Abstract

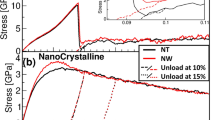

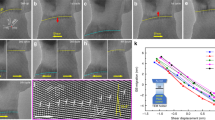

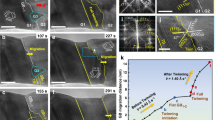

Silicon crystals have an important role in the electronics industry, and silicon nanoparticles have applications in areas such as nanoelectromechanical systems, photonics and biotechnology1,2. However, the elastic–plastic transition observed in silicon is not fully understood; in particular, it is not known if the plasticity of silicon is determined by dislocations or by transformations between phases. Here, based on compression experiments and molecular dynamics simulations, we show that the mechanical properties of bulk silicon3,4,5,6 and silicon nanoparticles are significantly different. We find that bulk silicon exists in a state of relative constraint, with its plasticity dominated by phase transformations, whereas silicon nanoparticles are less constrained and display dislocation-driven plasticity. This transition, which we call deconfinement, can also explain the absence of phase transformations in deformed silicon nanowedges7,8. Furthermore, the phenomenon is in agreement with effects observed in shape-memory alloy nanopillars9, and provides insight into the origin of incipient plasticity10,11,12,13,14,15,16,17,18,19.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ting, Z. & Li, J. Ultra-strength materials. Progr. Mater. Sci. 55, 710–757 (2010).

Craighead, H. G. Nanoelectromechanical systems. Science 290, 1532–1535 (2000).

Domnich, V., Gogotsi, Y. & Dub, S. Effect of phase transformations on the shape of the unloading curve in the nanoindentation of silicon. Appl. Phys. Lett. 76, 2214–2216 (2000).

Juliano, T., Domnich, V. & Gogotsi, Y. Examining pressure-induced phase transformations in silicon by spherical indentation and Raman spectroscopy: a statistical study. J. Mater. Res. 19, 3099–3108 (2004).

Chang, L. & Zhang, L. C. Deformation mechanisms at pop-out in monocrystalline silicon under nanoindentation. Acta Mater. 57, 2148–2153 (2009).

Bradby, J. E., Williams, J. S. & Swain, M. V. In situ electrical characterization of phase transformations in Si during indentation. Phys. Rev. B 67, 085205 (2003).

Minor, A. M. et al. Room temperature dislocation plasticity in silicon. Phil. Mag. 85, 323–330 (2005).

Ge, D., Minor, A. M., Stach, E. A. & Morris, J. W. Size effects in the nanoindentation of silicon at ambient temperature. Phil. Mag. 86, 4069–4080 (2006).

San Juan, J., No, M. L. & Schuh, C. A. Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nature Nanotech. 4, 415–419 (2009).

Li, J., Van Vliet, K. J., Zhu, T., Yip, S. & Suresh, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002).

Szlufarska, I. Nakano, A. & Vashishta, P. A Crossover in the mechanical response of nanocrystalline ceramics. Science 309, 911–914 (2005).

Schuh, C. A. Mason, J. K. & Lund, A. C. Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nature Mater. 4, 617–621 (2005).

Mason, J. K., Lund, A. C. & Schuh, C. A. Determining the activation energy and volume for the onset of plasticity during nanoindentation. Phys. Rev. B 73, 054102 (2006).

Gerberich, W. W. & Mook, W. M. Nanomechanics: a new picture of plasticity. Nature Mater. 4, 577–578 (2005).

Gerberich, W. W. et al. Superhard silicon nanospheres. J. Mech. Phys. Solids 51, 979–992 (2003).

Gerberich, W. W. et al. Reverse plasticity in single crystal silicon nanospheres. Int. J. Plast. 21, 2391–2405 (2005).

Chrobak, D., Nordlund, K. & Nowak, R. Nondislocation origin of GaAs nanoindentation pop-in event. Phys. Rev. Lett. 98, 045502 (2007).

Valentini, P., Gerberich, W. W. & Dumitrica, T. Phase-transition plasticity response in uniaxially compressed silicon nanospheres. Phys. Rev. Lett. 99, 175701 (2007).

Nowak, R. et al. An electric current spike linked to nanoscale plasticity. Nature Nanotech. 4, 287–291 (2009).

Nowak, R., Yoshida, F., Chrobak, D., Kurzydlowski, K. J., Takagi T. & Sasaki, T. in Encyclopedia of Nanoscience and Nanotechnology (ed. Nalwa, S. H.) 313–374 (American Scientific, 2010).

Stillinger, F. H. & Weber, T. A. Computer simulation of local order in condensed phases of silicon. Phys. Rev. B 31, 5262–5271 (1985).

Godet, J., Pizzagalli, L., Brochard, S. & Beauchamp, P. Theoretical study of dislocation nucleation from simple surface defects in semiconductors. Phys. Rev. B 70, 054109 (2004).

Tersoff, J. New empirical approach for the structure and energy of covalent systems. Phys. Rev. B 37, 6991–7000 (1988).

Bazant, M. Z., Kaxiras, E. & Justo, J. F. Environment-dependent interatomic potential for bulk silicon. Phys. Rev. B 56, 8542–8552 (1997).

Hertz, H. Über die Berührung fester elastischer Körper. J. Reine Angew. Math. 92, 156–171 (1882).

Mo, Y., Turner, K. T. & Szlufarska, I. Friction laws at the nanoscale. Nature 457, 1116–1119 (2009).

Li, X., Ono, T. & Wang, Y. & Esashi, M. Ultrathin single crystalline silicon cantilever resonators: fabrication technology and significant specimen size effect on Young's modulus, Appl. Phys. Lett. 83, 3081–3083 (2003).

Zimmerman, J. A., Kelchner, C. L., Klein, P. A., Hamilton, J. C. & Foiles, S. M. Surface step effects on nanoindentation. Phys. Rev. Lett. 87, 165507 (2001).

Choi, Y., Van Vliet, K. J., Li, J. & Suresh, S. Size effects on the onset of plastic deformation during nanoindentation of thin films and patterned lines. J. Appl. Phys. 94, 6050–6058 (2003).

Wu, Y. Q. & Xu, Y. B. Lattice-distortion-induced amorphization in indented [110] silicon. J. Mater. Res. 14, 682–687 (1999).

Lorenz, D. et al. Pop-in effect as homogeneous nucleation of dislocations during nanoindentation. Phys. Rev. B 67, 172101 (2003).

Piltz, R. O. et al. Structure and properties of silicon XII: a complex tetrahedrally bonded phase. Phys. Rev. B 52, 4072–4085 (1995).

Rao, N. P. et al. Hypersonic plasma particle deposition of nanostructured silicon and silicon carbide. J. Aerosol Sci. 29, 707–720 (1998).

Acknowledgements

The authors gratefully acknowledge the CSC–IT Center for Science for computation resources and the Ceramic Society of Japan for invaluable assistance. R.N., D.C. and N.T. thank the Academy of Finland for partial support under the FINNANO programme and NANOSPIKE research project. A.B. and W.W.G. acknowledge the support of the National Science Foundation (NSF; CTS-0506748 and CMMI-00800896). R.N. acknowledges the involvement of the Research Foundation of Helsinki University of Technology, as well as the NANOINDENT EU-research grant. D.C. and R.N. thank R. Nieminen and K. Niihara for valuable discussions. The authors also thank A. Poludniak for careful reading of the manuscript and stimulating comments.

Author information

Authors and Affiliations

Contributions

D.C. carried out the calculations and analysed the compatibility of the theoretical and experimental data. R.N. conceived the concept of deconfinement-driven transition and designed the research project. N.T. analysed the data. W.W.G. designed and supervised the experimental part, and A.B. and O.U. performed nanocompression tests and analysed the output. R.N. and D.C. wrote the paper. All authors discussed the results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 1484 kb)

Supplementary information

Supplementary movie 1 (AVI 2636 kb)

Supplementary information

Supplementary movie 2 (AVI 3534 kb)

Rights and permissions

About this article

Cite this article

Chrobak, D., Tymiak, N., Beaber, A. et al. Deconfinement leads to changes in the nanoscale plasticity of silicon. Nature Nanotech 6, 480–484 (2011). https://doi.org/10.1038/nnano.2011.118

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2011.118

This article is cited by

-

Plasticity in diamond nanoparticles: dislocations and amorphization during loading and dislocation multiplication during unloading

Journal of Materials Science (2023)

-

Mechanical behavior of surface-patterned and coated Si or Ge wafers for superhydrophobic and antireflective light transmitting windows

Journal of Materials Science (2022)

-

Mechanical properties, phase transitions, and fragmentation mechanisms of 6H, 3C, and amorphous SiC nanoparticles under compression

Applied Physics A (2021)

-

Molecular Dynamics Study on Tip-Based Nanomachining: A Review

Nanoscale Research Letters (2020)

-

Numerical study of three-body diamond abrasive nanoindentation of single-crystal Si by molecular dynamics simulation

Applied Physics A (2019)