Abstract

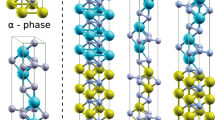

Ceramics based on Si3N4 have been comprehensively studied and are widely used in structural applications1,2. The development of an interlocking microstructure of elongated grains is vital to ensure that this family of ceramics have good damage tolerance3,4. Until now this has been accomplished by heating the appropriate powder compacts to temperatures above 1,700 °C for extended periods. This procedure involves a necessary step of controlling the size and population of seeds—added ex situ or formed in situ—to ensure selective grain growth5,6. Here we report the very fast (within minutes) in situ formation of a tough interlocking microstructure in Si3N4-based ceramics. The microstructures are obtained by a dynamic ripening mechanism, an anisotropic Ostwald ripening process that results from the rapid heating rate. The resulting microstructures are uniform and reproducible in terms of grain size distribution and mechanical properties, and are easily tailored by manipulating the kinetics. This process is very efficient and opens up new possibilities to optimize mechanical properties and cost-effectively manufacture ceramics.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Jack, K. H. in Proc. 6th Int. Symp. on Ceramic Materials and Components for Engines (ed. Niihara, K.) 203–207 (Japan Fine Ceramics Association, Tokyo, 1997)

Thompson, D. P. Tough cookery. Nature 389, 675–677 (1997)

Lange, F. F. Relations between strength, fracture energy, and microstructure of hot pressed Si3N4 . J. Am. Ceram. Soc. 56, 518–522 (1973)

Tani, E., Umebayashi, S., Kishi, K. & Kobayashi, K. Gas-pressure sintering of Si3N4 with concurrent addition of Al2O3 and 5wt% rare-earth oxide: high fracture toughness Si3N4 with fiber-like structure. Am. Ceram. Soc. Bull. 65, 1311–1315 (1986)

Chen, I.-W. & Rosenflanz, A. A tough SiAlON ceramic based on α-Si3N4 with a whisker-like microstructure. Nature 389, 701–704 (1997)

Kim, J., Rosenflanz, A. & Chen, I.-W. Microstructure control of in-situ-toughened α-SiAlON ceramics. J. Am. Ceram. Soc. 83, 1819–1821 (2000)

Hirao, K., Nagaoka, T., Brito, M. E. & Kanzaki, S. Microstructural control of silicon nitride by seeding with rodlike β-silicon nitride particles. J. Am. Ceram. Soc. 77, 1857–1862 (1994)

Mitomo, M. in Proc. 6th Int. Symp. on Ceramic Materials and Components for Engines (ed. Niihara, K.) 85–90 (Japan Fine Ceramics Association, Tokyo, 1997)

Park, D. S., Lee, S.-Y., Kim, H.-D., Yoo, B.-J. & Kim, B.-A. Extra large grains in the silicon nitride ceramics doped with yttria and hafnia. J. Am. Ceram. Soc. 81, 1876–1880 (1998)

Zhang, C., Komeya, K., Tatami, J. & Meguro, T. Inhomogeneous grain growth and elongation of Dy-α sialon ceramics at temperature above 1800 °C. J. Eur. Ceram. Soc. 20, 939–944 (2000)

Emoto, H. & Mitomo, M. Control and characterization of abnormally grown grains in silicon nitride ceramics. J. Eur. Ceram. Soc. 17, 797–804 (1997)

Kitayama, M., Hirao, K., Toriyama, M. & Kanzaki, S. Modeling and simulation of grain growth in Si3N4—anisotropic Ostwald ripening. Acta Mater. 46, 6541–6550 (1998)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing financial interests.

Supplementary information

Rights and permissions

About this article

Cite this article

Shen, Z., Zhao, Z., Peng, H. et al. Formation of tough interlocking microstructures in silicon nitride ceramics by dynamic ripening. Nature 417, 266–269 (2002). https://doi.org/10.1038/417266a

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/417266a

This article is cited by

-

Quasi-instantaneous materials processing technology via high-intensity electrical nano pulsing

Scientific Reports (2024)

-

Variation of plagioclase shape with size in intermediate magmas: a window into incipient plagioclase crystallisation

Contributions to Mineralogy and Petrology (2022)

-

Intermediate phase-enhanced Ostwald ripening for the elimination of phase segregation in efficient inorganic CsPbIBr2 perovskite solar cells

Science China Materials (2021)

-

Gel-Casting Prepared Porous Si3N4 Ceramics with Different Contents of Y2O3 and Al2O3 Additives

Journal of Materials Engineering and Performance (2020)

-

Superplastic Forging for Sialon-based Nanocomposite at Ultralow Temperature in the Electric Field

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.