Abstract

This is the first report on dual synthesis of poly[(R)-3-hydroxybutyric acid] (PHB) and protein polymer by recombinant microorganisms for use in the fabrication of a biofunctional PHB-based material hybridized with functional proteins. PHB and recombinant silk protein, a model protein developed in this study, were synthesized by a recombinant Escherichia coli system, and then films of PHB hybridized with the silk protein (PHB/Silk) were prepared. The presence of the silk protein in the amorphous phase of the PHB/Silk film was demonstrated based on wide-angle X-ray diffraction and differential scanning calorimetry measurements, which also revealed the enhanced tensile strength and elongation at break of the PHB/Silk film. The cell adhesion of human mesenchymal stem cells (hMSCs) for the PHB/Silk film increased because of the addition of silk molecules to the film. This might have been because the silk molecules existed in the amorphous phase at the surface of the PHB/Silk films, and were exposed to hMSCs. The overall results illustrate the potential of this dual synthesis system as a versatile and useful platform method for preparation of biofunctional PHB-based materials, especially for biomedical applications.

Similar content being viewed by others

Introduction

Poly[(R)-3-hydroxybutyric acid] (PHB), a biological and biodegradable polyester produced by various microorganisms in the natural environment, has attracted much attention in industrial and medical fields because of its eco-friendly properties, including biodegradability, biocompatibility and low cytotoxicity.1, 2, 3 Medical application of PHB and its copolymer, poly(hydroxyalkanoate) (PHA), has been investigated since the 1990s, and a PHA containing 4-hydroxybutyrate units was provisionally concluded to show higher biocompatibility and in vivo biodegradability than other PHAs.4, 5, 6, 7 In general, however, PHA materials exhibit few of the biological functions required of modern biomaterials. Many types of surface modifications of PHA films and fibrous mats, such as with collagen, C+ ion, chitosan, gelatin or hyaluronic acid, have therefore been used to enhance the biocompatibility and cell proliferation of PHB and PHA materials.8, 9 However, these modifications of PHA require several steps and the use of a limited number of substrates. Furthermore, recent advances in biomaterials research for tissue and regenerative engineering have demanded more functional and tailor-made materials, such as functional protein-based materials, for individual medical applications.

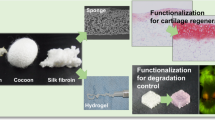

Silk proteins have been used successfully in the biomedical field as a suture material for decades, and have also been explored as biomaterials for cell culture and tissue engineering, achieving Food and Drug Administration approval for such expanded use because of their excellent mechanical properties, and versatility in processing and biocompatibility.10, 11, 12 In addition, the degradation products of silk proteins by α-chymotrypsin composed of β-sheet structures have been reported to show no significant cytotoxicity to neuron cells in vitro.13, 14, 15 On the basis of the biocompatibility of silk proteins, numerous silk-based products have been investigated and partially adopted for biomedical treatments, including sutures, scaffolds, films, coating, tubes, microspheres and polyion complexes.11, 16 In the last decade, remarkable progress has been made in understanding silk genetics, structures and biophysics.17, 18, 19, 20, 21, 22, 23, 24 Cloning and expression of native and synthetic silks have been achieved in various host systems using synthetic oligonucleotide versions of consensus repeats or variants of these repeats garnered from sequence data from native genes.25, 26, 27, 28

In this study, dual biosynthesis of both PHB and silk protein was designed and performed by double transformation into Escherichia coli to add biological functions to PHB-based biomaterials (Figure 1). This dual biosynthesis enabled a single-step preparation of PHB-based materials that exhibited several desirable biological functions. The PHB hybridized with silk protein (PHB/Silk) was characterized with respect to its mechanical, thermal and biological properties. On the basis of the results, the role of silk protein in silk-hybridized PHB materials was discussed and the potential of dual synthesis of PHB and functional proteins to create new types of biofunctional materials was evaluated.

Experimental procedure

Design and cloning of the recombinant silk sequence and PHB synthase

The spider silk sequence was selected based on the consensus repeat (SGRGGLGGQGAGAAAAAGGAGQGGYGGLGSQGT) derived from the native sequence of the dragline protein MaSp1 sequence from the spider Nephila clavipes (Accession P19837). The recombinant silk protein containing six contiguous copies of this repeat was developed through the transfer of cloned inserts to pET-15b, according to our previously published procedures.27, 29, 30 The sequences of the synthetic oligonucleotides encoding the consensus repeat were as follows: Silk-a, 5′-TATGGGTAGAGGCGGGCTGGGTGGCCAGGGTGCAGGTGCGGCTGCGGCTGCCGGCGGTGCCGGCCAAGGTGGCTATGGCGGCCTGGGTTCTCAGGGGG-3′; Silk-b, 5′-GATCCCCCCTGAGAACCCAGGCCGCCATAGCCACCTTGGCCGGCACCGCCGGCAGCCGCAGCCGCACCTGCACCCTGGCCACCCAGCCCGCCTCTACCCA-3′. The restriction sites for NdeI and BamHI are italicized. Both Silk-a and Silk-b are complementary oligonucleotides, which were annealed to form double-stranded DNA. The double-stranded DNAs of the sequences were ligated into pET15b to generate pET15b-Silk to encode a six-histidine tag sequence by DNA ligase (Ligation mix; Nippon Gene, Tokyo, Japan). The PHB biosynthesis genes, that is, the PHB synthase gene (phaC), the β-ketothiolase gene (phaA) and the acetoacetyl-CoA reductase gene (phaB), from Ralstonia eutropha H16 were inserted into pBBR1MCS-2.31 The plasmid pBBR1MCS2-phbCAB carrying the phaCAB gene from R. eutropha H16 was constructed by introduction of a BamHI fragment containing the phaCAB gene into pBBR1MCS2. The BamHI fragment was cloned and obtained from pGEM-phbCAB constructed by Taguchi et al.32 The plasmids used in this study are listed in Table 1. To maintain and select for plasmids within the recombinant E. coli, 100 μg of ampicillin and/or 50 μg of kanamycin were used as indicated.

Dual synthesis of PHB and silk protein

These plasmids were introduced into E. coli JM109 (DE3) for production of PHB and silk protein by heat shock transformation (Figure 2). In brief, cells were cultivated in the Luria-Bertani medium supplemented with glucose to a final concentration of 2 mg ml−1, containing an appropriate antibiotic (100 μg of ampicillin and/or 50 μg of kanamycin) at 30 °C. Protein expression was induced by the addition of 0.5 mM isopropyl β-D-thiogalactopyranoside (IPTG) (Sigma-Aldrich, St Louis, MO, USA) when OD600 nm reached 0.6. After the indicated number of hours of protein expression, cells were harvested by centrifugation at 13 000 g. Cell pellets were washed with MilliQ (Millipore, Billerica, MA, USA), followed by centrifugation at 13 000 g at for 30 min. SDS-PAGE was performed using 10–20% precast Tris-HCl ready gels (Bio-Rad, Hercules, CA, USA). The soluble-protein fractions were subjected to SDS-PAGE. The gel was stained with Commassie blue (Bio-Rad). Western blotting was performed using a Gel Code 6 × His Protein Tag Stain kit (Pierce, Rockford, IL, USA). Cell pellets were lyophilized and then PHB and/or silk protein were extracted with a mixture of chloroform/HFIP (1,1,1,3,3,3-hexafluoro-2-propanol) (50/50) for 72 h at room temperature, and then cells were removed by filtration. The extracted samples were purified by precipitation with methanol twice.

Characterization of PHB, silk protein and their complexes

The PHB and the silk protein were characterized by 1H nuclear magnetic resonance (NMR) spectroscopy, gel-permeation chromatography (GPC), differential scanning calorimetry and wide-angle X-ray diffraction (WAXD). 1H NMR spectra were recorded on JNM-Excalibur270 (Jeol Ltd, Tokyo, Japan) using CDCl3 and HFIP-d2 as solvents. The number-average molecular weight (Mn), weight-average molecular weight (Mw) and polydispersity (Mw/Mn) were measured by a GPC system with polystyrene standards (Shodex Standard SM-105, 1.3 × 103 to 3.1 × 106). GPC measurement was performed using a Shimadzu 10A GPC system (Shimadzu Corporation, Kyoto, Japan) with joint columns of Shodex K-806 and K-802 (Showa Denko, Tokyo, Japan) at 40 °C. Chloroform was used as a mobile phase at a flow rate of 0.8 ml min−1, and the sample concentration was set at 1.0 mg ml−1. Shimadzu CLASS-VP software (Shimadzu Corporation) was used to process the data.

Thick films were initially prepared by conventional solvent-cast techniques from HFIP solutions of PHB and silk protein (10 mg ml−1) using glass petri dishes as a casting surface. Solvent-cast films were inserted between two Teflon sheets with a Teflon sheet (0.1 mm thickness) as a spacer and were compression molded on a Mini Test Press (Toyo Seiki Seisaku-sho Ltd, Tokyo, Japan) by heating at 200 °C for 30 s under a pressure of 100 kg cm−2. The samples were then kept at room temperature (25 °C). The thin films of 0.1-mm thickness were analyzed by differential scanning calorimetry, WAXD and a tensile strength machine.

The glass transition temperature (Tg), the melting temperature (Tm), the crystallization temperature (Tc) and the melting enthalpy (ΔH) were measured by a differential scanning calorimetry (Pyris 1; Perkin-Elmer, Waltham, MA, USA) equipped with a cooling accessory. The samples (∼3 mg) were encapsulated in aluminum pans and heated from −50 to 200 °C at a rate of 20 °C min−1, and then maintained at 200 °C for 1 min. Subsequently, they were quenched to −100 °C at a rate of −200 °C min−1 and then heated from −100 to 200 °C at a rate of 20 °C min−1. The Tg was taken as the midpoint of the change in heat capacity during the second heating.

The WAXD patterns of the films were recorded at 25 °C on a Rigaku RINT 2500 system (Rigaku Corporation, Tokyo, Japan) using nickel-filtered Cu Kα radiation (λ=0.154 nm; 40 kV; 110 mA) in the 2θ range from 4 to 60 °C at a scan speed of 2.0 °C min−1. Degrees of crystallinity (Xc) of the polymeric films were calculated from diffracted intensity data according to the method proposed by Vonk.33

The tensile strength at break and elongation at break for the same thin films as used in the X-ray analysis were determined using a tensile strength machine (Eztest; Shimadzu Corporation) at a crosshead speed of 10 mm min−1. Gauge length and sample width were 5.0 and 2.0 mm, respectively. The average of three measured values was taken for each sample.

Cell culture and cell proliferation

Human mesenchymal stem cells (hMSCs) were used to investigate cell proliferation on synthesized PHB and silk samples. Cultures were grown to confluence using media consisting of Dulbecco's modified Eagle's medium and 10% fetal bovine serum, 0.1 mM nonessential amino acids, 1 ng ml−1 basic fibroblast growth factor in the presence of 100 Units ml−1 penicillin, 100 μg ml−1 streptomycin and 0.25 μg ml−1 fungizone at 37 °C in a 5% CO2 incubator. Cell cultures were detached from their substrates using 0.25% trypsin, and then seeded into 96-well plates (10 000 cells per well) coated with PHB and/or silk protein and cultured for 3, 6, 12, 24 or 36 h. After cultivation, media were completely replaced with new media to remove floating cells. Cell proliferation of hMSCs on the polymers was characterized by a standard MTS (3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxyphenyl)-2-(4-sulfophenyl)-2H-tetrazolium) assay (Promega, Madison, WI, USA) according to the manufacturer's instructions (n=4). The absorbance at 490 nm of the cell culture was measured after each incubation time. Statistical differences in cell proliferation and cell viability were determined by unpaired t-test with a two-tailed distribution and differences were considered statistically significant at P<0.05. The data in the cell transfection efficiency and cell viability experiments are expressed as means±s.d.

Results and Discussion

Dual synthesis of PHB and silk protein

The expression of the silk protein was characterized by SDS-PAGE as shown in Figure 3. The recombinant silk protein showed a band corresponding to a molecular weight of ∼27 kDa (Figures 3a and b), which was roughly in accordance with the theoretical molecular weights of 22 kDa, considering that silk-based polymers generally do not run true to size on SDS-PAGE gels because of the hydrophobic nature of the protein.25 On the basis of the results shown in Figures 3a and b, an incubation time of 3 or 4 h was considered optimal to express the silk protein. Therefore, an incubation of 4 h after the addition of IPTG was used for the expression of silk protein and PHB synthases throughout these experiments. Expression of the PHB synthase was also characterized by SDS-PAGE (Figure 3c), but almost no synthase (60 kDa) was detected because of aggregation of the synthases with PHB granules, according to previous reports.34, 35 Dual expression of the PHB synthase and silk protein by E. coli JM109 without glucose, which is not capable of synthesizing PHB, was characterized by SDS-PAGE (Figure 4). This result clearly demonstrates that the PHB synthase (60 kDa) and silk protein (27 kDa) were expressed in the present reactions (Figure 4, arrows 1 and 2), at the incubation time of 4 h. The faint bands (41 k and 26 kDa) corresponding to β-ketothiolase (PhaA) and acetoacetyl-CoA reductase (PhaB) were observed in Figure 4 (arrows 3 and 4). In addition to Figure 4, PHB production using glucose as a carbon source in E. coli, which contains no PHB biosynthesis genes, confirmed the expression of PhaA and PhaB. The expressed silk proteins were also confirmed by western blot analysis of histidine tag against the lysates cultured of silk, silk and PHB, as well as PHB (Figure 5). The level of silk protein expressed using recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk was significantly lower than that expressed using E. coli JM109 harboring pET15b-Silk, indicating that the expression of PHB synthase prevented the expression of the silk protein.

In all, 10–20% SDS-PAGE of samples during the expression of PHB synthase and silk protein with 2% glucose before (0 h) and after addition of 1 mM IPTG for 1–24 h. (a) Silk protein, (b) PHB synthases and silk protein, and (c) PHB synthases. White arrows indicate the expression of silk protein. M, molecular weight size marker; PHB, poly[(R)-3-hydroxybutyric acid].

In all, 10–20% SDS-PAGE of lysates of E. coli JM109 harboring pBBR1MCS-2-phbCABR cultured for (a) 4, (b) 8, (c) 12, (d) 24 or (e) 48 h without glucose. White arrows denote PHB synthase (PhaC) (1) and silk protein (2), and black arrows show PhaA (3) and PhaB (4), respectively. M, molecular weight size marker; PHB, poly[(R)-3-hydroxybutyric acid].

Production of PHB by incubation of 4 h after the addition of IPTG was also characterized quantitatively, as listed in Table 1. Dry cell weights demonstrated almost no difference, whereas PHB contents were significantly different among the samples. The molecular weights and polydispersity index of the PHB synthesized by recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk and harboring pBBR1MCS-2-phbCAB were determined by GPC (Table 2). The PHB synthesized by recombinant E. coli JM109 harboring pBBR1MCS-2-phbCAB showed an Mn and polydispersity index of 1 100 000 g mol−1 and 1.7, respectively. On the other hand, the molecular weight of the PHB synthesized by recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk was 723 000 g mol−1, which was obviously lower in comparison with the PHB synthesized by recombinant E. coli JM109 harboring pBBR1MCS-2-phbCAB. This difference in molecular weight would be caused by the expression of silk protein, which prevented the chain-elongation reaction of the PHB synthase in the microorganism. In addition, the yield of PHB without IPTG induction, namely without silk biosynthesis, was identical to PHB productivity of the E. coli JM109 harboring pBBR1MCS-2-phbCAB (Table 1, sample no. 2). On the basis of the results described above, it was concluded that the expression of the silk protein disturbs PHB production by PHB synthase, yielding lower molecular-weight PHB and lower PHB productivity.

NMR analysis of the PHB and silk hybrid

The PHB synthesized by recombinant E. coli JM109 harboring pBBR1MCS-2-phbCAB and that synthesized by recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk were subjected to 1H NMR analysis. 1H NMR spectra of the PHB samples synthesized by recombinant E. coli JM109 harboring pBBR1MCS-2-phbCAB (Supplementary Figure S1a) and recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk (Supplementary Figure S1b) measured in CDCl3 demonstrated the presence of PHB homopolymers. Moreover, the two spectra in Supplementary Figure S1 were not significantly different, because of the relatively low solubility of the silk protein into chloroform. Hence, the polymer samples dissolved in HFIP-d2 were further characterized by 1H NMR (Figure 6). The spectra of the PHB synthesized by recombinant E. coli JM109 harboring pBBR1MCS-2-phbCAB showed no additional peaks into the peaks assigned to PHB, whereas the spectra of the polymers synthesized by recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk (Figure 6b) demonstrated additional peaks assigned to poly(amino acid). As shown in Figure 6, the comparison between these spectra revealed that the PHB and silk protein coexisted in the polymers (PHB/Silk) extracted from the culture of recombinant E. coli JM109 harboring both pBBR1MCS-2-phbCAB and pET15b-Silk. The content of the silk protein in the PHB/Silk hybrid was calculated to be 4.1 mol% using the peaks assigned to methine protons of the PHB and silk protein. This silk content, 4.1 mol%, was enough to influence the mechanical properties and biocompatibility of PHB/Silk hybrid materials, according to the previous study on poly[(R)-3-hydroxybutyrate-co-hydroxyalkanoate].36

Effects of the silk protein on the thermal properties, crystalline state and mechanical properties of PHB/Silk materials

The thermal properties, namely Tg, Tm, Tc and ΔH, of the PHB and PHB/Silk hybrid films were determined by differential scanning calorimetry and are listed in Table 2. The presence of the silk protein with PHB decreased Tm as well as ΔH and increased Tc, implying that the presence of silk molecules reduced the crystal sizes and crystallinity of PHB in the PHB/Silk film. To confirm the effects of the silk protein on the crystalline state of the PHB/Silk hybrid, WAXD of the PHB, silk protein and PHB/Silk films were performed and Xc of each sample was determined (Figure 7). The diffraction patterns of PHB and PHB/Silk were almost identical, except for the intensity and broad background of the PHB/Silk film. This indicates that PHB lamellar crystals existed in both PHB and PHB/Silk films. The Xc of PHB film (61%) was significantly higher in comparison with the Xc of the PHB/Silk film (46%); in addition, the silk film was almost amorphous. Therefore, the presence of silk molecules in PHB materials surely decreased the crystallinity and reduced the crystal sizes based on the area and peaks in the WAXD patterns.

The tensile strength at break and elongation at break of the PHB and PHB/Silk hybrid films were also determined and are listed in Table 2. The hybridization of silk protein in the PHB/Silk film significantly enhanced tensile strength and elongation at break, which is an important factor for practical use of PHB-based materials as biomaterials. This increase in elongation at break was associated with a decrease in the crystallinity of PHB/Silk due to the hybridization of the silk protein and PHB. The results regarding the crystalline state and mechanical properties of PHB/Silk hybrid suggested that the silk molecules were not crystallized but hybridized with amorphous PHB and prevented lamellar crystallization of PHB molecules, leading to higher Tc and higher ductile mechanical properties of PHB/Silk.

Cell adhesion and proliferation

To evaluate the level of cellular adhesion to the PHB, silk and PHB/Silk films, the proliferation of hMSCs seeded on these films was analyzed using an MTS assay. A 96-well cell culture plate without any films was used as a control. After the removal of floating cells, the absorbance at 490 nm (A490) related to the numbers of hMSCs attached to the films after incubation for 3, 6, 12, 24 or 36 h were measured (Figure 8). The A490 of the cell culture incubated on the PHB/Silk, silk and PHB film at 1, 3 and 6 h significantly increased, whereas the A490 of cells adherent to those films from 12 to 36 h were maintained. This cell-adhesion behavior indicated that the initial cell-adhesion activity to PHB/Silk was successfully evaluated from the A490 measured at 1, 3 or 6 h, and that its plateau phase started at an incubation time of ∼12 h of all the samples. The silk films showed the highest A490, namely the cell-adhesion activity, whereas the PHB films demonstrated the lowest cell-adhesion activity except for the control. Therefore, the hybridization of the silk protein with PHB was concluded to increase cell adhesion in comparison with the PHB films. Although the results mentioned above implied the presence of the silk protein in the amorphous phase of the PHB/Silk film, the additional results on the cell adhesion to the PHB/Silk films suggest that some silk molecules existed at the surface of the PHB/Silk films and were exposed to hMSCs. The present overall results demonstrate that the dual synthesis of PHB and functional proteins has good potential for the fabrication of biofunctional PHB materials, and more importantly, the hybridization of silk molecules with PHB is a new type of modification for the practical use of PHB materials in biomedical applications.

Conclusion

Dual biosynthesis of the PHB and silk protein, a model protein used in this study, provided a new type of PHB-based material hybridized with silk protein, which showed significantly improved mechanical properties and cell adhesiveness. The presence of the silk protein in the amorphous phase of PHB restrains the crystallinity of the PHB/Silk hybrid. Moreover, the silk molecules may exist in the amorphous phase at the surface of the PHB/Silk film, with the result that the cell adhesion of the film containing silk molecules is enhanced. This present system, dual synthesis of PHB and functional protein, can serve as a versatile and useful platform method for the preparation of biofunctional PHB-based materials, especially for biomedical applications. This study provides the first example of the hybridization of PHB with functional proteins by this dual synthesis system.

References

Doi, Y. Microbial Polyesters (VCH Publishers, New York, USA, 1990).

Doi, Y. & Steinbüchel, A (eds). in Polyesters I and II Vol. 3 (Wiley-VCH, Weinheim, Germany, 2001).

Lenz, R. W. & Marchessault, R. H. Bacterial polyesters: biosynthesis, biodegradable plastics and biotechnology. Biomacromolecules 6, 1–8 (2005).

Martin, D. P., Peoples, O. P., Williams, S. F. & Zhong, L. H. Nutritional and therapeutic uses of 3-hydroxyalkanoate oligomers. US Patent Appl. 359 086 (1999).

Martin, D. P. & Williams, S. F. Medical applications of poly(4-hydroxybutyrate): a strong flexible absorbable biomaterial. Biochem. Eng. J. 16, 97–105 (2003).

Martin, D. P. & Williams, S. F. Medical applications of poly-4-hydroxybutyrate: a strong flexible absorbable biomaterial. Biochem. Eng. J. 16, 97–105 (2003).

Williams, S. F. & Martin, D. P. Therapeutic uses of polymers and oligomers comprising gamma-hydroxybutyrate. US Patent Appl. 661 948 (2000).

Chen, G. Q. A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem. Soc. Rev. 38, 2434–2446 (2009).

Chen, G. Q. & Wu, Q. The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials 26, 6565–6578 (2005).

Altman, G. H., Diaz, F., Jakuba, C., Calabro, T., Horan, R. L., Chen, J., Lu, H., Richmond, J. & Kaplan, D. L. Silk-based biomaterials. Biomaterials 24, 401–416 (2003).

Numata, K. & Kaplan, D. L. Silk-based delivery systems of bioactive molecules. Adv. Drug Deliv. Rev. 62, 1497–1508 (2010).

Wong Po Foo, C. & Kaplan, D. L. Genetic engineering of fibrous proteins: spider dragline silk and collagen. Adv. Drug Deliv. Rev. 54, 1131–1143 (2002).

Numata, K., Cebe, P. & Kaplan, D. L. Mechanism of enzymatic degradation of beta-sheet crystals. Biomaterials 31, 2926–2933 (2010).

Numata, K. & Kaplan, D. L. Mechanisms of enzymatic degradation of amyloid beta microfibrils generating nanofilaments and nanospheres related to cytotoxicity. Biochemistry 49, 3254–3260 (2010).

Numata, K. & Kaplan, D. L. Differences in cytotoxicity of beta-sheet peptides originated from silk and amyloid beta. Macromol. Biosci. 11, 60–64 (2011).

Omenetto, F. G. & Kaplan, D. L. New opportunities for an ancient material. Science 329, 528–531 (2010).

Hinman, M. B. & Lewis, R. V. Isolation of a clone encoding a second dragline silk fibroin. Nephila clavipes dragline silk is a two-protein fiber. J. Biol. Chem. 267, 19320–19324 (1992).

Mita, K., Ichimura, S. & James, T. C. Highly repetitive structure and its organization of the silk fibroin gene. J. Mol. Evol. 38, 583–592 (1994).

Hayashi, C. Y. & Lewis, R. V. Evidence from flagelliform silk cDNA for the structural basis of elasticity and modular nature of spider silks. J. Mol. Biol. 275, 773–784 (1998).

Hayashi, C. Y. & Lewis, R. V. Molecular architecture and evolution of a modular spider silk protein gene. Science 287, 1477–1479 (2000).

Gatesy, J., Hayashi, C., Motriuk, D., Woods, J. & Lewis, R. Extreme diversity conservation, and convergence, of spider silk fibroin sequences. Science 291, 2603–2605 (2001).

Garb, J. E., DiMauro, T., Vo, V. & Hayashi, C. Y. Silk genes support the single origin of orb webs. Science 312, 1762 (2006).

Askarieh, G., Hedhammar, M., Nordling, K., Saenz, A., Casals, C., Rising, A., Johansson, J. & Knight, S. D. Self-assembly of spider silk proteins is controlled by a pH-sensitive relay. Nature 465, 236–238 (2010).

Keten, S., Xu, Z., Ihle, B. & Buehler, M. J. Nanoconfinement controls stiffness, strength and mechanical toughness of beta-sheet crystals in silk. Nat. Mater. 9, 359–367 (2010).

Prince, J. T., McGrath, K. P., DiGirolamo, C. M. & Kaplan, D. L. Construction, cloning, and expression of synthetic genes encoding spider dragline silk. Biochemistry 34, 10879–10885 (1995).

Huang, J., Valluzzi, R., Bini, E., Vernaglia, B. & Kaplan, D. L. Cloning, expression, and assembly of sericin-like protein. J. Biol. Chem. 278, 46117–46123 (2003).

Numata, K., Subramanian, B., Currie, H. A. & Kaplan, D. L. Bioengineered silk protein-based gene delivery systems. Biomaterials 30, 5775–5784 (2009).

Numata, K., Hamasaki, J., Subramanian, B. & Kaplan, D. L. Gene delivery mediated by recombinant silk proteins containing cationic and cell binding motifs. J. Control Release 146, 136–143 (2010).

Numata, K., Hamasaki, J., Subramanian, B. & Kaplan, D. L. Gene delivery mediated by recombinant silk proteins containing cationic and cell binding motifs. J. Control Release 146, 136–143 (2010).

Numata, K. & Kaplan, D. L. Silk-based gene carriers with cell membrane destabilizing peptides. Biomacromolecules 11, 3189–3195 (2010).

Kovach, M. E., Elzer, P. H., Hill, D. S., Robertson, G. T., Farris, M. A., Roop, R. M. II & Peterson, K. M. Four new derivatives of the broad-host-range cloning vector pBBR1MCS, carrying different antibiotic-resistance cassettes. Gene 166, 175–176 (1995).

Taguchi, S., Maehara, A., Takase, K., Nakahara, M., Nakamura, H. & Doi, Y. Analysis of mutational effects of a polyhydroxybutyrate (PHB) polymerase on bacterial PHB accumulation using an in vivo assay system. FEMS Microbiol. Lett. 198, 65–71 (2001).

Vonk, C. G. Computerization of rulands X-ray method for determination of crystallinity in polymers. J. Appl. Crystallogr. 6, 148–152 (1973).

Peters, V. & Rehm, B. H. In vivo monitoring of PHA granule formation using GFP-labeled PHA synthases. FEMS Microbiol. Lett. 248, 93–100 (2005).

Jurasek, L. & Marchessault, R. H. Polyhydroxyalkanoate (PHA) granule formation in Ralstonia eutropha cells: a computer simulation. Appl. Microbiol. Biotechnol. 64, 611–617 (2004).

Koyama, N. & Doi, Y. Effects of solid-state structures on the enzymatic degradability of bacterial poly(hydroxyalkanoic acids). Macromolecules 30, 826–832 (1997).

Acknowledgements

This work was supported by a grant for the RIKEN Biomass Engineering Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on the Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Numata, K., Doi, Y. Dual biosyntheses of poly[(R)-3-hydroxybutyric acid] and silk protein for the fabrication of biofunctional bioplastic. Polym J 43, 642–647 (2011). https://doi.org/10.1038/pj.2011.27

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.27

Keywords

This article is cited by

-

Poly(amino acid)s/polypeptides as potential functional and structural materials

Polymer Journal (2015)

-

Secretion of polyhydroxybutyrate in Escherichia coli using a synthetic biological engineering approach

Journal of Biological Engineering (2013)