Abstract

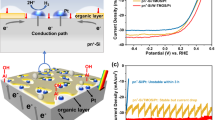

Metal oxide protection layers for photoanodes may enable the development of large-scale solar fuel and solar chemical synthesis, but the poor photovoltages often reported so far will severely limit their performance. Here we report a novel observation of photovoltage loss associated with a charge extraction barrier imposed by the protection layer, and, by eliminating it, achieve photovoltages as high as 630 mV, the maximum reported so far for water-splitting silicon photoanodes. The loss mechanism is systematically probed in metal–insulator–semiconductor Schottky junction cells compared to buried junction p+n cells, revealing the need to maintain a characteristic hole density at the semiconductor/insulator interface. A leaky-capacitor model related to the dielectric properties of the protective oxide explains this loss, achieving excellent agreement with the data. From these findings, we formulate design principles for simultaneous optimization of built-in field, interface quality, and hole extraction to maximize the photovoltage of oxide-protected water-splitting anodes.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Fujishima, A. & Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 238, 37–38 (1972).

Heller, A. Conversion of sunlight into electrical power and photoassisted electrolysis of water in photoelectrochemical cells. Acc. Chem. Res. 14, 154–162 (1981).

Bard, A. J. & Fox, M. A. Artificial photosynthesis: Solar splitting of water to hydrogen and oxygen. Acc. Chem. Res. 28, 141–145 (1995).

Turner, J. A. A realizable renewable energy future. Science 285, 687–689 (1999).

Grätzel, M. Photoelectrochemical cells. Nature 414, 338–344 (2001).

Lewis, N. S. Light work with water. Nature 414, 589–590 (2001).

Lewis, N. S. & Nocera, D. G. Powering the planet: Chemical challenges in solar energy utilization. Proc. Natl Acad. Sci. USA 103, 15729–15735 (2006).

Bassett, R. K. To the Digital Age: Research Labs, Startup Companies, and the Rise of MOS Technology (John Hopkins Univ. Press, 2007).

Chen, Y. W. et al. Atomic layer-deposited tunnel oxide stabilizes silicon photoanodes for water oxidation. Nature Mater. 10, 539–544 (2011).

Scheuermann, A. G., Prange, J. D., Gunji, M., Chidsey, C. E. D. & McIntyre, P. C. Effects of catalyst material and atomic layer deposited TiO2 oxide thickness on the water oxidation performance of metal–insulator–silicon anodes. Energy Environ. Sci. 6, 2487–2496 (2013).

Hu, S. et al. Amorphous TiO2 coatings stabilize Si, GaAs, and GaP photoanodes for efficient water oxidation. Science 344, 1005–1009 (2014).

Lichterman, M. F. et al. Stabilization of n-cadmium telluride photoanodes for water oxidation to O2(g) in aqueous alkaline electrolytes using amorphous TiO2 films formed by atomic-layer deposition. Energy Environ. Sci. 7, 3334–3337 (2014).

McDowell, M. T. et al. Improved stability of polycrystalline bismuth vanadate photoanodes by use of dual-layer thin TiO2/Ni coatings. J. Phys. Chem. C 118, 19618–19624 (2014).

Green, M. A. Limits on the open-circuit voltage and efficiency of silicon solar cells imposed by intrinsic Auger processes. IEEE Trans. Electron Devices ED-31, 671–678 (1984).

Green, M. A., Emery, K., Hishikawa, Y., Warta, W. & Dunlop, E. D. Solar cell efficiency tables (version 45). Prog. Photovolt. 23, 1–9 (2015).

Hu, S. et al. An analysis of the optimal band gaps of light absorbers in integrated tandem photoelectrochemical water-splitting systems. Energy Environ. Sci. 6, 2984–2993 (2013).

Kenney, M. J. et al. High-performance silicon photoanodes passivated with ultrathin nickel films for water oxidation. Science 342, 836–840 (2013).

Mei, B. et al. Protection of p+nSi photoanodes by sputter-deposited Ir/IrOx thin films. J. Phys. Chem. Lett. 5, 1948–1952 (2014).

Mei, B. et al. Iron-treated NiO as a highly transparent p-type protection layer for efficient Si-based photoanodes. J. Phys. Chem. Lett. 5, 3456–3461 (2014).

Green, M. A. & Godfrey, R. B. MIS solar cell—General theory and new experimental results for silicon. Appl. Phys. Lett. 29, 610–612 (1976).

Green, M. A. Effects of pinholes, oxide traps, and surface states on MIS solar cells. Appl. Phys. Lett. 33, 178–180 (1978).

Godfrey, R. B. & Green, M. A. 655 mV open-circuit voltage, 17.6% efficient silicon MIS solar cells. Appl. Phys. Lett. 34, 790–793 (1979).

Singh, R., Green, M. A. & Rajkanan, K. Review of conductor–insulator–semiconductor (CIS) solar cells. Solar Cells 3, 95–148 (1981).

Green, M. A. & Blakers, A. W. Advantages of metal–insulator–semiconductor structures for silicon solar cells. Solar Cells 8, 3–16 (1983).

Grauvogl, M. & Hezel, R. The truncated-pyramid MIS inversion-layer solar cell: A comprehensive analysis. Prog. Photovolt. Res. Appl. 6, 15–24 (1998).

McDowell, M. T. et al. The influence of structure and processing on the behavior of TiO2 protective layers for stabilization of n-Si/TiO2/Ni photoanodes for water oxidation. ACS Appl. Mater. Interfaces 7, 15189–15199 (2015).

Mei, B. et al. Crystalline TiO2: A generic and effective electron-conducting protection layer for photoanodes and -cathodes. J. Phys. Chem. C. 119, 15019–15027 (2015).

Levy, D., Ponpon, J. P., Grob, A., Grob, J. J. & Stuck, R. Rapid thermal annealing and titanium silicide formation. Appl. Phys. A 38, 23–29 (1985).

Mann, R. W., Clevenger, L. A., Agnello, P. D. & White, F. R. Silicides and local interconnections for high-performance VLSI applications. IBM J. Res. Dev. 39, 403–417 (1995).

Sekine, K., Saito, Y., Hirayama, M. & Ohmi, T. Silicon nitride film growth for advanced gate dielectric at low temperature employing high-density and low-energy ion bombardment. J. Vac. Sci. Technol. A 17, 3129–3133 (1999).

Sugawara, T. et al. Characterization of ultra thin oxynitride formed by radical nitridation with slot plane antenna plasma. Jpn. J. Appl. Phys. 44, 1232–1236 (2005).

Scheuermann, A. G., Lu, D. Q., Ito, T., Chidsey, C. E. D. & McIntyre, P. C. The effect of SPA-SiO2 tunnel oxide thickness for metal–insulator–silicon photoelectrochemical cells. ECS Trans. 64, 265–276 (2014).

Alamo, J. A. & Swanson, R. M. Modelling of minority-carrier transport in heavily doped silicon emitters. Solid-State Electron. 30, 1127–1136 (1987).

Tyagi, M. S. & Van Overstraeten, R. Minority carrier recombination in heavily-doped silicon. Solid-State Electron. 26, 577–597 (1983).

Chen, L. et al. p-type transparent conducting oxide/n-type semiconductor heterojunctions for efficient and stable solar water oxidation. J. Am. Chem. Soc. 137, 9595–9603 (2015).

Sze, S. M. Semiconductor Devices: Physics and Technology (John Wiley, 2008).

Swaminathan, S. & McIntyre, P. C. Titania/alumina bilayer gate dielectrics for Ge MOS devices: Frequency- and temperature-dependent electrical characteristics. Electrochem. Solid-State Lett. 13, G79–G82 (2010).

Bard, A. J., Bocarsly, A. B., Fan, F. R. F., Walton, E. G. & Wrighton, M. S. The concept of Fermi level pinning at semiconductor/liquid junctions. Consequences for energy conversion efficiency and selection of useful solution redox couples in solar devices. J. Am. Chem. Soc. 102, 3671–3677 (1980).

Scheuermann, A. G., Lawrence, J. P., Gunji, M., Chidsey, C. E. D. & McIntyre, P. C. ALD-TiO2 preparation and characterization for metal–insulator–silicon photoelectrochemical applications. ECS Trans. 58, 75–86 (2013).

Fuke, N. et al. Influence of TiO2/electrode interface on electron transport properties in back contact dye-sensitized solar cells. Solar Energy Mater. Solar Cells 93, 720–724 (2009).

Pattantyus-Abraham, A. G. et al. Depleted-heterojunction colloidal quantum dot solar cells. ACS Nano 4, 3374–3380 (2010).

Devore, J. R. Refractive index of rutile and sphalerite. J. Opt. Soc. Am. 41, 416–417 (1951).

Haynes, W. M., Bruno, T. J. & Lide, D. R. (eds) CRC Handbook of Chemistry and Physics 12–124 95th edn (CRC Press, 2014).

Acknowledgements

We thank T. Carver for metal e-beam evaporation and all the members of the RENEW collaboration—in addition to the authors: M. Pemble, A. Mills, I. Povey, J. Kegel, K. Cherkaoui, S. Monaghan and D. Hazafy–as well as A. Talin from Sandia for their insightful discussions. T. Burke is also acknowledged for insightful discussions on solar cell physics. A.G.S. would like to thank R. Long, E. Newton, P. F. Satterthwaite, D. Q. Lu and O. Hendricks from the McIntyre and Chidsey groups for their support and insights throughout this work. We also thank K. Tang, L. Zhang and M. Kitano for their help in building and maintaining the ALD chambers. This work was partially supported by the Stanford Global Climate and Energy Project and National Science Foundation programme CBET-1336844. A.G.S. graciously acknowledges financial support from a Stanford Graduate Fellowship and a National Science Foundation Graduate Fellowship. The authors from Tyndall National Institute acknowledge the financial support of Science Foundation (SFI) under the US-Ireland R&D Partnership Programme—Grant Number SFI/13/US/I2543. The Tyndall silicon fabrication facility is acknowledged for the p+n silicon junctions used in this study.

Author information

Authors and Affiliations

Contributions

A.G.S. and J.P.L. prepared all samples and performed all measurements for the initial TiO2 photovoltage series first observing the photovoltage loss. A.G.S. prepared all samples and performed all measurements for the SiO2 photovoltage series, capacitance voltage measurements, and buried junction p+nSi experiments. A.W. prepared all p+n buried junction substrates and performed all physical characterization of these junctions. K.W.K. performed Sentaurus modelling for light absorption in Type I and Type II cells, as well as simulating band diagrams. T.I. performed the SPA plasma oxidation for the experiments varying SiO2 thickness. A.G.S. and K.W.K. maintained the ALD chamber for TiO2 depositions and A.G.S. qualified and performed the runs. A.G.S., C.E.D.C. P.K.H. and P.C.M. designed the experiments and developed the solid-state capacitor model to explain the loss. All authors helped in the preparation of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 2087 kb)

Rights and permissions

About this article

Cite this article

Scheuermann, A., Lawrence, J., Kemp, K. et al. Design principles for maximizing photovoltage in metal-oxide-protected water-splitting photoanodes. Nature Mater 15, 99–105 (2016). https://doi.org/10.1038/nmat4451

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4451

This article is cited by

-

Construction of novel P-Si/TiO2/HfO2/MoS2/Pt heterophotocathode for enhanced photoelectrochemical water splitting

Nano Research (2023)

-

Review on light absorbing materials for unassisted photoelectrochemical water splitting and systematic classifications of device architectures

Discover Materials (2022)

-

Development of a photoelectrochemically self-improving Si/GaN photocathode for efficient and durable H2 production

Nature Materials (2021)

-

Reaction kinetics and interplay of two different surface states on hematite photoanodes for water oxidation

Nature Communications (2021)

-

Scalable, highly stable Si-based metal-insulator-semiconductor photoanodes for water oxidation fabricated using thin-film reactions and electrodeposition

Nature Communications (2021)