Abstract

Frictional processes entail the rupture1,2 of the ensemble of discrete contacts defining a frictional interface3,4. There are a variety of views on how best to describe the onset of dry frictional motion. These range from modelling friction with a single degree of freedom, a ‘friction coefficient’3,5, to theoretical treatments using dynamic fracture5,6,7,8 to account for spatial and temporal dynamics along the interface. We investigated the onset of dry frictional motion by performing simultaneous high-speed measurements of the real contact area and the strain fields in the region surrounding propagating rupture tips within the dry (nominally flat) rough interfaces formed by brittle polymer blocks. Here we show that the transition from ‘static’ to ‘dynamic’ friction is quantitatively described by classical singular solutions for the motion of a rapid shear crack5,9,10,11,12,13. We find that these singular solutions, originally derived to describe brittle fracture, are in excellent agreement with the experiments for slow propagation, whereas some significant discrepancies arise as the rupture velocity approaches the Rayleigh wave speed. In addition, the energy dissipated in the fracture of the contacts remains nearly constant throughout the entire range in which the rupture velocity is less than the Rayleigh wave speed, whereas the size of the dissipative zone undergoes a Lorentz-like contraction as the rupture velocity approaches the Rayleigh wave speed. This coupling between friction and fracture is critical to our fundamental understanding of frictional motion and related processes, such as earthquake dynamics.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Rubinstein, S. M., Cohen, G. & Fineberg, J. Detachment fronts and the onset of dynamic friction. Nature 430, 1005–1009 (2004)

Ben-David, O., Rubinstein, S. M. & Fineberg, J. Slip-stick and the evolution of frictional strength. Nature 463, 76–79 (2010)

Bowden, F. P. & Tabor, D. The Friction and Lubrication of Solids 2nd edn (Oxford Univ. Press, 2001)

Dieterich, J. H. & Kilgore, B. D. Imaging surface contacts: power law contact distributions and contact stresses in quartz, calcite, glass and acrylic plastic. Tectonophysics 256, 219–239 (1996)

Scholz, C. H. The Mechanics of Earthquakes and Faulting 2nd edn (Cambridge Univ. Press, 2002)

Brener, E. A. & Marchenko, V. I. Frictional shear cracks. JETP Lett. 76, 211–214 (2002)

Ben-Zion, Y. Collective behavior of earthquakes and faults: continuum-discrete transitions, progressive evolutionary changes, and different dynamic regimes. Rev. Geophys. 46, RG4006 (2008)

Johnson, K. L. Adhesion and friction between a smooth elastic spherical asperity and a plane surface. Proc. R. Soc. Lond. A 453, 163–179 (1997)

Fineberg, J. & Marder, M. Instability in dynamic fracture. Phys. Rep. 313, 1–108 (1999)

Freund, L. B. Dynamic Fracture Mechanics (Cambridge, 1990)

Palmer, A. C. & Rice, J. R. The growth of slip surfaces in the progressive failure of over-consolidated clay. Proc. R. Soc. Lond. A 332, 527–548 (1973)

Rice, J. R. in Physics of the Earth’s Interior (eds Dziewonski, A. M. & Boschi, E. ) 555–649 (Italian Physical Society and North-Holland, 1980)

Ida, Y. Cohesive force across tip of a longitudinal-shear crack and Griffiths specific surface energy. J. Geophys. Res. 77, 3796–3805 (1972)

Borcherdt, R. D., Johnston, M. J. S., Glassmoyer, G. & Dietel, C. Recordings of the 2004 Parkfield earthquake on the General Earthquake Observation System array: implications for earthquake precursors, fault rupture, and coseismic strain changes. Bull. Seismol. Soc. Am. 96, S73–S89 (2006)

Dunham, E. M. & Archuleta, R. J. Evidence for a supershear transient during the 2002 Denali fault earthquake. Bull. Seismol. Soc. Am. 94, S256–S268 (2004)

Okubo, P. G. & Dieterich, J. H. Effects of physical fault properties on frictional instabilities produced on simulated faults. J. Geophys. Res. 89, 5817–5827 (1984)

Ohnaka, M. The Physics of Rock Failure and Earthquakes (Cambridge Univ. Press, 2013)

Lykotrafitis, G., Rosakis, A. J. & Ravichandran, G. Self-healing pulse-like shear ruptures in the laboratory. Science 313, 1765–1768 (2006)

Ben-David, O., Cohen, G. & Fineberg, J. The dynamics of the onset of frictional slip. Science 330, 211–214 (2010)

Trømborg, J., Scheibert, J., Amundsen, D. S., Thogersen, K. & Malthe-Sorenssen, A. Transition from static to kinetic friction: insights from a 2D model. Phys. Rev. Lett. 107, 074301 (2011)

Kammer, D. S., Yastrebov, V. A., Spijker, P. & Molinari, J. F. On the propagation of slip fronts at frictional interfaces. Tribol. Lett. 48, 27–32 (2012)

Poliakov, A. N. B., Dmowska, R. & Rice, J. R. Dynamic shear rupture interactions with fault bends and off-axis secondary faulting. J. Geophys. Res. 107 (B11). 2295 (2002)

Nielsen, S., Taddeucci, J. & Vinciguerra, S. Experimental observation of stick-slip instability fronts. Geophys. J. Int. 180, 697–702 (2010)

Latour, S. et al. Ultrafast ultrasonic imaging of dynamic sliding friction in soft solids: the slow slip and the super-shear regimes. Europhys. Lett. 96, 59003 (2011)

Yamaguchi, T. et al. Gutenberg-Richter’s law in sliding friction of gels. J. Geophys. Res. 116, B12306 (2011)

Beroza, G. C. & Ide, S. Slow earthquakes and nonvolcanic tremor. Annu. Rev. Earth Planet. Sci. 39, 271–296 (2011)

Bar Sinai, Y., Brener, E. A. & Bouchbinder, E. Slow rupture of frictional interfaces. Geophys. Res. Lett. 39, L03308 (2012)

Kaproth, B. M. & Marone, C. Slow earthquakes, preseismic velocity changes, and the origin of slow frictional stick-slip. Science 341, 1229–1232 (2013)

Passelègue, F. X., Schubnel, A., Nielsen, S., Bhat, H. S. & Madariaga, R. From sub-Rayleigh to supershear ruptures during stick-slip experiments on crustal rocks. Science 340, 1208–1211 (2013)

Ben-David, O. & Fineberg, J. Static friction coefficient is not a material constant. Phys. Rev. Lett. 106, 254301 (2011)

Read, B. E. & Duncan, J. C. Measurement of dynamic properties of polymeric glasses for different modes of deformation. Polym. Test. 2, 135–150 (1981)

Rubinstein, S. M., Shay, M., Cohen, G. & Fineberg, J. Crack-like processes governing the onset of frictional slip. Int. J. Fract. 140, 201–212 (2006)

Rubinstein, S. M., Cohen, G. & Fineberg, J. Visualizing stick-slip: experimental observations of processes governing the nucleation of frictional sliding. J. Phys. D 42, 214016 (2009)

Gabriel, A. A., Ampuero, J. P., Dalguer, L. A. & Mai, P. M. Source properties of dynamic rupture pulses with off-fault plasticity. J. Geophys. Res. 118, 4117–4126 (2013)

Sharon, E., Gross, S. P. & Fineberg, J. Energy dissipation in dynamic fracture. Phys. Rev. Lett. 76, 2117–2120 (1996)

Acknowledgements

This work was supported by the James S. McDonnell Fund, the European Research Council (grant no. 267256) and the Israel Science Foundation (grant 76/11). We thank E. Bouchbinder and G. Cohen for comments. We especially thank M. Adda-Bedia for insights that helped us understand the data’s relation to LEFM.

Author information

Authors and Affiliations

Contributions

I.S. performed the measurements. Both authors contributed to the analysis and writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Extended data figures and tables

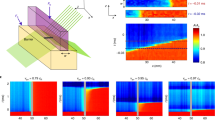

Extended Data Figure 1 Experimental techniques.

a, A method based on total internal reflection measures instantaneous changes in the real contact area, A(x,t), along the entire interface. A sheet of light incident on the frictional interface is totally reflected everywhere except at contact points. Top block, pink; bottom block, blue. b, Geometry and dimensions (in mm) of a single rosette strain gauge. The black rectangles represent the active area of the measuring components, ε1, ε2 and ε3. Yellow arrows represent the direction of the measured strains. c, By placing a reflective displacement sensor at the edge of a reflecting film (left), the change in the reflected signal is a monotonic function of the displacement of the film. The reflecting area was calibrated to obtain high resolution measurements of the motion of the strip edge in the x direction (right). a–c, Measurements described above were acquired continuously. A sensitive acoustic sensor, mounted on the top block, triggered storage of all data bracketing every slip event.

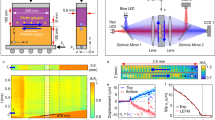

Extended Data Figure 2 Comparing different techniques for measuring  .

.

In several experiments, direct displacement measurements were performed slightly below the strain gauge. The numerical time derivative of the corresponding signal is presented in blue. We reconstruct  by an alternative method (green) that is based on measuring Cf, Δεxx and the assumptions presented in the text. a, b, Comparisons of

by an alternative method (green) that is based on measuring Cf, Δεxx and the assumptions presented in the text. a, b, Comparisons of  by using both methods for two typical examples at Cf = 0.3CR (a) and Cf = 0.9CR (b) show good agreement between the measurements. x axes are the times relative to the time, ttip, when the rupture fronts passed each measurement location.

by using both methods for two typical examples at Cf = 0.3CR (a) and Cf = 0.9CR (b) show good agreement between the measurements. x axes are the times relative to the time, ttip, when the rupture fronts passed each measurement location.

Extended Data Figure 3 LEFM solution for plane strain and plane stress boundary conditions.

a, b, Strain measurements of slow (a) and rapid (b) ruptures as presented in Fig. 2b. The top (bottom) panels are the strain components εxx (εyy ) relative to their initial values immediately prior to rupture. The data presented are coloured as noted in the keys in the upper panel of a and b. The solution for plane strain boundary conditions is shown in black. The solution for plane stress boundary conditions is shown in yellow. We see that plane strain conditions, as might be enforced by frictional pinning at the interface, provide a better fit to the data.

Extended Data Figure 4 Comparing LEFM to linear cohesive zone model predictions.

Strain measurements of a slow rupture as presented in Fig. 2a. Top, the strain component εxy , relative to the residual strain after the rupture passage. The centre (bottom) panels are the strain components εxx (εyy ) relative to their initial values immediately prior to rupture. The data presented are coloured as noted in the key in the upper panel. Black solid line, the universal LEFM solution at 3.5 mm above the interface. Yellow dashed line, prediction of LEFM coupled to a linear slip weakening model11,22 for Xc = 2.5 mm and using the same value of Γ as used in the LEFM solution 3.5 mm above the interface. In the slow rupture regime, for h/Xc ≈ 1 (h is distance of the strain gauge above the interface) linear slip weakening model is indistinguishable from the singular LEFM solution.

Extended Data Figure 5 Contributions of higher-order terms to LEFM.

Strain measurements of a rapid rupture as presented in Fig. 2b. Top, the strain component εxy , relative to the residual strain after the rupture passage. The centre (bottom) panels are the strain components εxx (εyy ) relative to their initial values immediately prior to rupture. The data presented are for three different measurements in which Cf = 0.96CR. The key in the upper panel denotes the terms that were considered for each coloured line. No value of the r1/2 (C1) and r3/2 (C3) coefficients could both resolve the discrepancy in Δεxy and reasonably fit Δεyy and Δεxx.

Rights and permissions

About this article

Cite this article

Svetlizky, I., Fineberg, J. Classical shear cracks drive the onset of dry frictional motion. Nature 509, 205–208 (2014). https://doi.org/10.1038/nature13202

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature13202

This article is cited by

-

Control of Static Friction by Designing Grooves on Friction Surface

Tribology Letters (2024)

-

Analytical simulation of mode I fracture generation from dynamic frictional surfaces governed by slip weakening model

Environmental Earth Sciences (2024)

-

Laboratory earthquakes decipher control and stability of rupture speeds

Nature Communications (2023)

-

Static friction coefficient depends on the external pressure and block shape due to precursor slip

Scientific Reports (2023)

-

How frictional slip evolves

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

.

.