Abstract

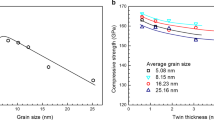

Cubic boron nitride (cBN) is a well known superhard material that has a wide range of industrial applications. Nanostructuring of cBN is an effective way to improve its hardness by virtue of the Hall–Petch effect—the tendency for hardness to increase with decreasing grain size1,2. Polycrystalline cBN materials are often synthesized by using the martensitic transformation of a graphite-like BN precursor, in which high pressures and temperatures lead to puckering of the BN layers3. Such approaches have led to synthetic polycrystalline cBN having grain sizes as small as ∼14 nm (refs 1, 2, 4, 5). Here we report the formation of cBN with a nanostructure dominated by fine twin domains of average thickness ∼3.8 nm. This nanotwinned cBN was synthesized from specially prepared BN precursor nanoparticles possessing onion-like nested structures with intrinsically puckered BN layers and numerous stacking faults. The resulting nanotwinned cBN bulk samples are optically transparent with a striking combination of physical properties: an extremely high Vickers hardness (exceeding 100 GPa, the optimal hardness of synthetic diamond), a high oxidization temperature (∼1,294 °C) and a large fracture toughness (>12 MPa m1/2, well beyond the toughness of commercial cemented tungsten carbide, ∼10 MPa m1/2). We show that hardening of cBN is continuous with decreasing twin thickness down to the smallest sizes investigated, contrasting with the expected reverse Hall–Petch effect below a critical grain size or the twin thickness of ∼10–15 nm found in metals and alloys.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Dubrovinskaia, N. et al. Superhard nanocomposite of dense polymorphs of boron nitride: noncarbon material has reached diamond hardness. Appl. Phys. Lett. 90, 101912 (2007)

Solozhenko, V. L., Kurakevych, O. O. & Le Godec, Y. Creation of nanostuctures by extreme conditions: high-pressure synthesis of ultrahard nanocrystalline cubic boron nitride. Adv. Mater. 24, 1540–1544 (2012)

Britun, V. F. & Kurdyumov, A. V. Mechanisms of martensitic transformations in boron nitride and conditions of their development. High Press. Res. 17, 101–111 (2000)

Sumiya, H., Uesaka, S. & Satoh, S. Mechanical properties of high purity polycrystalline cBN synthesized by direct conversion sintering method. J. Mater. Sci. 35, 1181–1186 (2000)

Dub, S. N. & Petrusha, I. A. Mechanical properties of polycrystalline cBN obtained from pyrolytic gBN by direct transformation technique. High Press. Res. 26, 71–77 (2006)

Wentorf, R. H., DeVries, R. C. & Bundy, F. P. Sintered superhard materials. Science 208, 873–880 (1980)

Liew, W. Y. H., Yuan, S. & Ngoi, B. K. A. Evaluation of machining performance of STAVAX with PCBN tools. Int. J. Adv. Manuf. Technol. 23, 11–19 (2004)

Krauss, A. R. et al. Ultrananocrystalline diamond thin films for MEMS and moving mechanical assembly devices. Diamond Related Materials 10, 1952–1961 (2001)

Hall, E. O. The deformation and ageing of mild steel: III. Discussion of results. Proc. Phys. Soc. B 64, 747–753 (1951)

Petch, N. J. The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25–28 (1953)

Irifune, T., Kurio, A., Sakamoto, S., Inoue, T. & Sumiya, H. Ultrahard polycrystalline diamond from graphite. Nature 421, 599–600 (2003)

Sumiya, H. & Irifune, T. Hardness and deformation microstructures of nano-polycrystalline diamonds synthesized from various carbons under high pressure and high temperature. J. Mater. Res. 22, 2345–2351 (2007)

Schiøtz, J., Di Tolla, F. D. & Jacobsen, K. W. Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561–563 (1998)

Schiøtz, J. & Jacobsen, K. W. A maximum in the strength of nanocrystalline copper. Science 301, 1357–1359 (2003)

Lu, L., Chen, X., Huang, X. & Lu, K. Revealing the maximum strength in nanotwinned copper. Science 323, 607–610 (2009)

Pande, C. S. & Cooper, K. P. Nanomechanics of Hall–Petch relationship in nanocrystalline materials. Prog. Mater. Sci. 54, 689–706 (2009)

He, L. L., Akaishi, M. & Horiuchi, S. Structural evolution in boron nitrides during the hexagonal–cubic phase transition under high pressure at high temperature. Microsc. Res. Tech. 40, 243–250 (1998)

Oku, T., Hiraga, K., Matsuda, T., Hirai, T. & Hirabayashi, M. Twin structures of rhombohedral and cubic boron nitride prepared by chemical vapor deposition method. Diamond Related Materials 12, 1138–1145 (2003)

Brazhkin, V. et al. What does ‘harder than diamond’ mean? Nature Mater. 3, 576–577 (2004)

Tian, Y., Xu, B. & Zhao, Z. Microscopic theory of hardness and design of novel superhard crystals. Int. J. Refract. Met. Hard Mater. 33, 93–106 (2012)

Harris, T. K., Brookes, E. J. & Taylor, C. J. The effect of temperature on the hardness of polycrystalline cubic boron nitride cutting tool materials. Int. J. Refract. Met. Hard Mater. 22, 105–110 (2004)

Solozhenko, V. L., Dub, S. N. & Novikov, N. V. Mechanical properties of cubic BC2N, a new superhard phase. Diamond Related Materials 10, 2228–2231 (2001)

Berger, C., Scheerer, H. & Ellermeier, J. Modern materials for forming and cutting tools—overview. Materialwiss. Werkstofftech. 41, 5–17 (2010)

Tse, J. S., Klug, D. D. & Gao, F. M. Hardness of nanocrystalline diamonds. Phys. Rev. B 73, 140102 (2006)

Gao, F. M. et al. Hardness of covalent crystals. Phys. Rev. Lett. 91, 015502 (2003)

Li, X., Wei, Y., Lu, L., Lu, K. & Gao, H. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 464, 877–880 (2010)

Oleinik, G. S., Petrusha, I. A., Danilenko, N. V., Kotko, A. V. & Shevchenko, S. A. Crystal-oriented mechanism of dynamic recrystallization nucleation in cubic boron nitride. Diamond Related Materials 7, 1684–1692 (1998)

Tang, C. C., Bando, Y., Huang, Y., Zhi, C. Y. & Golberg, D. Synthetic routes and formation mechanisms of spherical boron nitride nanoparticles. Adv. Funct. Mater. 18, 3653–3661 (2008)

Wang, Y. et al. The large-volume high-pressure facility at GSECARS: a ‘Swiss-army-knife’ approach to synchrotron-based experimental studies. Phys. Earth Planet. Inter. 174, 270–281 (2009)

Leinenweber, K. D. et al. Cell assemblies for reproducible multi-anvil experiments (the COMPRES assemblies). Am. Mineral. 97, 353–368 (2012)

Acknowledgements

We thank J. K. Yu for help with the differential scanning calorimetry measurements. Y.J.T. and Z.Y.L. acknowledge financial support from the Ministry of Science and Technology of China (grants 2011CB808205 and 2010CB731605), Y.J.T., D.L.Y., Y.M.M. and J.L.H. are grateful for financial support from the National Natural Science Foundation of China (grants 51121061, 51172197, 11025418 and 91022029), and Y.B.W. acknowledges financial support from the US National Science Foundation (EAR-0968456).

Author information

Authors and Affiliations

Contributions

Y.J.T. conceived the project. Y.J.T., B.X., D.L.Y. and Y.B.W. designed the experiments. C.C.T. synthesized oBN precursors, Y.J.T., B.X., D.L.Y., Y.B.W., Y.F.G., K.L. and Z.S.Z. performed the HPHT experiments, Y.B.J. and W.T.H. performed TEM observations, and B.W. performed molecular dynamics simulations. Y.J.T., B.X., D.L.Y., Y.M.M., Y.B.W., L.-M.W., J.L.H. and Z.Y.L. analysed the data. Y.J.T., B.X., Y.M.M. and Y.B.W. co-wrote the paper. Y.J.T., B.X. and D.L.Y. contributed equally to the study. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

This file contains Supplementary Figures 1-4, Supplementary Table 1 and additional references. (PDF 615 kb)

Rights and permissions

About this article

Cite this article

Tian, Y., Xu, B., Yu, D. et al. Ultrahard nanotwinned cubic boron nitride. Nature 493, 385–388 (2013). https://doi.org/10.1038/nature11728

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature11728

This article is cited by

-

Twisted-layer boron nitride ceramic with high deformability and strength

Nature (2024)

-

Structural, electronic, and optical properties of three types Ca3N2 from first-principles study

Journal of Molecular Modeling (2024)

-

Atomic stiffness for bulk modulus prediction and high-throughput screening of ultraincompressible crystals

Nature Communications (2023)

-

Wear and Corrosion Resistance of TiN/PEEK Composite Coatings Fabricated by Gas Twin-Tunnel Plasma Spraying

Journal of Thermal Spray Technology (2023)

-

Structure-Property Correlation of a Newly Synthesized 6351Al/Body-Centered Tetragonal Boron Nitride Composite

Journal of Materials Engineering and Performance (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.