Abstract

The total syntheses of codonopsinine (1) and 4-epi-codonopsinine (2) were accomplished. The key substituted pyrrole intermediate was constructed via gold-catalyzed addition–cyclization cascade of an aminoacetaldehyde acetal derivative and a terminal alkyne. After diastereoselective reduction of the pyrrole intermediate to the corresponding 3-pyrroline derivative with zinc dust and sulfonic acid, the total synthesis of 4-epi-codonopsinine (2) was achieved via stereoselective construction of the diol by dihydroxylation. In addition, the total synthesis of codonopsinine (1) was completed through stereochemical inversion of the hydroxyl group via epoxide and subsequent ring cleavage under the acidic aqueous condition.

Similar content being viewed by others

Introduction

Codonopsinine, isolated from Codonopsis clematidea by Matkhalikova and colleagues in 1969,1, 2, 3, 4, 5 has a 1,2,3,4,5-pentasubstituted pyrrolidine ring bearing a p-anisyl group at the C2 position. Two decades after its isolation, its structure was revised through a total synthesis of 1 by Kibayashi and colleagues.6, 7 Codonopsinine has garnered considerable attention from organic chemists because of its substantial biological activities, which include antibiotic activity and hypotensive pharmacological activity.8 4-epi-Codonopsinine, by contrast, exhibits inhibitory activity against α-fucosidase.9 Furthermore, compound 1 and its synthetic analogs were recently demonstrated to possess anti-methicillin-resistant Staphylococcus aureus activity.10 Because of these important biological activities, the development of new anti-infective agents through structure–activity relationships of these compounds is intriguing. However, the divergent synthesis of this class of compounds would be difficult because of the lack of an efficient and versatile synthetic route.11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23

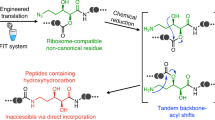

Recently, we developed a method for the synthesis of substituted pyrroles via gold-catalyzed addition–cyclization cascade (Scheme 1).24, 25 This reaction proceeds via gold-mediated auto-tandem catalysis,26 where the initially generated gold acetylide 527 adds to oxonium ion 6 to give intermediate 7, which cyclizes in 5-endo-dig manner by π-activation with the cationic gold catalyst. An advantage of this methodology is its versatility for the synthesis of substituted pyrroles 9. Thus a variety of substituted pyrroles can be synthesized in a modular manner by changing two fragments. We envisioned that this methodology would be effective for constructing the pyrrolidine core of codonopsinine and its analogs. Herein we describe the total syntheses of codonopsinine (1) and 4-epi-codonopsinine (2) featuring our gold-mediated tandem-catalyzed pyrrole synthesis.

Results and Discussion

Our retrosynthetic analysis of codonopsinine (1) and 4-epi-codonopsinine (2) is shown in Scheme 2. Compounds 1 and 2 could be derived from the common 3-pyrroline intermediate 10 via dihydroxylation of the olefin. 3-Pyrroline derivative 10 would be obtained from the corresponding pyrrole 12 by diastereoselective reduction. We planned to synthesize 5-alkyl-2-p-anisyl pyrrole 12 via our gold-catalyzed addition–cyclization cascade using 4-methoxyphenylacetylene 13 and N-benzoyl 2-aminopropanal acetal 14. The acetal segment 14 bearing a methyl group should be readily prepared from (L)-alanine (15). On the basis of our previous studies24 on the scope of the substituted pyrrole synthesis by this cascade reaction, we selected diisopropyl acetal 14 as a suitable substrate for construction of the methyl-substituted pyrrole 12.

First, we prepared N-benzoyl 2-aminopropanal diisopropyl acetal 14 according to the procedure established in our previous study24 (Scheme 3). Our preliminary studies revealed that the benzoyl protected substrate provided better yield than that of the substrate with carbamate group. Therefore, after conversion of N-Cbz alaninal 1628 to the corresponding diisopropyl acetal by heating with pyridinium p-toluenesulfonate (PPTS) in i-PrOH, the Cbz group was replaced with a benzoyl group in a two-step sequence to give the requisite acetal segment 14 in good yield. Then we conducted an optimization study of the gold-catalyzed addition–cyclization cascade to maximize the yield of pyrrole 12 (Table 1). The previously established conditions of 10 mol% of RuphosAuCl29 and AgOTf in toluene at 110 °C provided the desired pyrrole 12 in 55% yield (entry 1). We observed that the choice of silver salt is important (entries 1–4) and that the yield of 12 was slightly improved when AgBF4 was used (entry 4). Eventually, the desired pyrrole 12 was obtained in highest yield (84%) by treatment of a mixture of 13 and 14 with 10 mol% of RuphosAuCl and AgBF4 in xylene (0.25 m) at 140 °C.

Having successfully constructed the 1,2,5-trisubstituted pyrrole intermediate 12, we then focused on manipulating the pyrrole skeleton to complete the total syntheses of the target natural products. After removing the benzoyl group by heating 12 with aqueous KOH in a mixture of EtOH and CH2Cl2 (Scheme 4), we subjected the resulting pyrrole 17 to various reduction conditions to obtain the corresponding 2,5-trans-3,4-dehydropyrrolidine derivative 11 (Table 2). Initial trial by treatment of 17 with activated Zn dust30 in a mixture of 6 m HCl and MeOH gave 3-pyrroline derivative 11 as a mixture of diastereomers (trans/cis=5/4) in low yield associated with a mixture of 1-pyrroline and 5-pyrroline product (entry 1). Reaction using EtOH instead of MeOH gave 3-pyrroline derivative 11 in 27% yield (trans/cis=2/1) (entry 2). When sulfonic acid was used instead of HCl, the ratio of diastereomers was improved to 5:1 (entry 3). After further examinations, we observed that the ratio of diastereomers dramatically improved (trans/cis=33/1) when the solvent was switched from EtOH to MeCN (entry 4). Finally, we obtained the desired 3-pyrroline derivative 11 as a sole isomer by heating a MeCN solution of 17 in the presence of Zn dust and sulfonic acid at 70 °C. The plausible mechanisms would be initiated by protonation of the pyrrole ring at the 5-position to give α,β-unsaturated iminium ion intermediate. Then the intermediate would be reduced by single-electron reduction with zinc dust to generate a stable 2,5-trans radical species, which would be further reduced by zinc reagent to provide the trans product after protonation.

The endgame sequence of the total synthesis of codonopsinine (1) and 4-epi-codonopsinine (2) is depicted in Scheme 5. First, methoxycarbonylation of secondary amine of 11 produced the pivotal intermediate 10. The total synthesis of 4-epi-codonopsinine (2) was achieved by diastereoselective dihydroxylation of 10 and reductive transformation of methyl carbamate to the corresponding methyl amine. By contrast, conversion of 10 to codonopsinine (1) was executed by diastereoselective meta-3-chloroperoxybenzoic acid (mCPBA) epoxidation of the olefin, ring cleavage of the epoxide under acidic conditions and reduction with Red-Al according to the procedure13 developed by Correira et al. All the properties of synthetic 113 and 29 were identical to the published data.

In conclusion, we accomplished the total syntheses of codonopsinine (1) and 4-epi-codonopsinine (2). For the construction of the pentasubstituted pyrrolidine core, we utilized our original multisubstituted pyrroles synthesis by gold-mediated auto-tandem catalysis and diastereoselective reduction of the pyrrole ring to the 3-pyrroline derivative. Taking advantage of our modular synthesis of substituted pyrroles, the synthetic strategy developed in this work should be applicable to the versatile synthesis of a wide range of codonopsinine congeners.

Experimental procedure

Gereral remarks

Unless otherwise noted, all reactions were performed using oven-dried glassware, sealed with a rubber septum under a slight positive pressure of argon. Anhydrous tetrahydrofuran, MeCN, 1,4-dioxane and dichloromethane were purchased from Kanto Chemical Co., Inc. (Tokyo, Japan) Anhydrous toluene, xylene, acetone and dimethylformamide were purchased from Wako Pure Industries (Osaka, Japan). Anhydrous EtOH, MeOH and Et3N were dried and distilled according to the standard protocols. Unless otherwise mentioned, materials were obtained from commercial suppliers and used without further purification. Microwave irradiation experiments were performed on a CEM Discover Microwave Reactor (Discover-SP W/ACTIVENT, Tokyo, Japan). Reactions and chromatographical fractions were monitored by TLC analysis with precoated silica gel plates 60 F254 (Merck, Frankfurt, Germany). Flash column chromatography was carried out using Kanto silica gel 60N (spherical, neutral, 40–50 μm). Preparative TLC was performed on precoated silica gel plates 60 F254 (Merck). Gel permeation chromatography was carried out using a Japan Analytical Industry Co., Ltd., LC-9201 (Tokyo, Japan). IR spectra were measured on a Shimadzu FTIR-8300 spectrometer (Kyoto, Japan) or a JASCO FT/IR-4100 spectrometer (Tokyo, Japan). NMR spectra were measured on a JNM-AL400 spectrometer (JEOL Resonance Inc., Tokyo, Japan). For 1H spectra, chemical shifts were expressed in p.p.m. downfield from internal tetramethylsilane (δ 0) or relative internal CHCl3 (δ 7.26). For 13C spectra, chemical shifts were expressed in p.p.m. downfield from relative internal CHCl3 (δ 77.0). J values were expressed in Hertz. Elemental analyses were performed by a Yanaco CHN corder MT-6. Mass spectra (Kyoto, Japan) were recorded on a JEOL JMS-DX-303, a JMS-700, a JMS-T100GC (respectively, JEOL Ltd., Tokyo, Japan) and a Bruker micrOTOF spectrometer (MicrOTOF II-TH, Bruker Daltonics, Yokohama, Japan).

N-Carboxybenzylalaninal diisopropylacetal

To a solution of aldehyde 16 (1.23 g, 5.94 mmol) in i-PrOH (40 ml) was added PPTS (150 mg, 0.597 mmol). After stirring at reflux for 18 h with Dean–Stark trap containing MS4 Å, the reaction was quenched with saturated aqueous NaHCO3 and the mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by flash column chromatography on silica gel (hexanes/AcOEt=9:1) to afford the titled compund (1.35 g, 4.37 mmol, 74%) as a colorless oil; Rf=0.69 (silica gel, hexanes/AcOEt=7:3); IR (neat) 3344, 2972, 1715, 1504, 1454, 1332, 1229, 1053, 1028 cm–1; 1H NMR (400 MHz, CDCl3) δ 7.41–7.28 (m, 5H), 5.17–5.03 (m, 2H), 5.02–4.88 (m, 1H), 4.74 (s, 1H), 3.91–3.70 (m, 3H), 1.24–1.08 (m, 15H); 13C NMR (100 MHz, CDCl3) δ 156.0, 136.6, 128.5, 128.04, 128.01, 99.6, 69.5, 69.0, 66.5, 49.5, 23.00, 22.98, 22.4, 22.1, 14.6; LRMS (FAB) m/z 310.2 ([M+H]+); HRMS Calcd for C17H28NO4 ([M+H]+) 310.2019, found 310.2008.

N-Benzoylalaninal diisopropylacetal (14)

A suspension of the above diisopropyl acetal (1.33 g, 4.29 mmol) and 10% Pd/C (457 mg, 0.429 mmol) in EtOH (42 ml) was stirred under a hydrogen atmosphere at room temperature for 1.5 h. The reaction mixture was filtered through a pad of Celite and the filtrate was concentrated under reduced pressure. The residue was dissolved in CH2Cl2 (13 ml), and Et3N (1.69 ml, 12.1 mmol) and benzoyl chloride (510 μl, 4.40 mmol) were added at 0 °C. After stiring for 10 min, the reaction was quenched with saturated aqueous NH4Cl and the mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by flash column chromatography on silica gel (hexanes/AcOEt=8:2) to afford benzamide 14 (877 mg, 3.14 mmol, 73%) as a white solid; Rf=0.33 (silica gel, hexanes/AcOEt=7:3); Mp 89–90 °C; IR (KBr) 3292, 2970, 2361, 1636, 1558, 1377, 1339, 1159, 1047, 916, 693 cm–1; 1H NMR (400 MHz, CDCl3) δ 7.76 (d, J=8.0 Hz, 2H), 7.50 (t, J=8.0 Hz, 1H), 7.43 (dd, J=8.0, 8.0 Hz, 2H), 6.34 (br s, 1H), 4.59 (d, J=2.4 Hz, 1H), 4.36–4.26 (m, 1H), 3.88 (sep, J=6.0 Hz, 1H), 3.83 (sep, J=6.0 Hz, 1H), 1.32–1.17 (m, 12H), 1.13 (d, J=6.0 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 166.8, 134.7, 131.3, 128.5, 126.8, 99.5, 69.6, 69.0, 48.0, 23.01, 22.99, 22.5, 22.2, 14.2; Anal Calcd for C16H25NO3: C, 68.79; H, 9.02; N, 5.01. Found: C, 68.74; H, 9.26; N, 5.07.

1-Benzoyl-2-(4-methoxyphenyl)-5-methyl-1H-pyrrole (12)

A two necked round-bottom flask equipped with a magnetic stirring bar was charged with AgBF4 (18.1 mg, 92.8 μmol), RuPhosAuCl (64.9 mg, 92.8 μmol) and xylenes (3.7 ml, 0.25 M). To the solution were added benzamide 14 (260 mg, 0.928 mmol) and 1-ethynyl-4-methoxybenzene 13 (0.700 ml, 4.64 mmol) at room temperature. After stirring at 140 °C for 10 min, the reaction was quenched with saturated aqueous NaHCO3, and the mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by flash column chromatography on silica gel (hexanes/toluene =1:3) and preparative TLC on silica gel (hexanes/AcOEt=9:1) to afford N-benzoyl pyrrole 12 (226 mg, 0.776 mmol, 84%) as a pale yellow solid; Rf=0.40 (silica gel, hexanes/toluene=1:3); Mp 103–104 °C (hexanes/CH2Cl2); IR (KBr) 1697, 1531, 1493, 1333, 1290, 1242, 1032, 833, 802, 700 cm–1; 1H NMR (400 MHz, CDCl3) δ 7.56 (d, J=7.4 Hz, 2H), 7.40 (t, J=7.2 Hz, 1H), 7.33–7.20 (m, 2H), 7.09 (d, J=8.8 Hz, 2H), 6.66 (d, J=8.8 Hz, 2H), 6.21 (d, J=3.6 Hz, 1H), 6.10 (d, J=3.6 Hz, 1H), 3.71 (s, 3H), 2.34 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 171.6, 158.1, 135.1, 135.0, 133.2, 132.4, 130.4, 128.8, 128.2, 126.4, 113.6, 110.2, 110.0, 55.1, 14.0; Anal Calcd for C19H17NO2: C, 78.33; H, 5.88; N, 4.81. Found: C, 78.07; H, 5.93; N, 4.78.

2-(4-Methoxyphenyl)-5-methyl-1H-pyrrole (17)

To a solution of N-benzoyl pyrrol 12 (225 mg, 0.774 mmol) in a mixture of EtOH (2.6 ml), CH2Cl2 (1.3 ml) and H2O (0.7 ml) was added KOH (195 mg, 3.48 mmol). After stirring for 2 h at 50 °C, the mixture was concentrated under reduced pressure. The residue was extracted with CH2Cl2 three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by flash column chromatography on silica gel (hexanes/AcOEt=8:2) to afford pyrrol 17 (138 mg, 0.737 mmol, 95%) as a light yellow solid; Mp 129–131 °C; IR (neat) 3433, 3398, 2924, 1525, 1254, 824, 787 cm−1; 1H NMR (400 MHz, CDCl3) δ 8.01 (br s, 1H), 7.35 (d, J=8.8 Hz, 2H), 6.89 (d, J=8.8 Hz, 2H), 6.27 (dd, J=3.4, 2.8 Hz, 1H), 5.93 (m, 1H), 3.81 (s, 3H), 2.32 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 157.8, 130.8, 128.3, 126.1, 124.8, 114.3, 107.6, 105.0, 55.3, 13.1; ESI-MS m/z Calcd for C12H14NO 188.1060 (M++H), found 188.1070.

(2S*,5R*)-2-(4-Methoxyphenyl)-5-methyl-2,5-dihydro-1H-pyrrole (11)

To a suspension of pyrrole 17 (117 mg, 0.628 mmol) and zinc dust (activated, 367 mg, 5.61 mmol) in MeCN (6.3 ml) was added dropwise concentrated H2SO4 (0.402 ml). After stirring at 70 °C for 10 min, the mixture was filtered through a pad of Celite. The pH value of the filtrate was adjusted to 10 by addion of 2 m NaOH. The solution was saturated with NaCl and the mixture was extracted with AcOEt five times. The combined organic extracts were dried over Na2SO4, filtered and concentrated under reduced pressure to give a crude product as a single isomer. The crude material was purified by flash column chromatography on silica gel (CH2Cl2/MeOH=10:1) to afford 3-pyrroline derivative 11 (67.2 mg, 0.355 mmol, 57%) as a pale yellow oil. Rf=0.28 (Silica gel, MeOH/CH2Cl2=1:10); IR (neat) 2959, 2835, 1611, 1510, 1244, 1175, 1036 cm–1; 1H NMR (400 MHz, CDCl3) δ 7.21 (d, J=8.8 Hz, 2H), 6.86 (d, J=8.8 Hz, 2H), 5.90 (d, J=6.0 Hz, 1H), 5.80 (d, J=6.0 Hz, 1H), 5.14 (br s, 1H), 4.37–4.26 (m, 1H), 3.79 (s, 3H), 2.47 (br s, 1H), 1.26 (d, J=6.8 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 158.8, 136.4, 134.2, 131.3, 127.9, 113.9, 68.2, 60.3, 55.2, 22.7; ESI-MS m/z Calcd for C12H16NO 190.1226 (M++H), found 190.1235.

(2S*,5R*)-2-(4-Methoxyphenyl)-5-methyl-2,5-dihydro-1H-pyrrole-1-carboxylic acid methyl ester (10)

To a solution of 3-pyrroline derivative 11 (40.2 mg, 0.212 mmol) and Et3N (89 μl, 0.64 mmol) in CH2Cl2 (0.7 ml) was added methyl chloroformate (20 μl, 0.26 mmol) at 0 °C. After stirring for 2 h at room temperature, the reaction was quenched with saturated aqueous NH4Cl, and the mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by preparative TLC on silica gel (hexanes/AcOEt=3:7) to afford methyl carbamate 10 (43.1 mg, 0.174 mmol, 82%) as a clear oil; its 1H NMR spectral data were identical with those reported13; 1H NMR (400 MHz, CDCl3, a mixture of rotamers) δ 7.18 (d, J=8.8 Hz, 0.9H), 7.08 (d, J=8.8 Hz, 1.1H), 6.86 (d, J=8.8 Hz, 0.9H), 6.82 (d, J=8.8 Hz, 1.1H), 5.80–5.73 (m, 1H), 5.64 (ddd, J=6.4, 2.0, 0.5 Hz, 0.5H), 5.61 (ddd, J=6.4, 2.0, 0.5 Hz, 0.5H), 5.48 (m, 0.5H), 5.39 (m, 0.5H), 4.89–4.80 (m, 0.5H), 4.78–4.70 (m, 0.5H), 3.79 (s, 1.6H), 3.78 (s, 1.4H), 3.63 (s, 1.4H), 3.42 (s, 1.6H), 1.44 (d, J=6.0 Hz, 1.6H), 1.36 (d, J=6.0 Hz, 1.4H).

(2R*,3R*,4S*,5R*)-3,4-Dihydroxy-2-(4-methoxyphenyl)-5-methylpyrrolidine-1-carboxylic acid methyl ester

To a solution of 3-pyrroline derivative 10 (15.2 mg, 61.5 μmol) and N-methylmorpholine N-oxide (NMO) (10.8 ml, 92.3 μmol) in acetone (0.50 ml) and H2O (0.12 ml) was added OsO4 (1.0% in H2O, 78 μl, 3.1 μmol). After stirring for 5 days at room temperature, the reaction was quenched with saturated aqueous NaHSO3, and the mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by preparative TLC on silica gel (hexanes/AcOEt=1:1) to afford the titled cis-diol (15.6 mg, 55.5 μmol, 90%) as a colorless oil; Rf=0.20 (silica gel, hexanes/AcOEt=1:1); IR (neat) 3419, 3303, 2937, 1680, 1612, 1513, 1455, 1386, 1249 cm–1; 1H NMR (400 MHz, CD3CN, 60 °C) δ 7.08–7.00 (m, 2H), 6.92–6.80 (m, 2H), 4.72 (br s, 1H), 4.29–4.18 (m, 1H), 4.17–4.09 (m, 1H), 3.86 (br s, 1H), 3.78–3.72 (m, 3H), 3.67–3.29 (m, 4H), 3.14 (br s, 1H), 1.35–1.33 (m, 1H); 13C NMR (100 MHz, CD3CN, 60 °C) δ 160.1, 156.4, 130.3, 127.9, 115.1, 114.1, 70.9, 68.6, 64.3, 57.2, 56.2, 52.5; ESI-MS m/z Calcd for C14H19NNaO5 304.1155 (M++Na), found 304.1157.

(2R*,3R*,4S*,5R*)-2-(4-Methoxyphenyl)-1,5-dimethylpyrrolidine-3,4-diol; 4-epi-(±)-codonopsinine (2)

To a solution of the above cis-diol (12.1 mg, 43.0 μmol) in toluene (0.22 ml) was added Red-Al (65% w/v in toluene, 129 μl) at 0 °C. After heating at reflux for an hour, the reaction was quenched with saturated aqueous Rochell’s salt at 0 °C. The resulting mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by preparative TLC on silica gel (CHCl3/MeOH=3:1) to afford 4-epi-(±)-codonopsinine (2) (5.8 mg, 24.4 μmol, 57%) as a white solid; its 1H NMR spectral data were identical with those reported9; 1H NMR (400 MHz, CDCl3) δ 7.21 (d, J=8.4 Hz, 2H), 6.88 (d, J=8.4 Hz, 2H), 4.28 (dd, J=6.4, 6.4 Hz, 1H), 4.06 (dd, J=6.4, 5.2 Hz, 1H), 3.81 (s, 3H), 3.66 (d, J=5.2 Hz, 1H), 3.53–3.45 (m, 1H), 2.64 (br s, 1H), 1.12 (s, 3H).

(1S*,2S*,4S*,5R*)-2-(4-Methoxyphenyl)-4-methyl-6-oxa-3-azabicyclo[3.1.0]hexane-3-carboxylic acid methyl ester (18)

To a solution of pyrroline 10 (14.7 mg, 59.4 μmol) in toluene (0.3 ml) was added mCPBA (51.0 mg, 0.297 mmol) at 0 °C. After stirring at room temperature for 28 h, the reaction was quenched with saturated aqueous NaHCO3, and the resulting mixture was extracted with CH2Cl2 three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by preparative TLC on silica gel (hexanes/AcOEt=3:7) to afford epoxide 18 (8.6 mg, 33 μmol, 55%) as a clear oil; its 1H NMR spectral data were identical with those reported14; 1H NMR (400 MHz, CDCl3) δ 7.14 (d, J=8.4 Hz, 0.9H), 7.08 (d, J=8.8 Hz, 2.1H), 6.92–6.84 (m, 2H), 5.04 (br s, 0.3H), 4.96 (br s, 0.7H), 4.22–4.07 (m, 1H), 3.80 (s, 2.1H), 3.79 (m, 0.9H), 3.76–3.70 (m, 1H), 3.62 (s, 0.9H), 3.52–3.47 (m, 1H), 3.44 (s, 2.1H), 1.58 (d, J=6.0 Hz, 2.1H), 1.51 (d, J=6.0 Hz, 0.9H).

(2R*,3R*,4R*,5R*)-3,4-Dihydroxy-2-(4-methoxyphenyl)-5-methylpyrrolidine-1-carboxylic acid methyl ester

To a solution of epoxide 18 (8.6 mg, 33 μmol) in 1,4-dioxane (0.13 ml) and H2O (90 μl) was added dropwise concentrated H2SO4 (9.0 μl). After stirring for 9 h at 90 °C, the reaction was quenched with saturated aqueous NaHCO3. The resulting mixture was extracted with CH2Cl2 three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered and concentrated under reduced pressure. The residue was purified by preparative TLC on silica gel (hexanes/AcOEt=2:1) to afford the titled trans-diol (5.5 mg, 20 μmol, 60%) as a clear oil; its 1H NMR spectral data were identical with those reported13; 1H NMR (400 MHz, C5D5N, a mixture of rotamers) δ 7.65 (d, J=7.6 Hz, 1H), 7.45 (br s, 1H), 6.93 (d, J=8.4 Hz, 2H), 4.66 (br s, 1H), 4.61–4.33 (m, 2H), 3.69 (br s, 1H), 3.60 and 3.59 (s, 3H), 3.48 (s, 3H), 1.93 (d, J=6.4 Hz, 1.8H), 1.75 (d, J=6.4 Hz, 1.8H).

(2R*,3R*,4R*,5R*)-2-(4-Methoxyphenyl)-1,5-dimethylpyrrolidine-3,4-diol; codonopsinine (1)

To a solution of trans-diol compound (8.5 mg, 30.2 μmol) in toluene (0.15 ml) was added Red-Al (65% w/v in toluene, 233 μl) at 0 °C. After heating at reflux for 45 h, the reaction was quenched with saturated aqueous Rochell’s salt at 0 °C, and the mixture was extracted with AcOEt three times. The combined organic extracts were washed with brine, dried over Na2SO4, filtered, and concentrated under reduced pressure. The residue was purified by preparative TLC on silica gel (CHCl3/MeOH=4:1) to afford (±)-codonopsinine (1) (4.5 mg, 19 μmol, 63%) as a white solid; Mp 155–157 °C; IR (neat) 3365, 2919, 2837, 1611, 1514, 1459, 1249, 1180, 1035, 837 cm−1; 1H NMR (600 MHz, C5D5N) δ 7.58 (d, J=8.4 Hz, 2H), 6.97 (d, J=8.4 Hz, 2H), 4.60 (dd, J=6.0, 4.8 Hz, 1H), 4.36 (dd, J=6.0, 4.8 Hz, 1H), 4.02 (d, J=6.0 Hz, 1H), 3.67 (qd, J=6.4, 3.6 Hz, 1H), 3.66 (s, 3H), 2.20 (s, 3H), 1.31 (s, J=6.4 Hz, 3H); 13C NMR (150 MHz, C5D5N) δ 159.0, 134.7, 129.5, 113.8, 86.9, 84.7, 74.0, 64.7, 54.8, 34.4, 13.6; ESI-MS m/z Calcd for C13H20NO3 (M++H) 238.1438, found 238.1435.

Synthesis of pyrroles by gold-catalyzed addition–cyclization cascade.

Retrosynthetic analysis of codonopsinine (1) and its C-4 epimer (2).

Synthesis of key substrate 14.

Hydrolysis of benzoyl pyrrole 12.

Endgame of total syntheses of codonopsinine (1) and 4-epi-codonopsinine (2).

References

Matkhalikova, S. F., Malikov, V. M. & Yunusov, S. Y. Alkaloids of Codonopsis clematidea. Khim. Prir. Soedin 5, 30–32 (1969); Chem. Abstr. 71, 13245z.

Matkhalikova, C. F., Malikov, V. M. & Yunusov, S. Y. Structure of codonopsine. Khim. Prir. Soedin. 5, 606–607 (1969); Chem. Abstr. 73, 15050x.

Matkhalikova, S. F., Malikov, V. M. & Yunusov, S. Y. Structure of codonopsinine. Khim. Prir. Soedin. 5, 607 (1969); Chem. Abstr. 73, 25712d.

Yagudaev, M. R., Matkhalikova, S. F., Malikov, V. M. & Yusunov, S. Y. Study of stereochemistry of alkaloids of codonopsine and codonopsinine by NMR spectroscopy method. Khim. Prir. Soedin. 8, 495 (1972).

Shibano, M., Tsukamoto, D., Masuda, A., Tanaka, Y. & Kusano, G. Two new pyrrolidine alkaloids, radicamines A and B, as inhibitors of α-glucosidase from lobelia chinensis LOUR. Chem. Pharm. Bull. 49, 1362–1365 (2001).

Iida, H., Yamazaki, N. & Kibayashi, C. Total synthesis of (+)-codonopsinine and its stereoisomers: stereochemical assignment of natural (–)-codonopsinine. J. Org. Chem. 52, 1956–1962 (1987).

Iida, H., Yamazaki, N. & Kibayashi, C. Stereochemical revision and absolute configuration of codonopsinine. Tetrahedron Lett. 27, 5393–5396 (1986).

Khanov, M. T., Sultanov, M. B. & Egorova, M. R. Pharmacological study of the alkaloid codonopsine, extracted from Codonopsis clematidea. Farmakol. Alkaloidov Serdech. Glikoyidov 210–212 (1971); Chem. Abstr. 77, 135091r (1972).

Kotland, A., Accadbled, F., Robeyns, K. & Behr, J.-B. Synthesis and fucosidase inhibitory study of unnatural pyrrolidine alkaloid 4-epi-(+)-codonopsinine. J. Org. Chem. 76, 4094–4098 (2011).

Johari, S. A. et al. In vitro inhibitory and cytotoxic activity of MFM 501, a novel codonopsinine derivative, against methicillin-resistant Staphylococcus aureus clinical isolates. J. Chil. Chem. Soc. 56, 1–9 (2015).

Iida, H. Yamazaki & Kibayashi, N. C. Synthesis of (+)-codonopsinine: determination of absolute configuration of natural (−)-codonopsinine. Tetrahedron Lett. 26, 3255–3258 (1985).

Yoda, H., Nakajima, T. & Takabe, K. Total synthesis of natural (–)-codonopsinine employing stereoselective reduction of quaternary α-hydroxypyrrolidine. Tetrahedron Lett. 37, 5531–5534 (1996).

Severino, E. A. & Correia, C. R. D. Heck arylation of endocyclic enecarbamates with diazonium salts. Improvements and a concise enantioselective synthesis of (–)-codonopsinine. Org. Lett. 2, 3039–3042 (2000).

Goti, A. et al. T. Iterative organometallic addition to chiral hydroxylated cyclic nitrones: highly stereoselective syntheses of α,α‘- and α,α-substituted hydroxypyrrolidines. Org. Lett. 5, 4235–4238 (2003).

Toyao, A., Tamura, O., Takagi, H. & Ishibashi, H. A concise synthesis of (–)-codonopsinine and an approach to synthesis of (+)-hyacinthacines A1 and A2 from a polyhydroxylated cyclic nitrone. Synlett 2003, 35–38 (2003).

Haddad, M. & Larchevêque, M. Diastereocontrolled synthesis of (–)-codonopsinine. Synlett 2003, 274–276 (2003).

Chandrasekhar, S., Jagadeshwar, V. & Prakash, S. J. Total synthesis of the alkaloid (−)-codonopsinine from l-xylose. Tetrahedron Lett. 46, 3127–3129 (2005).

Chowdhury, M. A. & Reissig, H.-U. Syntheses of highly substituted furan and pyrrole derivatives via lithiated 3-aryl-1-methoxyallenes: application to the Synthesis of Codonopsinine. Synlett 17, 2383–2386 (2006).

Chandrasekhar, S., Saritha, B., Jagadeshwar, V. & Prakash, S. J. Practical and highly stereoselective approaches to the total synthesis of (−)-codonopsinine. Tetrahedron Asymm. 17, 1380–1386 (2006).

Reddy, J. S. & Rao, B. J. A short, efficient and stereoselective total synthesis of a pyrrolidine alkaloid: (−)-codonopsinine. J. Org. Chem. 72, 2224–2227 (2007).

Uraguchi, D., Nakamura, S. & Ooi, T. Catalytic asymmetric direct henry reaction of ynals: short syntheses of (2S,3R-(+)-xestoaminol C and (−)-codonopsinines. Angew. Chem. Int. Ed. 49, 7562–7565 (2010).

Davies, S. G., Lee, J. A., Roberts, P. M., Thomson, J. E. & West, C. J. Ring-closing iodoamination of homoallylic amines for the synthesis of polysubstituted pyrrolidines: application to the asymmetric synthesis of (–)-codonopsinine. Tetrahedron 68, 4302–4319 (2012).

Dharuman, S., Palanivel, A. K. & Vankar, Y. D. An easy route to synthetic analogues of radicamine B, codonopsine and codonopsinine from D-mannitol. Org. Biomol. Chem. 12, 4983–4998 (2014).

Ueda, H., Yamaguchi, M., Kameya, H., Sugimoto, K. & Tokuyama, H. Autotandem catalysis: synthesis of pyrroles by gold-catalyzed cascade reaction. Org. Lett. 16, 4948–4951 (2014).

Sugimoto, K. et al. Protecting-group-free total synthesis of (–)-rhazinilam and (–)-rhazinicine using a gold-catalyzed cascade cyclization. Angew. Chem. Int. Ed. 52, 7168–7171 (2013).

Fogg, D. E. & Santos, E. N. Tandem catalysis: a taxanomy and illustrative review. Coord. Chem. Rev. 248, 2365–2379 (2004).

Brown, T. J. & Widenhoefer, R. A. Cationic gold(I) π-complexes of terminal alkynes and their conversion to dinuclear σ,π-acetylide complexes. Organometallics 30, 6003–6009 (2011).

Randl, S. & Blechert, S. Concise total synthesis of (+)-carpamic acid. Tetrahedron Lett. 45, 1167–1169 (2004).

Nieto-Oberhuder, C., López, S. & Echavarren, A. M. Intramolecular [4+2] cycloadditions of 1,3-enynes or arylalkynes with alkenes with highly reactive cationic phosphine Au (I) complexes. J. Am. Chem. Soc. 127, 6178–6179 (2005).

Andrews, L. H. & McElvain, S. M. Gamma-pyrrolidino- and gamma-pyrrolinopropyl benzoates. J. Am. Chem. Soc. 51, 887–892 (1929).

Acknowledgements

This work was financially supported by the Cabinet Office, Government of Japan through its ‘Funding Program for Next Generation World-Leading Researchers (LS008), a Grant-in-aid for Scientific Research (A) (26253001) and for Young Scientists (B) (24790003) and Platform for Drug Discovery, Informatics, and Structural Life Science from the MEXT, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

This paper is dedicated to Professor Amos B Smith III on the occasion of his 70th birthday.

Supplementary Information accompanies the paper on The Journal of Antibiotics website

Supplementary information

Rights and permissions

About this article

Cite this article

Yamaguchi, M., Itagaki, D., Ueda, H. et al. Total syntheses of codonopsinine and 4-epi-codonopsinine via gold-mediated tandem-catalyzed pyrrole synthesis. J Antibiot 69, 253–258 (2016). https://doi.org/10.1038/ja.2016.13

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/ja.2016.13