Abstract

Polymer springs that twist under irradiation with light, in a manner that mimics how plant tendrils twist and turn under the effect of differential expansion in different sections of the plant, show potential for soft robotics and the development of artificial muscles. The soft springs prepared using this protocol are typically 1 mm wide, 50 μm thick and up to 10 cm long. They are made from liquid crystal polymer networks in which an azobenzene derivative is introduced covalently as a molecular photo-switch. The polymer network is prepared by irradiation of a twist cell filled with a mixture of shape-persistent liquid crystals, liquid crystals having reactive end groups, molecular photo-switches, some chiral dopant and a small amount of photoinitiator. After postcuring, the soft polymer film is removed and cut into springs, the geometry of which is determined by the angle of cut. The material composing the springs is characterized by optical microscopy, scanning electron microscopy and tensile strength measurements. The springs operate at ambient temperature, by mimicking the orthogonal contraction mechanism that is at the origin of plant coiling. They shape-shift under irradiation with UV light and can be pre-programmed to either wind or unwind, as encoded in their geometry. Once illumination is stopped, the springs return to their initial shape. Irradiation with visible light accelerates the shape reversion.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Finkelmann, H., Nishikawa, E., Pereira, G.G. & Warner, M.A. New opto-mechanical effect in solids. Phys. Rev. Lett. 87, 015501 (2001).

Yu, Y., Nakano, M. & Ikeda, T. Directed bending of a polymer film by light. Nature 425, 145 (2003).

White, T. & Broer, D.J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nature Mater. 14, 1087–1098 (2015).

Wang, J.-S. et al. Hierarchical chirality transfer in the growth of the Towel Gourd tendrils. Sci. Rep. 3, 3102 (2013).

Forterre, Y. & Dumais, J. Generating helices in nature. Science 333, 1715–1716 (2011).

Isnard, S. & Silk, W.K. Moving with climbing plants from Charles Darwin's time into the 21st century. Am. J. Bot. 96, 1205–1221 (2009).

Evangelista, D., Hotton, S. & Dumais, J. The mechanics of explosive dispersal and self-burial in the seeds of filaree erodium cicutarium. J. Exp. Biol. 214, 521–529 (2011).

Erb, R.M., Sander, J.S., Grisch, R. & Studart, A.R. Self-shaping composites with programmable bioinspired microstructures. Nat. Commun. 4, 1712 (2013).

Zhang, L. & Naumov, P. Light- and humidity-induced motion of an acidochromic film. Angew. Chem. Int. Ed. 54, 8642–8647 (2015).

Zhang, L., Chizhik, S., Wen, Y. & Naumov, P. Directed motility of hygroresponsive biomimetic actuators. Adv. Funct. Mater. 26, 1040–1053 (2016).

Wu, Z.L. et al. Three-dimensional shape transformations of hydrogel sheets induced by small-scale modulation of internal stresses. Nat. Commun. 4, 1586 (2013).

de Haan, L.T et al. Humidity-responsive liquid crystalline polymer actuators with an asymmetry in the molecular trigger that bend, fold, and curl. J. Am. Chem. Soc. 136, 10585–10588 (2014).

Iamsaard, S. et al. Conversion of light into macroscopic helical motion. Nature Chem. 6, 229–235 (2014).

Harris, K.D. et al. Large amplitude light-induced motion in high elastic modulus polymer actuators. J. Mater. Chem. 15, 5043–5048 (2005).

Yu, Y., Nakano, M., Shishido, A., Shiono, T. & Ikeda, T. Effect of cross-linking density on photoinduced bending behavior of oriented liquid-crystalline network films containing azobenzene. Chem. Mater. 16, 1637–1643 (2004).

Dumais, J. & Forterre, Y. Vegetable dynamicks: the role of water in plant movements. Annu. Rev. Fluid Mech. 44, 453–478 (2012).

Witztum, A. & Schulgasser, K. The mechanics of seed expulsion in Acanthaceae. J. Theor. Biol. 176, 531–542 (1995).

Dawson, C., Vincent, J.F.V. & Roca, A.M. How pine cones open. Nature 390, 668 (1997).

Elbaum, R., Zaltzman, L., Burgert, I. & Fratzl, P. The role of wheat awns in the seed dispersal unit. Science 316, 884–886 (2007).

Studart, A.R. & Erb, R.M. Bioinspired materials that self-shape through programmed microstructures. Soft Matter 10, 1284–1294 (2014).

Sawa, Y. et al. Shape selection of twist-nematic-elastomer ribbons. Proc. Natl. Acad. Sci. USA 108, 6364–6368 (2011).

Sawa, Y. et al. Shape and chirality transitions in off-axis twist nematic elastomer ribbons. Phys. Rev. E 88, 022502 (2013).

Teresi, L. & Varano, V. Modeling helicoid to spiral-ribbon transitions of twist-nematic elastomers. Soft Matter 9, 3081–3088 (2013).

Wie, J.J. et al. Torsional mechanical responses in azobenzene functionalized liquid crystalline polymer networks. Soft Matter 9, 9303–9310 (2013).

van Oosten, C.L. et al. Bending dynamics and directionality reversal in liquid crystal network photoactuators. Macromolecules 41, 8592–8596 (2008).

Liu, D. & Broer, D. J. Liquid crystal polymer networks: preparation, properties, and applications of films with patterned molecular alignment. Langmuir 30, 13499–13509 (2014).

Liu, D. & Broer, D.J. New insights into photoactivated volume generation boost surface morphing in liquid crystal coatings. Nat. Commun. 6, 8334 (2015).

Sanchez-Ferrer, A., Merekalov, A. & Finkelmann, H. Opto-mechanical effect in photoactive nematic side-chain liquid-crystalline elastomers. Macromol. Rapid Commun. 32, 671–678 (2011).

Zeng, H. et al. High-resolution 3D direct laser writing for liquid-crystalline elastomer microstructures. Adv. Mater. 26, 2319–2322 (2014).

Min Lee, K., Lynch, B.M., Luchette, P. & White, T.J. Photomechanical effects in liquid crystal polymer networks prepared with m-fluoroazobenzene. J. Polym. Sci. A 52, 876–882 (2014).

Shadmehr, R. & Arbib, A.M. A mathematical analysis of the force-stiffness characteristics of muscles in control of a single joint system. Biol. Cybern. 66, 463–477 (1992).

Mossety-Leszczak, B., Wlodarska, M., Galina, H. & Bak, G.W. Comparing liquid crystalline properties of two epoxy compounds based on the same azoxy group. Mol. Cryst. Liq. Cryst. 490, 52–66 (2008).

Li, C. et al. Synthesis of a photoresponsive liquid-crystalline polymer containing azobenzene. Macromol. Rapid Commun. 30, 1928–1935 (2009).

Acknowledgements

This work was supported financially by the European Research Council (Starting Grant 307784 to N.K.), the Netherlands Organization for Scientific Research (Vidi Grant to N.K.), the EPSRC (Standard Grant EP/M002144/1 to S.P.F.) and the Royal Society through an International Exchange Grant to S.P.F. and N.K. The authors gratefully acknowledge R. Carloni, A. Cremonese (Robotics and Mechatronics, University of Twente), T. Kudernac and A. Leoncini (Molecular Nanofabrication, University of Twente) for discussions on the mechanical properties of the springs.

Author information

Authors and Affiliations

Contributions

N.K. and S.P.F. initiated the project and designed the research. S.I., E.V., F.L. and S.-J.A. conducted the experiments and analyzed the data. F.L. conducted the tensile strength measurements. N.K., S.P.F., E.V. and F.L. wrote the manuscript and all authors contributed to discussing the results and the manuscript at all stages.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Integrated supplementary information

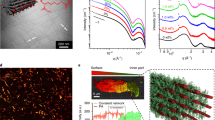

Supplementary Figure 1 Evaluating the thickness of the polymer springs

Cross-section of a liquid crystal polymer film prepared in a commercially available twist cell of nominal thickness 50 μm, observed by scanning electron microscopy. The measured thickness of the film is 43 μm. Scale bar 10 μm.

Supplementary Figure 2 Characterization of the liquid crystal mixture used for the preparation of the biomimetic polymer springs

Differential scanning calorimetry of the liquid crystal mixture without photoinitiator (Irgacure 819). The isotropic to nematic and nematic to crystalline transition are visible respectively at 64.8oC and 12.8 °C.

Supplementary Figure 3 Evaluating the mechanical properties of the springs

Photography of the set-up dedicated to stiffness measurements

Supplementary information

Supplementary Text and Figures

Supplementary Figures 1–3 (PDF 591 kb)

Supplementary Table 1

Soft synthetic springs from the literature (PDF 190 kb)

Rights and permissions

About this article

Cite this article

Iamsaard, S., Villemin, E., Lancia, F. et al. Preparation of biomimetic photoresponsive polymer springs. Nat Protoc 11, 1788–1797 (2016). https://doi.org/10.1038/nprot.2016.087

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2016.087

This article is cited by

-

Life-like motion driven by artificial molecular machines

Nature Reviews Chemistry (2019)

-

Modeling out-of-plane actuation in thin-film nematic polymer networks: From chiral ribbons to auto-origami boxes via twist and topology

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.