Abstract

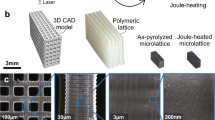

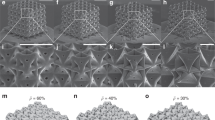

The strength of lightweight mechanical metamaterials, which aim to exploit material-strengthening size effects by their microscale lattice structure, has been limited by the resolution of three-dimensional lithography technologies and their restriction to mainly polymer resins. Here, we demonstrate that pyrolysis of polymeric microlattices can overcome these limitations and create ultra-strong glassy carbon nanolattices with single struts shorter than 1 μm and diameters as small as 200 nm. They represent the smallest lattice structures yet produced—achieved by an 80% shrinkage of the polymer during pyrolysis—and exhibit material strengths of up to 3 GPa, corresponding approximately to the theoretical strength of glassy carbon. The strength-to-density ratios of the nanolattices are six times higher than those of reported microlattices. With a honeycomb topology, effective strengths of 1.2 GPa at 0.6 g cm−3 are achieved. Diamond is the only bulk material with a notably higher strength-to-density ratio.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Christensen, J., Kadic, M., Wegener, M. & Kraft, O. Vibrant times for mechanical metamaterials. MRS Commun. 5, 453–462 (2015).

Lee, J. H., Singer, J. P. & Thomas, E. L. Micro-/nanostructured mechanical metamaterials. Adv. Mater. 24, 4782–4810 (2012).

Salari-Sharif, L., Schaedler, T. A. & Valdevit, L. Energy dissipation mechanisms in hollow metallic microlattices. J. Mater. Res. 29, 1755–1770 (2014).

Bückmann, T. et al. Tailored 3D mechanical metamaterials made by dip-in direct-laser-writing optical lithography. Adv. Mater. 24, 2710–2714 (2012).

Fleck, N. A., Deshpande, V. S. & Ashby, M. F. Micro-architectured materials: past, present and future. Proc. R. Soc. Lond. A 466, 2495–2516 (2010).

Jacobsen, A. J., Barvosa-Carter, W. & Nutt, S. Micro-scale Truss structures formed from self-propagating photopolymer waveguides. Adv. Mater. 19, 3892–3896 (2007).

Zheng, X. et al. Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Rev. Sci. Instrum. 83, 125001 (2012).

von Freymann, G. et al. Three-dimensional nanostructures for photonics. Adv. Funct. Mater. 20, 1038–1052 (2010).

Arpin, K. A. et al. Multidimensional architectures for functional optical devices. Adv. Mater. 22, 1084–1101 (2010).

Gansel, J. K. et al. Gold helix photonic metamaterial as broadband circular polarizer. Science 325, 1513–1515 (2009).

Fratzl, P. & Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 52, 1263–1334 (2007).

Schaedler, T. A. et al. Ultralight metallic microlattices. Science 334, 962–965 (2011).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Jang, D., Meza, L. R., Greer, F. & Greer, J. R. Fabrication and deformation of three-dimensional hollow ceramic nanostructures. Nature Mater. 12, 893–898 (2013).

Bauer, J., Hengsbach, S., Tesari, I., Schwaiger, R. & Kraft, O. High-strength cellular ceramic composites with 3D microarchitecture. Proc. Natl Acad. Sci. USA 111, 2453–2458 (2014).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Gu, X. W. & Greer, J. R. Ultra-strong architected Cu meso-lattices. Extreme Mech. Lett. 2, 7–14 (2015).

George, T., Deshpande, V. S. & Wadley, H. N. G. Mechanical response of carbon fiber composite sandwich panels with pyramidal truss cores. Composites A 47, 31–40 (2013).

Dong, L., Deshpande, V. & Wadley, H. Mechanical response of Ti–6Al–4V octet-truss lattice structures. Int. J. Solids Struct. 60, 107–124 (2015).

Weiner, S. & Wagner, H. D. The material bone: structure-mechanical function relations. Annu. Rev. Mater. Sci. 28, 271–298 (1998).

Yilmaz, E. D., Bechtle, S., Özcoban, H., Schreyer, A. & Schneider, G. A. Fracture behavior of hydroxyapatite nanofibers in dental enamel under micropillar compression. Scr. Mater. 68, 404–407 (2013).

Meyers, M. A., Lin, A. Y.-M., Chen, P.-Y. & Muyco, J. Mechanical strength of abalone nacre: role of the soft organic layer. J. Mech. Behav. Biomed. Mater. 1, 76–85 (2008).

Gao, H., Ji, B., Jaeger, I. L., Arzt, E. & Fratzl, P. Materials become insensitive to flaws at nanoscale: lesson from nature. Proc. Natl Acad. Sci. USA 100, 5597–5600 (2003).

Zhu, T., Li, J., Ogata, S. & Yip, S. Mechanics of ultra-strength materials. MRS Bull. 34, 167–172 (2009).

George, S. M. Atomic layer deposition: an overview. Chem. Rev. 110, 111–131 (2010).

Fischer, J. & Wegener, M. Three-dimensional direct laser writing inspired by stimulated-emission-depletion microscopy. Opt. Mater. Express 1, 614–624 (2011).

Bauer, J. et al. Push-to-pull tensile testing of ultra-strong nanoscale ceramic-polymer composites made by additive manufacturing. Extreme Mech. Lett. 3, 105–112 (2015).

Schueller, O. & Brittain, S. Fabrication and characterization of glassy carbon MEMS. Chem. Mater. 4756, 1399–1406 (1997).

Wang, C., Jia, G., Taherabadi, L. H. & Madou, M. J. A novel method for the fabrication of high-aspect ratio C-MEMS structures. J. Microelectromech. Syst. 14, 348–358 (2005).

Lim, Y., Heo, J., Madou, M. & Shin, H. Monolithic carbon structures including suspended single nanowires and nanomeshes as a sensor platform. Nanoscale Res. Lett. 8, 492 (2013).

Burckel, D. B. et al. Lithographically defined porous carbon electrodes. Small 5, 2792–2796 (2009).

Lee, J. H., Wang, L. F., Boyce, M. C. & Thomas, E. L. Periodic bicontinuous composites for high specific energy absorption. Nano Lett. 12, 4392–4396 (2012).

Cowlard, F. C. & Lewis, J. C. Vitreous carbon—a new form of carbon. J. Mater. Sci. 2, 507–512 (1967).

Harris, P. J. F. Fullerene-related structure of commercial glassy carbons. Phil. Mag. 84, 3159–3167 (2004).

Zhao, J. X., Bradt, R. C. & Walker, P. L. J. The fracture toughness of glassy carbons at elevated temperatures. Carbon N. Y. 23, 15–18 (1985).

Mcaleavey, A., Coles, G., Edwards, R. L. & Sharpe, W. N. Mechanical properties of SU-8. MRS Proc. 546, 213–218 (1998).

Jacobsen, A. J., Mahoney, S., Carter, W. B. & Nutt, S. Vitreous carbon micro-lattice structures. Carbon N. Y. 49, 1025–1032 (2011).

Shin, S. J., Kucheyev, S. O., Worsley, M. A. & Hamza, A. V. Mechanical deformation of carbon-nanotube-based aerogels. Carbon N. Y. 50, 5340–5342 (2012).

Deshpande, V. S. & Fleck, N. A. Collapse of truss core sandwich beams in 3-point bending. Int. J. Solids Struct. 38, 6275–6305 (2001).

Gibson, L. J. & Ashby, M. F. Cellular Solids: Structure and Properties Vol. 2, 2nd edn (Cambridge Univ. Press, 1999).

Wadley, H. N. G. Multifunctional periodic cellular metals. Phil. Trans. R. Soc. Lond. A 364, 31–68 (2005).

Berdova, M. et al. Mechanical assessment of suspended ALD thin films by bulge and shaft-loading techniques. Acta Mater. 66, 370–377 (2014).

Liu, A. ASM Handbook Volume 19, Fatigue And Fracture 980–1000 (ASM International, 1996).

Bullock, R. E. & Kaae, J. L. Size effect on the strength of glassy carbon. J. Mater. Sci. 14, 920–930 (1979).

Kawamura, K. & Jenkins, G. A new glassy carbon fibre. J. Mater. Sci. 5, 262–267 (1970).

Manoharan, M. P., Lee, H., Rajagopalan, R., Foley, H. C. & Haque, M. A. Elastic properties of 4–6 nm-thick glassy carbon thin films. Nanoscale Res. Lett. 5, 14–19 (2010).

Yakobson, B. I. & Avouris, P. Carbon Nanotubes: Synthesis, Structure, Properties, and Applications (eds Dresselhaus, M. S., Dresselhaus, G. & Avouris, P.) 287–327 (Springer, 2001).

Singh, A., Jayaram, J., Madou, M. & Akbar, S. Pyrolysis of negative photoresists to fabricate carbon structures for microelectromechanical systems and electrochemical applications. J. Electrochem. Soc. 149, 78–83 (2002).

Kim, H.-J., Joo, Y.-H., Lee, S.-M. & Kim, C. Characteristics of photoresist-derived carbon nanofibers for Li-ion full cell electrode. Trans. Electr. Electron. Mater. 15, 265–269 (2014).

Groner, M. D., Fabreguette, F. H., Elam, J. W. & George, S. M. Low-temperature Al2O3 atomic layer deposition. Chem. Mater. 16, 639–645 (2004).

Acknowledgements

The authors thank M. Madou for stimulating discussions introducing us to the concept of pyrolysis of resist structures. Financial support of this work by the Robert Bosch-Foundation is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

J.B. and O.K. designed the research; J.B. designed structures; J.B. and A.S. manufactured samples; J.B., performed ex situ measurements; J.B. and R.S. performed in situ measurements; J.B. performed analytical and finite element calculations; J.B., O.K. and R.S. analysed data; J.B. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1238 kb)

Supplementary Information

Supplementary Movie 1 (MP4 21145 kb)

Rights and permissions

About this article

Cite this article

Bauer, J., Schroer, A., Schwaiger, R. et al. Approaching theoretical strength in glassy carbon nanolattices. Nature Mater 15, 438–443 (2016). https://doi.org/10.1038/nmat4561

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4561

This article is cited by

-

Accurate additive manufacturing of lightweight and elastic carbons using plastic precursors

Nature Communications (2024)

-

Obtaining auxetic and isotropic metamaterials in counterintuitive design spaces: an automated optimization approach and experimental characterization

npj Computational Materials (2024)

-

Rapid inverse design of metamaterials based on prescribed mechanical behavior through machine learning

Nature Communications (2023)

-

Three dimensional architected thermoelectric devices with high toughness and power conversion efficiency

Nature Communications (2023)

-

Dynamic diagnosis of metamaterials through laser-induced vibrational signatures

Nature (2023)