Abstract

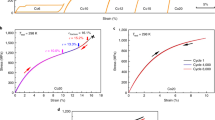

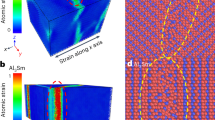

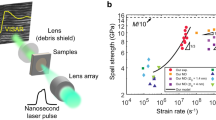

Strain-stiffening—an increase in material stiffness at large strains—is a vital mechanism by which many soft biological materials thwart excessive deformation to protect tissue integrity1,2,3. Understanding the fundamental science of strain-stiffening and incorporating this concept into the design of metals and ceramics for advanced applications is an attractive prospect. Using cementite (Fe3C) and aluminium borocarbide (Al3BC3) as prototypes, here we show via quantum-mechanical calculations that strain-stiffening also occurs, surprisingly, in simple inorganic crystalline solids and confers exceptionally high strengths to these two solids, which have anomalously low resistance to deformation near equilibrium. For Fe3C and Al3BC3, their ideal shear strength to shear modulus ratios attain remarkably high values of 1.14 and 1.34 along the (010)[001] and  slip systems, respectively. These values are more than seven times larger than the original Frenkel value of 1/2π (refs 4, 5) and are the highest yet reported for crystalline solids. The extraordinary stiffening of Fe3C arises from the strain-induced reversible ‘cross-linking’ between weakly coupled edge- and corner-sharing Fe6C slabs. This new bond formation creates a strong, three-dimensional covalent bond network that resists large shear deformation. Unlike Fe3C, no new bond forms in Al3BC3 but stiffening still occurs because strong repulsion between Al and B in a compressed Al–B bond unsettles the existing covalent bond network. These discoveries challenge the conventional wisdom that large shear modulus is a reliable predictor of hardness and strength of materials4,5,6,7, and provide new lessons for materials selection and design.

slip systems, respectively. These values are more than seven times larger than the original Frenkel value of 1/2π (refs 4, 5) and are the highest yet reported for crystalline solids. The extraordinary stiffening of Fe3C arises from the strain-induced reversible ‘cross-linking’ between weakly coupled edge- and corner-sharing Fe6C slabs. This new bond formation creates a strong, three-dimensional covalent bond network that resists large shear deformation. Unlike Fe3C, no new bond forms in Al3BC3 but stiffening still occurs because strong repulsion between Al and B in a compressed Al–B bond unsettles the existing covalent bond network. These discoveries challenge the conventional wisdom that large shear modulus is a reliable predictor of hardness and strength of materials4,5,6,7, and provide new lessons for materials selection and design.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Storm, C., Pastore, J. J., Mackintosh, F. C., Lubensky, T. C. & Janmey, P. A. Nonlinear elasticity in biological gels. Nature 435, 191–194 (2005)

Shadwick, R. E. Mechanical design in arteries. J. Exp. Biol. 202, 3305–3313 (1999)

Meyers, M. & Chawla, K. Mechanical Behavior of Materials Ch. 2 (Cambridge Univ. Press, 2008)

Frenkel, J. Zur theorie der elastizitätsgrenze und der festigkeit kristallinischer körper. Z. Phys. 37, 572–609 (1926)

Kelly, A. Strong Solids Ch. 1 (Clarendon Press, 1973)

Teter, D. M. Computational alchemy: the search for new superhard materials. Mater. Res. Bull. 23, 22–27 (1998)

Jhi, S. H., Ihm, J., Louie, S. G. & Cohen, M. L. Electronic mechanism of hardness enhancement in transition-metal carbonitrides. Nature 399, 132–134 (1999)

Wood, B. J. Carbon in the core. Earth Planet. Sci. Lett. 117, 593–607 (1993)

Jiang, C., Srinivasan, S. G., Caro, A. & Maloy, S. A. Structural, elastic, and electronic properties of Fe3C from first principles. J. Appl. Phys. 103, 043502 (2008)

Wang, H. & Li, M. Ab initio calculations of second-, third-, and fourth-order elastic constants for single crystals. Phys. Rev. B 79, 224102 (2009)

Nikolussi, N. et al. Extreme elastic anisotropy of cementite, Fe3C: first-principles calculations and experimental evidence. Scr. Mater. 59, 814–817 (2008)

Fang, C. M., Sluiter, M. H. F., van Huis, M. A., Ande, C. K. & Zandbergen, H. W. Origin of predominance of cementite among iron carbides in steel at elevated temperature. Phys. Rev. Lett. 105, 055503 (2010)

Umemoto, M., Liu, Z. G., Masuyama, K. & Tsuchiy, K. Influence of alloy additions on production and properties of bulk cementite. Scr. Mater. 45, 391–397 (2001)

Alkorta, J. & Sevillano, J. G. Assessment of elastic anisotropy and incipient plasticity in Fe3C by nanoindentation. J. Mater. Res. 27, 45–52 (2012)

Legut, D., Friak, M. & Sob, M. Phase stability, elasticity, and theoretical strength of polonium from first principles. Phys. Rev. B 81, 214118 (2010)

Grimvall, G., Magyari-Kope, B., Ozolins, V. & Persson, K. A. Lattice instabilities in metallic elements. Rev. Mod. Phys. 84, 945–986 (2012)

Roundy, D., Krenn, C. R., Cohen, M. L. & Morris, J. W. Ideal shear strengths of fcc aluminum and copper. Phys. Rev. Lett. 82, 2713–2716 (1999)

Telling, R. H., Pickard, C. J., Payne, M. C. & Field, J. E. Theoretical strength and cleavage of diamond. Phys. Rev. Lett. 84, 5160–5163 (2000)

Chacham, H. & Kleinman, L. Instabilities in diamond under high shear stress. Phys. Rev. Lett. 85, 4904–4907 (2000)

Jhi, S. H., Louie, S. G., Cohen, M. L. & Morris, J. W. Mechanical instability and ideal shear strength of transition metal carbides and nitrides. Phys. Rev. Lett. 87, 075503 (2001)

Ogata, S., Li, J. & Yip, S. Ideal pure shear strength of aluminum and copper. Science 298, 807–811 (2002)

Zhao, H. E. & Suo, Z. G. Theory of dielectric elastomers capable of giant deformation of actuation. Phys. Rev. Lett. 104, 178302 (2010)

Šob, M., Wang, L. G. & Vitek, V. Theoretical tensile stress in tungsten single crystals by full-potential first-principles calculations. Mater. Sci. Eng. A 234–236, 1075–1078 (1997)

Krenn, C. R., Roundy, D., Cohen, M. L., Chrzan, D. C. & Morris, J. W. Connecting atomistic and experimental estimates of ideal strength. Phys. Rev. B 65, 134111 (2002)

Minor, A. M. et al. A new view of the onset of plasticity during the nanoindentation of aluminium. Nature Mater. 5, 697–702 (2006)

Lee, S. H. et al. Chemical composition and microstructure of Al3BC3 prepared by different densification methods. J. Eur. Ceram. Soc. 30, 1015–1020 (2010)

Wang, J. Y., Zhou, Y. C., Liao, T. & Lin, Z. J. First-principles prediction of low shear-strain resistance of Al3BC3: a metal borocarbide containing short linear BC2 units. Appl. Phys. Lett. 89, 021917 (2006)

Teter, D. M. & Hemley, R. J. Low-compressibility carbon nitrides. Science 271, 53–55 (1996)

Dubrovinsky, L. S. et al. The hardest known oxide. Nature 410, 653–654 (2001)

Kaner, R. B., Gilman, J. & Tolbert, S. H. Designing superhard materials. Science 308, 1268–1269 (2005)

Acknowledgements

C.J. acknowledges the support of a Director’s Fellowship at Los Alamos National Laboratory (LANL), where a systematic study of cementite was conceived and initiated. S.G.S. acknowledges support from the National Science Foundation (grant number 0846444). We also thank J. Wills, M. I. Baskes, A. Caro, A. Misra, S. Maloy, A. Srivastava, V. Vitek and S. Ranganathan for their discussions.

Author information

Authors and Affiliations

Contributions

C.J. and S.G.S. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

This file contains Supplementary Methods, a Supplementary Discussion, Supplementary References and Supplementary Figures 1-3. (PDF 1554 kb)

Rights and permissions

About this article

Cite this article

Jiang, C., Srinivasan, S. Unexpected strain-stiffening in crystalline solids. Nature 496, 339–342 (2013). https://doi.org/10.1038/nature12008

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature12008

This article is cited by

-

Unconventional mechanical and thermal behaviours of MOF CALF-20

Nature Communications (2024)

-

Ultimate mechanical properties of enstatite

Physics and Chemistry of Minerals (2022)

-

Tension–compression asymmetry in amorphous silicon

Nature Materials (2021)

-

Interface dominated cooperative nanoprecipitation in interstitial alloys

Nature Communications (2018)

-

Ductile deformation mechanism in semiconductor α-Ag2S

npj Computational Materials (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.