Abstract

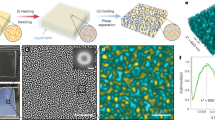

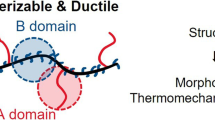

The incorporation of nanoparticles into engineering thermoplastics affords engineers an opportunity to synthesize polymer nanocomposites that potentially rival the most advanced materials in nature. Development of these materials is difficult because thermodynamic and kinetic barriers inhibit the dispersal of inorganic, often hydrophilic nanoparticles in hydrophobic polymer matrices. Using a new solvent-exchange approach, we preferentially reinforce the hard microdomains of thermoplastic elastomers with smectic clay of similar characteristic dimensions. The strong adhesion between the clay and the hard microdomains coupled with the formation of a percolative network not only stiffens and toughens, but increases the heat distortion temperature of the material and induces reversible thermotropic liquid-crystalline transitions. The discotic clay platelets induce morphological ordering over a range of length scales, which results in significant thermomechanical enhancement and expands high-temperature applications. Merging block-copolymer processing techniques with this method for preferential ordering of nanoparticle facilitates the development of new, hierarchically ordered materials.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Knight, D. P. & Vollrath, F. Biological liquid crystal elastomers. Phil. Trans. R. Soc. Lond. B 357, 155–163 (2002).

Vollrath, F. & Knight, D. P. Liquid crystalline spinning of spider silk. Nature 410, 541–548 (2001).

Termonia, Y. Molecular modeling of spider silk elasticity. Macromolecules 27, 7378–7381 (1994).

Simmons, A. H., Michal, C. A. & Jelinski, L. W. Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk. Science 271, 84–87 (1996).

van Beek, J. D. et al. Solid-state NMR determination of the secondary structure of Samia cynthia ricini silk. Nature 405, 1077–1079 (2000).

Gao, H. J., Ji, B. H., Jager, I. L., Arzt, E. & Fratzl, P. Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc. Natl Acad. Sci. USA 100, 5597–5600 (2003).

Smith, B. L. et al. Molecular mechanistic origin of the toughness of natural adhesives, fibres and composites. Nature 399, 761–763 (1999).

Gosline, J., Guerette, P., Ortlepp, C. & Savage, K. The mechanical design of spider silks: From fibroin sequence to mechanical function. J. Exp. Biol. 202, 3295–3303 (1999).

Koerner, H., Price, G., Pearce, N. A., Alexander, M. & Vaia, R. A. Remotely actuated polymer nanocomposites—stress-recovery of carbon-nanotube-filled thermoplastic elastomers. Nature Mater. 3, 115–120 (2004).

Vaia, R. A. & Wagner, H. D. Framework for nanocomposites. Mater. Today 7, 32–37 (2004).

Szycher, M. Szycher’s Handbook of Polyurethanes (CRC Press, Boca Raton, 1999).

Wiggins, M. J., MacEwan, M., Anderson, J. M. & Hiltner, A. Effect of soft-segment chemistry on polyurethane biostability during in vitro fatigue loading. J. Biomed. Mater. Res. A 68, 668–683 (2004).

Finnigan, B. et al. Segmented polyurethane nanocomposites: Impact of controlled particle size nanofillers on the morphological response to uniaxial deformation. Macromolecules 38, 7386–7396 (2005).

Yeh, F., Hsiao, B. S., Sauer, B. B., Michel, S. & Siesler, H. W. In-situ studies of structure development during deformation of a segmented poly(urethane-urea) elastomer. Macromolecules 36, 1940–1954 (2003).

Kim, H. D., Lee, T. J., Huh, J. H. & Lee, D. J. Preparation and properties of segmented thermoplastic polyurethane elastomers with two different soft segments. J. Appl. Polym. Sci. 73, 345–352 (1999).

Nair, B. R., Gregoriou, V. G. & Hammond, P. T. FT-IR studies of side chain liquid crystalline thermoplastic elastomers. Polymer 41, 2961–2970 (2000).

Yeganeh, H. & Shamekhi, M. A. Poly(urethane-imide-imide), a new generation of thermoplastic polyurethane elastomers with enhanced thermal stability. Polymer 45, 359–365 (2004).

Stanford, J. L., Still, R. H. & Wilkinson, A. N. Effects of soft-segment prepolymer functionality on structure—property relations in RIM copolyurethanes. Polymer 44, 3985–3994 (2003).

Martin, D. J., Meijs, G. F., Gunatillake, P. A., Yozghatlian, S. P. & Renwick, G. M. The influence of composition ratio on the morphology of biomedical polyurethanes. J. Appl. Polym. Sci. 71, 937–952 (1999).

Ryan, A. J., Stanford, J. L. & Birch, A. J. Copolyureas formed by reaction injection moulding: Correlations between chemical structure, thermal properties and microphase separation. Polymer 34, 4874–4881 (1993).

Lee, D. K. & Tsai, H. B. Properties of segmented polyurethanes derived from different diisocyanates. J. Appl. Polym. Sci. 75, 167–174 (2000).

Knight, D. P., Knight, M. M. & Vollrath, F. Beta transition and stress-induced phase separation in the spinning of spider dragline silk. Int. J. Biol. Macromol. 27, 205–210 (2000).

Porter, D., Vollrath, F. & Shao, Z. Predicting the mechanical properties of spider silk as a model nanostructured polymer. Eur. Phys. J. E 16, 199–206 (2005).

Sinha Ray, S. & Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Sci. 28, 1539–1641 (2003).

Thostenson, E. T., Li, C. & Chou, T.-W. Nanocomposites in context. Compos. Sci. Technol. 65, 491–516 (2005).

Eisenbach, C. D., Ribbe, A. & Gunter, C. Morphological-studies of model polyurethane elastomers by element-specific electron-microscopy. Macromol. Rapid Commun. 15, 395–403 (1994).

Alexandre, M. & Dubois, P. Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater. Sci. Eng. R 28, 1–63 (2000).

Njuguna, J. & Pielichowski, K. Polymer nanocomposites for aerospace applications: Fabrication. Adv. Eng. Mater. 6, 193–203 (2004).

Burgentzle, D., Duchet, J., Gerard, J. F., Jupin, A. & Fillon, B. Solvent-based nanocomposite coatings: I. Dispersion of organophilic montmorillonite in organic solvents. J. Colloid Interface Sci. 278, 26–39 (2004).

Finnigan, B., Martin, D., Halley, P., Truss, R. & Campbell, K. Morphology and properties of thermoplastic polyurethane nanocomposites incorporating hydrophilic layered silicates. Polymer 45, 2249–2260 (2004).

Dai, X. H. et al. Study on structure and orientation action of polyurethane nanocomposites. Macromolecules 37, 5615–5623 (2004).

Rhoney, I., Brown, S., Hudson, N. E. & Pethrick, R. A. Influence of processing method on the exfoliation process for organically modified clay systems. I. Polyurethanes. J. Appl. Polym. Sci. 91, 1335–1343 (2004).

Kumar, N., Liff, S. M. & McKinley, G. H. Method to disperse and exfoliate nanoparticles. US Patent Application 11/253,219 (Filed October 18, 2005).

Lee, H. S., Yoo, S. R. & Seo, S. W. Domain and segmental deformation behavior of thermoplastic elastomers using synchrotron SAXS and FTIR methods. J. Polym. Sci. B 37, 3233–3245 (1999).

Wang, C. B. & Cooper, S. L. Morphology and properties of segmented polyether polyurethaneureas. Macromolecules 16, 775–786 (1983).

Young, R. J. & Lovell, P. A. Introduction to Polymers (Chapman and Hall, London, 1991).

Guth, E. Theory of filler reinforcement. J. Appl. Phys. 16, 20–25 (1945).

Trappe, V., Prasad, V., Cipelletti, L., Segre, P. N. & Weitz, D. A. Jamming phase diagram for attractive particles. Nature 411, 772–775 (2001).

O’Hern, C. S., Silbert, L. E., Liu, A. J. & Nagel, S. R. Jamming at zero temperature and zero applied stress: The epitome of disorder. Phys. Rev. E 68, 011306 (2003).

Petrovic, Z. S., Javni, I., Waddon, A. & Banhegyi, G. Structure and properties of polyurethane-silica nanocomposites. J. Appl. Polym. Sci. 76, 133–151 (2000).

Frogley, M. D., Ravich, D. & Wagner, H. D. Mechanical properties of carbon nanoparticle-reinforced elastomers. Compos. Sci. Technol. 63, 1647–1654 (2003).

Zhang, T. et al. Synthesis, properties of fullerene-containing polyurethane-urea and its optical limiting absorption. Polymer 44, 2647–2654 (2003).

Tang, Z. Y., Kotov, N. A., Magonov, S. & Ozturk, B. Nanostructured artificial nacre. Nature Mater. 2, 413–418 (2003).

Dierking, I. Liquid crystalline fractals: Dilatation invariant growth structures in the phase ordering process of ‘banana-phases’. Liq. Cryst. Today 12, 1–10 (2003).

Aneja, A. & Wilkes, G. L. A systematic series of ‘model’ PTMO based segmented polyurethanes reinvestigated using atomic force microscopy. Polymer 44, 7221–7228 (2003).

Acierno, D. et al. Synthesis and characterisation of a nematic homo-polyurethane. Polymer 44, 4949–4958 (2003).

Kojio, K., Nakamura, S. & Furukawa, M. Effect of side methyl groups of polymer glycol on elongation-induced crystallization behavior of polyurethane elastomers. Polymer 45, 8147–8152 (2004).

Korley, L. T. J., Liff, S. M., Kumar, N., McKinley, G. H. & Hammond, P. T. Preferential association of segment blocks in polyurethane nanocomposites. Macromolecules 39, 7030–7036 (2006).

Grillo, I., Levitz, P. & Zemb, T. Insertion of small anisotropic clay particles in swollen lamellar or sponge phases of nonionic surfactant. Eur. Phys. J. E 5, 377–386 (2001).

Malwitz, M. M., Lin-Gibson, S., Hobbie, E. K., Butler, P. D. & Schmidt, G. Orientation of platelets in multilayered nanocomposite polymer films. J. Polym. Sci. B 41, 3237–3248 (2003).

Acknowledgements

The authors acknowledge S. Kooi, M. Johnson and B. Pate for TEM sample preparation using the FIB, TEM examination of the FIB samples and WAXD collection between 2∘ and 38∘, respectively. This research was supported by the US Army through the Institute for Soldier Nanotechnologies, under contract DAAD-19-02-0002 with the US Army Research Office. S.M.L. was supported by a National Science Foundation Graduate Research Fellowship.

Author information

Authors and Affiliations

Contributions

N.K. developed the solvent-exchange process and carried out the thermal annealing–polarization study. S.M.L prepared the samples and carried out the AFM, DMA, DSC, mechanical analyses and initial TEM. The creep experiments and x-ray diffraction studies were carried out jointly.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary figures S1, S2, S3, S5, S6 (PDF 2851 kb)

Supplementary Information

Supplementary movie: figure S4 (MOV 2461 kb)

Rights and permissions

About this article

Cite this article

Liff, S., Kumar, N. & McKinley, G. High-performance elastomeric nanocomposites via solvent-exchange processing. Nature Mater 6, 76–83 (2007). https://doi.org/10.1038/nmat1798

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1798

This article is cited by

-

Highly Ordered Thermoplastic Polyurethane/Aramid Nanofiber Conductive Foams Modulated by Kevlar Polyanion for Piezoresistive Sensing and Electromagnetic Interference Shielding

Nano-Micro Letters (2023)

-

Polymer Matrix-Based Carbon Nanocomposites for Neural Tissue Engineering

Transactions of the Indian National Academy of Engineering (2022)

-

Finite volume simulations of particle-laden viscoelastic fluid flows: application to hydraulic fracture processes

Engineering with Computers (2022)

-

Enhancement effect of acylated cellulose nanocrystals on waterborne polyurethane

Journal of Polymer Research (2022)

-

Synthesis and characterization of Chitosan-sodium titanate nanocomposite beads for separation of radionuclides from aqueous radioactive waste

Journal of Radioanalytical and Nuclear Chemistry (2021)