Abstract

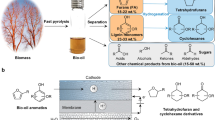

Terrestrial plants contain ~70% hemicellulose and cellulose that are a significant renewable bioresource with potential as an alternative to petroleum feedstock for carbon-based fuels. The efficient and selective deconstruction of carbohydrates to their basic components, carbon monoxide and hydrogen, so called synthesis gas, is an important key step towards the realization of this potential, because the formation of liquid hydrocarbon fuels from synthesis gas are known technologies. Here we show that by using a polyoxometalate as an electron transfer–oxygen transfer catalyst, carbon monoxide is formed by cleavage of all the carbon–carbon bonds through dehydration of initially formed formic acid. In this oxidation–reduction reaction, the hydrogen atoms are stored on the polyoxometalate as protons and electrons, and can be electrochemically released from the polyoxometalate as hydrogen. Together, synthesis gas is formed. In a hydrogen economy scenario, this method can also be used to convert carbon monoxide to hydrogen.

Similar content being viewed by others

Introduction

Environmental concerns and decreasing amounts of fossil fuels, especially oil, is leading to the development of renewable resources for liquid fuels and feedstock for petrochemicals. Solar energy and solar fuels have been touted as the ultimate, indefatigable sources of energy, but the storage of sunlight and its use in a practical way remains a major challenge of our generation. In this context, the storage of solar energy in terrestrial biomass takes advantage of natural photosynthetic pathways and further biosynthetic reactions using CO2 and H2O as carbon and hydrogen atom sources. Typically, biomass contains 35–50% cellulose, 20–35% hemicellulose and 10–25% lignin. An emerging field is biorefining of biomass and processes, including catalytic hydrolysis, solvolysis, liquefaction, pyrolysis, gasification, hydrogenolysis and hydrogenation, are all being considered1,2. The transformation of cellulose to D-glucose, its sole component, and then to ethanol to be used as a biofuel by fermentation is perhaps the most developed technology; however, the failure of simple acids to hydrolyse cellulose selectively3 remains a problem that requires the use of more expensive cellusomes4. The hydrolysis/fermentation approach also has the disadvantage that hemicellulose and its major hydrolysis product, D-xylose, still cannot be used to form ethanol. On the other hand, cellulose/hemicellulose hydrolysis has been suggested as a route to platform chemicals such as sugars, formic acid, levulinic acid and hydroxymethylfurfuraldehyde among others5,6. Other efforts have been made to convert cellulose or cellulose-derived materials to hydrocarbons7,8,9, hydrogen10,11 and furans12. Despite the aforementioned advances, reaction selectivity is typically low and process schemes are quite complicated5,6,7,8,9,10,11,12.

Here we describe a two-step, one-pot conversion of both cellulose and hemicellulose to synthesis gas, CO and H2 with high selectivity at mild conditions combining an anaerobic oxidation with the electrochemical release of H2. Synthesis gas is a known industrial commodity that can be used in various ways, including for the formation of hydrocarbon fuels via the Fischer–Tropsch process13, the synthesis of methanol14 and in transformations such as hydroformylation15. We also demonstrate that synthesis gas can be transformed to H2 via a variant water gas shift reaction16, using the same catalytic system.

Results

Mechanism of the carbon–carbon bond cleavage

The transformation of cellulose and hemicellulose polysaccharides, (CnH2nOn)m where n=6 for D-glucose and n=5 for D-xylose to synthesis gas is based on our previous studies that showed that the H5PV2Mo10O40 polyoxometalate catalyses reaction by an electron transfer–oxygen transfer-type mechanism17,18. In such a generic reaction, oxygen atoms are transferred from the polyoxometalate to the organic substrate; the polyoxometalate is reduced. Typically, in a second step molecular oxygen is used to reoxidize the polyoxometalate. In particular, H5PV2Mo10O40 was found to catalyse the carbon–carbon bond cleavage of vicinal diols and primary alcohols by an oxygen insertion reaction into the carbon–carbon bond19. As D-glucose has both these moieties, a predictive analysis shows that it could yield 5 equivalents of HCOOH, 1 equivalent of HCHO and 6 equivalents of reduced polyoxometalate, H7PVIV2Mo10O40 according to a series of reactions presented in Fig. 1.

The reaction of glucose, presented as a Fisher projection for simplicity, with 6 equivalents of H5PVV2Mo10O40 shows the carbon–carbon bond cleavage reactions. The molecular structure of the 1,2 isomer of H5PVV2Mo10O40 is shown in the insert; P: yellow, Mo: blue, V: green and O: red. Other isomers have similar reactivity17.

The reaction is surmised to ideally proceed via an oxygen atom insertion from the polyoxometalate accompanied by carbon–carbon bond cleavage to yield formic acid (HCOOH) from the C-1 to C-5 carbon atoms and formaldehyde (HCHO) from the C-6 carbon atom. The deoxygenated and reduced polyoxometalate, H5PVIV2Mo10O39 reacts with H2O to yield H7PVIV2Mo10O40. If the reaction is carried out in the presence of O2, its reaction with H7PVIV2Mo10O40 will yield H5PVV2Mo10O40 and H2O as shown in Fig. 1. Thus, the oxidation of D-glucose was studied under such conditions using 1:1 methanol/water as a solvent, which allowed reaction at low O2 pressure. Essentially quantitative conversions of D-glucose were obtained according to Fig. 2, where the presence of methanol in the acidic reaction medium leads to further partial ester, hemiacetal and acetal formation. Methanol is oxidized only in trace amounts under these conditions.

The results showed a good correlation with the expected theoretical results presented in Fig. 1. There was only slight overoxidation to CO2. To further delineate and support the proposed reaction scheme, reactions were carried out with isotopically labelled carbon-13 glucose derivatives. A reaction using 13C6H12O6 revealed peaks in the 13C NMR spectrum at 165.3, 164.1, 97.0, 89.7 and 82.2 p.p.m. assignable to HCOOH, HCOOCH3, CH2(OCH3)2, CH2(OH)(OCH3) and CH2(OH)2, respectively (Supplementary Fig. 1). Six individual reactions carried out with 13C12C5H12O6 where D-glucose was labelled at the C-1 to C-6 carbon atoms showed that most of the formaldehyde derivatives originated from the C-6 carbon atom with a small amount originating from the C-1 carbon atom. The C-2 to C-5 carbon atoms yielded formic acid and its methyl ester only and the C-1 carbon atom likewise yielded mostly, >95%, these products. The labelling experiments also support the reaction presented in Fig. 1. Interestingly, aliquots taken from the gas phase and analysed by gas chromatography (GC)–mass spectrometry showed 13CO2 was formed mostly from the C-5 carbon atom. This suggests that the hemiacetal present in the pyranose conformation leads to more formation of CO2. Finally, a stoichiometric reaction where one equivalent polyoxometalate per carbon atom was reacted under anaerobic conditions yielded reduced polyoxometalate and showed 12±0.2 electron equivalents per equivalent D-glucose as expected from the reaction stoichiometry (Fig. 1). Other saccharides reacted similarly (Supplementary Table 1).

Formation of synthesis gas from cellulose and hemicelluloses

It has been shown that H5PV2Mo10O40 can convert carbohydrates such as hemicellulose in water under rather high O2 pressures (30 bar) to formic acid in only a 50% yield with co-formation of 50% CO2 but cellulose reacted in only low yields20,21. Vanadium oxide and sodium vanadate gave similar results22,23. The maximum yield of formic acid is around 50% for hemicellulose and around only 7% for cellulose in the presence of O2 (refs 20, 21, 22, 23). Formic acid has been suggested as an energy carrier or chemical intermediate in numerous scenarios. It can be transformed to H2 and CO2 (refs 24, 25, 26), or acid-catalysed dehydration of formic acid to CO and H2O can be contemplated27. Notably, formic acid alone cannot yield both CO and H2. Analysis of the H5PV2Mo10O40 electron transfer–oxygen transfer oxidation of glucose, Fig. 1, shows that initially hydrogen atoms are ‘stored’ on polyoxometalate as electrons and protons, which under O2 leads to formation of H2O. Reoxidation of the polyoxometalate under anaerobic conditions will prevent H2O formation and allow the formation of H2.

As a saccharide unit such as D-glucose, C6H12O6, has the theoretical potential to yield 6 equivalents of both CO and H2, three major questions were asked: (1) can the electron transfer–oxygen transfer oxidation reactivity found for D-glucose be realized also for polysaccharides, specifically for hemicellulose and cellulose; (2) how can the originally formed formic acid and formaldehyde be converted to CO; and (3) how can H2 be formed? Initial experiments showed that formic acid could be quantitatively converted to 99% CO and 1% CO2 in concentrated H2SO4 (1 ml formic acid, 100 mg 98% H2SO4, 100 °C, 8 h). Not surprisingly, the addition of water proportionally reduced the reaction conversion but did not affect selectivity. Based on this observation, cellulose and hemicellulose were reacted with H5PV2Mo10O40 in concentrated H2SO4 under anaerobic conditions as shown in Fig. 3. The cellulose used was microcrystalline powder from natural wood pulp and the hemicellulose was xylan from beechwood. Both were used without any pre-treatment. The reactions were carried out by mixing 100 mg polysaccharide, 7.80 g (3.3 mmol) H5PV2Mo10O40·32H2O in 8 ml 98% H2SO4 at 70 °C for 5 h under N2. As the polyoxometalate is solvated by 32 water molecules, the concentration of H2SO4 during the reaction is ~80 vol%. There was complete conversion for both cellulose and hemicellulose as verified by the absence of any 1H NMR signals when the reaction was carried out in D2SO4. Notably, there was no observable char formation (Supplementary Fig. 2). Analysis of the gas phase by GC with a thermal conductivity detector (GC-TCD) showed the formation of only CO and CO2 in a ratio that was on the average 65±3:35±3 over five experiments. In addition, quantitative analysis using the GC-TCD with N2 as the internal standard showed quantitative formation, that is, 97±4% of CO and CO2. Other acids were also suitable for this reaction (Supplementary Table 2).

The reason for the formation of CO2 under anaerobic conditions was not immediately clear. As after only 30 min the CO:CO2 ratio was 5:1, it was suspected that CO was being oxidized also by an electron transfer–oxygen transfer mechanism by H5PV2Mo10O40 according to equation 1 below27.

The observation that CO was partially oxidized further after it was initially formed also allowed some further mechanistic insight into the oxidation of saccharides by H5PV2Mo10O40. Thus, six individual reactions were carried out with 13C12C5H12O6 where D-glucose was labelled individually at the C-1 to C-6 carbon atoms (10 mg (0.056 mmol) D-glucose (13C12C5H12O6), 0.78 g (0.33 mmol) H5PV2Mo10O40·32H2O, 1 ml 98% H2SO4, 3 h, 70 °C, N2). The results showing the 13CO/13CO2 ratio for each of the six reactions are shown in Table 1.

Clearly, the results indicate that the C-5 and C-4 atoms yield the most CO2, leading to the conclusion that these positions were the first to be oxidized/dehydrated to CO. The C-5 hemiacetal in pyranose form of D-glucose and the adjacent C-4 appear to be most susceptible to oxidation with H5PV2Mo10O40. Interestingly, the aldehydic C-1 atom yielded less CO2 than the primary C-6 atom consistent with the previously observed unusual reactivity of H5PV2Mo10O40 with primary alcohols that gives C–C bond cleavage rather than oxidation at the primary alcohol19. Note that the pathway for the formation of CO from the C-6 atom could be directly from the initially formed formaldehyde or through formic acid. It seems likely to be that cellulose is oxidized in a similar way, although the question remains whether glycosidic bonds are initially hydrolysed or not.

At the completion of the reaction, the original orange solution associated with oxidized H5PVV2Mo10O40 turns deep blue. Titration with KMnO4 showed an average over five experiments of 2.7±0.2 equivalent electrons per equivalent carbon atom. As vanadium is reduced before molybdenum17,18, reaction stoichiometry H7PVIV2MoVI10O40 and H8PVIV2MoVMoVI9O40 are apparently present in the reaction mixture in a ~7:3 ratio. The cyclic voltammetry measurements of this reaction solution, 0.42 M H5PV2Mo10O40 in H2SO4, reduced by 2.7 electrons, Fig. 4 (left), showed a redox potential of 0.4 V versus normal hydrogen electrode. Oxidation of 25–30% of the polyoxometalate at 0.6 V resulted in a change in the colour of the solution to a dark green and a shift of the redox potential to 0.05 V versus normal hydrogen electrode, Fig. 4 (right). From this, it would appear that first H8PVIV2MoVMoVI9O40 is oxidized to H7PVIV2MoVI10O40, which is then oxidized to H5PVV2Mo10O40. The exact reason for this change in redox potential is still uncertain but previous studies have shown that the degree of reduction of the polyoxometalate has structural implications, wherein different coordinatively unsaturated compounds are formed18. These different coordinatively unsaturated compounds are likely to have different redox potentials. Therefore, to form H2 quantitatively the solution was oxidized using a Pt gauze electrode. Oxidation was at 0.6 V for 25–30% of the total number of coulombs needed and then the oxidation of the polyoxometalate was completed at 0.2 V. The total coulomb count gave the same average number of electrons as the KMnO4 titration (Supplementary Fig. 3). Hydrogen was collected and its quantitative formation verified by GC.

Cyclic voltammogram of a reaction solution originally containing 0.42 M H5PV2Mo10O40 in H2SO4. Pt was used as the working and counter electrode and the H+/H2 couple catalysed by Pt was the reference. Scan rate: 200 mV s−1. Left: at the end of cellulose oxidation, which is 2.7 electrons/H5PV2Mo10O40. Right:after oxidation at 0.6 V and 25–30% oxidation of the polyoxometalate leaving 2.0 electrons/H5PV2Mo10O40.

Water gas shift reaction

As noted above, CO is partially oxidized to CO2 in the absence of O2 during the transformation of the carbohydrates. In the past, such a transformation has been carried out using a polyoxometalate together with a gold catalyst28. This leads to the possibility that H5PV2Mo10O40 alone in a mineral acid could be used to carry out a water gas shift reaction at very low temperatures. In this context, such a water gas transformation is in itself an interesting alternative to the higher temperature water gas shift reaction presently practiced, because (1) it is thermodynamically more efficient at low temperature (ΔGr,g,25 °C=−5.8 kcal mol−1 although the ΔGr in H2SO4 is unknown) and (ii) the separate catalytic CO2 and electrochemical H2-forming steps obviate the necessity of separating CO2 from H2. For example, in a glass pressure tube 2 bar of CO was reacted with 1.4 mmol H5PV2Mo10O40·32H2O dissolved in 8 ml 80% aqueous H2SO4. After 5 h at 100 °C, complete conversion was attained and H2 was released electrochemically as described above.

Discussion

A representation of the transformation of cellulose and hemicellulose using cellulose as a representative substrate is presented in Fig. 5, where both the electron transfer–oxygen transfer oxidation of the carbohydrate and the oxidation of CO are shown along with the electrochemical oxidation of the electrons and protons initially stored on the polyoxometalate.

Several summary points are notable. (1) This is the first reported use of concentrated sulphuric acid, an inexpensive industrial commodity, in a polyoxometalate-catalysed reaction that now allows the complete transformation of both cellulose and hemicellulose at mild reaction temperatures. The initially formed formic acid is formed in a high yield and then quantitatively dehydrated to CO. The electrochemical release of H2 for the most part at a relatively low over-potential of 0.2 V allows the overall formation of synthesis gas, 1 equivalent of CO and H2 per carbon atom. (2) The use of H2SO4 has the added advantage that it significantly increases the rate of the electron transfer–oxygen transfer oxidation and is a convenient medium for the release of H2 at low potentials. (3) Fast removal of the CO formed by purging the reaction mixture can prevent its further oxidation to CO2. However, if H2 were the target, the complete conversion of CO by a water–gas shift reaction using this catalytic system can be used. In this way, 2 equivalents of H2 can be formed per carbon atom in the polysaccharide. (4) The separate electrochemical release of H2 can allow separate formation of H2 and CO. (5) Importantly, after the formation of only gaseous products, the reaction solution, that is, H5PV2Mo10O40 in H2SO4, can be recycled and reused without any additional treatment. Ten reaction cycles using cellulose as substrate showed no change in reactivity. In this context, it can be noted that we observed that vanadium oxide also can oxidize carbohydrates in H2SO4; however, H2 cannot be recovered electrochemically.

The research presented herein could be the foundation for a new technology for the formation of synthesis gas from biomass. Purported advantages of the proposed concept are: (1) as solar energy and other sources (wind, geothermal and nuclear) are more simply transformed to electric power compared with their storage as a chemical fuel, the low-temperature electrochemical approach presented here has the potential for considerable total energy saving and (2) the synthesis gas yield can be significantly higher than what can be obtained with high-temperature steam reforming of biomass where the need to use O2 from air leads to formation of CO2 as the major product, which is not compensated by H2 formation, and which require noble metal-based catalysts for quantitative conversions29. (3) The concept presented herein indicates a requirement of 1 mole equivalent of polyoxometalate per carbon atom; for example, 10 mg of cellulose per 780 mg polyoxometalate in a one-pot reaction. However, as the cellulose conversion is quantitative, all the products are gaseous and the catalyst is very stable under reaction conditions, in a perceived technological application using a continuous reaction mode carbohydrates can be fed and synthesis gas can be removed continuously with a fixed amount of catalyst.

Methods

Materials

Microcrystalline cellulose, hemicellulose and the other sugars were purchased from Sigma-Aldrich. Microcrystalline cellulose was from natural wood pulp and was of an unknown molecular weight. It was used without pre-treatment. Hemicellulose was xylan from beechwood and was used without any pre-treatment. The seven carbon-13-labelled glucose compounds, and CD3OD, D2O and D2SO4 were purchased from Cambridge Isotope Laboratories. H5PV2Mo10O40·32H2O was prepared by a known procedure30.

Aerobic reactions

Aerobic reactions in water/methanol were carried out by dissolving 100 mg saccharide or polysaccharide, 88 mg H5PV2Mo10O40·32H2O (0.038 mmol) in 3 ml of a (1:1) mixture of CD3OD and D2O in a 50-ml glass pressure tube. Reactions were carried at 2 bar O2, 110 °C for 18 h. The amount of products formed, formic acid, methyl formate, dimethoxymethane, methoxymethanol and methanediol were calculated using 300 MHz 1H NMR and ethanol as an external standard. As the peak for H2O (always present to some degree) partially overlapped with those of the formaldehyde derivatives, two drops of 35% HCl were added to shift the peak of water downfield. CO2 and CO were determined by GC-TCD using a GowMac instrument with a 20′ × 1/8″ stainless steel column packed with molecular Sieve 5 Å in series with a 4′ × 1/8″ stainless steel column packed with HayeSep T. The carrier gas was Ar, column T=120 °C. Retention times for CO2 was 4.5 min and for CO was 30.2 min. Supplementary Table 1 shows the results for a variety of saccharides and polysaccharides.

Anaerobic reactions

Anaerobic oxidation in concentrated (98%) sulphuric acid and hydrogen formation were carried out by mixing 100 mg cellulose or hemicellulose, and 7.80 g (3.3 mmol) H5PV2Mo10O40·32H2O in 8 ml H2SO4. At room temperature, this is a slurry but on heating a clear solution is obtained. The reaction was carried out at 70 °C for 5 h under N2. CO and CO2 were analysed as described above. H2 was formed electrochemically using a platinum gauze, 25–30% oxidation at 0.6 V and the remainder at 0.2 V. H2 was quantified by GC-TCD using a GowMac instrument with a 20′ × 1/8″ stainless steel column packed with molecular Sieve 5 Å in series with a 4′ × 1/8″ stainless steel column packed with HayeSep T. The carrier gas was Ar, column T=120 °C. Retention time was 10.0 min. Similar anaerobic reactions of cellulose in various acid solvents were carried out by mixing 100 mg cellulose and 7.80 g (3.3 mmol) H5PV2Mo10O40·32H2O in 8 ml solvent. Reactions were performed under N2. The results are summarized in Supplementary Table 2. Anaerobic oxidation of 13C labelled D-glucose isomers by H5PV2Mo10O40 in H2SO4 were carried out by dissolving 10 mg (0.056 mmol) D-glucose (13C12C5H12O6) and 0.78 g (0.33 mmol) H5PV2Mo10O40 in 98% H2SO4 and the reaction mixture was heated for 5 h at 70 °C under N2. The relative amounts of 13CO and 13CO2 were measured by GC–mass spectrometry.

Cyclic voltammetry experiments

Cyclic voltammetry experiments were performed using a potentiostat (CHI660A) connected to a personal computer. The measurements were performed in a three-electrode cell configuration consisting of (i) Platinum gauze (working electrode), (ii) a Pt wire (counter electrode), and (iii) Pt (a reference electrode). The experiments were performed at room temperature. The scan rate was 200 mV s−1. The observed change in the cyclic voltammetry curve is due to the oxidation of Mo (V) to Mo (VI) before V (IV) to V (V). From our pervious studies, it is known that on reduction of H5PV2Mo10O40, vanadium atoms can be both incorporated within the polyoxometalate framework and supported as a vanayl-like cation on the polyoxmetalate surface31. Such different species may have different oxidation potentials.

Titration with KMnO4

The concentrations of fresh KMnO4 solutions were determined by volumetric titration with standard oxalic acid solutions. The reduced polyoxometalate solutions were titrated volumetrically using the disappearance of the peak of the reduced polyoxometalate at 750 nm as indicator. The titrations go clearly to Mn(II).

Additional information

How to cite this article: Sarma, B. B. and Neumann, R. Polyoxometalate-mediated electron transfer–oxygen transfer oxidation of cellulose and hemicellulose to synthesis gas. Nat. Commun. 5:4621 doi: 10.1038/ncomms5621 (2014).

References

Zhou, C.-H., Xia, X., Lin, C.-X., Tong, D.-S. & Beltramini, J. Catalytic conversion of lignocellulosic biomass to fine chemicals and fuels. Chem. Soc. Rev. 40, 5588–5617 (2011).

Melero, J. A., Iglesias, J. & Garcia, A. Biomass as renewable feedstock in standard refinery units. Feasibility, opportunities and challenges. Energy Environ. Sci. 5, 7393–7420 (2012).

Zhu, L., O’Dwyer, J. P., Chang, V. S., Brabda, C. B. & Holtzapple, M. Y. Structural features affecting biomass enzymatic digestibility. Bioresource Technol. 99, 3817–3828 (2008).

Fan, L. T., Gharpuray, M. M. & Lee, Y. H. Cellulose Hydrolysis Springer-Verlag (1987).

Chheda, J. N., Huber, G. W. & Dumesic, J. A. Liquid-phase catalytic processing of biomass-derived oxygenated hydrocarbons to fuels and chemicals. Angew. Chem. Int. Ed. 46, 7164–7183 (2007).

Huber, G. W., Iborra, S. & Corma, A. Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering. Chem. Rev. 106, 4044–4098 (2006).

Kunkes, E. L. et al. Catalytic conversion of biomass to monofunctional hydrocarbons and targeted liquid-fuel classes. Science 322, 417–421 (2008).

Huber, G. W., Chheda, J. N., Barrett, C. J. & Dumesic, J. A. Production of liquid alkanes by aqueous-phase processing of biomass-derived carbohydrates. Science 308, 1446–1449 (2005).

Sutton, A. D. et al. The hydrodeoxygenation of bioderived furans into alkanes. Nature Chem. 5, 428–432 (2013).

Huber, G. W., Shabaker, J. W. & Dumesic, J. A. Raney Ni-Sn catalyst for H2 production from biomass-derived hydrocarbons. Science 300, 2075–2077 (2003).

Matson, T. D., Barta, K., Iretskii, A.V. & Peter, C. Ford, one-pot catalytic conversion of cellulose and of woody biomass solids to liquid fuels. J. Am. Chem. Soc. 133, 14090–14097 (2011).

Binder, J. B. & Raines, R. T. Simple chemical transformation of lignocellulosic biomass into furans for fuels and chemicals. J. Am. Chem. Soc. 131, 1979–1985 (2009).

Maitlis, P. M. & de Klerk, A. Greener-Fischer-Tropsch-Processes for Fuels and Feedstocks Wiley-VCH (2013).

Stiles, A. B. Methanol, past, present, and speculation on the future. AIChE J. 23, 362–375 (1977).

Cornils, B, Herrmann, W. A., Rasch, M. & Roelen, Otto Pioneer in Industrial Homogeneous Catalysis. Angew. Chem. Int. Ed. 33, 2144–2163 (1994).

Jacobs, G. & Davis, B. H. Low temperature water-gas shift catalysts. Catalysis 20, 122–285 (2007).

Neumann, R. Activation of molecular oxygen, polyoxometalates and liquid phase catalytic oxidation. Inorg. Chem. 49, 3594–3601 (2010).

Efremenko, I. & Neumann, R. Computational insight into the initial steps of the Mars-van Krevelen mechanism: electron transfer and surface defects in the reduction of polyoxometalates. J. Am. Chem. Soc. 134, 20669–20680 (2012).

Khenkin, A. M. & Neumann, R. Oxidative C-C bond cleavage of primary alcohols and vicinal diols catalyzed by H5PV2Mo10O40 by an electron transfer and oxygen transfer mechanism. J. Am. Chem. Soc. 130, 14474–14476 (2008).

Wölfel, R., Taccardi, N., Bösmann, A. & Wasserscheid, P. Selective catalytic conversion of biobased carbohydrates to formic acid using molecular oxygen. Green Chem. 11, 2759–2763 (2011).

Albert, J., Lu¨ders, D., Bösmann, A., Guldi, D. M. & Wasserscheid, P. Spectroscopic and electrochemical characterization of heteropoly acids for their optimized application in selective biomass oxidation to formic acid. Green Chem. 16, 226–237 (2014).

Li, J., Ding, D.-J., Deng, L., Guo, Q.-X. & Fu, Y. Catalytic air oxidation of biomass-derived carbohydrates to formic acid. ChemSusChem 5, 1313–1318 (2012).

Wang, W. et al. Catalytic conversion of biomass-derived carbohydrates to formic acid using molecular oxygen. Green Chem. 16, 2614–2618 (2014).

Fellay, C., Dyson, P. J. & Laurenczy, G. A viable hydrogen-storage system based on selective formic acid decomposition with a ruthenium catalyst. Angew. Chem. Int. Ed. 47, 3966–3968 (2008).

Boddien, A. et al. Efficient dehydrogenation of formic acid using an iron catalyst. Science 333, 1733–1736 (2011).

Wang, Z.-L. et al. An efficient CoAuPd/C catalyst for hydrogen generation from formic acid at room temperature. Angew. Chem. Int. Ed. 52, 4406–4409 (2013).

Trillo, J. M., Munuera, G. & Criado, J. M. Catalytic decomposition of formic acid on metal oxides. Catal. Rev. Sci. Eng. 7, 51–86 (1972).

Kim, W. B., Voitl, T., Rodriguez-Rivera, G. J. & Dumesic, J. A. Powering fuel cells with CO via aqueous polyoxometalates and gold catalysts. Science 305, 1280–1283 (2004).

Asadullah, M., Fujimoto, K. & Tomishige, K. Catalytic performance of Rh/CeO2 in the gasification of cellulose to synthesis gas at low temperature. Ind. Eng. Chem. Res. 40, 5894–5900 (2001).

Tsigdinos, G. A. & Hallada, C. J. Molybdovanadophosphoric acids and their salts. I. Investigation of methods of preparation and characterization. Inorg. Chem. 7, 437–441 (1968).

Kaminker, I., Goldberg, H., Neumann, R. & Goldfarb, D. High field pulsed EPR spectroscopy for the speciation of the reduced [PV2Mo10O40]6– polyoxometalate catalyst used in electron transfer oxidations. Chem. Eur. J. 16, 10014–10020 (2010).

Acknowledgements

This research was supported by the Israel Ministry of Science (grant 3-9093), the Israel Science Foundation (grant 816/11) and the I-CORE Program of the Planning and Budgeting Committee and The Israel Science Foundation (grant 152/11). R.N. is the Rebecca and Israel Sieff Professor of Organic Chemistry.

Author information

Authors and Affiliations

Contributions

B.B.S. carried out the research; B.B.S. and R.N. planned the research; R.N. oversaw the research and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-3, Supplementary Tables 1-2 (PDF 619 kb)

Rights and permissions

About this article

Cite this article

Sarma, B., Neumann, R. Polyoxometalate-mediated electron transfer–oxygen transfer oxidation of cellulose and hemicellulose to synthesis gas. Nat Commun 5, 4621 (2014). https://doi.org/10.1038/ncomms5621

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms5621

This article is cited by

-

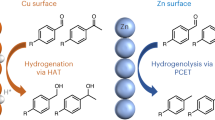

Photo splitting of bio-polyols and sugars to methanol and syngas

Nature Communications (2020)

-

Electrochemistry Investigation of the Monolacunary and Their Transition Metal Substituent Keggin-Type Polyoxometalates

Electrocatalysis (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.