Abstract

Although stoichiometric transformations using transition metal–N2 complexes have been well investigated towards the goal of nitrogen fixation under mild reaction conditions, only a few examples of the catalytic transformations of N2 using transition metal–N2 complexes as catalysts have been reported. In almost all the catalytic systems, the use of Mo is essential to realize the catalytic transformation of N2, where Mo–N2 complexes are considered to work as effective catalysts. Here we show the first successful example of the Fe-catalysed transformation of N2 into N(SiMe3)3 under ambient conditions, in which iron complexes such as iron pentacarbonyl [Fe(CO)5] and ferrocenes have been found to work as effective catalysts. A plausible reaction pathway is proposed, where Fe(II)–N2 complex bearing two Me3Si groups as ancillary ligands has an important role as a key reactive intermediate, with the aid of density-functional-theory calculations.

Similar content being viewed by others

Introduction

Nitrogen fixation, the production of ammonia (NH3) from N2, is one of the most important processes for our continued survival as NH3 is widely used as an essential source of nitrogen fertilizer. However, N2 is regarded as one of the most inert molecules, which hardly undergoes chemical transformation under usual reaction conditions. Industrially, NH3 is produced from N2 and H2 using Fe-based heterogeneous catalysts under harsh reaction conditions, where enormous energy is also necessary for the production of H2 from fossil fuels such as natural gas1. Although the stoichiometric transformation using transition metal–N2 complexes has been well investigated towards the goal of nitrogen fixation under mild reaction conditions2,3,4, only a few examples of the catalytic transformation of N2 using transition metal–N2 complexes5,6 as catalysts have been reported7,8,9. In fact, only two types of Mo–N2 complexes bearing triamidoamine7 ligand and 2,6-bis(di-tert-butylphosphinomethyl)pyridine9 ligand, respectively, worked as effective catalysts to promote the direct conversion of N2 into NH3 under ambient reaction conditions.

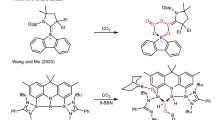

The method for the catalytic formation of N(SiMe3)3 (1) from N2 has been known as an alternative nitrogen fixation route because 1 is quantitatively converted to NH3 upon hydrolysis. The first example of the catalytic formation of 1 was reported for the reaction of N2 with Li as a reducing agent and Me3SiCl in the presence of various metal salts, such as CrCl3 as catalysts, where up to 5.4 equiv. of 1 was produced based on the catalyst10. In this reaction system, the possibility of the formation of lithium nitride (Li3N) as a reactive intermediate cannot be completely excluded (similarly, Mori11 also reported the transformation of N2 using Li as a reducing agent in the presence of Ti complexes). Later, the Mo-catalysed conversion of N2 into 1 using Na as a reducing agent was reported by Hidai and co-workers12, where up to 24 equiv. of 1 was produced based on the catalyst. More recently, we have found a more efficient catalytic system using a Mo–N2 complex bearing two ferrocenyldiphosphines as a key catalyst, where up to 226 equiv. of 1 was produced based on the catalyst, and have proposed a possible reaction pathway based on density-functional-theory (DFT) calculations13.

In almost all the catalytic systems mentioned above, the use of Mo in the catalyst is essential to realize the catalytic transformation of N2 under ambient conditions, where Mo–N2 complexes are considered to work as effective catalysts. As an extension of our study13,14,15, we now report the Fe-catalysed reduction of N2 into 1 under ambient conditions, where up to 34 equiv. of 1 was produced based on the catalyst. In this reaction system, simple and commercially available Fe complexes such as [Fe(CO)5] and ferrocenes have been found to work as effective catalysts. This is the first successful example of the Fe-catalysed conversion of N2 under ambient conditions. An Fe–N2 complex bearing two Me3Si ligands has been proposed to work as a key reactive intermediate following DFT calculations on the real reaction system.

Results

Iron-catalysed reaction of N2 into N(SiMe3)3

The catalytic reduction of N2 into 1 using [Fe(CO)5] (0.10 mmol) as a catalyst was investigated according to the following procedure. A mixture of Na (600 equiv. to the Fe atom in the catalyst), Me3SiCl (600 equiv. to the Fe atom in the catalyst) and [Fe(CO)5] in tetrahydrofuran (THF) (40 ml) was stirred at room temperature for 20 h under 1 atm of N2. After the reaction, 1 (25 equiv. to the Fe atom in the catalyst) was revealed to be formed together with other trimethylsilylated compounds such as hexamethyldisilane (2), butoxytrimethylsilane (3) and trimethyl(4-(trimethylsilyl)butoxy)silane (4) (see Supplementary Table S1). The scheme for the catalytic formation of 1 is shown in Fig. 1a, and typical results are summarized in Table 1. Separately, we confirmed that the produced 1 can be readily converted into NH3 quantitatively (25 equiv. to the Fe atom in the catalyst) after hydrolysis of the crude reaction mixture. The present method for the formation of 1 is considered to provide a direct approach to produce NH3 equivalent from N2 under ambient conditions.

The amount of 1 did not increase even for a longer reaction time such as 100 h. When the catalytic reaction was carried out at a higher reaction temperature, such as 60 °C for 20 h, the amount of 1 slightly decreased, where 16 equiv. amount of 1 were produced based on the Fe atom. In the reaction with Li as a reducing agent in place of Na, only a small amount of 1 was formed together with a large amount of 2. The use of other polar and non-polar solvents such as diethyl ether, 1,4-dioxane, 1,2-dimethoxyethane, benzene and hexane were not effective for the present catalytic reaction. Separately, we confirmed that no formation of 1 was observed in the absence of N2 (under argon atmosphere) or [Fe(CO)5]. These results indicate that [Fe(CO)5] in THF worked as an effective catalyst for the formation of 1 from N2.

When bis(trimethylsilyl)iron tetracarbonyl complex [Fe(SiMe3)2(CO)4] (ref. 16) was used in place of [Fe(CO)5], a slightly larger amount of 1 (29 equiv.) was produced under similar reaction conditions. Some other iron carbonyl complexes bearing a cyclopentadienyl moiety such as cyclopentadienyliron dicarbonyl dimer [CpFe(CO)2]2 (Cp=η5-C5H5) also worked as catalysts, where a slightly smaller amount of 1 was produced based on the Fe atom of the catalyst. Interestingly, a simple and historic iron complex, ferrocene [Cp2Fe], also worked as a catalyst towards the formation of 1 under similar reaction conditions, although slightly less effectively. Here the introduction of Me3Si moieties to the cyclopentadienyl ring of the ferrocene as electron-withdrawing groups to the aromatic rings substantially improved the catalytic activity. In fact, 1,1′,2,2′,4,4′-hexakis(trimethylsilyl)ferrocene [{η5-C5H2(SiMe3)3}2Fe] (ref. 17) worked as the most effective catalyst, where the largest amount of 1 (34 equiv.) was produced based on the Fe atom in the catalyst. In sharp contrast, the introduction of alkyl groups, such as methyl and butyl moieties, at the cyclopentadienyl ring of the ferrocene [(η5-C5H4R)2Fe] (R=Me, tBu) dramatically decreased the amount of 1. It is noteworthy that iron salts such as FeCl2 and [Fe{N(SiMe3)2}2] did not work as effective catalysts under the present reaction conditions.

Time profile of iron-catalysed reaction of N2 into N(SiMe3)3

In order to obtain more information on the reaction pathway, the relationship between the reaction time and the yields of 1 was investigated in the reaction of N2 (1 atm) with Na and Me3SiCl in the presence of a catalytic amount of [Fe(CO)5] in THF at room temperature. The time profile is shown in Fig. 1b. An induction period (ca. 1 h) was observed at first, probably because of the formation of an active Fe catalyst. Then, the formation of 1 proceeded until 20 h parallel to that of other trimethylsilylated compounds, such as 2, 3 and 4. No further formation of all products was observed after 20 h. These results indicate that 2, 3 and 4 were produced simultaneously together with 1.

Discussion

Next, we would like to discuss Fe species serving as catalysts in our reaction systems, although unfortunately, no Fe–N2 species have yet been isolated and identified from the reaction mixture. Our speculation will be logically supported by some experimental findings with the aid of quantum chemical calculations. First, we have investigated the catalytic reaction in the presence of a large excess amount of Hg as mercury-poison test18. However, no influence of Hg was observed at all. As a result, we removed the possibility that Fe nanoparticles generated in situ work as true active species in the present reaction system. This result apparently indicates that the catalytic active species is a homogeneous Fe complex. Second, the experimental result that both [Fe(CO)5] and ferrocenes have almost the same catalytic activity towards the formation of 1 suggests that common Fe complexes, generated in situ from Na, Me3SiCl and Fe species, work as real catalysts. Third, for the formation of 1 catalysed by a Mo–N2 complex, we have already proposed a reaction mechanism, where a Me3Si radical has an important role to promote the catalytic reduction of N2 (ref. 13). It should be stressed that [Fe(SiMe3)2(CO)4] (ref. 16) worked as one of the most effective catalysts towards the formation of 1. The reaction of [Na2Fe(CO)4], prepared from [Fe(CO)5] and Na, with Me3SiCl has been known to give [Fe(SiMe3)2(CO)4], whereas the reactions of ferrocene with reducing agents have recently been reported to give the corresponding low-valent Fe(0 or -II) complexes19,20, which may be easily converted into the Fe(II)(SiMe3)2 species by treatment with Me3SiCl and/or Me3Si radical. These results indicate that two Me3Si groups can readily be introduced to the Fe atom of the Fe complexes under the catalytic conditions.

For the reasons listed above, we propose [Fe(II)(SiMe3)2(THF)] (I) and [Fe(II)(SiMe3)2Cl]− (I′) as the common catalysts in our reaction systems. Optimized geometries of I and I′ are depicted in Fig. 2. In fact, their Fe(II) analogues, such as [Fe{Si(SiMe3)3}2(THF)]21 and [Fe{Si(SiMe3)3}2Cl]− (ref. 22), have been prepared and characterized spectroscopically. Recently, Fe–N2 complexes bearing two silyl ligands [(η6-arene) Fe(Me2SiC6H4SiMe2)]2(μ-η1:η1-N2) have been prepared and characterized by X-ray analysis23.

In order to examine the N2-activating ability of I and I′, we have performed DFT calculations on the corresponding N2 complexes [Fe(SiMe3)2(N2)(THF)] (II) and [Fe(SiMe3)2(N2)Cl]− (II′). Optimized geometries of II and II′ depicted in Fig. 2 adopt a slightly deformed tetrahedral structure. The Fe–N2 bond energy of II (12.1 kcal mol−1) is higher than that of II′ (7.7 kcal mol−1). The N–N bond distance (the N–N stretching frequency) is 1.126 Å (2,122 cm−1) for II and 1.131 Å (2,082 cm−1) for II′. The coordinated N2 on the Fe atom is moderately activated relative to free N2 (1.098 Å (2,422 cm−1)), although the calculated Fe–N2 bond energies suggest that II and II′ are hard to be isolated experimentally.

Based on the results of catalytic reaction and the calculations on the Fe–N2 complexes, we propose the reaction pathway for catalytic transformation of N2 into 1 as shown in Fig. 3. At first, a Fe(II)–N2 complex bearing two Me3Si groups, such as II, is formed via I, which generated in situ Na, Me3SiCl and Fe species (vide supra). A sequential addition of three Me3Si radicals to the distal N atom of the coordinated N2 ligand in II proceeds to form [Fe(IV)(SiMe3)2(THF)(NN(SiMe3)3)] (A). The N–N bond cleavage of the complex A occurs to afford the first molecule of 1 together with the formation of [Fe(II)(SiMe3)2(N(SiMe3)3)(THF)] (B) after the addition of further three Me3Si radicals. Finally, the complex B liberates the second molecule of 1 to regenerate the starting complex I. We have theoretically confirmed that this catalytic mechanism is reasonable by assuming I as the catalyst (see Supplementary Figs S2–S10 and Supplementary Tables S4–S34).

In summary, we have found some iron complexes such as iron pentacarbonyl [Fe(CO)5] and ferrocenes work as effective catalysts for the formation of tris(trimethylsilyl)amine (N(SiMe3)3), which is readily converted into NH3, from the reaction of molecular dinitrogen (N2) with Na as a reducing agent and trimethylsilyl chloride (Me3SiCl) under ambient conditions. In this reaction system, up to 34 equiv. of N(SiMe3)3 have been produced based on the Fe atom of the catalyst. This is the first successful example of the Fe-catalysed transformation of N2 into N(SiMe3)3 under ambient conditions. Two possible Fe(II)-N2 complexes bearing two Me3Si groups as ancillary ligands have been proposed as a key reactive intermediate in the catalytic cycle. Recently, the preparation of Fe–N2 complexes and their stoichiometric reactivity have been intensively studied24,25,26,27, but the Fe-catalysed transformation of N2 by using Fe–N2 complexes has not yet been reported until now28. We believe that the results described here provide valuable and useful information to develop the Fe-catalysed transformation of N2. Further work is currently under way to develop more effective Fe catalysts and the isolation and characterization of reactive intermediates in the catalytic reaction.

Methods

A typical procedure for catalytic reduction of N2 into N(SiMe3)3

To a suspension of sodium (1.38 g, 60 mmol) in THF (40 ml) were added Me3SiCl (7.6 ml, 60 mmol) and Fe(CO)5 (13.2 μl, 0.10 mmol) under dinitrogen atmosphere. The mixture was stirred at room temperature (22–24 °C) for 20 h under a gentle stream of dinitrogen. To the reaction mixture was added cyclododecane (0.100 g) as an internal standard for gas–liquid chromatography (GLC) analysis. After stirring for 5 min, the mixture was centrifuged to remove insoluble materials. The resultant clear supernatant was subjected to GLC and capillary gas chromatography mass spectrometry analyses. Then the supernatant was stirred with an aqueous solution of H2SO4 (0.5 M, 10 ml) for 12 h. After the addition of an aqueous solution of KOH (30 wt %, 10 ml), NH3 was distilled into an aqueous solution of H2SO4 (0.5 M, 10 ml) under reduced pressure. The amount of NH3 was determined by the indophenol method. Separately, we confirmed that the following Fe complexes such as [(η5-C5H4R)2Fe] (R=Me, tBu), FeCl2 and [Fe{N(SiMe3)2}2] did not work as effective catalysts under the same reaction conditions. See Supplementary Tables S1 and S2.

Time profile of catalytic formation of N(SiMe3)3 from N2

To a suspension of sodium (1.38 g, 60 mmol) in THF (40 ml) were added Me3SiCl (7.6 ml, 60 mmol), Fe(CO)5 (13.2 μl, 0.10 mmol) and cyclododecane (0.102 g) under dinitrogen atmosphere. The mixture was stirred at room temperature under a gentle stream of dinitrogen. An aliquot of the reaction mixture was periodically analysed by GLC. See Supplementary Table S3.

Computational methods

DFT calculations were performed to search all intermediates and transition structures on potential energy surfaces by using the Gaussian 09 program29. Because the relative energy of different spin states was found to be of great importance in the present monoiron system, we adopted the B3LYP* functional,30,31,32 which is a reparametrised version of the B3LYP hybrid functional33,34 developed by Reiher et al.30,31 The B3LYP functional is known to be reliable when applied for molecular and enzymatic systems containing transition metals, but it tends to overestimate the spin-state splitting35,36,37,38. Advantages of the B3LYP* functional in the evaluation of the spin-state splitting have been reported for several iron complexes exhibiting spin-crossover phenomena30,31,32,39. The B3LYP and B3LYP* energy expression is shown in equation (1):

where a0=0.20 (B3LYP) or 0.15 (B3LYP*), ax=0.72, ac=0.81; and in which EXHF is the Hartree–Fock exchange energy; EXLSDA is the local exchange energy from the local spin density approximation; EXB88 is Becke’s gradient correction40 to the exchange functional; ECLYP is the correlation functional developed by Lee et al.41; and ECVMN is the correlation energy calculated using the local correlation functional of Vosko et al.42 The 6-311+G** basis set was employed for all atoms throughout the present work.

Systematic vibrational analyses were carried out for all reaction species to characterize stationary-point structures. An appropriate connection between a reactant and a product for each reaction step was confirmed by intrinsic reaction coordinate (IRC)43,44,45 and quasi-IRC calculations. In the quasi-IRC calculation, the geometry of a transition state was at first shifted by perturbing the geometries very slightly along the reaction coordinate and released for equilibrium optimization. The energy profile of the proposed catalytic cycle in Supplementary Fig. S2 is presented using the SCF energies with the zero-point energy correction. In the present reaction system, Me3Si radical is a possible active silyl species. The formation of Me3Si radical in the presence of sodium in THF (solvent) is theoretically deduced in elsewhere.13

Additional information

How to cite this article: Yuki, M. et al. Iron-catalysed transformation of molecular dinitrogen into silylamine under ambient conditions. Nat. Commun. 3:1254 doi: 10.1038/ncomms2264 (2012).

References

Ribbe M. W. (ed.) Nitrogen Fixation Humana Press (2011).

Chatt J., Pearman A. J. & Richards R. L. The reduction of mono-coordinated molecular nitrogen to ammonia in a protic environment. Nature 253, 39–40 (1975).

Takahashi T., Mizobe Y., Sato M., Uchida Y. & Hidai M. Protonation reactions of molybdenum and tungsten dinitrogen complexes with halogen acids. Hydride hydrazido(2-) and diazenido complexes as intermediate stages of reduction. J. Am. Chem. Soc. 102, 7461–7467 (1980).

Hidai M. & Mizobe, Y. Research inspired by the chemistry of nitrogenase-Novel metal complexes and their reactivity toward dinitrogen, nitriles, and alkynes. Can. J. Chem. 83, 358–374 (2005).

MacKay B. A. & Fryzuk M. D. Dinitrogen coordination chemistry: on the biomimetic borderlands. Chem. Rev. 104, 385–401 (2004).

Shibata Y., Seino H., Mizobe Y. & Hidai M. Ammonia synthesis-homogeneous. Encyclopedia of Catalysis (Wiley VCH, 2010) doi: 10.1002/0471227617.eoc016.pub2.

Yandulov D. V. & Schrock R. R. Catalytic reduction of dinitrogen to ammonia at a single molybdenum center. Science 301, 76–78 (2003).

Shilov A. E. Catalytic reduction of molecular nitrogen in solutions. Russ. Chem. Bull. 52, 2555–2562 (2003).

Arashiba K., Miyake Y. & Nishibayashi Y. A molybdenum complex bearing PNP-type pincer ligands leads to the catalytic reduction of dinitrogen into ammonia. Nat. Chem. 3, 120–125 (2011).

Shiina K. Reductive silylation of molecular nitrogen via fixation to tris(trialkylsilyl)amine. J. Am. Chem. Soc. 94, 9266–9267 (1972).

Mori M. Activation of nitrogen for organic synthesis. J. Organomet. Chem. 689, 4210–4227 (2004).

Komori K., Oshita H., Mizobe Y. & Hidai M. Catalytic conversion of molecular nitrogen into silylamines using molybdenum and tungsten dinitrogen complexes. J. Am. Chem. Soc. 111, 1939–1940 (1989).

Tanaka H. et al. Molybdenum-catalyzed transformation of molecular dinitrogen into silylamine: experimental and DFT study on the remarkable role of ferrocenyldiphosphine ligands. J. Am. Chem. Soc. 133, 3498–3506 (2011).

Nishibayashi Y. Molybdenum-catalyzed reduction of molecular dinitrogen under mild reaction conditions. Dalton Trans. 41, 7447–7453 (2012).

Tanaka H. et al. DFT study on chemical N2 fixation by using a cubane-type RuIr3S4 cluster: energy profile for binding and reduction of N2 to ammonia via Ru-N-NHx (x=1-3) intermediates with unique structures. J. Am. Chem. Soc. 130, 9037–9047 (2008).

Blakeney A. J., Johnson D. L., Donovan P. W. & Gladysz J. A. Synthesis of iron carbonyl trimethylsilanes: preparations and interconversions of cis-(CO)4Fe[Si(CH3)3]2, M+[(CO)4FeSi(CH3)3]−, and trans-[-Fe(CO)4Si(CH3)3]2 . Inorg. Chem. 20, 4415–4419 (1981).

Okuda J. & Herdtweck E. Complexes with sterically demanding ligands II. synthesis and structure of 1,1′,2,2′,4,4′- hexakis(trimethylsilyl)ferrocene. Chem. Ber. 121, 1899–1905 (1988).

Widegren J. A. & Finke R. G. A review of the problem of distinguishing true homogeneous catalysis from soluble or other metal-particle heterogeneous catalysis under reducing conditions. J. Mol. Cat. A: Chemical 198, 317–341 (2003).

Fürstner A. et al. A cheap metal for a ‘noble’ task: preparative and mechanistic aspects of cycloisomerization and cycloaddition reactions catalyzed by low-valent iron complexes. J. Am. Chem. Soc. 130, 1992–2004 (2008).

Fürstner A. et al. Preparation, structure, and reactivity of nonstabilized organoiron compounds. implications for iron-catalyzed cross coupling reactions. J. Am. Chem. Soc. 130, 8773–8787 (2008).

Heyn R. H. & Tilley T. D. Coordinatively and electronically unsaturated tris(trimethylsilyl)silyl complexes of manganese and iron. Inorg. Chim. Acta 341, 91–98 (2002).

Roddick D. M., Tilley T. D., Rheingold A. L. & Geib S. J. Coordinatively unsaturated tris(trimethylsilyl)silyl complexes of chromium, manganese, and iron. J. Am. Chem. Soc. 109, 945–946 (1987).

Sunada Y., Imaoka T. & Nagashima H. Half-sandwich (η6-arene)iron(II) dinitrogen complexes bearing a disilaferracycle skeleton as a precursor for double silylation of ethylene and alkynes. Organometallics 29, 6157–6160 (2010).

Hazari N. Homogeneous iron complexes for the conversion of dinitrogen into ammonia and hydrazine. Chem. Soc. Rev. 39, 4044–4056 (2010).

Crossland J. L. & Tyler D. R. Iron-dinitrogen coordination chemistry: dinitrogen activation and reactivity. Coord. Chem. Rev. 254, 1883–1894 (2010).

Lee Y., Mankad N. P. & Peters J. C. Triggering N2 uptake via redox-induced expulsion of coordinated NH3 and N2 silylation at trigonal bipyramidal iron. Nat. Chem. 2, 558–565 (2010).

Rodriguez M. M., Bill E., Brennessel W. W. & Holland P. L. N2 reduction and hydrogenation to ammonia by a molecular iron-potassium complex. Science 334, 780–783 (2011).

Nishibayashi Y. Nitrogen fixation: nitrido complexes step up. Nat. Chem. 3, 502–504 (2011).

Frisch M. J. et al. Gaussian 09, Revision B.01 Gaussian, Inc. (2010).

Reiher M., Salomon O. & Hess B. A. Reparametrization of hybrid functionals based on energy differences of states of different multiplicity. Theor. Chem. Acc. 107, 48–55 (2001).

Reiher M. Theoretical study of the [Fe(phen)2(NCS)2] spin-crossover complex with reparametrized density functionals. Inorg. Chem. 41, 6928–6935 (2002).

Scherlis D. A. & Estrin D. A. Structure and spin-state energetics of an iron porphyrin model: an assessment of theoretical methods. Int. J. Quantum Chem. 87, 158–166 (2002).

Becke A. D. Density-functional thermochemistry. III. The role of exact exchange. J. Chem. Phys. 98, 5648–5652 (1993).

Stephens P. J., Devlin F. J., Chabalowski C. F. & Frisch M. J. Ab initio calculation of vibrational absorption and circular dichroism spectra using density functional force fields. J. Phys. Chem. 98, 11623–11627 (1994).

Fouqueau A. et al. Comparison of density functionals for energy and structural differences between the high- [5T2g: (t2g)4(e g)2] and low- [1A1g: (t2g)6(e g)0] spin states of the hexaquoferrous cation [Fe(H2O)6]2+. J. Chem. Phys. 120, 9473–9486 (2004).

Fouqueau A., Casida M. E., Lawson Daku L. M., Hauser A. & Neese F. Comparison of density functionals for energy and structural differences between the high- [5T2g: (t2g)4(e g)2] and low- [1A1g: (t2g)6(e g)0] spin states of iron(II) coordination compounds. II. More functionals and the hexaminoferrous cation [Fe(NH3)6]2+. J. Chem. Phys. 122, 0441101–13 (2005).

Lawson Daku L. M., Vargas A., Hauser A., Fouqueau A. & Casida M. E. Assessment of density functinals for the high-spin/low-spin energy difference in the low-spin iron(II) tris(2,2′-bipyridine) complex. Chem. Phys. Chem. 6, 1393–1410 (2005).

Simaan A. J. et al. Electric, vibrational, and structural properties of a spin-crossover catecholato-iron system in the solid state: Theoretical study of the electronic nature of the doublet and sextet states. Chem. Eur. J. 11, 1779–1793 (2005).

Shiota Y., Sato D., Juhász G. & Yoshizawa K. Theoretical study of thermal spin transition between the singlet state and the quintet state in the [Fe(2-picolylamine)3]2+ spin crossover system. J. Phys. Chem. A 114, 5862–5869 (2010).

Becke A. D. Density-functional exchange-energy approximation with correct asymptotic behavior. Phys. Rev. A 38, 3098–3100 (1988).

Lee C., Yang W. & Parr R. G. Development of the Colle-Salvetti correlation-energy formula into a functional of the electron density. Phys. Rev. B 37, 785–789 (1988).

Vosko S. H., Wilk L. & Nusair M. Accurate spin-dependent electron liquid correlation energies for local spin density calculations: A critical analysis. Can. J. Phys. 58, 1200–1211 (1980).

Fukui K. Formulation of the reaction coordinate. J. Phys. Chem. 74, 4161–4163 (1970).

Fukui K. The path of chemical reactions—the IRC approach. Acc. Chem. Res. 14, 363–368 (1981).

Gonzalez C. & Schlegel H. B. Reaction path following in mass-weighted internal coordinates. J. Phys. Chem. 94, 5523–5527 (1990).

Acknowledgements

K.Y. was supported by Grants-in-Aid (Nos. 22245028 and 24109014) for Scientific Research from Japan Society for the Promotion of Science (JSPS) and the Ministry of Education, Culture, Sports, Science and Technology of Japan (MEXT), the Nanotechnology Support Project of MEXT, the MEXT Project of Integrated Research on Chemical Synthesis, and the Kyushu University Global COE Project for their support of this work. Y.N. was supported by the Funding Program for Next Generation World-Leading Researchers (GR025), and received financial support from Toyota Motor Corporation. We thank the Research Hub for Advanced Nano Characterization at The University of Tokyo.

Author information

Authors and Affiliations

Contributions

K.Y. and Y.N. directed and conceived this project. M.Y. and K.S. conducted the experimental work. H.T. conducted the computational work. All authors discussed the results and wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures S1-S10, Supplementary Tables S1-S34, Supplementary Methods and Supplementary References (PDF 2120 kb)

Rights and permissions

About this article

Cite this article

Yuki, M., Tanaka, H., Sasaki, K. et al. Iron-catalysed transformation of molecular dinitrogen into silylamine under ambient conditions. Nat Commun 3, 1254 (2012). https://doi.org/10.1038/ncomms2264

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms2264

This article is cited by

-

Nitrogen reduction by the Fe sites of synthetic [Mo3S4Fe] cubes

Nature (2022)

-

Coupling dinitrogen and hydrocarbons through aryl migration

Nature (2020)

-

Catalysts for nitrogen reduction to ammonia

Nature Catalysis (2018)

-

Examining the relationship between coordination mode and reactivity of dinitrogen

Nature Reviews Chemistry (2017)

-

Catalytic transformation of dinitrogen into ammonia and hydrazine by iron-dinitrogen complexes bearing pincer ligand

Nature Communications (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.