Abstract

Light-emitting diodes are becoming the alternative for future general lighting applications, with huge energy savings compared to conventional light sources owing to their high efficiency and reliability. Polarized light sources would largely enhance the efficiency in a number of applications, such as in liquid-crystal displays, and also greatly improve contrast in general illumination due to the reduction in indirect glare. Here, we demonstrate light-emitting diodes presenting high-brightness polarized light emission by combining the polarization-preserving and directional extraction properties of embedded photonic-crystals applied to non-polar gallium nitride. A directional enhancement of up to 1.8-fold was observed in the total polarized light emission together with a high polarization degree of 88.7% at 465 nm. We discuss the mechanisms of polarized light emission in non-polar gallium nitride and the photonic-crystal design rules to further increase the light-emitting diode brightness. This work could open the way to polarized white-light emitters through their association with polarization-preserving down-converting phosphors.

Similar content being viewed by others

Introduction

Due to a continuously improved performance, light-emitting diodes (LEDs) are not only the major contender for future general lighting sources,1 but also play an important role in a growing number of other applications—from backlight for high-efficiency televisions and mobile phone displays, to car lights and headlights—replacing the classical white sources owing to their high efficiency, brightness, reliability and low operation cost. Polarized light sources would largely improve the efficiency of most of these applications: from general illumination, with an improved contrast due to reduced glare,2 which also minimizes eye discomfort and ultimately eye strain,3 to high-efficiency displays which operate through the spatial modulation of polarized light4 (for completeness, we also note that polarized light and other forms of artificial light could be harmful for the life of animals and other species relying on natural light cycles to live5). However, common light sources are usually unpolarized, since the electric field of the light emitted has no preferred orientation. This is also the case for most of the nitride-based LEDs commercialized nowadays. A strongly linearly polarized source, however, is obtained in m-plane GaN LEDs where the asymmetric in-plane biaxial stress on the quantum wells (QWs) orients the light emitting dipoles preferentially along the in-plane a direction. Non-polar m-plane GaN LEDs were first developed and more intensively investigated due to the possible reduction of polarization-induced electric fields in the QWs, which for c-plane GaN LEDs degrade their radiative recombination rate as a result of quantum confined stark effects.6,7 Today, the availability of high-quality free-standing substrates along non-polar and semipolar crystal planes of GaN allowed the demonstration of high-effciency optoelectronic devices.8,9

High polarization ratios (defined in equation (1)) have been reported in m-plane GaN LEDs,10,11,12,13 however, such LEDs present poor light-extraction efficiency due to total internal reflection at the flat GaN/air interface. The common light-extraction improving schemes applied to LEDs rely on randomizing the light reflected off the interfaces (roughened interfaces14 or patterned substrates15) which increases the light output of m-plane LEDs but also randomizes the original intrinsic polarization of the emitted light. The diffraction of light by optical gratings (or photonic crystals (PhCs)) offers one possible polarization-preserving light-extraction mechanism, in addition to the high light-extraction efficiency demonstrated in GaN LEDs.16,17

In this work, we embed periodically distributed air rods (embedded PhCs) within the LED structure to form a highly diffractive optical medium that offers high light-extraction efficiency. The coherent nature of the diffraction by PhCs not only retains the original polarization of light but also offers directional light extraction, resulting in high-brightness polarized LEDs. We develop a theoretical model of light emission in m-plane GaN and of its interaction with PhCs, and discuss the important parameters to design and enhance the directional polarized light emission. We demonstrate highly polarized emission with a degree of polarization of 88.7% at 465 nm and enhancement up to 1.8-fold in directional polarized emission. We show that more than increasing the polarized light emission, PhCs offer a tool to control and design the angular emission pattern of LEDs. The association of such high-brightness polarized blue LEDs with polarization-preserving down-converting phosphors,18 such as oriented dye systems19 or quantum dashes,8 could open the way to polarized white-light emitters.

Materials and methods

Embedded PhC fabrication

The reported devices were grown by metal-organic chemical vapor deposition (MOCVD) on commercially available free-standing m-plane GaN substrates with −1° miscut. The one-dimensional (1D) PhCs with period a′=270 nm and depth of ∼160 nm were patterned on the surface of the m-plane substrates by interference lithography using THMR-M100 photoresist, XHRiC-16 anti-reflective coating and a 220-nm-thick SiO2 hard mask deposited over GaN. The stripes were transferred to GaN by inductive coupled plasma. After the removal of the lithography resist and the SiO2 hard mask, the GaN patterned substrate was ready for the MOCVD growth. The coalescence of a thin layer over the air-groove stripes aligned parallel to the a direction was achieved, using a similar method of Ref. 20 adapted to m-plane GaN. Its detailed description will be reported later.

LED fabrication

The LED structure consisted of a ∼1-µm-thick Si-doped n-GaN layer, followed by 3× InGaN/GaN (4/10 nm) QW/barriers, a 15-nm-thick Mg-doped Al0.18Ga0.82N electron-blocking layer and a 200-nm-thick Mg-doped p-GaN. Layer thicknesses and compositions were estimated from X-ray diffraction on calibration samples, grown separately. An m-plane substrate without PhCs was coloaded in the same LED growth run for comparison. The LEDs were processed on both samples using a 250-nm-thick indium tin oxide as transparent contact layer to the p-GaN. Individual mesas were etched through the active layers to reach the n-type GaN using inductive coupled plasma etch. The n-type contact layer consisted of an annealed metal stack of Ti, Al, Ni and Au (10/100/10/100 nm). Contact pads were formed using Ti/Au (15/350 nm), deposited by electron beam evaporation.

Optical characterization

The diffraction of polarized guided light by the PhCs was assessed by polarized angle-resolved spectral measurements, where the spectrum of the LED under electric bias was measured by a rotating optical fiber at angles θ from −90° to 90° (0° being the vertical direction normal to the LED). A polarizer was placed in front of the optical fiber to select between the  and

and  polarizations. The samples were measured on wafer with adjacent LEDs covered using an aperture that exposed only the device of interest. This procedure eliminated most of the scattered light from the sidewalls and from the other devices; however, in the angle-resolved measurements, it is expected that a small portion of the light could still be scattered by the sidewalls of the LEDs mesas (∼600 nm of height), which reduces the measured polarization ratio. The backside of the wafers was polished to minimize scattering and depolarization of the emitted light. The LEDs were driven at 2 mA. Recent reports in the literature showed that the polarization ratio in m-plane GaN LEDs is nearly independent of current density,13 and a large polarization ratio can be maintained over a wide range of current densities from 0.5 to 1000 A⋅cm−2, which is important for lighting applications where LEDs are usually operated at high current densities.

polarizations. The samples were measured on wafer with adjacent LEDs covered using an aperture that exposed only the device of interest. This procedure eliminated most of the scattered light from the sidewalls and from the other devices; however, in the angle-resolved measurements, it is expected that a small portion of the light could still be scattered by the sidewalls of the LEDs mesas (∼600 nm of height), which reduces the measured polarization ratio. The backside of the wafers was polished to minimize scattering and depolarization of the emitted light. The LEDs were driven at 2 mA. Recent reports in the literature showed that the polarization ratio in m-plane GaN LEDs is nearly independent of current density,13 and a large polarization ratio can be maintained over a wide range of current densities from 0.5 to 1000 A⋅cm−2, which is important for lighting applications where LEDs are usually operated at high current densities.

To precisely determine the polarization ratio using equation (1), the sidewalls, backside and part of the top surface of the devices were covered with light absorbing material based on carbon nanoparticles (Superior Graphite Co., Chicago, IL, USA) to eliminate the collection of extra scattered light.11,13,21

Polarized emission in m-plane GaN LEDs: electric dipole description

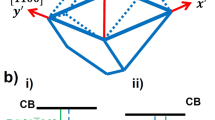

Spontaneous radiative recombination from electrons in the conduction band (CB), with atomic s orbital character, and holes in the valence bands (VB), with atomic px, py and pz orbital characters (Figure 1a), is given by Fermi's golden rule and is proportional to the quantum mechanical dipole moments between these states. The correspondence principle states that these quantum mechanical dipole moments are well described by electric oscillating dipole moments from classic electromagnetism,22 oriented parallel to the direction of the corresponding p orbital.

Light emission from m-plane InGaN QWs. (a) Schematic of the orientation of the atomic orbitals and the conduction and valence bands in compressively strained m-plane GaN. (b) Top view of the radiation pattern of a single dipole along a indicating the wavevector  , electric

, electric  and magnetic

and magnetic  fields, both proportional to cosα and the radiated intensity I(α)∼cos2α. (c) Three-dimensional representation of the single dipole-like radiation pattern (torus) from an m-plane QW. The Px dipole radiates polarized light to air through the air cone. The emission outside the air cone excites polarized guided light in the semiconductor slab. The plane represents the QWs and the complete LED structure is not shown for simplicity. LED, light-emitting diode; QW, quantum well.

fields, both proportional to cosα and the radiated intensity I(α)∼cos2α. (c) Three-dimensional representation of the single dipole-like radiation pattern (torus) from an m-plane QW. The Px dipole radiates polarized light to air through the air cone. The emission outside the air cone excites polarized guided light in the semiconductor slab. The plane represents the QWs and the complete LED structure is not shown for simplicity. LED, light-emitting diode; QW, quantum well.

For InGaN QWs grown on m-plane GaN, the anisotropic compressive biaxial stress in the QWs breaks the symmetry of the original |X±iY〉-like heavy and light-hole valence bands of unstrained wurtzite GaN, into |X〉- and |Y〉-like bands. The compressive stress raises the |X〉 state and lowers the |Y〉 state below the spin-orbit crystal-field splitting |Z〉 band (Figure 1a), resulting in a smaller energy of the interband transitions between CB and |X〉 compared to that between CB and |Y〉.23

In such QWs, the more intense emission comes from the lower energy CB–|X〉 recombinations corresponding to x-oriented dipoles, Px , radiating an electric field  mostly parallel to the a direction, while the less intense CB–|Z〉 recombination yields a Pz dipole, emitting mostly in the x–y plane with an electric field polarized along c.11,24 The even less intense CB–|Y〉 recombination corresponds to Py dipoles radiating electric field mostly along the m direction (negligible emission compared to the other two dipoles).

mostly parallel to the a direction, while the less intense CB–|Z〉 recombination yields a Pz dipole, emitting mostly in the x–y plane with an electric field polarized along c.11,24 The even less intense CB–|Y〉 recombination corresponds to Py dipoles radiating electric field mostly along the m direction (negligible emission compared to the other two dipoles).

The difference between the intensities emitted vertically from the dipoles is quantified by the polarization ratio, defined as

where I‖a and I‖c are the intensities of light polarized along the a and c directions emitted in the vertical direction.

In m-plane InGaN QWs where high polarization ratios have been reported—∼92% at wavelengths of 485 nm12 and even higher at longer wavelengths13—the intensity emitted from the a-oriented dipole can be 20 times higher than that emitted from the c-oriented dipole. Therefore, the light emitted in m-plane GaN can be treated to very good approximation by a single emitting dipole along the a direction of the plane. This is a unique property in solid-state light-emitters: m-plane GaN LEDs radiate as a macroscopic single dipole. Oscillating electric dipoles radiate in the far-field radially in all directions. The electric field  lies in the same plane of the dipole and the magnetic field

lies in the same plane of the dipole and the magnetic field  is perpendicular to this plane (Figure 1b). The amplitude of these fields is proportional to cosα (intensity proportional to cos2α), being most intense at the directions perpendicular to the dipole and vanishing along the dipole axis. The direction of the Poynting vector

is perpendicular to this plane (Figure 1b). The amplitude of these fields is proportional to cosα (intensity proportional to cos2α), being most intense at the directions perpendicular to the dipole and vanishing along the dipole axis. The direction of the Poynting vector  is radial, perpendicular to

is radial, perpendicular to  and

and  (Figure 1b). In three dimensions, the radiation pattern of the main dipole Px follows a torus (Figure 1c). Light emitted with angles within the air cone (green cone) is radiated to air (green wave vector), and the emission outside the air cone excites guided light in the semiconductor slab (red wave vector). The guided modes are polarized by the dominant emission with

(Figure 1b). In three dimensions, the radiation pattern of the main dipole Px follows a torus (Figure 1c). Light emitted with angles within the air cone (green cone) is radiated to air (green wave vector), and the emission outside the air cone excites guided light in the semiconductor slab (red wave vector). The guided modes are polarized by the dominant emission with  and propagate mainly perpendicularly to the orientation of the dipole.

and propagate mainly perpendicularly to the orientation of the dipole.

To be relevant for applications, one needs to enhance the emission of polarized light from m-plane GaN LED, since only the small fraction of light emitted within the air cone is radiated to air. The single dipole-like emission of m-plane QWs motivates the use of 1D PhCs aligned along the a direction (perpendicular to the preferential plane of propagation of the guided modes), which act as a diffraction grating for the polarized guided modes, out-coupling them to air (treated in more details in the last section of this paper). To effectively extract the guided light in the rather thick free-standing m-plane GaN substrates, the PhCs were placed within the LED structure, which increases their interaction with the guided modes (schematics in Figure 2a).25 An improved diffraction efficiency is obtained by embedding air gaps within the GaN, which results in a large contrast in refractive index. The extraction of polarized light by embedded PhCs in m-plane GaN LEDs was further motivated by the high extraction efficiency previously observed in c-plane GaN LEDs.17

Embedded PhC LEDs in m-plane GaN. (a) Schematic of the LED structure (not in scale). (b) TEM image of the cross-section of the embedded PhC structure showing a defect-free coalesced layer over the air-grooves (corresponding to the region below the dashed line in a). The features observed below the air grooves are artifacts from the focused ion beam used to prepare the sample for TEM measurement. The inset shows a top-view image of the embedded PhC LED under bias. ITO, indium tin oxide; LED, light-emitting diode; PhC, photonic crystal; TEM, transmission electron microscope.

Directional enhancement of polarized light emission

The fabrication of embedded PhCs relied in a simple process, consisting of patterning a free-standing m-plane GaN substrate with grooves by dry etch followed by a quick growth by MOCVD to coalesce a thin layer of m-plane GaN over the air-gap PhCs (see the section on ‘Materials and methods’). The coalescence was mainly determined by the growth rates and stability of different crystallographic facets of GaN upon specific growth conditions,20 it did not rely on the deposition of growth-blocking material inside the air gaps. Figure 2a and 2b shows the schematic of the LED structure and the transmission electron microscopy image revealing the coalescence of a 290-nm-thick defect-free layer over the air grooves. This is an important result, especially for optoelectronic devices, where some defects can act as non-radiative recombination centers which reduce the overall quantum efficiency of the device. LED structures were grown over both the m-plane substrates with embedded PhCs and without PhCs, coloaded in the same LED growth run for comparison. A picture of the embedded PhC LED under bias, processed as described in the section on ‘Materials and methods’, is shown in the inset of Figure 2b.

The extraction of polarized guided light by the embedded PhCs was assessed by angle-resolved spectral measurements (see the section on ‘Materials and methods’). Figure 3a shows such measurement for both devices combined in a single image, where θ=0° is the vertical direction normal to the LED. The sample without PhCs (Figure 3a) shows the regular angular emission pattern of a flat surface LED, corresponding to the emission of dipoles in a quasi semi-infinite medium through a flat top surface of the LED, which results in the absence of Fabry–Perot fringes in the experimental data. For the embedded PhC LED, the angle-resolved measurement reveals the extraction of different guided modes with  polarization, represented by the sharp lines in the left-hand side of Figure 3a. The measured radiation is composed of direct polarized emission within the air cone from the non-polar QWs, as for the sample without PhCs, plus the extra polarized light from the extracted guided modes.

polarization, represented by the sharp lines in the left-hand side of Figure 3a. The measured radiation is composed of direct polarized emission within the air cone from the non-polar QWs, as for the sample without PhCs, plus the extra polarized light from the extracted guided modes.

Optical characterization of polarized emission. (a) Comparison of angle-resolved measurements along the m–c plane for the  -polarized spectra, for LEDs with (left hand side) and without embedded PhCs (right hand side). The radiation from embedded PhC LED is composed of direct polarized emission (similar to the LED without PhCs), plus the extra polarized light from the extracted guided modes. A slight shift in the emission wavelength was observed between the embedded PhC (465 nm) and the LED without PhCs (470 nm). (b) Intensity versus angle at the peak wavelength for both

-polarized spectra, for LEDs with (left hand side) and without embedded PhCs (right hand side). The radiation from embedded PhC LED is composed of direct polarized emission (similar to the LED without PhCs), plus the extra polarized light from the extracted guided modes. A slight shift in the emission wavelength was observed between the embedded PhC (465 nm) and the LED without PhCs (470 nm). (b) Intensity versus angle at the peak wavelength for both  and

and  polarizations, scanned along the m-c plane. A directional enhancement in

polarizations, scanned along the m-c plane. A directional enhancement in  -polarized emission is observed due to the extraction of polarized modes by the embedded PhCs whereas only slight changes are observed for the

-polarized emission is observed due to the extraction of polarized modes by the embedded PhCs whereas only slight changes are observed for the  polarization. The direct light emission can be written as Ia,direct(θ)∝cosθ (see Supplementary Information). (c) Integrated angle-resolved measurement of the

polarization. The direct light emission can be written as Ia,direct(θ)∝cosθ (see Supplementary Information). (c) Integrated angle-resolved measurement of the  polarization, in wavelength, for the LEDs without and with embedded PhCs scanned along the m–c and m–a planes of GaN. A plot in polar coordinates is shown in the inset revealing the directional enhancement for the

polarization, in wavelength, for the LEDs without and with embedded PhCs scanned along the m–c and m–a planes of GaN. A plot in polar coordinates is shown in the inset revealing the directional enhancement for the  polarization along both m–c and m–a planes. LED, light-emitting diode; PhC, photonic crystal.

polarization along both m–c and m–a planes. LED, light-emitting diode; PhC, photonic crystal.

The intensity versus angle at the peak wavelength for both  and

and  polarizations is shown in Figure 3b, where the enhancement in

polarizations is shown in Figure 3b, where the enhancement in  -polarized emission by the embedded PhC LED can be more clearly observed. The emission of the

-polarized emission by the embedded PhC LED can be more clearly observed. The emission of the  polarization is nearly unchanged by the embedded PhCs due to the preferential extraction of polarized guided modes propagating perpendicularly to the 1D embedded PhCs (

polarization is nearly unchanged by the embedded PhCs due to the preferential extraction of polarized guided modes propagating perpendicularly to the 1D embedded PhCs ( -polarized guided modes). The small changes on the

-polarized guided modes). The small changes on the  polarization observed in Figure 3c are attributed mainly to scattering of the stronger

polarization observed in Figure 3c are attributed mainly to scattering of the stronger  polarization at sidewalls and neighboring devices which depolarizes the scattered light and contributes to increase the weak emission from

polarization at sidewalls and neighboring devices which depolarizes the scattered light and contributes to increase the weak emission from  polarization. This effect was later minimized by covering the sidewalls, backside and part of the top surface of the devices with light absorbing material11,13,21 (see the section on ‘Materials and methods’). The observation of a clear mode dispersion demonstrates the preservation of polarization of the guided modes extracted by the embedded PhCs. The embedded PhC LED presented a high polarization ratio of 88.7% (see the section on ‘Materials and methods’), which was similar to the sample without PhC. This quantity, however, does not fairly reflect the enhancement in polarized light emission because, by definition, it accounts only for intensities at vertical emission. Moreover, the polarization ratio as defined in equation (1) is sensitive to the presence (or absence) of peaks from the extracted modes by the PhCs at 0°. These results show that the embedded PhCs enhance the total polarized light emission maintaining the high intrinsic polarization ratio of m-plane GaN LEDs. The directional extraction of polarized light by the embedded PhCs is seen in Figure 3b, where the enhancement in polarized light emission is observed for angles up to 43°, and beyond that the emitted intensity is similar for both samples. The directional light emission from the embedded PhC LED was quantified by integrating the angle-resolved measurement in wavelength, as shown in Figure 3c, where the peaks from the extraction of guided modes observed in Figure 3b were averaged, forming a plateau up to 43°. An enhancement up to 1.8-fold was observed in the integrated emission of the

polarization. This effect was later minimized by covering the sidewalls, backside and part of the top surface of the devices with light absorbing material11,13,21 (see the section on ‘Materials and methods’). The observation of a clear mode dispersion demonstrates the preservation of polarization of the guided modes extracted by the embedded PhCs. The embedded PhC LED presented a high polarization ratio of 88.7% (see the section on ‘Materials and methods’), which was similar to the sample without PhC. This quantity, however, does not fairly reflect the enhancement in polarized light emission because, by definition, it accounts only for intensities at vertical emission. Moreover, the polarization ratio as defined in equation (1) is sensitive to the presence (or absence) of peaks from the extracted modes by the PhCs at 0°. These results show that the embedded PhCs enhance the total polarized light emission maintaining the high intrinsic polarization ratio of m-plane GaN LEDs. The directional extraction of polarized light by the embedded PhCs is seen in Figure 3b, where the enhancement in polarized light emission is observed for angles up to 43°, and beyond that the emitted intensity is similar for both samples. The directional light emission from the embedded PhC LED was quantified by integrating the angle-resolved measurement in wavelength, as shown in Figure 3c, where the peaks from the extraction of guided modes observed in Figure 3b were averaged, forming a plateau up to 43°. An enhancement up to 1.8-fold was observed in the integrated emission of the  polarization, measured along the m–c plane of the embedded PhC LED. A directional extraction of

polarization, measured along the m–c plane of the embedded PhC LED. A directional extraction of  polarization was also observed along the m–a plane (green triangles in Figure 3c). The enhancement in brightness of the

polarization was also observed along the m–a plane (green triangles in Figure 3c). The enhancement in brightness of the  -polarized emission is shown in polar coordinates in the inset of Figure 3c. The detailed explanation of these results and the PhC design rules for a directional polarized light emitter are given in the next section.

-polarized emission is shown in polar coordinates in the inset of Figure 3c. The detailed explanation of these results and the PhC design rules for a directional polarized light emitter are given in the next section.

Photonic-crystal design rules

The small fraction of the polarized emission from the Px dipole going inside the air cone is radiated to air, the remainder excites preferentially  -polarized guided modes propagating mostly in the y–z (m–c) plane (α=0). The excitation of guided modes propagating off this plane with angle α (generally referred here as off-axis direction) is reduced according to the toroidal emission pattern from the dipole (intensity proportional to cos2α). For a given wavelength λ in air, the wave vector emitted by the dipole inside the semiconductor slab (refractive index nGaN) is nGaNk0, and its projection in the x–z (a–c) plane is k‖=nGaNk0sinθi, where θi is the internal angle between the wave vector and the vertical direction. When the magnitude of the in-plane wave vector k‖ is smaller than the in-plane projection of the air cone, defined as a circle of radius k0=2π/λ, the wave is radiated to air. On the other hand, if k‖>k0, the wave stays inside the semiconductor slab as polarized guided light.

-polarized guided modes propagating mostly in the y–z (m–c) plane (α=0). The excitation of guided modes propagating off this plane with angle α (generally referred here as off-axis direction) is reduced according to the toroidal emission pattern from the dipole (intensity proportional to cos2α). For a given wavelength λ in air, the wave vector emitted by the dipole inside the semiconductor slab (refractive index nGaN) is nGaNk0, and its projection in the x–z (a–c) plane is k‖=nGaNk0sinθi, where θi is the internal angle between the wave vector and the vertical direction. When the magnitude of the in-plane wave vector k‖ is smaller than the in-plane projection of the air cone, defined as a circle of radius k0=2π/λ, the wave is radiated to air. On the other hand, if k‖>k0, the wave stays inside the semiconductor slab as polarized guided light.

In the present case, the embedded air gaps form a layer of lower effective index of refraction within the LED structure which creates a thin waveguide above the PhCs.26 A discrete set of nine guided modes is supported (Figure 4a) with effective indices neffective (where neffective=k‖/k0) between nGaN ∼2.41 and nPhC ∼2.03 (see Supplementary Information). The calculated dispersion relation of these modes, which corresponds to the in-plane wave vector k‖ guided in this waveguide structure for a given wavelength λ, is shown in Figure 4b.

Guided mode diffraction by PhCs. (a) Schematics of the single cavity formed in the layer above the embedded PhCs (not in scale) along with the electric field profile of three confined guided modes: a low (blue), a mid (pink) and a high (green) order modes, their in-plane (k‖) and diffracted (k‖,−1) wave vectors, and the PhC reciprocal vector G. The low order mode, which propagates originally in a glancing angle, is diffracted with a k‖,−1 close to the edge of the air cone (k0), therefore with a glancing angle in air (θ=90°), while the mid-order mode is diffracted at a smaller angle. The other extreme case is depicted by the high order mode, where k‖ is equal to G (k‖,−1=0), resulting in a diffracted wave vector along the vertical direction (θ=0°). (b) Calculated dispersion relation of all guided modes confined in the top layer above the PhCs. These modes are diffracted by the PhC reciprocal vector  inside the air cone, which correspond to the modes observed in Figure 3, where k‖,−1 is converted into θ by arcsin(k‖,−1/k0). (c) In-plane PhC reciprocal space, represented by the dots, showing the diffraction of polarized guided light within the air cone (red-dotted semicircles). Along the c direction (left), the incident guided mode with in-plane wave vector k‖ (solid-blue) and polarization Ea is diffracted by the PhC reciprocal vector

inside the air cone, which correspond to the modes observed in Figure 3, where k‖,−1 is converted into θ by arcsin(k‖,−1/k0). (c) In-plane PhC reciprocal space, represented by the dots, showing the diffraction of polarized guided light within the air cone (red-dotted semicircles). Along the c direction (left), the incident guided mode with in-plane wave vector k‖ (solid-blue) and polarization Ea is diffracted by the PhC reciprocal vector  , resulting in a diffracted in-plane wave vector kc,−1 (solid-red). Modes propagating off-axis (right) are also diffracted by 1D PhCs, in both the m–c and m–a planes (dotted-red wave vectors). These modes have polarization components Ea and Ec in both directions, which are diffracted to air. 1D, one-dimensional; PhC, photonic crystal.

, resulting in a diffracted in-plane wave vector kc,−1 (solid-red). Modes propagating off-axis (right) are also diffracted by 1D PhCs, in both the m–c and m–a planes (dotted-red wave vectors). These modes have polarization components Ea and Ec in both directions, which are diffracted to air. 1D, one-dimensional; PhC, photonic crystal.

PhCs (or optical gratings) diffract-guided modes by modifying their in-plane wave vector  , where

, where  is the PhC reciprocal vector (G=2π/a′ for 1D PhCs and a′ is the PhC period) and m is an integer. A guided mode is diffracted to air, along with its original polarization, when one of its infinite set of harmonics

is the PhC reciprocal vector (G=2π/a′ for 1D PhCs and a′ is the PhC period) and m is an integer. A guided mode is diffracted to air, along with its original polarization, when one of its infinite set of harmonics  is within the air cone,27 or

is within the air cone,27 or  (Figure 4a). The original polarization of the direct light and guided modes is not disturbed, neither by the LED structure, nor by the PhCs, since their different interfaces are parallel to each other, as well as to the direction of the main electric field

(Figure 4a). The original polarization of the direct light and guided modes is not disturbed, neither by the LED structure, nor by the PhCs, since their different interfaces are parallel to each other, as well as to the direction of the main electric field  , denoted by Ea (see Supplementary Information).28,29 Figure 4a shows the electric field profile of three of the guided modes supported in the thin waveguide diffracted by the PhCs. The diffracted in-plane wave vectors are conserved in different media, and different guided modes are diffracted by the PhCs at different well defined angles. For a given PhC design (given G), the low order mode (blue in Figure 4a) is diffracted with a k‖,−1 close to the edge of the air cone (k0), therefore propagating at a glancing angle in air. The other extreme is depicted by the high order mode (green), where the diffracted in-plane wave vector k‖,−1 is zero, resulting in a diffracted wave vector along the vertical direction. The effect of the PhC diffraction can also be seen in the calculated dispersion relation of the guided modes. Guided modes are extracted to air when diffracted by

, denoted by Ea (see Supplementary Information).28,29 Figure 4a shows the electric field profile of three of the guided modes supported in the thin waveguide diffracted by the PhCs. The diffracted in-plane wave vectors are conserved in different media, and different guided modes are diffracted by the PhCs at different well defined angles. For a given PhC design (given G), the low order mode (blue in Figure 4a) is diffracted with a k‖,−1 close to the edge of the air cone (k0), therefore propagating at a glancing angle in air. The other extreme is depicted by the high order mode (green), where the diffracted in-plane wave vector k‖,−1 is zero, resulting in a diffracted wave vector along the vertical direction. The effect of the PhC diffraction can also be seen in the calculated dispersion relation of the guided modes. Guided modes are extracted to air when diffracted by  inside the air cone, shown in dashed-lines in Figure 4b, which corresponds to the modes experimentally observed in Figure 3a, where k‖,−1 is converted into θ by θ=arcsin(k‖,−1/k0).

inside the air cone, shown in dashed-lines in Figure 4b, which corresponds to the modes experimentally observed in Figure 3a, where k‖,−1 is converted into θ by θ=arcsin(k‖,−1/k0).

For a more complete analysis, one should also look at the projection of the air cone and wave vectors in the plane of the PhCs (x–z plane) shown in Figure 4c. Guided modes are represented by a circle of radius k‖ (black semicircles), and their diffracted wave vector by the dashed-red semicircles in Figure 4c. 1D PhCs can be directly described in this in-plane wave vector representation by dots spaced by  . Along the c direction, the incident guided mode, with in-plane wave vector k‖ and polarization Ea, is diffracted by the PhC reciprocal vector

. Along the c direction, the incident guided mode, with in-plane wave vector k‖ and polarization Ea, is diffracted by the PhC reciprocal vector  , resulting in a diffracted in-plane wave vector kc,−1 (solid-red vector). The magnitude of kc,−1 varies with the ratio a′/λ, which determines the angle of diffraction of a mode and ultimately gives the PhC control over the direction of the diffracted light. For the present values of a′ and λ, the first low order guided mode, with neffective∼nGaN, determines the maximum angle at which the directional enhancement of light extraction occurs. Along the m–c plane, this angle is written as θe=arcsin(kc,−1/k0) (Figure 5a) which can be approximated by

, resulting in a diffracted in-plane wave vector kc,−1 (solid-red vector). The magnitude of kc,−1 varies with the ratio a′/λ, which determines the angle of diffraction of a mode and ultimately gives the PhC control over the direction of the diffracted light. For the present values of a′ and λ, the first low order guided mode, with neffective∼nGaN, determines the maximum angle at which the directional enhancement of light extraction occurs. Along the m–c plane, this angle is written as θe=arcsin(kc,−1/k0) (Figure 5a) which can be approximated by

Directional diffraction of guided modes by PhCs. (a) Top view of the air cone showing the diffraction of all guided modes supported in the embedded PhC LED within the air cone for a′/λ ratios of 0.58. The blue dots correspond to modes diffracted in the m–c plane, and the red dots to modes diffracted in the m–a plane. The lowest order mode defines the angle at the limit of diffraction θ=θe, which in this case is 43°. (b) Cross-sectional view of the air cone showing more clearly the light extraction angle θe and the directional emission of polarized light. (c) In-plane PhC reciprocal space for a′/λ ratios of 0.5, which results in a more directional extraction of polarized guided modes, with θe=24°. LED, light-emitting diode; PhC, photonic crystal.

For a′/λ=0.58, θe is equal to 43°, in agreement with the measurements in Figure 3b.

To increase the directional emission through a vertical extraction of the polarized guided light, the PhC period needs to be designed such that the diffracted kc,−1 is zero. Since the structure supports several guided modes and kc,−1 is different for each mode, this condition cannot be met by all modes. Moreover, the LED light emission is polychromatic (typical spontaneous luminescence linewidth δλ/λ≈0.05); even if the waveguide only supported one mode it would be extracted by the PhCs over some angular range. The design condition kc,−1=0 should then be applied to a mid-order mode (neffective≈2), which results in a′/λ=1/neffective≈0.5 and a more directional light-extraction angle θe=24° (Figure 5b). Figure 5a–5c shows all the diffracted modes in the in-plane representation for a′/λ=0.58 and a′/λ=0.5, which illustrates the increase in directional light extraction achieved for a′/λ=0.5.

Off-axis modes propagating at an angle α can also be diffracted into the air cone (solid-red wave vectors in Figure 4c), with diffracted wave vector components along both the a and c directions, as well as polarization components Ea and Ec along both directions (Figure 4c). Along the next direction of symmetry, the a direction, the diffracted wave vectors ka,−1 of off-axis modes (red dots in Figure 5a) have a sinusoidal dispersion relation λ=a′neffective cosα (see Supplementary Information).

The directional emission of  -polarized light along the m–a plane (observed in Figure 3c) is a result of the reduced excitation of the off-axis modes as α increases. The intensity of off-axis modes is proportional to their excitation by the Px dipoles which decreases as cos2α. The measured intensity of such modes after the polarization selection by the polarizer is also proportional to cos2α, due to the angle α between the mode's polarization and polarizer aligned to the a direction. Finally, the intensity of light collected by the rotating optical fiber needs to be corrected by a term cosθ that accounts for the change in solid angle with respect to θ (see Supplementary Information). This term also explains the angular response of the direct emission

-polarized light along the m–a plane (observed in Figure 3c) is a result of the reduced excitation of the off-axis modes as α increases. The intensity of off-axis modes is proportional to their excitation by the Px dipoles which decreases as cos2α. The measured intensity of such modes after the polarization selection by the polarizer is also proportional to cos2α, due to the angle α between the mode's polarization and polarizer aligned to the a direction. Finally, the intensity of light collected by the rotating optical fiber needs to be corrected by a term cosθ that accounts for the change in solid angle with respect to θ (see Supplementary Information). This term also explains the angular response of the direct emission  observed from the sample without PhCs (Figure 3b). Combining all these terms with the direct polarized emission results in

observed from the sample without PhCs (Figure 3b). Combining all these terms with the direct polarized emission results in

where α can also be expressed as a function of θ (see Supplementary Information).

From the same previous arguments, considering now a polarizer aligned to the c direction, the measured intensity of off-axis modes with  polarization is I‖c(θ)=Ic,0cos2αsin2αcosθ+Ic,direct(θ). This model is in good agreement with the experimental intensity of an extracted mode in the m–a plane for both a and c polarizations. Figure 6 shows the plot of the measured and calculated intensity versus angle using this model for both polarizations. The experimental intensity of a single mode (neffective=1.78) with

polarization is I‖c(θ)=Ic,0cos2αsin2αcosθ+Ic,direct(θ). This model is in good agreement with the experimental intensity of an extracted mode in the m–a plane for both a and c polarizations. Figure 6 shows the plot of the measured and calculated intensity versus angle using this model for both polarizations. The experimental intensity of a single mode (neffective=1.78) with  polarization was simply determined from the angle resolved measurement. For the

polarization was simply determined from the angle resolved measurement. For the  polarization, the modes and their respective replicas are simultaneously present in the measurements (see Supplementary Figure S1b). The intensity of the

polarization, the modes and their respective replicas are simultaneously present in the measurements (see Supplementary Figure S1b). The intensity of the  polarization shown in Figure 6 therefore corresponds to intensities originating from several direct modes and their diffracted replicas. We compare the measurement with our model calculated for two different modes, with effective indexes of 1.1 and 2, which represent the range of extracted modes along the m–a plane with

polarization shown in Figure 6 therefore corresponds to intensities originating from several direct modes and their diffracted replicas. We compare the measurement with our model calculated for two different modes, with effective indexes of 1.1 and 2, which represent the range of extracted modes along the m–a plane with  polarization.

polarization.

Intensity of extracted polarized modes. Measured intensity of an extracted mode in the m–a plane for both  and

and  polarizations along with the model of

polarizations along with the model of  and

and  . For the

. For the  polarization, an extra cosθ term was included in equation (3) to account for the fact that the polarizer is aligned to the direction of rotation, therefore at θ=90°, the polarizer is parallel to the m direction.

polarization, an extra cosθ term was included in equation (3) to account for the fact that the polarizer is aligned to the direction of rotation, therefore at θ=90°, the polarizer is parallel to the m direction.

The  polarization, which is originally weak as it originates from the Pz dipole, benefits now from a component Ec from the strong dipole Px that was propagating off-axis prior to diffraction by the PhCs. The contribution to the

polarization, which is originally weak as it originates from the Pz dipole, benefits now from a component Ec from the strong dipole Px that was propagating off-axis prior to diffraction by the PhCs. The contribution to the  polarization from the Pz or Px dipoles is distinguished by their wavelength, where longer wavelengths correspond to emission from Px dipole and short wavelengths to Pz dipole30 (see Supplementary Information).

polarization from the Pz or Px dipoles is distinguished by their wavelength, where longer wavelengths correspond to emission from Px dipole and short wavelengths to Pz dipole30 (see Supplementary Information).

The extraction of  polarized light originated from the main Px dipole does not deteriorate the polarization ratio of LEDs with 1D PhC since it occurs mainly at large angles. However, if one were to use two-dimensional PhCs, the two-dimensional network of reciprocal points would result in more diffraction channels, increasing the projection of the strong polarization into the c direction. Moreover, the extraction of Ec would happen in smaller angles which would be more detrimental to the polarization ratio. A reduction in the period a′ (or in the a′/λ ratio) of the 1D PhCs would not only increase the directional emission of polarized light but also diminish the extraction of

polarized light originated from the main Px dipole does not deteriorate the polarization ratio of LEDs with 1D PhC since it occurs mainly at large angles. However, if one were to use two-dimensional PhCs, the two-dimensional network of reciprocal points would result in more diffraction channels, increasing the projection of the strong polarization into the c direction. Moreover, the extraction of Ec would happen in smaller angles which would be more detrimental to the polarization ratio. A reduction in the period a′ (or in the a′/λ ratio) of the 1D PhCs would not only increase the directional emission of polarized light but also diminish the extraction of  -polarized mode. A smaller a′ (larger G) results in smaller in-plane angle α which reduces the intensity I‖c, even though in this case lower order modes are extracted in the m–a plane, which are generally better excited modes due to their larger overlap with the QWs.

-polarized mode. A smaller a′ (larger G) results in smaller in-plane angle α which reduces the intensity I‖c, even though in this case lower order modes are extracted in the m–a plane, which are generally better excited modes due to their larger overlap with the QWs.

Conclusions

We demonstrated in this paper a high-brightness polarized LED, achieved through the use of embedded PhCs. The air gap-embedded PhCs were introduced in m-plane GaN with a simple process, requiring only the patterning of the m-plane substrate prior to the LED growth by MOCVD. The resulting defect-free GaN layer coalesced over the embedded PhC is an important requirement for high-efficiency optoelectronic devices.

The polarization-preserving and directional light extraction properties from PhCs, along with the enhanced interaction of the embedded PhCs with the guided light, were combined to yield a directional polarized light emitting diode. We demonstrated that both direct and diffracted beams were highly polarized. A directional enhancement of the  -polarized emission, of up to 1.8-fold, was observed from the embedded PhCs with negligible changes in the

-polarized emission, of up to 1.8-fold, was observed from the embedded PhCs with negligible changes in the  polarization. A high degree of polarization of 88.7% at 465 nm was achieved.

polarization. A high degree of polarization of 88.7% at 465 nm was achieved.

Embedded PhCs offer a tool not only to increase polarized light emission in m-plane GaN LEDs, but to design their angular emission pattern. We discussed the important parameters to reduce even further the emission of  polarization and to enhance the directional emission of the

polarization and to enhance the directional emission of the  polarization, leading to polarized light emitters with higher brightness. This is not only desirable for LCD displays and polarized back-light sources in high efficiency TV displays and cell phones but also in general illumination, and could potentially lead the way to polarized white-light emitters.

polarization, leading to polarized light emitters with higher brightness. This is not only desirable for LCD displays and polarized back-light sources in high efficiency TV displays and cell phones but also in general illumination, and could potentially lead the way to polarized white-light emitters.

References

Pimputkar S, Speck JS, DenBaars SP, Nakamura S . Prospects for LED lighting. Nat Photon 2009; 3: 180–182.

Clear R, Mistrick RG . Multilayer polarizers: a review of the claims. J Illum Eng Soc 1996; 25: 70–88.

Japuntich DA . Polarized task lighting to reduce reflective glare in open-plan office cubicles. Appl Ergon 2001; 32: 485–499.

Cornelissen HJ, Jagt HJ, Broer DJ, Bastiaansen CW . Efficient and cost-effective polarized-light backlights for LCDs. Proc SPIE 2008; 7058: 70580X1.

Ecological Society of America. Polarized Light Leads Animals Astray: ‘Ecological Traps’ Cause Animal Behaviors That Can Lead To Death. ScienceDaily. Available at: http://www.sciencedaily.com/releases/2009/01/090107092714.htm (accessed 7 January 2009).

Chichibu S, Azuhata T, Sota T, Nakamura S . Spontaneous emission of localized excitons in InGaN single and multiquantum well structures. Appl Phys Lett 1996; 69: 4188–4190.

Waltereit P, Brandt O, Trampert A, Grahn HT, Menniger J et al. Nitride semiconductors free of electrostatic fields for efficient white light-emitting diodes. Nature 2000; 406: 865–868.

Chakraborty A, Haskell BA, Keller S, Speck JS, Denbaars SP et al. Demonstration of nonpolar m-plane InGaN/GaN light-emitting diodes on free-standing m-plane GaN substrates. J Appl Phys 2005; 44: L173–L175.

Schmidt MC, Kim KC, Sato H, Fellows N, Masui H et al. High power and high external efficiency m-plane InGaN light emitting diodes. J Appl Phys 2007; 46: L126–L128.

Gardner NF, Kim JC, Wierer JJ, Shen YC, Krames MR . Polarization anisotropy in the electroluminescence of m-plane InGaN–GaN multiple-quantum-well light-emitting diodes. Appl Phys Lett 2005; 86: 111101.

Tsujimura H, Nakagawa S, Okamoto K, Ohta H . Characteristics of polarized electroluminescence from m-plane InGaN-based light emitting diodes. J Appl Phys 2007; 46: L1010–L1012.

Kubota M, Okamoto K, Tanaka T, Ohta H . Temperature dependence of polarized photo-luminescence from nonpolar m-plane InGaN multiple quantum wells for blue laser diodes. Appl Phys Lett 2008; 92: 011920.

Brinkley SE, Lin YD, Chakraborty A, Pfaff N, Cohen D et al. Polarized spontaneous emission from blue-green m-plane GaN-based light emitting diodes. Appl Phys Lett 2011; 98: 011110.

Fujii T, Gao Y, Sharma R, Hu EL, DenBaars SP et al. Increase in the extraction efficiency of GaN-based light-emitting diodes via surface roughening. Appl Phys Lett 2004; 84: 855–857.

Yamada M, Mitani T, Narukawa Y, Shioji S, Niki I et al. InGaN-based near-ultraviolet and blue light emitting diodes with high external quantum efficiency using a patterned sapphire substrate and a mesh electrode. J Appl Phys 2002; 41: L1431–L1433.

Wierer JJ, David A, Megens MM . III-nitride photonic-crystal light-emitting diodes with high extraction efficiency. Nat Photon 2009; 3: 163–169.

Matioli E, Rangel E, Iza M, Fleury B, Pfaff N et al. High extraction efficiency LED based on embedded air-gap photonic-crystals. Appl Phys Lett 2010; 96: 031108.

DeMille NF, Denbaars SP, Nakamura S . Linearly polarized backlight source in conjunction with polarized phosphor emission screens for use in liquid crystal displays. US Patent 12/536,400, 5 August 2009.

Mulder CL, Reusswig PD, Beyler AP, Kim H, Rotschild C et al. Dye alignment in luminescent solar concentrators: II. Horizontal alignment for energy harvesting in linear polarizers. Opt Express 2010; 18: A91.

Matioli E, Keller S, Wu F, Choi YS, Hu E et al. Growth of embedded photonic crystals for GaN-based optoelectronic devices. J Appl Phys 2009; 106: 024309.

Getty A, Matioli E, Iza M, Weisbuch C, Speck J . Electroluminescent measurement of the internal quantum efficiency of light emitting diodes. Appl Phys Lett 2009; 94: 181102.

Born M . Atomic physics. 8th ed. London: Blackie & Son Limited, 1969.

Ghosh S, Waltereit P, Brandt O, Grahn HT, Ploog KH . Electronic band structure of wurtzite GaN under biaxial strain in the M plane investigated with photoreflectance spectroscopy. Phys. Rev B 2002; 65: 075202.

Sun YJ, Brandt O, Ramsteiner M, Grahn HT, Ploog KH . Polarization anisotropy of the photoluminescence of m-plane (In,Ga)N/GaN multiple quantum wells. Appl Phys Lett 2003; 82: 22.

Matioli E, Fleury B, Rangel E, Melo T, Hu E et al. High extraction efficiency GaN-based photonic-crystal light-emitting diodes: comparison of extraction lengths between surface and embedded photonic-crystals. Appl Phys Express 2010; 3: 032103.

Matioli E, Weisbuch C . Impact of photonic crystals on LED light extraction efficiency: approaches and limits to vertical structure designs. J Phys D: Appl Phys 2010; 43: 354005.

David A, Benisty H, Weisbuch C . Optimization of light-diffracting photonic-crystals for high extraction efficiency LEDs. J Display Technol 2007; 3: 133–148.

Lai CF, Chi JY, Yen HH, Kuo HC, Chao CH et al. Polarized light emission from photonic crystal light-emitting diodes. Appl Phys Lett 2008; 92: 243118.

Jackson JD . Classical electrodynamics. New York: Wiley, 1998.

Matioli E, Brinkley S, Kelchner K, Nakamura S, DenBaars S et al. Polarized light extraction in m-plane GaN light-emitting diodes by embedded photonic crystals. Appl Phys Lett 2011; 98: 251112.

Acknowledgements

The experimental part of this work was performed at University of California, Santa Barbara. This study is based upon work partially supported as part of the ‘Center for Energy Efficient Materials’ at University of California, Santa Barbara, an Energy Frontier Research Center funded by the US Department of Energy, Office of Science, Office of Basic Energy Sciences under Award Number DE-SC0001009 and by the Solid State Lighting and Energy Center (SSLEC) at the University of California, Santa Barbara.

Author information

Authors and Affiliations

Corresponding author

Additional information

Note: Supplementary information is available on the Light: Science & Applications' website.

Supplementary information

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Matioli, E., Brinkley, S., Kelchner, K. et al. High-brightness polarized light-emitting diodes. Light Sci Appl 1, e22 (2012). https://doi.org/10.1038/lsa.2012.22

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/lsa.2012.22

Keywords

This article is cited by

-

Unidirectional luminescence from InGaN/GaN quantum-well metasurfaces

Nature Photonics (2020)

-

Strong and robust polarization anisotropy of site- and size-controlled single InGaN/GaN quantum wires

Scientific Reports (2020)

-

A novel strategy for high color purity virescent Er3+-doped SrLaAlO4 nanocrystals for solid-state lighting applications

Journal of Materials Science: Materials in Electronics (2020)

-

Tailoring magnetic characteristics of (Fe1−xCox)81Zr9B10 amorphous alloys via engineering crystallization processes

Applied Physics A (2019)

-

Carrier behavior in the vicinity of pit defects in GaN characterized by ultraviolet light-assisted Kelvin probe force microscopy

Science China Physics, Mechanics & Astronomy (2019)