Abstract

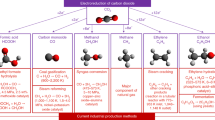

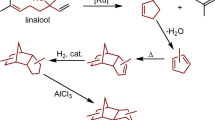

The production of biodiesel from the transesterification of plant-derived triglycerides with methanol has been commercialized extensively. Impure glycerol is obtained as a by-product at roughly one-tenth the mass of the biodiesel. Utilization of this crude glycerol is important in improving the viability of the overall process. Here we show that crude glycerol can be reacted with water over very simple basic or redox oxide catalysts to produce methanol in high yields, together with other useful chemicals, in a one-step low-pressure process. Our discovery opens up the possibility of recycling the crude glycerol produced during biodiesel manufacture. Furthermore, we show that molecules containing at least two hydroxyl groups can be converted into methanol, which demonstrates some aspects of the generality of this new chemistry.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Huber, G. W., Cortright, R. D. & Dumesic, J. A. Renewable alkanes by aqueous phase reforming of biomass derived oxygenates. Angew. Chem. Int. Ed. 43, 1549–1551 (2004).

Klass, D. L. Biomass for Renewable Energy, Fuels and Chemicals (Academic Press, 1998).

Huber, G. W., Iborra, S. & Corma, A. Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering. Chem. Rev. 106, 4044–4098 (2006).

Cortright, R. D., Davda, R. R. & Dumesic, J. A. Hydrogen from catalytic reforming of biomass-derived hydrocarbons in liquid water. Nature 418, 964–967 (2002).

Braden, D. J., Henao, C. A., Heltzel, J., Maravelias, C. C. & Dumesic, J. A. Production of liquid hydrocarbon fuels by catalytic conversion of biomass-derived levulinic acid. Green Chem. 13, 1755–1765 (2011).

Han, J., Sen, S. M., Alonso, D. M., Dumesic, J. A. & Maravelias, C. T. A strategy for the simultaneous catalytic conversion of hemicellulose and cellulose from lignocellulosic biomass to liquid transportation fuels. Green Chem. 24, 653–661 (2014).

Ertl, G., Knözinger, H., Schûth, F. & Weitkamp, J. Handbook of Heterogeneous Catalysis Vol. 6 (Wiley-VCH, 2008).

Lloyd, L. L., Ridler, D. E. & Twigg, M. V. Catalyst Handbook 2nd edn (Wolfe Publishing, 1989).

Farmer, T. J. & Clark, J. H. Green chemistry for 21st century industry. Catal. Rev. 25, 7–14 (2012).

Lin, C. S. K., Luque, R., Clark, J. H., Webb, C. & Du, C. A seawater-based biorefining strategy for fermentative production and chemical transformations of succinic acid. High Energ. Dens. Phys. 4, 1471–1479 (2011).

Budarin, V. L. et al. Use of green chemical technologies in an integrated biorefinery. Energ. Env. Sci. 4, 471–479 (2011).

Atabani, A. E. et al. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sust. Energ. Rev. 16, 2020–2093 (2012).

He, L. et al. Biodiesel synthesis from the esterification of free fatty acids and alcohol catalyzed by long-chain Brønsted acid ionic liquid. Catal. Sci. Technol. 3, 1102–1107 (2013).

Schwab, A. W., Bagby, M. O. & Freedman, B. Preparation and properties of diesel fuels from vegetable oils. Fuel 66, 1372–1378 (1987).

Otera, J. Tranesterification. Chem. Rev. 93, 1449–1470 (1993).

Lee, S. in Handbook of Alternative Fuel Technology (eds Lee, S., Speight, J. G. & Loyalka, S.) 297–322 (CRC Press, 2007).

Twigg, M. V. & Spencer, M. S. Deactivation of supported copper metal catalysts for hydrogenation reactions. Appl. Catal. A 212, 161–174 (2001).

Wainwright, M. S. Catalytic processes for methanol synthesis—established and future. Stud. Surf. Sci. Catal. 36, 95–108 (1988).

Thompson, J. C. & He, B. B. Characterisation of crude glycerol from biodiesel production from multiple feedstocks. Appl. Eng. Agric. 22, 261–265 (2006).

Carrettin, S., McMorn, P., Johnston, P., Griffin, K. & Hutchings, G. J. Selective oxidation of glycerol to glyceric acid using a gold catalyst. Chem. Commun. 696–697 (2002).

Haider, M. H. et al. Rubidium and cesium doped silicotungstic acid catalysts supported on alumina for the catalytic dehydration of glycerol to acrolein. J. Catal. 286, 206–213 (2012).

Atia, H., Armbruster, U. & Martin, A. Dehydration of glycerol in gas phase using heteropoly acid catalysts as active compounds. J. Catal. 258, 71–82 (2008).

Chai, S.-H., Wang, H.-P., Liang, Y. & Xu, B.-Q. Sustainable production of acrolein: gas-phase of glycerol over 12-tungstophosphoric acid supported on ZrO2 and SiO2 . Green Chem. 10, 1087–1093 (2008).

Tsukuda, E., Sato, S., Takahashi, R. & Sodesawa, T. Production of acrolein from glycerol over silica supported heteropoly acids. Catal. Commun. 8, 1349–1353 (2007).

Haider, M. H. et al. Effect of grafting zirconia and ceria onto alumina as a support for silicotungstic acid for the catalytic dehydration of glycerol to acrolein. Chem. Eur. J. 20, 1743–1752 (2014).

Tsang, S. C. E., Oduru, W. O. & Redman, D. J. Methanol production process. Patent application WO 2009130452 A1 (2009).

Wu, C. T. et al. A non-syn gas catalytic route to methanol production. Nature Commun. 3, 1050 (2012).

Yang, F., Hanna, M. A. & Sun, R. Value-added uses for crude glycerol—a byproduct of biodiesel production. Biotech. Biofuels 5, 13 (2012).

Burghardt, H. et al. in Proc. 18th World Hydrogen Energy Conf. (eds Stolten, D. & Grube, T.) 343–348 (Jülich, 2010).

Acknowledgements

The authors acknowledge the financial support of Cardiff University, the Engineering and Physical Sciences Research Council (Grant No. EP/J013420/1), the European Research Council (ERC-2011-ADG, Grant Agreement No. 291319: ‘After The Gold Rush’) and the Technology Strategy Board. This work initially formed part of the Glycerol Challenge and was cofunded by the Technology Strategy Board's Collaborative Research and Development programme after an open competition. The Technology Strategy Board is an executive body established by the UK Government to drive innovation. The authors also thank Biodiesel Amsterdam BV for supplying crude glycerol.

Author information

Authors and Affiliations

Contributions

M.H.H. prepared and tested the catalysts and designed the initial experiments, N.F.D designed the reactor and provided assistance with experimental design and D.W.K. provided mechanistic insights into the chemistry. Detailed analysis was provided by R.L.J. S.H.T provided expertise on catalyst preparation. G.J.H. directed the overall research and all the authors contributed to the analysis of the data and the writing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 958 kb)

Rights and permissions

About this article

Cite this article

Haider, M., Dummer, N., Knight, D. et al. Efficient green methanol synthesis from glycerol. Nature Chem 7, 1028–1032 (2015). https://doi.org/10.1038/nchem.2345

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nchem.2345

This article is cited by

-

Scalable electrosynthesis of commodity chemicals from biomass by suppressing non-Faradaic transformations

Nature Communications (2023)

-

Pt1 enhanced C-H activation synergistic with Ptn catalysis for glycerol cascade oxidation to glyceric acid

Nature Communications (2022)

-

Engineering synthetic microbial consortium for cadaverine biosynthesis from glycerol

Biotechnology Letters (2022)

-

Facile Synthesis, Characterization, Catalytic and Photocatalytic Activity of Multiferroic BiFeO3 Perovskite Nanoparticles

Journal of Inorganic and Organometallic Polymers and Materials (2022)

-

Photo splitting of bio-polyols and sugars to methanol and syngas

Nature Communications (2020)