Abstract

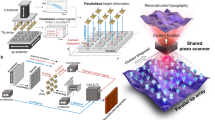

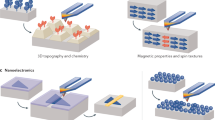

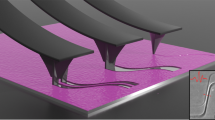

Nanofabrication strategies are becoming increasingly expensive and equipment-intensive, and consequently less accessible to researchers. As an alternative, scanning probe lithography has become a popular means of preparing nanoscale structures, in part owing to its relatively low cost and high resolution, and a registration accuracy that exceeds most existing technologies1,2,3,4,5,6. However, increasing the throughput of cantilever-based scanning probe systems while maintaining their resolution and registration advantages has from the outset been a significant challenge7,8,9,10,11,12,13,14,15,16,17. Even with impressive recent advances in cantilever array design, such arrays tend to be highly specialized for a given application, expensive, and often difficult to implement. It is therefore difficult to imagine commercially viable production methods based on scanning probe systems that rely on conventional cantilevers. Here we describe a low-cost and scalable cantilever-free tip-based nanopatterning method that uses an array of hard silicon tips mounted onto an elastomeric backing. This method—which we term hard-tip, soft-spring lithography—overcomes the throughput problems of cantilever-based scanning probe systems and the resolution limits imposed by the use of elastomeric stamps and tips: it is capable of delivering materials or energy to a surface to create arbitrary patterns of features with sub-50-nm resolution over centimetre-scale areas. We argue that hard-tip, soft-spring lithography is a versatile nanolithography strategy that should be widely adopted by academic and industrial researchers for rapid prototyping applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Braunschweig, A. B., Huo, F. & Mirkin, C. A. Molecular printing. Nature Chem. 1, 353–358 (2009)

Salaita, K., Wang, Y. & Mirkin, C. A. Applications of dip-pen nanolithography. Nature Nanotechnol. 2, 145–155 (2007)

Quate, C. F. Scanning probes as a lithography tool for nanostructures. Surf. Sci. 386, 259–264 (1997)

Tseng, A. A., Notargiacomo, A. & Chen, T. P. Nanofabrication by scanning probe microscope lithography: A review. J. Vac. Sci. Technol. B 23, 877–894 (2005)

Rosa, L. G. & Liang, J. Atomic force microscope nanolithography: dip-pen nanoshaving, nanografting, tapping mode, electrochemical and thermal nanolithography. J. Phys. Condens. Matter 21, 483001 (2009)

Saavedra, H. M. et al. Hybrid strategies in nanolithography. Rep. Prog. Phys. 73, 036501 (2010)

Bullen, D. et al. Parallel dip-pen nanolithography with arrays of individually addressable cantilevers. Appl. Phys. Lett. 84, 789–791 (2004)

Salaita, K. et al. Massively parallel dip-pen nanolithography with 55000-pen two-dimensional arrays. Angew. Chem. Int. Edn 45, 7220–7223 (2006)

Vettiger, P. et al. Ultrahigh density, high-data-rate NEMS-based AFM data storage system. Microelectron. Eng. 46, 11–17 (1999)

Vettiger, P. et al. The ‘Millipede’—more than one thousand tips for future AFM data storage. IBM J. Res. Dev. 44, 323–340 (2000)

Hong, S. H. & Mirkin, C. A. A nanoplotter with both parallel and serial writing capabilities. Science 288, 1808–1811 (2000)

Zhang, M. et al. MEMS nanoplotter with high-density parallel dip-pen nanolithography probe arrays. Nanotechnology 13, 212–217 (2002)

Salaita, K. et al. Sub-100 nm, centimeter-scale, parallel dip-pen nanolithography. Small 1, 940–945 (2005)

Lenhert, S., Sun, P., Wang, Y. H., Fuchs, H. & Mirkin, C. A. Massively parallel dip-pen nanolithography of heterogeneous supported phospholipid multilayer patterns. Small 3, 71–75 (2007)

Mirkin, C. A. The power of the pen: development of massively parallel dip-pen nanolithography. ACS Nano 1, 79–83 (2007)

Eigler, D. M. & Schweizer, E. K. Positioning single atoms with a scanning tunneling microscope. Nature 344, 524–526 (1990)

Leung, O. M. & Goh, M. C. Orientational ordering of polymer by atomic force microscope tip-surface interaction. Science 255, 64–66 (1992)

Xia, Y. & Whitesides, G. M. Soft lithography. Angew. Chem. Int. Edn 37, 550–575 (1998)

Gates, B. D. et al. New approaches to nanofabrication: molding, printing, and other techniques. Chem. Rev. 105, 1171–1196 (2005)

Ginger, D. S., Zhang, H. & Mirkin, C. A. The evolution of dip-pen nanolithography. Angew. Chem. Int. Edn 43, 30–45 (2004)

Kumar, A. & Whitesides, G. M. Features of gold having micrometer to centimeter dimensions can be formed through a combination of stamping with an elastomeric stamp and an alkanethiol “ink” followed by chemical etching. Appl. Phys. Lett. 63, 2002–2004 (1993)

Zheng, Z., Jang, J.-W., Zheng, G. & Mirkin, C. A. Topographically flat, chemically patterned PDMS stamps made by dip-pen nanolithography. Angew. Chem. Int. Edn 47, 9951–9954 (2008)

Piner, R. D., Zhu, J., Xu, F., Hong, S. H. & Mirkin, C. A. “Dip-pen” nanolithography. Science 283, 661–663 (1999)

Hong, S. H., Zhu, J. & Mirkin, C. A. Multiple ink nanolithography: toward a multiple-pen nano-plotter. Science 286, 523–525 (1999)

Huo, F. et al. Polymer pen lithography. Science 321, 1658–1660 (2008)

Liao, X., Braunschweig, A. B. & Mirkin, C. A. “Force-feedback” leveling of massively parallel arrays in polymer pen lithography. Nano Lett. 10, 1335–1340 (2010)

Liu, J., Betzner, T. M. & Henderson, H. T. Etching of self-sharpening {338} tips in (100) silicon. J. Micromech. Microeng. 5, 18–24 (1995)

Yun, M. H., Burrows, V. A. & Kozicki, M. N. Analysis of KOH etching of (100) silicon on insulator for the fabrication of nanoscale tips. J. Vac. Sci. Technol. B 16, 2844–2848 (1998)

Jang, J., Maspoch, D., Fujigaya, T. & Mirkin, C. A. A. “Molecular eraser” for dip-pen nanolithography. Small 3, 600–605 (2007)

Nie, Z. & Kumacheva, E. Patterning surfaces with functional polymers. Nature Mater. 7, 277–290 (2008)

Acknowledgements

C.A.M. acknowledges the US Air Force Office of Scientific Research (AFOSR), the US Defense Advanced Research Projects Agency (DARPA) and the US NSF (NSEC program) for support of this research. C.A.M is grateful for a NSSEF Fellowship from the US Department of Defense. A.B.B is grateful for a NRSA fellowship from the US NIH. We thank Z. Zheng for discussions.

Author information

Authors and Affiliations

Contributions

W.S. and C.A.M designed all experiments. W.S., A.B.B. and C.A.M contributed to this work in analysing results and drafting the manuscript. W.S., A.B.B., X.L., J.C., J.K.L. and G.Z. also performed experiments and helped with revisions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Figures

The file contains Supplementary Figures 1-9 with legends. (PDF 2706 kb)

Supplementary Movie 1

The movie shows the Si tip array alignment procedure. (MOV 7938 kb)

Supplementary Movie 2

The movie shows the resiliency of the tip architecture. (MOV 3500 kb)

Rights and permissions

About this article

Cite this article

Shim, W., Braunschweig, A., Liao, X. et al. Hard-tip, soft-spring lithography. Nature 469, 516–520 (2011). https://doi.org/10.1038/nature09697

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature09697

This article is cited by

-

Metal-organic framework template-guided electrochemical lithography on substrates for SERS sensing applications

Nature Communications (2023)

-

Binary-state scanning probe microscopy for parallel imaging

Nature Communications (2022)

-

Massively parallel cantilever-free atomic force microscopy

Nature Communications (2021)

-

Printing High-resolution Micro-patterns by Solution Processes

Chemical Research in Chinese Universities (2021)

-

Dip-Pen Nanolithography(DPN): from Micro/Nano-patterns to Biosensing

Chemical Research in Chinese Universities (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.