M. I. Electrowetting of nonwetting liquids and liquid marbles. Langmuir 23, 918–924 (2007).

Dupin, D., Armes, S. P. & Fujii, S. Stimulus-responsive liquid marbles. J. Am. Chem. Soc. 131, 5386–5387 (2009).

Fujii, S., Kameyama, S., Armes, S. P., Dupin, D., Suzaki, M. & Nakamura, Y. pH-responsive liquid marbles stabilized with poly(2-vinylpyridine) particles. Soft Matter 6, 635–640 (2010).

Lattuada, M. & Hatton, T. A. Preparation and controlled self-assembly of Janus magnetic nanoparticles. J. Am. Chem. Soc. 129, 12878–12889 (2007).

Zhao, Y. & Perrier, S. Reversible addition-fragmentation chain transfer graft polymerization mediated by fumed silica supported chain transfer agents. Macromolecules 40, 9116–9124 (2007).

Mitsukami, Y., Donovan, M. S., Lowe, A. B. & McCormick, C. L. Water-soluble polymers. 81. Direct synthesis of hydrophilic styrenic-based homopolymers and block copolymers in aqueous solution via RAFT. Macromolecules 34, 2248–2256 (2001).

Shibaev, V. P., Platé, N. A. & Freidzon, Y. S. Thermotropic liquid crystalline polymers. I. Cholesterol-containing polymers and copolymers. J. Polym. Sci. Chem. Ed. 17, 1655–1670 (1979).

Li, C., Han, J., Ryu, C. Y. & Benicewicz, B. C. A versatile method to prepare RAFT agent anchored substrates and the preparation of PMMA grafted nanoparticles. Macromolecules 39, 3175–3183 (2006).

Li, C. & Benicewicz, B. C. RAFT polymerization of methyl methacrylate from silica nanoparticles. Polym. Prep. 46, 459–460 (2005).

Newton, M. I., Herbertson, D. L., Elliott, S. J., Shirtcliffe, N. J. & McHale, G. Electrowetting of liquid marbles. J. Phys. D. Appl. Phys. 40, 20–24 (2007).

Berger, S., Synytska, A., Ionov, L., Eichhorn, K. J. & Stamm, M. Stimuli-responsive bicomponent polymer Janus particles by ‘grafting from’/’grafting to’ approaches. Macromolecules 41, 9669–9676 (2008).

Ionov, L., Zdyrko, B., Sidorenko, A., Minko, S., Klep, V., Luzinov, I. & Stamm, M. Gradient polymer layers by ‘grafting to’ approach. Macromol. Rapid Commun. 25, 360–365 (2004).

Zhao, Y. & Perrier, S. Synthesis of well-defined homopolymer and diblock copolymer grafted onto silica particles by z-supported RAFT polymerization. Macromolecules 39, 8603–8608 (2006).

Acknowledgements

We are grateful to Dr H Kawasaki (Kansai University) for ATR-FTIR investigations. This work was supported by a Grant-in-Aid (No. 21106518) for Scientific Research on Innovative Areas, ‘Molecular Soft-Interface Science,’ from the Ministry of Education, Culture, Sports, Science and Technology of Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Inoue, M., Fujii, S., Nakamura, Y. et al. pH-responsive disruption of ‘liquid marbles’ prepared from water and poly(6-(acrylamido) hexanoic acid)-grafted silica particles. Polym J 43, 778–784 (2011). https://doi.org/10.1038/pj.2011.55

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.55

Keywords

This article is cited by

-

Stimulus-responsive soft dispersed systems developed based on functional polymer particles: bubbles and liquid marbles

Polymer Journal (2019)

-

Dynamic behaviour of a magnetically actuated floating liquid marble

Microfluidics and Nanofluidics (2017)

-

Manipulation of liquid marbles

Microfluidics and Nanofluidics (2015)