Abstract

Radical involved transformations are now considered as extremely important processes in modern organic synthetic chemistry. According to the demand by atom-economic and sustainable chemistry, direct C(sp3)–H functionalization through radical oxidative coupling represents an appealing strategy for C–C bond formations. However, the selectivity control of reactive radical intermediates is still a great challenge in these transformations. Here we show a selective radical oxidative C(sp3)–H/C(sp)–H cross-coupling of unactivated alkanes with terminal alkynes by using a combined Cu/Ni/Ag catalytic system. It provides a new way to access substituted alkynes from readily available materials. Preliminary mechanistic studies suggest that this reaction proceeds through a radical process and the C(sp3)–H bond cleavage is the rate-limiting step. This study may have significant implications for controlling selective C–C bond formation of reactive radical intermediates by using multimetallic catalytic systems.

Similar content being viewed by others

Introduction

Substituted alkynes are fundamental structural motifs in numerous natural products, bioactive molecules and functional materials1,2,3. They also serve as versatile intermediates in many chemical transformations. Continuous efforts have been devoted to their synthesis throughout the history of organic chemistry. During the last decades, the transition-metal-catalysed Sonogashira coupling has been proven to be one of the most popular and efficient approach for the synthesis of substituted alkynes4. While early studies focused on C(sp2)–C(sp) coupling of terminal alkynes with vinyl/aryl electrophiles, recent attention has been paid to the C(sp3)–C(sp) coupling of terminal alkynes with unactivated alkyl halides. In 2003, Eckhardt and Fu5 pioneered the cross-coupling of terminal alkynes with unactivated primary bromides and iodides by using Pd/Cu synergistic catalysis with N–heterocyclic carbene ligands. Later on, this reaction protocol was extended to unactivated secondary bromides and iodides by Altenhoff et al.6. In 2009, Vechorkin et al.7 applied a combined Ni/Cu catalytic system to achieve the coupling of terminal alkynes with unactivated primary halides. Similarly, a modified Ni/Cu co-catalysed system was developed by Yi et al.8 to deal with the coupling with secondary bromides and iodides. More recently, Chen et al.9 developed a photo–promoted, transition-metal-free protocol to couple terminal alkynes with all types of unactivated alkyl iodides. As an alternative process for achieving the direct alkynylation of terminal alkynes, our group demonstrated a Pd-catalysed oxidative cross-coupling between terminal alkynes and alkylzinc reagents for the synthesis of substituted alkynes. Echoing the pursuit of atom-economic and sustainable chemistry, direct utilization of unactivated alkanes to replace unactivated alkyl halides and alkylzinc reagents in the synthesis of substituted alkynes has great significance in terms of both concept innovation and practical application.

Direct C(sp3)–H functionalization is a highly attractive approach for converting alkanes into functionalized organic compounds. However, the development of direct and selective methods for alkane functionalization is still in its infancy due to the low reactivity of C(sp3)–H bonds10,11,12,13,14,15. With the rapid development of C–H functionalization, direct C–H alkynylation with terminal alkynes has recently emerged as one of the most attractive approaches to access substituted alkynes16,17,18,19,20,21,22,23,24,25,26. This transformation has been considered to be challenging because of the facile homo-coupling and polymerization of terminal alkynes under oxidative conditions. Methods for the oxidative C(sp3)–H alkynylation of tertiary amines27,28,29,30 or benzylic ethers31,32 have been developed through normal cross-dehydrogenative coupling33 pathway (Fig. 1a), but direct oxidative C(sp3)–H alkynylation of unactivated alkanes with terminal alkynes to form substituted alkynes is still a great challenge and remains undeveloped.

Herein, we report a Cu/Ni/Ag co-catalysed oxidative C(sp3)–H alkynylation of unactivated alkanes with terminal alkynes. This protocol provides a new approach for the synthesis of substituted alkynes from readily available materials. Various alkanes and terminal alkynes are suitable in this transformation, affording the C(sp3)–C(sp) coupling product in good to high yields.

Results

Designing strategy

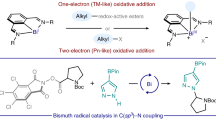

Radicals have been widely utilized in a large range of processes such as organic synthesis, biological processes and polymerization34,35,36,37. Generally, radicals with a single electron have a strong tendency to form chemical bonds. However, selective bond formation from radical intermediates was less developed compared with the ionic intermediates. Recent achievements showed that radical cross-coupling can provide a new opportunity for the formation of C–C bonds38,39,40. Considering that unactivated alkanes can be converted into corresponding alkyl radicals in the presence of oxidants, we envisioned that a radical oxidative cross-coupling pathway might provide a solution for the C(sp3)–H/C(sp)–H cross-coupling between unactivated alkanes and terminal alkynes (Fig. 1b). Nevertheless, the direct coupling of an alkyl radical with terminal alkynes usually ends up with reductive addition or difunctionalization to afford internal alkenes41,42,43,44. It was difficult to control the selectivity toward direct alkynylation rather than simple addition to alkyne. To deal with this challenging transformation, we wish to report a selective radical oxidative C(sp3)–H/C(sp)–H cross-coupling of unactivated alkanes with terminal alkynes by using a multimetallic catalysis45 system (Fig. 1b).

Optimization of reaction conditions

We started our research by examining the model reaction between cyclohexane (1a) and p-tolylacetylene (2a) under various conditions. After considerable efforts, we found that the combination of Cu(OTf)2, Ni(acac)2 and AgOAc as catalysts, 1,4–bis(diphenylphosphino)butane (dppb) as ligand, and di-tert-butyl peroxide (DTBP) as oxidant in chlorobenzene at 130 °C gave the best result (see Supplementary Tables 1–5 for detailed condition optimization). A 75% GC yield could be obtained within 3 h (Table 1, entry 1). The effect of each reaction parameter was examined and listed in Table 1. Both copper and nickel catalysts were crucial for this C(sp3)–C(sp) coupling reaction. Only 6% yield of the desired product was obtained in the absence of Ni(acac)2 (Table 1, entry 2). No desired products could be observed in the absence of Cu(OTf)2 (Table 1, entry 3). Instead, direct addition product 4a was obtained in 13% yield (Fig. 2a). Moreover, CuOTf failed to furnish the coupling product (Table 1, entry 4). Ligand was not indispensable for this oxidative cross-coupling reaction. A moderate yield could be obtained in the absence of ligand (Table 1, entry 5). Addition of bipyridine did not improve the reaction yield (Table 1, entry 6). PPh3 was less effective than dppb in this transformation (Table 1, entry 7). Control experiments regarding the role of silver were also performed (Table 1, entries 8–9). In the absence of AgOAc, a good but slightly decreased yield could still be obtained (Table 1, entry 8). When CsOAc was used instead of AgOAc, the reaction resulted in a poor yield (Table 1, entry 9). Silver likely plays a role in the C(sp)–H activation step since it could coordinate with the alkynyl group46,47,48. Solvent effects were also investigated in this transformation. Without additional solvent, the reaction yield decreased significantly (Table 1, entry 10). Benzene gave a similar result with chlorobenzene (Table 1, entry 11). Different oxidants were also applied in this transformation. Dicumyl peroxide could furnish the desired product in a lower yield (Table 1, entry 12). Benzoyl peroxide was not suitable in this transformation (Table 1, entry 13). In addition, the influence of temperature was also explored. Both decreased and increased temperatures gave decreased yields (Table 1, entries 14–15). It is worthy of note that oligomerization of 2a was the major side reaction pathway in all the above conditions.

Scope of unactivated alkanes

To further demonstrate the applicability of this transformation, the reaction system was applied to other unactivated alkanes for the synthesis of substituted alkynes (Fig. 3). Both cyclohexane and methylcyclohexane showed a good reaction efficiency toward alkynylation (3aa and 3ba). Other cycloalkanes were applied as substrates in this transformation. The ring size had evident effect on the yield of the corresponding alkynylation products. For example, cyclopentane and cycloheptane did furnish the desired products but with decreased reaction efficiency (3ca and 3da). Unactivated acyclic alkanes including linear alkanes and branched alkanes were tested in this oxidative C(sp3)–H alkynylation reaction. The reaction of 2a with linear alkanes including n-pentane, n-hexane and n-heptane proceeded smoothly but afforded a mixture of regioisomers (3ea–3ga). The reaction result of a branched alkane was also presented. Neohexane was also able to couple with 2a and afforded the desired product as two regioisomers (3ha). Oxidative C(sp3)–H alkynylation of norbornane proceeded with single-site selectivity and gave 3ia in 49% yield. Despite simple alkanes, toluene derivatives were also suitable in this transformation. Direct oxidative benzylic C(sp3)–H alkynylation of toluene derivatives could be obtained in good yields under similar conditions (3ja–3la). Since tert-butoxyl radical can undergo β–Me scission to generate a methyl radical49,50,51,52, direct methylation of terminal alkyne was observed as a competing side reaction in the above cases. Importantly, efficient methylation of terminal alkyne could be achieved in the absence of alkane substrates (Fig. 2b).

Reaction conditions A: 1 (4.0 ml), 2a (0.50 mmol), Cu(OTf)2 (7.5 mol%), Ni(acac)2 (7.5 mol%), AgOAc (10 mol%), dppb (7.5 mol%) and DTBP (2.0 mmol), PhCl (3.0 ml), 130 °C, 3 h. The ratio of regioisomers shown in parentheses was determined by GC–MS. Reaction conditions B: 1 (7.0 ml), 2a (0.50 mmol), Cu(OTf)2 (10 mol%), Ni(acac)2 (10 mol%), AgOAc (5 mol%), dppb (10 mol%) and DTBP (0.75 mmol), 130 °C, 3 h. †DTBP (1.5 mmol) was used. ‡Yields of all regioisomers.

Scope of terminal alkynes

Different terminal alkynes were applied as substrates to react with cyclohexane (Fig. 4). The reactions of simple phenylacetylene, meta- and ortho-methyl substituted phenylacetylene all proceeded well and afforded the corresponding aliphatic internal alkynes in good yields (3ab and 3ad). 4–Ethynyl–1,1′–biphenyl also gave the desired products in good yields (3ae). To our delight, electron-rich phenylacetylenes were more reactive, furnishing the desired products in higher yields (3af and 3ag). At the same time, strongly electron-deficient phenylacetylenes were also suitable but with slightly decreased efficiency in this reaction system (3ah and 3ai). It is noteworthy that silver had evident effect on the reaction yield of electron-deficient phenylacetylenes. For example, the yield of 3ah decreased markedly (14%) in the absence of AgOAc. Notably, halide substituents such as F, Cl and Br were all tolerated in this transformation, which provides the possibility for further functionalization (3aj–3am). Other aromatic alkynes were also applied in this transformation. 2-ethynylnaphthalene and 2-ethynylthiophene both furnished the desired products in good yields (3an and 3ao). Delightfully, aliphatic alkyne such as 1-heptyne and cyclohexylacetylene were also suitable in the oxidative C(sp3)–H/C(sp) cross-coupling and afforded the desired product in good to excellent yields (3ap and 3aq). Late-stage modification of a bioactive molecule is highly important for medical chemistry studies. Delightfully, 3-ethynylestrone containing carbonyl group and four continuous chiral centres furnished the desired coupling product in 70% yield under the standard conditions (3ar).

Discussion

Since the method had been established, we then tried to gain some insights into the catalytic pathway. To confirm the existence of radical intermediates, a radical trapping experiment was carried out by using 1 equiv of (2, 2, 6, 6–tetramethylpiperidin–1–yl)oxy (TEMPO). No cross-coupling product 3aa was obtained in this reaction (Fig. 5). Instead, the GC–MS and 1H NMR analysis of the reaction mixture showed the existence of cyclohexyl radical trapped by TEMPO (Supplementary Figs 66,67).

Next, kinetic isotopic effect studies with separate kinetic experiments were performed to gain insights into the rate-determining step for this C–H/C–H cross-coupling reaction. Both the C(sp3)–H bond cleavage of 1a and the C(sp)–H bond cleavage of 2a were studied. A primary kinetic isotopic effect was observed for C(sp3)–H bond cleavage (Fig. 6a, kH/kD=2.2) while no obvious kinetic isotopic effect was observed for the C(sp)–H cleavage (Fig. 6b, kH/kD=0.9), suggesting that C(sp3)–H bond cleavage was probably the rate-determining step in this transformation (for details, see Supplementary Fig. 68)53.

In the next step, the reactions with alkynyl metal species were performed to get some insights into the radical cross-coupling step. (Phenylethynyl)copper (2d–[Cu]) and (phenylethynyl)silver (2d–[Ag]) were prepared and used as substrates to react with 1a under the standard conditions (Fig. 7). However, neither of them could furnish the cross-coupling product. Thus, both alkynyl Cu(I) complex and alkynyl Ag(I) complex are not likely to be involved in the C(sp3)–C(sp) cross-coupling process. An alkynyl Cu(II) complex is more possibly to be generated in this transformation.

On the basis of the experimental results and previous reports50,51, a plausible reaction mechanism is presented in Fig. 8. Copper and silver work synergistically in the C(sp)–H activation of terminal alkyne, which leads to the formation of an alkynyl Cu(II) complex. The alkynyl copper complex is then transmetaled with Ni(II) species to generate an alkynyl Ni(II) complex. At the same time, an alkyl radical can be generated through hydrogen abstraction by in situ generated tert-butoxyl radical. This radical then reacts with the Ni(II) alkynyl complex54,55,56,57,58,59. The C(sp3)–C(sp) bond can be formed either through radical homolytic substitution or reductive elimination (see Supplementary Fig. 69 for details). Finally, the released Ni(I) species can be oxidized to Ni(II) species by DTBP to complete the nickel catalytic cycle.

In conclusion, we have developed a combined Cu/Ni/Ag catalytic system to achieve the challenging oxidative C(sp3)–H/C(sp)–H cross-coupling of unactivated alkanes with terminal alkynes. The utilization of multimetallic catalysis was the key for controlling the reaction selectivity toward C(sp3)–C(sp) bond formation. Various substituted alkynes were synthesized in good to high yields with a good functional group tolerance. Preliminary mechanistic studies suggest that the reaction proceeds through a transition-metal-catalysed radical reaction pathway and that the C(sp3)–H bond cleavage of unactivated alkanes is the rate-limiting step. This work not only provides an environmentally friendly approach to access alkyne compounds, but also contributes new knowledge to radical cross-coupling chemistry. The application of the radical alkynylation strategy in the synthesis of other substituted alkynes is underway in our laboratory.

Methods

General procedure (3aa)

In an oven-dried Teflon septum screw-capped tube equipped with a stir bar, Cu(OTf)2 (13.6 mg, 0.038 mmol), Ni(acac)2 (9.6 mg, 0.038 mmol), dppb (16.0 mg, 0.038 mmol) and AgOAc (8.3 mg, 0.050 mmol) were combined and sealed. The tube was then charged with nitrogen. Then cyclohexane (4.0 ml) and PhCl (3.0 ml) were injected into the tube by syringe. After stirring for 5 min, DTBP (135 mg, 1.5 mmol) and p-tolylacetylene (58.0 mg, 0.50 mmol) were subsequently injected into the reaction tube. The reaction was then heated to 130 °C. After stirring for 3 h, the reaction was cooled down to room temperature and quenched with saturated Na2S2O3 solution. After extraction with ethyl acetate (3 × 10 ml), the organic layers were combined and dried over anhydrous Na2SO4, the pure product was obtained by flash column chromatography on silica gel (petroleum:ethyl ether=10:1). Colourless oil was obtained in 73% isolated yield. 1H NMR (400 MHz, CDCl3) δ 7.28 (d, J=8.1 Hz, 2H), 7.06 (d, J=7.9 Hz, 2H), 2.56 (tt, J=9.0, 3.6 Hz, 1H), 2.31 (s, 3H), 1.92–1.82 (m, 2H), 1.80–1.69 (m, 2H), 1.59–1.46 (m, 3H), 1.40–1.28 (m, 3H). 13C NMR (101 MHz, CDCl3) δ 137.26, 131.38, 128.84, 120.99, 93.58, 80.47, 32.75, 29.65, 25.92, 24.90, 21.34. For 1H NMR, 13C NMR, 19F NMR and GC–MS (if applicable) spectra of compounds 3aa-3la, 3ab–3ar, 6 see Supplementary Figs 1–66. For the general information of the analytical methods and the mechanistic studies, please see Supplementary Methods.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information files.

Additional information

How to cite this article: Tang, S. et al. Multimetallic catalysed radical oxidative C(sp3)–H/C(sp)–H cross-coupling between unactivated alkanes and terminal alkynes. Nat. Commun. 7:11676 doi: 10.1038/ncomms11676 (2016).

References

Stang, P. J. Diederich Fo. Modern acetylene chemistry VCH (1995).

Negishi, E.–i. & Anastasia, L. Palladium-catalysed alkynylation. Chem. Rev. 103, 1979–2018 (2003).

Liu, J., Lam, J. W. Y. & Tang, B. Z. Acetylenic polymers: syntheses, structures, and functions. Chem. Rev. 109, 5799–5867 (2009).

Chinchilla, R. & Nájera, C. The sonogashira reaction: a booming methodology in synthetic organic chemistry. Chem. Rev. 107, 874–922 (2007).

Eckhardt, M. & Fu, G. C. The first applications of carbene ligands in cross-couplings of alkyl electrophiles: Sonogashira reactions of unactivated alkyl bromides and iodides. J. Am. Chem. Soc. 125, 13642–13643 (2003).

Altenhoff, G., Würtz, S. & Glorius, F. The first palladium–catalysed Sonogashira coupling of unactivated secondary alkyl bromides. Tetrahedron. Lett. 47, 2925–2928 (2006).

Vechorkin, O., Barmaz, D., Proust, V. & Hu, X. Ni–catalysed Sonogashira coupling of nonactivated alkyl halides: orthogonal functionalization of alkyl iodides, bromides, and chlorides. J. Am. Chem. Soc. 131, 12078–12079 (2009).

Yi, J., Lu, X., Sun, Y.–Y., Xiao, B. & Liu, L. Nickel–catalysed sonogashira reactions of non–activated secondary alkyl bromides and iodides. Angew. Chem. Int. Ed. 52, 12409–12413 (2013).

Chen, M., Zheng, X., Li, W., He, J. & Lei, A. Palladium–catalysed aerobic oxidative cross–coupling reactions of terminal alkynes with alkylzinc reagents. J. Am. Chem. Soc. 132, 4101–4103 (2010).

Zhang, S.–Y., Zhang, F.–M. & Tu, Y.–Q. Direct Sp3 [small alpha]–C–H activation and functionalization of alcohol and ether. Chem. Soc. Rev. 40, 1937–1949 (2011).

Girard, S. A., Knauber, T. & Li, C.–J. The cross-dehydrogenative coupling of C(sp)3–H Bonds: a versatile strategy for C–C bond formations. Angew Chem. Int. Ed. 53, 74–100 (2014).

Chen, H., Schlecht, S., Semple, T. C. & Hartwig, J. F. Thermal, catalytic, regiospecific functionalization of alkanes. Science 287, 1995–1997 (2000).

White, M. C. Adding aliphatic C–H bond oxidations to synthesis. Science 335, 807–809 (2012).

Antonchick, A. P. & Burgmann, L. Direct selective oxidative cross–coupling of simple alkanes with heteroarenes. Angew Chem. Int. Ed. 52, 3267–3271 (2013).

Li, K., Wu, Q., Lan, J. & You, J. Coordinating activation strategy for C(sp3)-H/C(sp3)-H cross-coupling to access [beta]-aromatic [alpha]-amino acids. Nat. Commun. 6, 8404 (2015).

Haro, T. d. & Nevado, C. Gold–catalysed ethynylation of arenes. J. Am. Chem. Soc. 132, 1512–1513 (2010).

Wei, Y., Zhao, H., Kan, J., Su, W. & Hong, M. Copper–catalysed direct alkynylation of electron–deficient polyfluoroarenes with terminal alkynes using O2 as an oxidant. J. Am. Chem. Soc. 132, 2522–2523 (2010).

Yang, L., Zhao, L. & Li, C.–J. Palladium–catalysed direct oxidative Heck–Cassar–Sonogashira type alkynylation of indoles with alkynes under oxygen. Chem. Commun. 46, 4184–4186 (2010).

Matsuyama, N., Kitahara, M., Hirano, K., Satoh, T. & Miura, M. Nickel– and Copper–catalysed direct alkynylation of azoles and polyfluoroarenes with terminal alkynes under O2 or atmospheric conditions. Org. Lett. 12, 2358–2361 (2010).

Patil, S. S., Jadhav, R. P., Patil, S. V. & Bobade, V. D. Ligand and solvent–free iron catalysed oxidative alkynylation of azoles with terminal alkynes. Tetrahedron. Lett. 52, 5617–5619 (2011).

Kim, S. H., Park, S. H. & Chang, S. Palladium-catalysed oxidative alkynylation of arene C–H bond using the chelation-assisted strategy. Tetrahedron 68, 5162–5166 (2012).

Shibahara, F., Dohke, Y. & Murai, T. Palladium-catalysed C–H bond direct alkynylation of 5–membered heteroarenes: a well–defined synthetic route to azole derivatives containing two different alkynyl groups. J. Org. Chem. 77, 5381–5388 (2012).

Jie, X., Shang, Y., Hu, P. & Su, W. Palladium-catalysed oxidative cross–coupling between heterocycles and terminal alkynes with low catalyst loading. Angew Chem. Int. Ed. 52, 3630–3633 (2013).

Shang, M., Wang, H.–L., Sun, S.–Z., Dai, H.–X. & Yu, J.–Q. Cu(II)–mediated ortho C–H alkynylation of (hetero)arenes with terminal alkynes. J. Am. Chem. Soc. 136, 11590–11593 (2014).

Liu, Y.–H., Liu, Y.–J., Yan, S.–Y. & Shi, B.–F. Ni(II)–catalysed dehydrative alkynylation of unactivated (hetero)aryl C–H bonds using oxygen: a user-friendly approach. Chem. Commun. 51, 11650–11653 (2015).

Liu, Y.–J., Liu, Y.–H., Yin, X.–S., Gu, W.–J. & Shi, B.–F. Copper/Silver-mediated direct ortho–ethynylation of unactivated (hetero)aryl C–H Bonds with terminal alkyne. Chem. Eur. J. 21, 205–209 (2015).

Li, Z. & Li, C.–J. CuBr–catalysed efficient alkynylation of sp3 C−H bonds adjacent to a nitrogen atom. J. Am. Chem. Soc. 126, 11810–11811 (2004).

Volla, C. M. R., Vogel, P. & Chemoselective, C−H bond activation: Ligand and solvent free iron–catalysed oxidative C−C cross–coupling of tertiary amines with terminal alkynes. Reaction scope and mechanism. Org. Lett. 11, 1701–1704 (2009).

Xu, X. & Li, X. Copper/diethyl azodicarboxylate mediated regioselective alkynylation of unactivated aliphatic tertiary methylamine with terminal alkyne. Org. Lett. 11, 1027–1029 (2009).

Sugiishi, T. & Nakamura, H. Zinc(II)–catalysed redox cross–dehydrogenative coupling of propargylic amines and terminal alkynes for synthesis of N–tethered 1,6–enynes. J. Am. Chem. Soc. 134, 2504–2507 (2012).

Correia, C. A. & Li, C. J. Silver–catalysed oxidative coupling of terminal aromatic alkynes and benzylic ethers. Heterocycles 82, 555–562 (2010).

Xiang, S.–K., Zhang, B., Zhang, L.–H., Cui, Y. & Jiao, N. Iron–mediated cross dehydrogenative coupling (CDC) of terminal alkynes with benzylic ethers and alkanes. Sci. China Chem. 55, 50–54 (2012).

Li, C.–J. Cross–dehydrogenative Ccoupling (CDC): exploring C−C bond formations beyond functional group transformations. Acc. Chem. Res. 42, 335–344 (2009).

Tōgō, H. Advanced free radical reactions for organic synthesis 1st edn Elsevier (2004).

Jasperse, C. P., Curran, D. P. & Fevig, T. L. Radical reactions in natural product synthesis. Chem. Rev. 91, 1237–1286 (1991).

Riley, P. A. Free radicals in biology: oxidative stress and the effects of ionizing radiation. Int. J. Radiat. Biol. 65, 27–33 (1994).

Carraher, C. E. Introduction to polymer chemistry 2nd edn CRC Press (2010).

Liu, Q., Jackstell, R. & Beller, M. Oxidative catalytic coupling reactions: selective formation of C–C and C–X bonds using radical processes. Angew Chem. Int. Ed. 52, 13871–13873 (2013).

Liu, C., Liu, D. & Lei, A. Recent advances of transition–metal catalysed radical oxidative cross–couplings. Acc. Chem. Res. 47, 3459–3470 (2014).

Studer, A. & Curran, D. P. Catalysis of radical reactions: a radical chemistry perspective. Angew Chem. Int. Ed. 55, 58–102 (2015).

Ichinose, Y., Matsunaga, S.–I., Fugami, K., Oshima, K. & Utimoto, K. Triethylborane-induced radical adsdition of alkyl iodides to acetylenes. Tetrahedron. Lett. 30, 3155–3158 (1989).

Liu, Z.–Q. et al. Free-radical-initiated coupling reaction of alcohols and alkynes: Not C−O but C−C bond formation. Org. Lett. 11, 1437–1439 (2009).

Cheung, C. W., Zhurkin, F. E. & Hu, X. Z–Selective olefin synthesis via iron–catalysed reductive coupling of alkyl halides with terminal Arylalkynes. J. Am. Chem. Soc. 137, 4932–4935 (2015).

Li, J., Zhang, J., Tan, H. & Wang, D. Z. Visible-light-promoted vinylation of tetrahydrofuran with alkynes through direct C–H bond functionalization. Org. Lett. 17, 2522–2525 (2015).

Ackerman, L. K. G., Lovell, M. M. & Weix, D. J. Multimetallic catalysed cross-coupling of aryl bromides with aryl triflates. Nature 524, 454–457 (2015).

Létinois–Halbes, U., Pale, P. & Berger, S. Ag NMR as a tool for mechanistic studies of Ag–catalysed reactions: Evidence for in situ formation of alkyn–1–yl silver from alkynes and silver salts. J. Org. Chem. 70, 9185–9190 (2005).

Halbes–Letinois, U., Weibel, J.–M. & Pale, P. The organic chemistry of silver acetylides. Chem. Soc. Rev. 36, 759–769 (2007).

Vitérisi, A., Orsini, A., Weibel, J.–M. & Pale, P. A mild access to silver acetylides from trimethylsilyl acetylenes. Tetrahedron. Lett. 47, 2779–2781 (2006).

Walling, C. Free radicals in solution Wiley (1957).

Tran, B. L., Driess, M. & Hartwig, J. F. Copper-catalysed oxidative dehydrogenative carboxylation of unactivated alkanes to allylic esters via alkenes. J. Am. Chem. Soc. 136, 17292–17301 (2014).

Tran, B. L., Li, B., Driess, M. & Hartwig, J. F. Copper-catalysed intermolecular amidation and imidation of unactivated alkanes. J. Am. Chem. Soc. 136, 2555–2563 (2014).

Bunescu, A., Wang, Q. & Zhu, J. Synthesis of functionalized epoxides by copper-catalysed alkylative epoxidation of allylic alcohols with alkyl nitriles. Org. Lett. 17, 1890–1893 (2015).

Simmons, E. M. & Hartwig, J. F. On the interpretation of deuterium kinetic isotope effects in C–H bond functionalizations by transition-metal complexes. Angew Chem. Int. Ed. 51, 3066–3072 (2012).

Jones, G. D. et al. Ligand redox effects in the synthesis, electronic structure, and reactivity of an alkyl−alkyl cross–coupling catalyst. J. Am. Chem. Soc. 128, 13175–13183 (2006).

Lin, X. & Phillips, D. L. Density functional theory studies of negishi alkyl–alkyl cross–coupling reactions catalysed by a methylterpyridyl–Ni(I) complex. J. Org. Chem. 73, 3680–3688 (2008).

Lin, X., Sun, J., Xi, Y. & Lin, D. How racemic secondary alkyl electrophiles proceed to enantioselective products in Negishi cross–coupling reactions. Organometallics 30, 3284–3292 (2011).

Biswas, S. & Weix, D. J. Mechanism and selectivity in nickel-catalysed cross-electrophile coupling of aryl halides with alkyl halides. J. Am. Chem. Soc. 135, 16192–16197 (2013).

Breitenfeld, J., Ruiz, J., Wodrich, M. D. & Hu, X. Bimetallic oxidative addition involving radical intermediates in nickel-catalysed alkyl–alkyl Kumada coupling reactions. J. Am. Chem. Soc. 135, 12004–12012 (2013).

Schley, N. D. & Fu, G. C. Nickel-catalysed Negishi arylations of propargylic bromides: A mechanistic investigation. J. Am. Chem. Soc. 136, 16588–16593 (2014).

Acknowledgements

This work was supported by the 973 Program (2012CB725302), the National Natural Science Foundation of China (21390400, 21520102003, 21272180 and 21302148), the Hubei Province Natural Science Foundation of China (2013CFA081), the Research Fund for the Doctoral Program of Higher Education of China (20120141130002), and the Ministry of Science and Technology of China (2012YQ120060). The Program of Introducing Talents of Discipline to Universities of China (111 Program) is also appreciated.

Author information

Authors and Affiliations

Contributions

A.L. and S.T. contributed to the conception and design of the experiments. S.T., P.W. and H.L. performed the experiments. A.L. and S.T. wrote the manuscript and all authors contributed to data analysis and scientific discussion.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-69, Supplementary Tables 1-5, Supplementary Methods and Supplementary References (PDF 5189 kb)

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Tang, S., Wang, P., Li, H. et al. Multimetallic catalysed radical oxidative C(sp3)–H/C(sp)–H cross-coupling between unactivated alkanes and terminal alkynes. Nat Commun 7, 11676 (2016). https://doi.org/10.1038/ncomms11676

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms11676

This article is cited by

-

A nickel-iron layered double hydroxide-supported Au catalyst for efficient electrocatalytic C-C coupling reaction coupled with H2 production

Science China Chemistry (2022)

-

Photocatalytic regio- and stereoselective C(sp3)–H functionalization of benzylic and allylic hydrocarbons as well as unactivated alkanes

Nature Catalysis (2019)

-

Oxidation-induced ortho-selective C–H bond functionalization of 2-naphthylamine derivative

Science China Chemistry (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.