Abstract

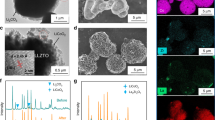

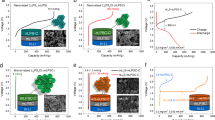

Garnet-type solid-state electrolytes have attracted extensive attention due to their high ionic conductivity, approaching 1 mS cm−1, excellent environmental stability, and wide electrochemical stability window, from lithium metal to ∼6 V. However, to date, there has been little success in the development of high-performance solid-state batteries using these exceptional materials, the major challenge being the high solid–solid interfacial impedance between the garnet electrolyte and electrode materials. In this work, we effectively address the large interfacial impedance between a lithium metal anode and the garnet electrolyte using ultrathin aluminium oxide (Al2O3) by atomic layer deposition. Li7La2.75Ca0.25Zr1.75Nb0.25O12 (LLCZN) is the garnet composition of choice in this work due to its reduced sintering temperature and increased lithium ion conductivity. A significant decrease of interfacial impedance, from 1,710 Ω cm2 to 1 Ω cm2, was observed at room temperature, effectively negating the lithium metal/garnet interfacial impedance. Experimental and computational results reveal that the oxide coating enables wetting of metallic lithium in contact with the garnet electrolyte surface and the lithiated-alumina interface allows effective lithium ion transport between the lithium metal anode and garnet electrolyte. We also demonstrate a working cell with a lithium metal anode, garnet electrolyte and a high-voltage cathode by applying the newly developed interface chemistry.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Xu, X. et al. Self-organized core–shell structure for high-power electrode in solid-state lithium batteries. Chem. Mater. 23, 3798–3804 (2011).

Inada, T. et al. All solid-state sheet battery using lithium inorganic solid electrolyte, thio-LISICON. J. Power Sources 194, 1085–1088 (2009).

Feng, J. K., Yan, B. G., Liu, J. C., Lai, M. O. & Li, L. All solid state lithium ion rechargeable batteries using NASICON structured electrolyte. Mater. Technol. 28, 276–279 (2013).

Noguchi, Y., Kobayashi, E., Plashnitsa, L. S., Okada, S. & Yamaki, J.-I. Fabrication and performances of all solid-state symmetric sodium battery based on NASICON-related compounds. Electrochim. Acta 101, 59–65 (2013).

Ihlefeld, J. F. et al. Fast lithium-ion conducting thin-film electrolytes integrated directly on flexible substrates for high-power solid-state batteries. Adv. Mater. 23, 5663–5667 (2011).

Lü, X. et al. Antiperovskite Li3OCl superionic conductor films for solid-state Li-ion batteries. Adv. Sci. 3, 1500359 (2016).

Takahashi, K. et al. All-solid-state lithium battery with LiBH4 solid electrolyte. J. Power Sources 226, 61–64 (2013).

Trevey, J. E., Jung, Y. S. & Lee, S.-H. High lithium ion conducting Li2S–GeS2–P2S5 glass–ceramic solid electrolyte with sulfur additive for all solid-state lithium secondary batteries. Electrochim. Acta 56, 4243–4247 (2011).

Yersak, T. A. et al. An all-solid-state Li-ion battery with a pre-lithiated Si–Ti–Ni alloy anode. J. Electrochem. Soc. 160, A1497–A1501 (2013).

Buschmann, H. et al. Structure and dynamics of the fast lithium ion conductor “Li7La3Zr2O12”. Phys. Chem. Chem. Phys. 13, 19378–19392 (2011).

Djenadic, R. et al. Nebulized spray pyrolysis of Al-doped Li7La3Zr2O12 solid electrolyte for battery applications. Solid State Ion. 263, 49–56 (2014).

Murugan, R., Thangadurai, V. & Weppner, W. Fast lithium ion conduction in garnet-type Li7La3Zr2O12 . Angew. Chem. Int. Ed. 46, 7778–7781 (2007).

Ren, Y. et al. Effects of Li source on microstructure and ionic conductivity of Al-contained Li6.75La3Zr1.75Ta0.25O12 ceramics. J. Eur. Ceram. Soc. 35, 561–572 (2015).

Thangadurai, V., Schwenzel, J. & Weppner, W. Tailoring ceramics for specific applications: a case study of the development of all-solid-state lithium batteries. Ionics 11, 11–23 (2005).

Kamaya, N. et al. A lithium superionic conductor. Nat. Mater. 10, 682–686 (2011).

Yada, C. et al. Dielectric modification of 5 V-class cathodes for high-voltage all-solid-state lithium batteries. Adv. Energy Mater. 4, 1301416 (2014).

Takada, K. et al. Interfacial phenomena in solid-state lithium battery with sulfide solid electrolyte. Solid State Ion. 225, 594–597 (2012).

Sakuda, A. et al. All-solid-state lithium secondary batteries with metal-sulfide-coated LiCoO2 prepared by thermal decomposition of dithiocarbamato complexes. J. Mater. Chem. 22, 15247–15254 (2012).

Sakuda, A. et al. All-solid-state lithium secondary batteries using Li2S-P2S5 solid electrolytes and LiFePO4 electrode particles with amorphous surface layer. Chem. Lett. 41, 260–261 (2012).

Seino, Y., Ota, T. & Takada, K. High rate capabilities of all-solid-state lithium secondary batteries using Li4Ti5O12-coated LiNi0.8Co0.15Al0.05O2 and a sulfide-based solid electrolyte. J. Power Sources 196, 6488–6492 (2011).

Ohta, N. et al. LiNbO3-coated LiCoO2 as cathode material for all solid-state lithium secondary batteries. Electrochem. Commun. 9, 1486–1490 (2007).

Kato, T. et al. In-situ Li7La3Zr2O12/LiCoO2 interface modification for advanced all-solid-state battery. J. Power Sources 260, 292–298 (2014).

Ohta, S. et al. All-solid-state lithium ion battery using garnet-type oxide and Li3BO3 solid electrolytes fabricated by screen-printing. J. Power Sources 238, 53–56 (2013).

Van den Broek, J., Afyon, S. & Rupp, J. L. M. Interface-engineered all-solid-state Li-ion batteries based on garnet-type fast Li + conductors. Adv. Energy Mater. 6, 1600736 (2016).

Thangadurai, V., Pinzaru, D., Narayanan, S. & Baral, A. K. Fast solid-state Li ion conducting garnet-type structure metal oxides for energy storage. J. Phys. Chem. Lett. 6, 292–299 (2015).

Sudo, R. et al. Interface behavior between garnet-type lithium-conducting solid electrolyte and lithium metal. Solid State Ion. 262, 151–154 (2014).

Ohta, S. et al. Co-sinterable lithium garnet-type oxide electrolyte with cathode for all-solid-state lithium ion battery. J. Power Sources 265, 40–44 (2014).

Jin, Y. & McGinn, P. J. Bulk solid state rechargeable lithium ion battery fabrication with Al-doped Li7La3Zr2O12 electrolyte and Cu0.1V2O5 cathode. Electrochim. Acta 89, 407–412 (2013).

Thangadurai, V., Kaack, H. & Weppner, W. J. F. Novel fast lithium ion conduction in garnet-type Li5La3M2O12 (M = Nb, Ta). J. Am. Ceram. Soc. 86, 437–440 (2003).

O’Callaghan, M. P., Powell, A. S., Titman, J. J., Chen, G. Z. & Cussen, E. J. Switching on fast lithium ion conductivity in garnets: the structure and transport properties of Li3+xNd3Te2−xSbxO12 . Chem. Mater. 20, 2360–2369 (2008).

Jalem, R. et al. Concerted migration mechanism in the Li ion dynamics of garnet-type Li7La3Zr2O12 . Chem. Mater. 25, 425–430 (2013).

Thompson, T. et al. A tale of two sites: on defining the carrier concentration in garnet-based ionic conductors for advanced Li batteries. Adv. Energy Mater. 5, 150096 (2015).

Cheng, L. et al. The origin of high electrolyte-electrode interfacial resistances in lithium cells containing garnet type solid electrolytes. Phys. Chem. Chem. Phys. 16, 18294–18300 (2014).

Kihira, Y., Ohta, S., Imagawa, H. & Asaoka, T. Effect of simultaneous substitution of alkali earth metals and Nb in Li7La3Zr2O12 on lithium-ion conductivity. ECS Electrochem. Lett. 2, A56–A59 (2013).

Wolfenstine, J., Allen, J. L., Read, J. & Sakamoto, J. Chemical stability of cubic Li7La3Zr2O12 with molten lithium at elevated temperature. J. Mater. Sci. 48, 5846–5851 (2013).

Jung, S. C. & Han, Y.-K. How do Li atoms pass through the Al2O3 coating layer during lithiation in Li-ion batteries? J. Phys. Chem. Lett. 4, 2681–2685 (2013).

Jung, S. C., Kim, H.-J., Choi, J. W. & Han, Y.-K. Sodium ion diffusion in Al2O3: a distinct perspective compared with lithium ion diffusion. Nano Lett. 14, 6559–6563 (2014).

Han, X. et al. Atomic-layer-deposition oxide nanoglue for sodium ion batteries. Nano Lett. 14, 139–147 (2013).

Wang, D. N. et al. Atomic layer deposited coatings to significantly stabilize anodes for Li ion batteries: effects of coating thickness and the size of anode particles. J. Mater. Chem. A 2, 2306–2312 (2014).

Lotfabad, E. M. et al. Si nanotubes ALD coated with TiO2, TiN or Al2O3 as high performance lithium ion battery anodes. J. Mater. Chem. A 2, 2504–2516 (2014).

Kohandehghan, A. et al. Silicon nanowire lithium-ion battery anodes with ALD deposited TiN coatings demonstrate a major improvement in cycling performance. J. Mater. Chem. A 1, 12850–12861 (2013).

Li, Y. et al. Tuning electrochemical performance of Si-based anodes for lithium-ion batteries by employing atomic layer deposition alumina coating. J. Mater. Chem. A 2, 11417–11425 (2014).

Liu, T. et al. Achieving high capacity in bulk-type solid-state lithium ion battery based on Li6.75La3Zr1.75Ta0.25O12 electrolyte: interfacial resistance. J. Power Sources 324, 349–357 (2016).

Sharafi, A., Meyer, H. M., Nanda, J., Wolfenstine, J. & Sakamoto, J. Characterizing the Li–Li7La3Zr2O12 interface stability and kinetics as a function of temperature and current density. J. Power Sources 302, 135–139 (2016).

Tsai, C. L. et al. Li7La3Zr2O12 interface modification for Li dendrite prevention. ACS Appl. Mater. Interfaces 8, 10617–10626 (2016).

Mo, Y., Ong, S. P. & Ceder, G. First principles study of the Li10GeP2S12 lithium super ionic conductor material. Chem. Mater. 24, 15–17 (2012).

Zhang, Z. et al. Fluorinated electrolytes for 5 V lithium-ion battery chemistry. Energy Environ. Sci. 6, 1806–1810 (2013).

Kawai, H., Nagata, M., Tabuchi, M., Tukamoto, H. & West, A. R. Novel 5 V spinel cathode Li2FeMn3O8 for lithium ion batteries. Chem. Mater. 10, 3266–3268 (1998).

Jain, A. et al. Commentary: the Materials Project: a materials genome approach to accelerating materials innovation. APL Mater. 1, 011002 (2013).

Acknowledgements

This work was supported by the US Department of Energy ARPA-E (Contract No. DE-AR0000384) and EERE (Contract No. DE-EE0006860). We acknowledge S.-C. Liou for TEM and EELS characterization and data analysis, and the support of the Maryland NanoCenter and its FabLab and AIMLab. We acknowledge K. Xu from the US Army Research Laboratory for supplying the liquid electrolyte. We acknowledge computational facilities from the University of Maryland supercomputing resources, the Maryland Advanced Research Computing Center (MARCC), and the Extreme Science and Engineering Discovery Environment (XSEDE) supported by National Science Foundation Award No. DMR150038. The XPS measurements were supported by Nanostructures for Electrical Energy Storage (NEES), an Energy Frontier Research Center funded by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, under Award Number DESC0001160.

Author information

Authors and Affiliations

Contributions

X.H., Y.G. and K.F. fabricated the samples and carried out the experiments, characterizations, data analysis, and manuscript preparation. X.H. and Y.M. conducted the theoretical analysis. G.T.H. helped prepare samples and analysed the experimental results. J.D. drew the schematics and prepared FIB samples. A.P. and G.R. carried out the XPS and XPS data analysis. B.L. prepared samples and conducted ALD. H.W. carried out NDP and NDP data analysis. V.T. helped review the results, and E.D.W. and L.H. managed the project and reviewed the results, data analysis, and manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 910 kb)

Rights and permissions

About this article

Cite this article

Han, X., Gong, Y., Fu, K. et al. Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nature Mater 16, 572–579 (2017). https://doi.org/10.1038/nmat4821

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4821

This article is cited by

-

Self-assembled hydrated copper coordination compounds as ionic conductors for room temperature solid-state batteries

Nature Communications (2024)

-

Lithium anode interlayer design for all-solid-state lithium-metal batteries

Nature Energy (2024)

-

Transition metals for stabilizing lithium metal anode: advances and perspectives

Tungsten (2024)

-

Enhanced 3D framework composite solid electrolyte with alumina-modified Li1.4Al0.4Ti1.6(PO4)3 for solid-state lithium battery

Ionics (2024)

-

From Liquid to Solid-State Lithium Metal Batteries: Fundamental Issues and Recent Developments

Nano-Micro Letters (2024)