Abstract

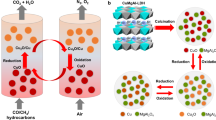

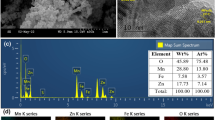

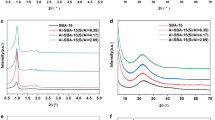

Hydrogen sulphide is found in raw fuels such as natural gas and coal/biomass-derived syngas. It is poisonous to catalysts and corrosive to metals and therefore needs to be removed. This is often achieved using metal oxides as reactive adsorbents, but metal oxides perform poorly when subjected to repeated cycles of sulphidation and re-oxidation1,2,3,4,5,6,7,8,9,10,11,12 as a result of complex structural and chemical changes. Here, we show that Zn–Ti–O-based adsorbents with nanofibrous morphology can sustain their initial reactivity and sulphur removal capacity over multiple regeneration cycles. These nanostructured sorbents offer rapid reaction rates that overcome the gas-transport limitations of conventional pellet-based sorbents1,13 and allow all of the material to be used efficiently. Regeneration can be carried out at the same temperature as the sulphidation step because of the higher reactivity, which prevents sorbent deterioration and reduces energy use. The efficient regeneration of the adsorbent is also aided by structural features such as the growth of hierarchical nanostructures and preferential stabilization of a wurtzite phase in the sulphidation product.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gibson, J. B. & Harrison, D. P. The reaction between hydrogen sulphide and spherical pellets of zinc oxide. Ind. Eng. Chem. Proc. Des. Dev. 19, 231–237 (1980).

Lew, S., Jothimurugesan, K. & Flytzani-Stephanopoulos, M. High-temperature hydrogen sulphide removal from fuel gases by regenerable zinc oxide-titanium dioxide sorbents. Ind. Eng. Chem. Res. 28, 535–541 (1989).

Lew, S., Sarofim, A. F. & Flytzani-Stephanopoulos, M. Sulphidation of zinc titanate and zinc oxide solids. Ind. Eng. Chem. Res. 31, 1890–1899 (1992).

Siriwardane, R. V. & Poston, J. A. Interaction of H2S with zinc titanate in the presence of H2 and CO. Appl. Surf. Sci. 45, 131–139 (1990).

Siriwardane, R. V., Poston, J. A. & Evans, G. Spectroscopic characterization of molybdenum-containing zinc titanate desulphurization sorbents. Ind. Eng. Chem. Res. 33, 2810–2818 (1994).

Poston, J. A. A reduction in the spalling of zinc titanate desulphurization sorbents through the addition of lanthanum oxide. Ind. Eng. Chem. Res. 35, 875–882 (1996).

Kobayashi, M., Shirai, H. & Nunokawa, M. Investigation on desulphurization performance and pore structure of sorbents containing zinc ferrite. Energy Fuels 11, 887–896 (1997).

Atimtay, A. T. & Harrison, D. P. Desulfurization of Hot Coal Gas. Vol. 42, NATO ASI Series G (Springer, 1998).

Jothimurugesan, K. & Gangwal, S. K. Regeneration of zinc titanate H2S sorbents. Ind. Eng. Chem. Res. 37, 1929–1933 (1998).

Sa, L. N., Focht, G. D., Ranade, P. V. & Harrison, D. P. High-temperature desulphurization using zinc ferrite: solid structural property changes. Chem. Eng. Sci. 44, 215–224 (1989).

Skrzypski, J., Bezverkhyy, J., Heintz, O. & Bellat, J. Low temperature H2S removal with metal-doped nanostructure ZnO sorbents: study of the origin of enhanced reactivity in Cu-containing materials. Ind. Eng. Chem. Res. 50, 5714–5722 (2011).

Flytzani-Stephanopoulos, M., Sakbodin, M. & Wang, Z. Regenerative adsorption and removal of H2S from hot fuel gas streams by rare earth oxides. Science 312, 1508–1510 (2006).

Efthimiadis, E. A. & Sotirchos, S. V. Reactivity evolution during sulphidation of porous zinc oxide. Chem. Eng. Sci. 48, 829–843 (1993).

Carnes, C. L. & Klabunde, K. J. Unique chemical reactivities of nanocrystalline metal oxides toward hydrogen sulphide. Chem. Mater. 14, 1806–1811 (2002).

Li, D. & Xia, Y. Fabrication of titania nanofibres by electrospinning. Nano Lett. 3, 555–560 (2003).

Ramaseshan, R., Sundarrajan, S., Jose, R. & Ramakrishna, S. Nanostructured ceramics by electrospinning. J. Appl. Phys. 102, 111101 (2007).

Dai, Y., Liu, W., Forno, E., Sun, Y. & Xia, Y. Ceramic nanofibres fabricated by electrospinning and their applications in catalysis, environmental science, and energy technology. Polym. Adv. Technol. 22, 326–338 (2011).

Liu, R., Ye, H., Xiong, X. & Liu, H. Fabrication of TiO2/ZnO composite nanofibres by electrospinning and their photocatalytic property. Mater. Chem. Phys. 121, 432–439 (2010).

Levenspiel, O. Chemical Reaction Engineering. 3rd edn (Wiley, 1999).

Zevenhoven, C. A. P., Yrjas, K. P. & Hupa, M. M. Hydrogen sulphide capture by limestone and dolomite at elevated pressure—2. Sorbent particle conversion modeling. Ind. Eng. Chem. Res. 35, 943–949 (1996).

Shen, G., Chen, D. & Lee, C. J. Hierarchical saw-like ZnO nanobelt/ZnS nanowire heterostructures induced by polar surfaces. J. Phys. Chem. B 110, 15689–15693 (2006).

Yin, Y. D. et al. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science 304, 711–714 (2004).

Moore, D. & Wang, Z. L. Growth of anisotropic one-dimensional ZnS nanostructures. J. Mater. Chem. 16, 3898–3905 (2006).

Qadri, S. B. et al. Size-induced transition-temperature reduction in nanoparticles of ZnS. Phys. Rev. B 60, 9191–9193 (1999).

Wang, Z. et al. Morphology-tuned wurtzite-type ZnS nanobelts. Nature Mater. 4, 922–927 (2005).

Schultze, D., Steinike, U., Kussin, J. & Kretzschmar, U. Thermal oxidation of ZnS modifications sphalerite and wurtzite. Cryst. Res. Technol. 30, 553–558 (1995).

Acknowledgements

M.B. acknowledges the Dow Chemical Company for a graduate fellowship and thanks Q. Yang for assistance with sample preparation. P.K.J. acknowledges startup support from the Frederick Seitz Materials Research Laboratory where characterization was performed. M.A.S. acknowledges support from the NSF Science and Technology Center WaterCAMPWS.

Author information

Authors and Affiliations

Contributions

M.B., J.Y. and M.A.S. developed the concept. M.B., M.A.S. and P.K.J designed the experiments. M.B. and Q.L. carried out the experiments. M.B. and J.Y. performed material characterization. Data analysis was performed by M.B., J.Y. and P.K.J. The manuscript was written by M.B., J.Y., P.K.J. and M.A.S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 2715 kb)

Rights and permissions

About this article

Cite this article

Behl, M., Yeom, J., Lineberry, Q. et al. A regenerable oxide-based H2S adsorbent with nanofibrous morphology. Nature Nanotech 7, 810–815 (2012). https://doi.org/10.1038/nnano.2012.194

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2012.194