Abstract

Traditional metallic alloys are mixtures of elements in which the atoms of minority species tend to be distributed randomly if they are below their solubility limit, or to form secondary phases if they are above it. The concept of multiple-principal-element alloys has recently expanded this view, as these materials are single-phase solid solutions of generally equiatomic mixtures of metallic elements. This group of materials has received much interest owing to their enhanced mechanical properties1,2,3,4,5. They are usually called medium-entropy alloys in ternary systems and high-entropy alloys in quaternary or quinary systems, alluding to their high degree of configurational entropy. However, the question has remained as to how random these solid solutions actually are, with the influence of short-range order being suggested in computational simulations but not seen experimentally6,7. Here we report the observation, using energy-filtered transmission electron microscopy, of structural features attributable to short-range order in the CrCoNi medium-entropy alloy. Increasing amounts of such order give rise to both higher stacking-fault energy and hardness. These findings suggest that the degree of local ordering at the nanometre scale can be tailored through thermomechanical processing, providing a new avenue for tuning the mechanical properties of medium- and high-entropy alloys.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Yeh, J. W. et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004).

Cantor, B., Chang, I. T. H., Knight, P. & Vincent, A. J. B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377, 213–218 (2004).

Li, Z., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227–230 (2016).

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Yang, T. et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 362, 933–937 (2018).

Ding, J., Yu, Q., Asta, M. & Ritchie, R. O. Tunable stacking fault energies by tailoring local chemical order in CrCoNi medium-entropy alloys. Proc. Natl Acad. Sci. USA 115, 8919–8924 (2018).

Li, Q.-J., Sheng, H. & Ma, E. Strengthening in multi-principal element alloys with local-chemical-order roughened dislocation pathways. Nat. Commun. 10, 3563 (2019).

Zhang, Y. et al. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014).

Gao, M. C., Yeh, J. W., Liaw, P. K. & Zhang, Y. High-Entropy Alloys: Fundamentals and Applications (Springer International, 2016).

Senkov, O. N., Miracle, D. B., Chaput, K. J. & Couzinie, J. P. Development and exploration of refractory high entropy alloys — a review. J. Mater. Res. 33, 3092–3128 (2018).

Miracle, D. B. High entropy alloys as a bold step forward in alloy development. Nat. Commun. 10, 1805 (2019).

George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019).

Li, Z., Zhao, S., Ritchie, R. O. & Meyers, M. A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 102, 296–345 (2019).

Gludovatz, B. et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7, 10602 (2016).

Zhang, Z. et al. Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat. Commun. 8, 14390 (2017).

Zaddach, A. J., Niu, C., Koch, C. C. & Irving, D. L. Mechanical properties and stacking fault energies of NiFeCrCoMn high-entropy alloy. J. Miner. Met. Mater. Soc. 65, 1780–1789 (2013).

Zhang, Y. H., Zhuang, Y., Hu, A., Kai, J. J. & Liu, C. T. The origin of negative stacking fault energies and nano-twin formation in face-centered cubic high entropy alloys. Scr. Mater. 130, 96–99 (2017).

Zhao, S., Stocks, G. M. & Zhang, Y. Stacking fault energies of face-centered cubic concentrated solid solution alloys. Acta Mater. 134, 334–345 (2017).

Niu, C., LaRosa, C. R., Miao, J., Mills, M. J. & Ghazisaeidi, M. Magnetically-driven phase transformation strengthening in high entropy alloys. Nat. Commun. 9, 1363 (2018).

Laplanche, G. et al. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 128, 292–303 (2017).

Okamoto, N. L. et al. Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci. Rep. 6, 35863 (2016).

Smith, T. M. et al. Atomic-scale characterization and modeling of 60° dislocations in a high-entropy alloy. Acta Mater. 110, 352–363 (2016).

Zhang, F. X. et al. Local structure and short-range order in a NiCoCr solid solution alloy. Phys. Rev. Lett. 118, 205501 (2017).

Van Tendeloo, G. & Amelinckx, S. The origin of diffuse intensity in electron diffraction patterns. Phase Transit. 67, 101–135 (1998).

Tamm, A., Aabloo, A., Klintenberg, M., Stocks, M. & Caro, A. Atomic-scale properties of Ni-based FCC ternary, and quaternary alloys. Acta Mater. 99, 307–312 (2015).

Zhang, R. et al. Direct imaging of short-range order and its relationship to deformation in Ti-6Al. Sci. Adv. 5, eaax2799 (2019).

Laplanche, G. et al. Elastic moduli and thermal expansion coefficients of medium-entropy subsystems of the CrMnFeCoNi high-entropy alloy. J. Alloys Compd. 746, 244–255 (2018).

Ophus, C., Ciston, J. & Nelson, C. T. Correcting nonlinear drift distortion of scanning probe and scanning transmission electron microscopies from image pairs with orthogonal scan directions. Ultramicroscopy 162, 1–9 (2016).

Gerold, V. & Karnthaler, H. P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 37, 2177–2183 (1989).

Pekin, T. C., Gammer, C., Ciston, J., Ophus, C. & Minor, A. M. In situ nanobeam electron diffraction strain mapping of planar slip in stainless steel. Scr. Mater. 146, 87–90 (2018).

Neeraj, T. & Mills, M. J. Short-range order (SRO) and its effect on the primary creep behavior of a Ti-6wt.%Al alloy. Mater. Sci. Eng. A 319–321, 415–419 (2001).

van de Walle, A. & Asta, M. First-principles investigation of perfect and diffuse antiphase boundaries in HCP-based Ti-Al alloys. Metall. Mater. Trans. A 33, 735–741 (2002).

Gouldstone, A. et al. Indentation across size scales and disciplines: recent developments in experimentation and modeling. Acta Mater. 55, 4015–4039 (2007).

Fisher, J. C. C. On the strength of solid solution alloys. Acta Metall. 2, 9–10 (1954).

Britton, T. B., Dunne, F. P. E. & Wilkinson, A. J. On the mechanistic basis of deformation at the microscale in hexagonal close-packed metals. Proc. R. Soc. A 471, 20140881 (2015).

Hamdi, F. & Asgari, S. Influence of stacking fault energy and short-range ordering on dynamic recovery and work hardening behavior of copper alloys. Scr. Mater. 62, 693–696 (2010).

Miracle, D. B. et al. Exploration and development of high entropy alloys for structural applications. Entropy 16, 494–525 (2014).

Williams, J. C. & Starke, E. A. Progress in structural materials for aerospace systems. Acta Mater. 51, 5775–5799 (2003).

Ma, Y. et al. Chemical short-range orders and the induced structural transition in high-entropy alloys. Scr. Mater. 144, 64–68 (2018).

Singh, P., Smirnov, A. V. & Johnson, D. D. Atomic short-range order and incipient long-range order in high-entropy alloys. Phys. Rev. B 91, 224204 (2015).

Lucas, M. S. et al. Absence of long-range chemical ordering in equimolar FeCoCrNi. Appl. Phys. Lett. 100, 251907 (2012).

Niu, C. et al. Spin-driven ordering of Cr in the equiatomic high entropy alloy NiFeCrCo. Appl. Phys. Lett. 106, 161906 (2015).

Linden, Y., Pinkas, M., Munitz, A. & Meshi, L. Long-period antiphase domains and short-range order in a B2 matrix of the AlCoCrFeNi high-entropy alloy. Scr. Mater. 139, 49–52 (2017).

Fultz, B. & Howe, J. M. Transmission Electron Microscopy and Diffractometry of Materials (Springer, 2008).

Phillips, P. J., Brandes, M. C., Mills, M. J. & de Graef, M. Diffraction contrast STEM of dislocations: imaging and simulations. Ultramicroscopy 111, 1483–1487 (2011).

Phillips, P. J. et al. Atomic-resolution defect contrast in low angle annular dark-field STEM. Ultramicroscopy 116, 47–55 (2012).

Cockayne, D. J. H. The weak-beam technique as applied to dissociation measurements. J. Phys. Colloq. 35, C7-141–C7-148 (1974).

Cockayne, D. J. H., Ray, I. L. F. & Whelan, M. J. Investigations of dislocation strain fields using weak beams. Phil. Mag. 20, 1265–1270 (1969).

Anderson, P. M., Hirth, J. P. & Lothe, J. Theory of Dislocations (Cambridge Univ. Press, 2017).

Pierce, D. T. et al. The influence of manganese content on the stacking fault and austenite/ε-martensite interfacial energies in Fe–Mn–(Al–Si) steels investigated by experiment and theory. Acta Mater. 68, 238–253 (2014).

Acknowledgements

This work was primarily supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, Materials Sciences and Engineering Division, under contract no. DE-AC02-05-CH11231 within the Damage-Tolerance in Structural Materials (KC 13) programme. R.Z., S.Z. and Y.C. acknowledge support from the US Office of Naval Research under grant nos. N00014-12-1-0413, N00014-17-1-2283 and N00014-11-1–0886, respectively. Work at the Molecular Foundry was supported by the Office of Science, Office of Basic Energy Sciences, of the US Department of Energy under contract no. DE-AC02-05CH11231. X-ray diffraction measurements were made at the Stanford Nano Shared Facilities (SNSF), supported by the National Science Foundation under award ECCS-1542152. This research used resources of the National Energy Research Scientific Computing Center (NERSC), a US Department of Energy Office of Science User Facility operated under contract no. DE-AC02-05CH11231. We thank E. Ma at Johns Hopkins University for providing a 600 °C aged alloy.

Author information

Authors and Affiliations

Contributions

R.Z., S.Z., M.A., R.O.R. and A.M.M. conceived the project.; R.Z. and S.Z. conducted the energy-filtered TEM imaging and dislocation analysis; C.O. and R.Z. developed and optimized the domain recognition algorithm; R.Z. and S.Z. conducted the nanoindentation tests; R.Z., S.Z and Y.C. conducted the tensile tests. J.D. conducted the DFT simulations. T.J. conducted the XRD experiments. R.Z., S.Z., R.O.R., M.A. and A.M.M. prepared the manuscript, which was reviewed and edited by all authors. Project administration, supervision and funding acquisition was performed by R.O.R., M.A. and A.M.M.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks Elena Pereloma, Christopher Woodward and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

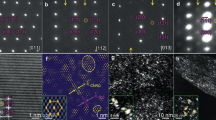

Extended Data Fig. 1 Energy-filtered TEM diffraction patterns and dark-field images formed with diffuse superlattice streaks.

a–c, Energy-filtered diffraction patterns taken from CrCoNi MEA samples that were water-quenched, aged at 600 °C for one week or aged at 1,000 °C for one week, respectively. The contrast is pseudo-coloured for better visibility. The line plots of intensity show the periodic intensity of the diffuse superlattice streaks. d–f, Energy-filtered dark-field images taken from water-quenched, 600 °C aged and 1,000 °C aged samples, respectively. The aperture positions are marked by the g vectors (labelled arrows). The images of the water-quenched and the 1,000 °C aged samples are the same as in Fig. 1 but are presented again here for comparison with the 600 °C aged sample.

Extended Data Fig. 2 Geometrical phase analysis strain mapping of a 1,000 °C aged sample and a water-quenched sample.

a–d, 1,000 °C aged alloy; e–h, water-quenched sample. a, e, Drift-corrected HRSTEM images of the 1,000 °C aged sample and the water-quenched sample, respectively. The fast Fourier transformed images are shown inset. b–d, Strain maps of a showing nanometre-sized local fluctuations of strain (εxx, normal strain in the x direction; εyy, normal strain in the y direction). f–h, Strain maps of e showing similar but much weaker contrast of local strain.

Extended Data Fig. 3 Results of X-ray diffraction experiments on a water-quenched sample and a 1,000 °C aged sample of the CrCoNi MEA.

The indexed (111) and (200) peaks are marked. The lattice constants a are calculated on the basis of the 2θ angles of the identified peaks..

Extended Data Fig. 4 Diffuse anti-phase boundary (DAPB) energy as a function of successive dislocation slip events from a calculated SRO model.

The data in the inset table represent different states of SRO and the plot is from the state marked blue.

Extended Data Fig. 5 Detailed ‘g·b’ analysis of partial dislocations in the CrCoNi MEA.

a–e, Water-quenched sample; f–j, sample aged at 1,000 °C. a, f, Diffraction references showing the diffraction conditions (g vectors) used for the analysis. b, g, Lower-magnification DC-STEM images of dislocations in the water-quenched and aged samples, respectively. c–e, h–j, Two-beam DC-STEM images of the boxed areas in b and g, respectively; the Burgers vectors of the visible dislocations are noted on the images.

Extended Data Fig. 6 Detailed statistical analysis of the pop-in events.

Pop-in events were observed during nanoindentation tests (see Methods section ‘Nanoindentation experiments’ for details). a, b, Distribution of the pop-in load from water-quenched and 1,000 °C aged samples, respectively. c, d, Distribution of the pop-in depth from water-quenched and 1,000 °C aged samples, respectively. The fitted normal distribution functions are listed in the panels. The results of numerical analysis are summarized in Extended Data Table 1.

Extended Data Fig. 7 Element mapping of the water-quenched and aged CrCoNi samples using EDS.

a–e, Water quenched sample; f–j, sample aged at 1,000 °C. a, f, Reference HAADF (high-angle annular dark field) images showing the regions of interest of a water-quenched sample and a 1,000 °C aged sample, respectively. b–d, g–i, Element mapping of Co, Ni and Cr of the water-quenched sample and the 1,000 °C aged sample, respectively. e, j, Quantitative results of line scans of the water-quenched sample and the 1,000 °C aged sample, respectively. The line scan directions are marked by the dashed lines in a and f.

Rights and permissions

About this article

Cite this article

Zhang, R., Zhao, S., Ding, J. et al. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 581, 283–287 (2020). https://doi.org/10.1038/s41586-020-2275-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-020-2275-z

This article is cited by

-

Serrated plastic flow in deforming complex concentrated alloys: universal signatures of dislocation avalanches

Journal of Materials Science: Materials Theory (2024)

-

Rejuvenation as the origin of planar defects in the CrCoNi medium entropy alloy

Nature Communications (2024)

-

Harnessing instability for work hardening in multi-principal element alloys

Nature Materials (2024)

-

Combined effect of interstitial-substitutional elements on dislocation dynamics in nitrogen-added austenitic stainless steels

Scientific Reports (2024)

-

Anomalies in the short-range local environment and atomic diffusion in single crystalline equiatomic CrMnFeCoNi high-entropy alloy

Nano Research (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.