Abstract

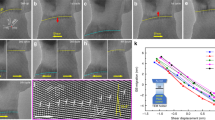

Nanoscale metallic crystals have been shown to follow a ‘smaller is stronger’ trend. However, they usually suffer from low ductility due to premature plastic instability by source-limited crystal slip. Here, by performing in situ atomic-scale transmission electron microscopy, we report unusual room-temperature super-elongation without softening in face-centred-cubic silver nanocrystals, where crystal slip serves as a stimulus to surface diffusional creep. This interplay mechanism is shown experimentally and theoretically to govern the plastic deformation of nanocrystals over a material-dependent sample diameter range between the lower and upper limits for nanocrystal stability by surface diffusional creep and dislocation plasticity, respectively, which extends far beyond the maximum size for pure diffusion-mediated deformation (for example, Coble-type creep). This work provides insight into the atomic-scale coupled diffusive–displacive deformation mechanisms, maximizing ductility and strength simultaneously in nanoscale materials.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Oh, S. H., Legros, M., Kiener, D. & Dehm, G. In situ observation of dislocation nucleation and escape in a submicrometre aluminium single crystal. Nat. Mater. 8, 95–100 (2009).

Zhu, T., Li, J., Samanta, A., Leach, A. & Gall, K. Temperature and strain-rate dependence of surface dislocation nucleation. Phys. Rev. Lett. 100, 025502 (2008).

Lu, L., Sui, M. L. & Lu, K. Superplastic extensibility of nanocrystalline copper at room temperature. Science 287, 1463–1466 (2000).

McFadden, S. X., Mishra, R. S., Valiev, R. Z., Zhilyaev, A. P. & Mukherjee, A. K. Low-temperature superplasticity in nanostructured nickel and metal alloys. Nature 398, 684–686 (1999).

Raj, R. & Ashby, M. F. On grain boundary sliding and diffusional creep. Metall. Trans. 2, 1113–1127 (1971).

Yamakov, V., Wolf, D., Phillpot, S. R. & Gleiter, H. Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation. Acta Mater. 50, 61–73 (2002).

Shan, Z. W. et al. Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305, 654–657 (2004).

Guo, W., Wang, Z. & Li, J. Diffusive versus displacive contact plasticity of nanoscale asperities: temperature- and velocity-dependent strongest size. Nano Lett. 15, 6582–6585 (2015).

Yamakov, V., Wolf, D., Phillpot, S. R., Mukherjee, A. K. & Gleiter, H. Deformation-mechanism map for nanocrystalline metals by molecular-dynamics simulation. Nat. Mater. 3, 43–47 (2004).

Chokshi, A. H., Rosen, A., Karch, J. & Gleiter, H. On the validity of the Hall–Petch relationship in nanocrystalline materials. Scr. Metall. 23, 1679–1683 (1989).

Meyers, M. A., Mishra, A. & Benson, D. J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427–556 (2006).

Tian, L., Li, J., Sun, J., Ma, E. & Shan, Z. W. Visualizing size-dependent deformation mechanism transition in Sn. Sci. Rep. 3, 2113 (2013).

Wang, Y. M. & Ma, E. Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 52, 1699–1709 (2004).

Dao, M., Lu, L., Asaro, R. J., De Hosson, J. T. M. & Ma, E. Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55, 4041–4065 (2007).

Wei, Q., Cheng, S., Ramesh, K. T. & Ma, E. Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater. Sci. Eng. A 381, 71–79 (2004).

Ma, E. Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scr. Mater. 49, 663–668 (2003).

Nieman, G. W., Weertman, J. R. & Siegel, R. W. Mechanical-behavior of nanocrystalline Cu and Pd. J. Mater. Res. 6, 1012–1027 (1991).

Richter, G. et al. Ultrahigh strength single crystalline nanowhiskers grown by physical vapor deposition. Nano Lett. 9, 3048–3052 (2009).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Greer, J. R., Oliver, W. C. & Nix, W. D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821–1830 (2005).

Chen, L. Y., He, M. R., Shin, J., Richter, G. & Gianola, D. S. Measuring surface dislocation nucleation in defect-scarce nanostructures. Nat. Mater. 14, 707–713 (2015).

Sun, J. et al. Liquid-like pseudoelasticity of sub-10-nm crystalline silver particles. Nat. Mater. 13, 1007–1012 (2014).

Zhu, Y. et al. Size effects on elasticity, yielding, and fracture of silver nanowires: in situ experiments. Phys. Rev. B 85, 045443 (2012).

Wolf, D., Yamakov, V., Phillpot, S. R., Mukherjee, A. & Gleiter, H. Deformation of nanocrystalline materials by molecular-dynamics simulation: relationship to experiments? Acta Mater. 53, 1–40 (2005).

Zheng, H. et al. Discrete plasticity in sub-10-nm-sized gold crystals. Nat. Commun. 1, 144 (2010).

Li, J. et al. Diffusive molecular dynamics and its application to nanoindentation and sintering. Phys. Rev. B 84, 054103 (2011).

Mishra, R. S., Valiev, R. Z., McFadden, S. X. & Mukherjee, A. K. Tensile superplasticity in a nanocrystalline nickel aluminide. Mater. Sci. Eng. A 252, 174–178 (1998).

Zhong, L., Wang, J. W., Sheng, H. W., Zhang, Z. & Mao, S. X. Formation of monatomic metallic glasses through ultrafast liquid quenching. Nature 512, 177–180 (2014).

Wang, J. W. et al. In situ atomic-scale observation of twinning-dominated deformation in nanoscale body-centred cubic tungsten. Nat. Mater. 14, 594–600 (2015).

Wu, Z. X., Zhang, Y. W., Jhon, M. H., Gao, H. J. & Srolovitz, D. J. Nanowire failure: long = brittle and short = ductile. Nano Lett. 12, 910–914 (2012).

Rice, J. R. Dislocation nucleation from a crack tip: an analysis based on the Peierls concept. J. Mech. Phys. Solids 40, 239–271 (1992).

Kim, S. Y., Lee, I. H. & Jun, S. Transition-pathway models of atomic diffusion on fcc metal surfaces. I. Flat surfaces. Phys. Rev. B 76, 245407 (2007).

Kim, S. Y., Lee, I. H. & Jun, S. Transition-pathway models of atomic diffusion on fcc metal surfaces. II. Stepped surfaces. Phys. Rev. B 76, 245408 (2007).

Fisher, S. B. On the temperature rise in electron irradiated foils. Radiat. Eff. 5, 239–243 (1970).

Ala-Nissila, T., Ferrando, R. & Ying, S. C. Collective and single particle diffusion on surfaces. Adv. Phys. 51, 949–1078 (2002).

Greer, J. R. & Nix, W. D. Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 73, 245410 (2006).

Masumura, R. A., Hazzledine, P. M. & Pande, C. S. Yield stress of fine grained materials. Acta Mater. 46, 4527–4534 (1998).

Ramachandramoorthy, R., Gao, W., Bernal, R. & Espinosa, H. High strain rate tensile testing of silver nanowires: rate-dependent brittle-to-ductile transition. Nano Lett. 16, 255–263 (2016).

Filleter, T. et al. Nucleation-controlled distributed plasticity in penta-twinned silver nanowires. Small 8, 2986–2993 (2012).

Zheng, H., Wang, J. W., Huang, J. Y., Wang, J. B. & Mao, S. X. Void-assisted plasticity in Ag nanowires with a single twin structure. Nanoscale 6, 9574–9578 (2014).

Peng, C., Zhan, Y. J. & Lou, J. Size-dependent fracture mode transition in copper nanowires. Small 8, 1889–1894 (2012).

Kiener, D. & Minor, A. M. Source truncation and exhaustion: insights from quantitative in situ TEM tensile testing. Nano Lett. 11, 3816–3820 (2011).

Shan, Z. W., Mishra, R. K., Asif, S. A. S., Warren, O. L. & Minor, A. M. Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nat. Mater. 7, 115–119 (2008).

Yu, Q. et al. The nanostructured origin of deformation twinning. Nano Lett. 12, 887–892 (2012).

Huang, L. et al. A new regime for mechanical annealing and strong sample-size strengthening in body centred cubic molybdenum. Nat. Commun. 2, 547 (2011).

Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 117, 1–19 (1995).

Wu, H. H. & Trinkle, D. R. Cu/Ag EAM potential optimized for heteroepitaxial diffusion from ab initio data. Comput. Mater. Sci. 47, 577–583 (2009).

Sheng, H. W., Kramer, M. J., Cadien, A., Fujita, T. & Chen, M. W. Highly optimized embedded-atom-method potentials for fourteen fcc metals. Phys. Rev. B 83, 134118 (2011).

Castro, T., Reifenberger, R., Choi, E. & Andres, R. P. Size-dependent melting temperature of individual nanometer-sized metallic clusters. Phys. Rev. B 42, 8548–8556 (1990).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Modelling Simul. Mater. Sci. Eng. 18, 015012 (2010).

Acknowledgements

S.X.M. acknowledges support from NSF CMMI 1536811 through University of Pittsburgh. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the US Department of Energy (DOE) Office of Science by Los Alamos National Laboratory (Contract DE-AC52-06NA25396) and Sandia National Laboratories (Contract DE-AC04-94AL85000), and at the William R. Wiley Environmental Molecular Sciences Laboratory, a national scientific user facility sponsored by US Department of Energy, Office of Biological and Environmental Research and located at PNNL. PNNL is operated by Battelle for the US Department of Energy under contract DE-AC05-76RLO1830. F.S. acknowledges support from NSF grant No. DMR-1410646 and the computational resources provided by the Extreme Science and Engineering Discovery Environment (XSEDE) supported by NSF grant No. ACI-1053575.

Author information

Authors and Affiliations

Contributions

L.Z. and S.X.M. conceived and designed the experiments. L.Z. and Y.H. conducted the in situ TEM experiments under the direction of S.X.M. L.Z. performed the experimental data analysis. F.S. carried out the computer simulations. F.S. and L.Z. developed the kinetic model. All authors contributed to discussion of the results. L.Z., F.S. and S.X.M. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 2753 kb)

Supplementary Movie 1

Supplementary Movie 1 (MOV 11479 kb)

Supplementary Movie 2

Supplementary Movie 2 (MOV 13122 kb)

Supplementary Movie 3

Supplementary Movie 3 (MOV 7719 kb)

Supplementary Movie 4

Supplementary Movie 4 (MOV 3991 kb)

Supplementary Movie 5

Supplementary Movie 5 (MOV 21820 kb)

Supplementary Movie 6

Supplementary Movie 6 (MOV 4460 kb)

Supplementary Movie 7

Supplementary Movie 7 (MOV 5942 kb)

Rights and permissions

About this article

Cite this article

Zhong, L., Sansoz, F., He, Y. et al. Slip-activated surface creep with room-temperature super-elongation in metallic nanocrystals. Nature Mater 16, 439–445 (2017). https://doi.org/10.1038/nmat4813

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4813

This article is cited by

-

Atomic-scale observation of nucleation- and growth-controlled deformation twinning in body-centered cubic nanocrystals

Nature Communications (2024)

-

Room-temperature super-elongation in high-entropy alloy nanopillars

Nature Communications (2023)

-

Size-dependent deformation behavior in nanosized amorphous metals suggesting transition from collective to individual atomic transport

Nature Communications (2023)

-

Atomistic observation on diffusion-mediated friction between single-asperity contacts

Nature Materials (2022)

-

One-step plasmonic welding and photolithographic patterning of silver nanowire network by UV-programable surface atom diffusion

Nano Research (2022)