Small temperature changes can affect the packing of granular materials without mechanical disturbance.

Abstract

A long-standing problem in managing the behaviour of a collection of solid grains concerns the nature of the grain packing1, a property that is typically controlled by how the grains are poured or shaken. Here we show that a systematic and controllable increase in granular packing can be induced by simply raising and then lowering the temperature, without the input of mechanical energy. This thermal processing may have important practical implications for the handling and storage of granular materials.

Similar content being viewed by others

Main

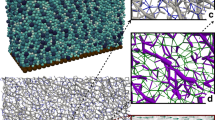

The packing fraction of a granular material is defined as the fraction of sample volume that is filled by grains rather than by empty space, and typically varies between 57% and 64% for randomly arranged, spherical grains and even more widely for other grain shapes. The density of packing can be increased by vibration or tapping, which induce small rearrangements that allow the grains to settle2,3,4.

When a granular material is heated, the grains and their container both undergo thermal expansion. This can lead to settling because of the metastable nature of disordered grain configurations (especially if the grains and their container are made of different materials), and such settling should not be reversible upon cooling to ambient temperature. It has been shown that temperature changes affect silos in industrial settings5,6 and the stress state of a granular pile7,8. But the grain dynamics induced by thermal cycling have not been analysed until now.

We examined the change in packing fraction for glass spheres contained in vertical plastic cylinders in response to thermal cycling (using both single thermal cycles from room temperature and repeated cycles over the same temperature range; for methods, see supplementary information). We found that there was a clear increase in packing even for a single cycle to 10 °C above ambient room temperature (Fig. 1a). The results were not affected by the height to which the cylinders were filled (to within ±10%), the heating rate, or the time spent at the cycle temperature after thermal equilibrium was reached. They changed only slightly (<20%) if the cylinder diameter was changed by an order of magnitude (Fig. 1b). This latter result is physically sensible, because the expansion of the grains and of the container scales with the size of the sample.

a,b, Change in packing fraction as a, a function of cycle temperature from room temperature for a single cycle (cylinder diameter, 60.6 mm) and, b, a function of cylinder diameter for a single cycle (cycle temperature, 107±2 °C). c, Change in packing fraction after multiple thermal cycles (cycle temperatures: red, 107±2 °C; blue, 41±1 °C). Lines represent fits of the data to a double-relaxation model (ref. 9; for details, see supplementary information). Error bars represent the standard deviationdetermined from several repeated measurements (a,b, 12 or more measurements; c, 6 measurements).

The packing fraction continues to increase over multiple thermal cycles (Fig. 1c). The increase can be described by a double-exponential density-relaxation model, consistent with a combination of large-scale (relaxation of granular blocks) and small-scale (relaxation of individual particles) rearrangements (for details of the model and fits to the data, see supplementary information)9. Although the limited range of the experimental data restricts thorough testing of this double-relaxation model, the 'time constants' of the two different relaxation times observed for each cycle temperature do increase with decreasing cycle temperature — consistent with smaller thermal expansion, as more cycles are needed to achieve the same change in packing fraction at a lower cycle temperature.

The primary cause of the changes in packing fraction noted here is probably the difference between the thermal expansion of the container and of the grains. This explanation is confirmed by our observation (results not shown) of similar changes in packing of plastic spheres in glass cylinders (where the grains expand more than the container), and of smaller changes in packing for glass spheres contained in glass cylinders.

Our results indicate that there may be many thermal effects in granular media, analogous to the effects of vibration. For example, a geophysical form of granular segregation ('stone heave') has been associated with thermal effects10. Temperature changes can also cause granular pressure to increase in outdoor silos with each diurnal cycle — potentially leading to catastrophic failure of the silo6. Our results demonstrate that thermal cycling can provide an almost 'adiabatic' alternative to mechanical agitation for altering grain packing.

References

Donev, A. et al. Science 303, 990–993 (2004).

Nowak, E. R., Knight, J. B., Ben-Naim, E., Jaeger, H. M. & Nagel, S. R. Phys. Rev. E 57, 1971–1982 (1998).

Philippe, P. & Bideau, D. Europhys. Lett. 60, 677–683 (2002).

Richard, P., Nicodemi, M., Delannay, R., Ribière, P. & Bideau, D. Nature Mater. 4, 121–128 (2005).

Blight, G. E. Int. J. Bulk Solids Storage 1, 1–7 (1985).

Flow of Solids 1–2 (Fall, 2001); http://www.jenike.com/pages/education/cases/pdf_docs/02jjcase.pdf

Liu, C. H. Phys. Rev. B 50, 782–794 (1994).

Puri, V. M., Zhang, Q. & Manbeck, H. B. Int. J. Bulk Solids Storage 2, 1–7 (1986).

Barker, G. C. & Mehta, A. Phys. Rev. E 47, 184–188 (1993).

Viklander, P. Cold Region Sci. Technol. 27, 141–152 (1997).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

About this article

Cite this article

Chen, K., Cole, J., Conger, C. et al. Packing grains by thermal cycling. Nature 442, 257 (2006). https://doi.org/10.1038/442257a

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/442257a

This article is cited by

-

Thermal shakedown in granular materials with irregular particle shapes

Scientific Reports (2024)

-

Thermal effects on the shear behaviour of saturated coarse-grained soils with reference to post-earthquake deposits

Acta Geophysica (2024)

-

Peering into lunar permanently shadowed regions with deep learning

Nature Communications (2021)

-

Finite element analyses of rate-dependent thermo-hydro-mechanical behaviors of clayey soils based on thermodynamics

Acta Geotechnica (2021)

-

Thermal cycling effects on the structure and physical properties of granular materials

Granular Matter (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.