Abstract

A stretchable organic digital information storage device has been developed, which potentially advances the development of future smart and digital stretchable electronic systems. The stretchable organic memory with a buckled structure was configured by a mechanically flexible and elastic graphene bottom electrode and polymer compound. The current–voltage curve of the wrinkled memory device demonstrated electrical bistability with typical write-once-read-many times memory features and a high ON/OFF current ratio (∼105). Even under repetitive stretching, the stretchable organic memory exhibited excellent electrical switching functions and memory effects. We believe the first proof-of-concept presentation of the stretchable organic nonvolatile memory may accelerate the development of information storage device in various stretchable electronic applications, such as stretchable display, wearable computer and artificial skin.

Similar content being viewed by others

Introduction

Stretchable electronics are a new class of electronics that are undergoing rapid development.1, 2 Such emerging elastic devices have attracted keen interest owing to their tremendous potential in a wide variety of future applications, such as in wearable computers, highly flexible paper displays with stretchability, artificial electronic skin, biomedical applications for health monitoring and biological actuation.3, 4, 5 Future ‘intelligent’ stretchable electronic modules will require the integration of multiple crucial electronic devices, such as logic memory, a power supply and a display, into an elastic polymeric substrate.2 So far, successful progress toward stretchable electronics has been reported for various core electronic devices, such as transistors,6, 7 light-emitting diodes,8, 9 sensors,10, 11 antennas,12 solar cells13, 14 and batteries.15, 16

In digital applications, information storage devices, such as programmable read-only memory and flash memory, have key roles as fundamental components in modern and future ‘smart’ electronic systems.17 Without doubt, for stretchable electronics to be utilized in applications, the fabrication of stretchable digital memory devices onto elastic electronic modules or peripheral circuitries is essential. A major problem in the fabrication of stretchable information storage devices like Flash memories is the complex and rigid metal-oxide-semiconductor structures with floating gates as additional sources and drains.18 Interestingly, flexible information storage devices based on organic transistor devices with floating gate structures have been demonstrated previously in the literature;19, 20 the potential stretchability of these devices is implied if they are fabricated via ultrathin polymer films. Alternatively, recent progress toward resistive random access memory has effectively simplified traditional complex Flash memory into a simple sandwich configuration.21, 22 Among various materials, organic memory has been considered to be a promising candidate for next-generation information devices in soft electronic systems.22, 23, 24 The primary benefits of organic memory are often listed as simple fabrication, low cost and rapid access, as well as compatibility with roll-to-roll printability for mass industrial production.22, 23, 24 The unique elasticity and flexibility of organic materials hold great promise for future stretchable and foldable electronic systems. Moreover, the low-temperature fabrication process of organic memory also offers benefits for integrating memory devices into stretchable electronic systems on an elastic polymeric substrate. The combination of these advantages makes it possible that organic memory devices will be integrated into future stretchable electronic modules, such as stretchable smart pads, artificial skin and wearable electronics for learning and retaining digital information or original driver codes. However, the active polymer and organic materials are typically deposited by solution processes, such as spin-coating and various ink-jet printing methods.23 A serious hurdle in the utilization of stretchable organic memory is the fact that the solvent used in the deposition of the organic active layer is less compatible with soft substrates such as plastics and elastomers.25 Damage caused by the solvents can be magnified when there is vertical integration with other organic stretchable devices.26 In addition, the fabrication of the organic devices on the elastic soft substrates involves difficult handling and processing requirements. Therefore, a suitable processing strategy is essential for realizing stretchable organic memory.

Another challenge for stretchable electronics comes from the brittleness of the metal electrode. Recently, graphene, one of the thinnest known materials, has gained a large amount of attention from many researchers and companies because of its exceptional physical and electrical properties.27 The excellent mechanical flexibility and elastic properties of graphene, together with its superior carrier mobility, transparency and inexpensive features make it an outstanding choice as an electrode for next-generation flexible and foldable electronics.28, 29, 30 A chemical vapor deposition (CVD) method for growing large-scale graphene film was successfully developed, allowing further use of graphene in practical applications and mass roll-to-roll manufacturing.29 In addition, graphene provides a good interfacial substrate and possesses low contact resistance with organic materials.31 More importantly, a combination of its flexibility and strong adhesive force to the substrate, that is, Van der Waals interaction (adhesive energy of 0.45 J m−2 on SiO2),32 makes graphene an excellent electrode that can naturally adhere onto an elastic substrate to generate flexible and stretchable electronic applications. Previously, elastic, wrinkled graphene has shown promise for use in different applications, such as in strain sensing and field emission.33, 34 Recently, using a novel method to control the crumpling and unfolding of a large area of graphene with polymer laminates has also been reported for artificial-muscle actuators.35 Taking the advantages of graphene and the mechanical flexibility of the organic material may open up a path for stretchable devices. However, the issues in transferring CVD-graphene and the chemical washing of the protective layer in the stripping process are shortcomings for the application of graphene in stretchable electronics.

In this contribution, we have successfully demonstrated a stretchable organic memory device based on wrinkled structures, which represents a proof-of-concept for stretchable organic digital information storage devices. The stretchable organic memory structured with a graphene electrode and polymer compound was fabricated onto a ∼50% pre-strained poly (dimethylsiloxane) (PDMS) elastomer (here, strain is defined as (L−Lo)/Lo × 100%, where L is the elongate length and Lo is the original length). Through a transfer method, we can simply avoid the coating and solvent issue from the organic active layer and the chemical treatment for removal of the protective layer of the graphene electrode. After carefully releasing the device from the specific pre-strain, the organic memory device with a graphene bottom electrode spontaneously buckled to waves from the compressive strain from the adhered PDMS. The resultant buckled organic memory with the underlying graphene electrode can be elongated by conversion of the vertical displacement and planar strain, which realizes the device’s stretchability. The stretchable memory devices exhibited typical write-once-read-many (WORM)-type memory features with a high ON/OFF ratio (∼105). Excellent retention ability of over 104 s for the coded ON/OFF states was maintained by the memory devices even under re-stretching up to 50% strain. In addition, the WORM-type electrical switching behaviors can be normally programmed under various stretching levels from zero to the pre-strain. For the stretching duration tests, the programmed ON/OFF states did not significantly fluctuate even when undergoing successive strain cycles of 30% over 500 times. Moreover, after hundreds of stretching cycles at 30%, the stretchable organic memory retained its original electrical switching function. It is thought that this is the first demonstration of a stretchable organic memory device and may pave the way for generating stretchable digital information storage devices as well as advance the development of smarter digitized stretchable electronic systems, such as stretchable displays, wearable computers and artificial skin.

Materials and methods

Substrate preparation

To start the preparation of the PDMS substrate, a curing agent and PDMS prepolymer (Sylgard 184, Dow Corning, Taipei, Taiwan) were mixed in a 1:20 weight ratio. The mixture was degassed by reducing pressure for 1 h to avoid any air bubbles in the mixture, and then it was poured onto the polished side of a silicon wafer. After curing, the PDMS membranes that were produced possessed a thickness of ∼2 mm. The PDMS membranes were then peeled off the wafer, and the PDMS substrate was cut out into a rectangle with an area of 2 cm × 6 cm. The elastic PDMS substrate was subsequently clamped on one side to a glass slide and then stretched along the length of the glass slide to a pre-strain of ∼50%. The other side was then clamped, with a slight component force in the orthogonal direction.

Device fabrication

For preparation of organic memory from the poly (methyl methacrylate): poly (3-butylthiophene) with a graphene bottom electrode, poly (3-butylthiophene) (10 mg, Sigma-Aldrich, St Louis, MO, USA) was first dissolved in chlorobenzene (0.5 ml) and then blended with poly (methyl methacrylate) (0.5 ml, 950k A4, Micro-Chem, Newton, MA, USA) with stirring at 50 °C for 1 day. Next, the prepared solution was then dropped on an as-prepared CVD-graphene/copper foil and allowed to rest for 10 min, and then the spin-coating process was performed at a rate of 2500 r.p.m. for 20 s. After drying under reduced pressure, the polymer-coated CVD-graphene/Cu foil was immersed into a copper etchant, for example, an aqueous solution of iron nitrate (Fe(NO3)3) (0.05 g ml−1), for ∼4 h to etch the sacrificial copper foil. The poly (methyl methacrylate): poly (3-butylthiophene)/graphene film was subsequently transferred to a deionized water bath to wash away the copper etchant and was then transferred onto the pre-strained PDMS substrate. After drying naturally, 300-nm aluminum electrodes were thermally deposited onto the top of polymer layer in circular patterns. Finally, after carefully removing the clamps, the resultant devices spontaneously contracted and buckled on the released PDMS substrates.

Device measurement

Electrical characterization of the stretchable organic memory was carried out using a Keithley 4200-SCS semiconductor parameter analyzer purchased from Keithley (Cleveland, OH, USA). All electrical properties were measured at room temperature and under ambient conditions.

Results and Discussion

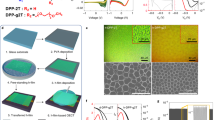

Figure 1 presents the schematic processes involving in generating the stretchable organic memory. First, the graphene was grown by a typical CVD method.36 The CVD-graphene sheet with few defects was characterized by Raman spectroscopy (see Supplementary Figure 1). The as-prepared blending solution of PMMA and P3BT was then spin coated onto the CVD-graphene. The PMMA and P3HT acted as the active layer for the organic memory and also played a role as the protective layer for transferring the graphene electrode. After etching away the supporting copper foil, the substrate-free graphene/PMMA:P3BT membrane was transferred onto a pre-strained PDMS substrate. The elastomer PDMS substrate was pre-stretched by ∼50% and clamped onto a glass slide. To probe the bottom graphene, a gold contact film was pre-deposited onto the border of the PDMS and was in partial contact with the bottom graphene electrode. After the transferred film dried naturally, the clamps were removed, and the device was carefully separated from the glass. The resultant film then spontaneously contracted and formed a ripple on the released substrate. The fabrication process outlined here can be carried out without any solvents, thereby eliminating issues with coating and with chemical removal of the protective layer in the stripping of graphene, which may be beneficial for the fabrication of devices on an elastic polymeric substrate and which paves the way for vertically integrating this device with other stretchable organic devices. In addition, the combination of the organic memory and the protective layer of graphene may effectively simplify the fabrication processes and provide an advantage for roll-to-roll industrial fabrication.23, 29

Figures 2a and b show top-view and angled-view scanning electron microscopy images of the resultant rippled film. The stress strain distribution within the resultant film has been calculated by finite element simulation, and the results are shown in Supplementary Figure 2. As shown in Figure 2, after releasing the pre-strained PDMS, the film exhibited numerous ripples perpendicular to the pre-stretched tensile direction. The resultant buckled organic memory with the graphene underlay can be elongated by conversion of the vertical delaminated displacement and planar strain into a larger size of the device, which realizes the stretchability of the buckled memory.33, 35, 37 In the atomic force microscope analysis (Supplementary Figure 3), the released film also showed numerous nano-scale wrinkles.

The electrical switching behaviors and memory effects of the wrinkled organic memory are illustrated by the current–voltage (I–V) measurement, as shown in Figure 3a. Supplementary Figure 4 shows the schematic of the measurement set-up. Initially, the current level of the memory device remained low and gradually increased to the range of 10−11–10−9 A during the low-bias regime. When the bias was larger than the threshold voltage of approximately 2.6 V, the current level of the memory device sharply increased and switched to a high-current state (from ∼10−9 to ∼10−4 A). This transition of the electrical characteristics from a low-current (OFF, ‘0’) state to a high-current (ON, ‘1’) state corresponds to the ‘writing’ command in the digital memory device.22, 23 As shown in Figure 3b, a high ON/OFF current ratio (∼105) at the reading voltage of 1 V rendered the data stored in the buckled organic memory ready to be accessed with a low probability of misreading the data. Once the device was switched to the ON-state, the programmed state was not retrievable during the following forward/negative sweep, indicating that the buckled organic memory exhibits the typical features of WORM-type memory devices.23 The programmed ON-state remained in the high-current level even if the applied voltage was removed, indicative of the non-volatile feature of this memory behavior. The electrical switching effect of the memory is explained by the charge-trapping mechanism and percolation effects as shown in previous reports.23, 38

After characterizing the WORM-type organic memory under relaxed conditions, we then analyzed a programmed ON-state under different stretching conditions to confirm that the coded high-conductivity ON-state can be maintained after strain. As shown in Figure 4a, the device in its ON-state can keep its programmed high-current status regardless of being re-strained from 10% to pre-strain, indicating that the memory effects were not affected by re-stretching the memory to pre-strain conditions, which is promising for its use with memory applications in stretchable electronic systems. After we stretched the device to over 60% strain, the programmed ON-state suddenly lost its high-conductivity status (as shown in Supplementary Figure 5), which indicates that the maximum strain of the code ON-state is 60%. The reason that the memory cells can work at strain levels above the pre-strain level is the interconnections within the fractured graphene underlay.33, 39 However, if the pre-strain level exceeds a critical magnitude and causes the breakdown of the interconnections, the memory cell will cease to function.

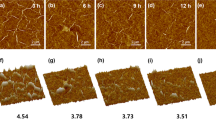

For memory devices, the data storage time is an important characteristic for practical, stretchable WORM-type memory applications. Thus, the ability to retain the coded digital data under various stretching conditions was tested. Coding of memory began with the OFF/ON-state at the original un-strained length and then the device’s data retention ability was tested before the device was stretched. As shown in Figure 4b, the electrical WORM-type memory exhibited an excellent retention ability for over 104 s, and the high ON/OFF current ratio (∼105) did not change after a considerable duration of time. After confirming the retention ability at the un-strained length, the data retention ability of the buckled organic memory was tested under various uniaxially elongating conditions by stretching from 10 to 50% strain. As seen in Figure 4b, the programmed low-conductivity ON-state demonstrated a strong retention ability (up to 104 s), and no significant degradation was found when the device was re-stretched from 10 to 50% pre-strain. In additionally, the ON/OFF current ratio maintained its value in the same order of magnitude before the stretching of the device. A longer retention test of up to 12 h can be found in Supplementary Figure 6. These results suggest that the programmed digital signal can be accurately accessed for prolonged retention, even when re-stretching the device up to an initial pre-stretched value of 50% strain. The stability of the long-term retention might be expected because of the high activation energy of the P3BT-trapped charge carriers.38 At the writing voltage, numerous carriers were injected from the electrode, which filled up the P3BT trapping sites, and the percolation pathways of the carriers were formed among these charge-filled P3BTs, resulting in the electrical switching behavior and the subsequent high conductivity ON-state. Owing to the stability of the P3BT-trapped charges within the PMMA matrix, the organic memory can retain the programmed high conductivity state over the long term even after the power supply has been removed. Similar results have been reported in WORM-type memory fabricated from high concentration ratio of P3HT molecules embedded in a PMMA layer.40 Park et al.40 suggested that the long-term stability of the WORM-type memory might be attributed to the lowest unoccupied molecular orbital of the P3HT polymers being much deeper than the lowest unoccupied molecular orbital level of PMMA matrix. Thus, the charge carriers trapped in the P3HT media are unable to be emitted. The data stability of stretchable organic WORM-type memory can provide excellent digital information storage under various stretching conditions, which is also beneficial for the development of a wide variety of stretchable data storage applications, such as stretchable and portable disks, stretchable smart cards, biomedical skin markers and stretchable radio-frequency identification tags.23

To evaluate the feasibility of using stretchable organic memory in stretchable electronic applications, the electrical switching behaviors from the different memory devices were tested under different stretching conditions (Multimedia in Supplementary Information). As shown in Figures 5a–e, the organic memory exhibited similar WORM-type memory switching behaviors under re-stretching from 10 to 50% strain. Under various strain conditions, a low-writing voltage (below 4 V) was retained, demonstrating the advantage of low-power consumption of stretchable memory applications. It is also worth mentioning that the distinguishable ON/OFF states at the reading voltage of 1 V were preserved under each stretching condition, holding the promise of a low probability of misreading data under different stretching conditions. These results suggest that WORM-type memory can operate well and be programmed well for digital data even if the organic memory is being elongated.

Next, the durability of the programmed ON/OFF state under stretching conditions was further investigated. In exploring the effect of cyclical stretching, the buckled WORM-type organic memory was initially programmed to the ON-state (Figure 6a) and successively stretched to 30% and then released to its un-strained length. As shown in Figure 6b, the coded ON state could preserve its programmed high-current conductivity and did not show obvious degradation after 500 cycles of being stretched by 30%, which is indicative of durability of the coded data even under numerous cycles of elongation and hence stretching. Identical testing was also conducted for the initial OFF-state. As shown in Figure 6c, the initial low-conductivity OFF-state was not altered by successive stretching of 30% for 500 times. Figure 6d shows the electrically programmed process of the WORM-type memory after stretching by 30% for 500 cycles. As seen in Figure 6d, even after 500 cycles of 30% strain, the electrical switching behavior operated normally from the OFF-state to the ON-state with a similar high ON/OFF ratio (∼105) at a reading bias of 1 V compared with the unstrained device. These results suggest that the coded ON/OFF state can be correctly read out even after numerous cycles of elongation and contraction, demonstrating the durability of the stretchable memory for keeping the coded digital information (see Multimedia in Supplementary Information). In addition, the stretchable organic memory was programmed normally, and its original electrical switching functions were retained even when the devices underwent numerous cycles of stretching, indicating their appropriateness for stretchable memory applications.

The durability test for the coded state under repetitive stretching (30% strain) and relaxing (0% strain) cycles. (a) The stretchable organic memory under 30% strain. (b) The coded ON-state under repetitive stretching (30% strain) and relaxing (0% strain) for 500 cycles. (c) The initial OFF-state under repetitive stretching (30% strain) and relaxing (0% strain) for 500 cycles. (d) The stretchable organic memory under 500 cycles of stretching with 30% strain.

It is worth noting that the compressive stress in the orthogonal direction is likely to cause fractures and cracks after relaxation of the pre-strain tension. This issue will limit the degree of the pre-strain of the transferred memory film in this device. In this experiment, the cracks introduced by the orthogonal compression decreased the yield of stretchable memory cells but did not affect the electrical switching effect during post-stretching. Owing to the interconnections within the graphene underlay and the side contacts with the Au film, the bottom electrode can conduct normally.33 In addition, the conductivity switching effect may arise from an area that is small compared with the top electrode and cracks, still allowing the conductivity switching behavior to be retained in the presence of cracks. To overcome the above difficulty, pre-strain in the orthogonal direction can release the cracks and increase the yield of memory cells.35 A scanning electron microscopy image of the relaxed film with a biaxially pre-strained substrate is shown in Supplementary Figure 7. It was found that the cracks in the film can be greatly reduced by using a biaxially pre-strained substrate. Another method is to use a uniaxial compressive film for re-stretching. In the literature, White et al.8 and Kaltenbrunner et al.14 have demonstrated stretchable polymer light-emitting devices and stretchable organic solar cells, respectively, by using compressive ultrathin devices. Alternatively, this situation can also be mitigated by using thin strip geometries oriented along the long axis, which is along the direction of the pre-strain.33 Clearly, the methodology needed to avoid the cracks formed by the orthogonal compression requires further investigation.

We emphasize that the transfer process presented here has several exceptional functions and features for generating stretchable organic memory. First, owing to the adhesive features and the ready-to-conduct graphene underlay without other supports, it is possible to transfer the memory devices onto stretchable electronics or circuitries while eliminating the solvent issue. In addition, using the transferrable organic memory with the graphene electrode may be beneficial for solving the handling and processing issue in the fabrication of organic memory devices on elastic polymeric substrates. Moreover, both of the organic materials and the bottom Cu/CVD-graphene are compatible with roll-to-roll fabricating processes. Consequently, the resultant stretchable organic memory may be beneficial for future industrial large-area printing and modular manufacture.

Conclusions

In summary, we have successfully demonstrated proof-of-concept of a stretchable organic memory device with a graphene bottom electrode, which represents the first stretchable organic information storage device. The stretchable organic memory was structured by the mechanically flexible and elastic graphene bottom electrode and polymer compound. Using a transfer method, we simply labeled the organic memory onto a 50% pre-strained PDMS substrate without any solvent issues or chemical treatment. After releasing the pre-strained PDMS, the resultant organic memory showed buckled structures and possessed typical WORM-type memory features with a high ON/OFF current ratio (∼105). The buckled organic WORM-type memory exhibited excellent retention of the coded ON state over 104 s and did not significantly degrade under re-stretching to less than 50% strain. In addition, the WORM-type memory functioned and was programmed normally under various stretching conditions from 10% to pre-strain tension. In stretching duration tests, the programmed ON/OFF states preserved the original coded state even under successive cycles of 30% strain up to 500 times while the device retained normal functionality. We believe that the first demonstration of stretchable organic WORM-type memory shown here will greatly advance the development of stretchable digital information storage devices for use in various soft electronic applications, such as stretchable displays, wearable computers and artificial skin.

References

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Sekitani, T. & Someya, T. Stretchable, large-area organic electronics. Adv. Mater. 22, 2228–2246 (2010).

Kim, D. H., Lu, N., Ma, R., Kim, Y. S., Kim, R. H., Wang, S., Wu, J., Won, S. M., Tao, H., Islam, A., Yu, K. J., Kim, T. i., Chowdhury, R., Ying, M., Xu, L., Li, M., Chung, H. J., Keum, H., McCormick, M., Liu, P., Zhang, Y. W., Omenetto, F. G., Huang, Y., Coleman, T. & Rogers, J. A. Epidermal electronics. Science 333, 838–843 (2011).

Kim, R. H., Kim, D. H., Xiao, J., Kim, B. H., Park, S. I., Panilaitis, B., Ghaffari, R., Yao, J., Li, M., Liu, Z., Malyarchuk, V., Kim, D. G., Le, A. P., Nuzzo, R. G., Kaplan, D. L., Omenetto, F. G., Huang, Y., Kang, Z. & Rogers, J. A. Waterproof AlInGaP optoelectronics on stretchable substrates with applications in biomedicine and robotics. Nat. Mater. 9, 929–937 (2010).

Hammock, M. L., Chortos, A., Tee, B. C. K., Tok, J. B. H. & Bao, Z. 25th Anniversary Article: The evolution of electronic skin (E-Skin): a brief history, design considerations, and recent progress. Adv. Mater. 25, 5997–6038 (2013).

Chae, S. H., Yu, W. J., Bae, J. J., Duong, D. L., Perello, D., Jeong, H. Y., Ta, Q. H., Ly, T. H., Vu, Q. A., Yun, M., Duan, X. & Lee, Y. H. Transferred wrinkled Al2O3 for highly stretchable and transparent graphene–carbon nanotube transistors. Nat. Mater. 12, 403–409 (2013).

Kaltenbrunner, M., Sekitani, T., Reeder, J., Yokota, T., Kuribara, K., Tokuhara, T., Drack, M., Schwödiauer, R., Graz, I., Bauer-Gogonea, S., Bauer, S. & Someya, T. An ultra-lightweight design for imperceptible plastic electronics. Nature 499, 458–463 (2013).

White, M. S., Kaltenbrunner, M., Glowacki, E. D., Gutnichenko, K., Kettlgruber, G., Graz, I., Aazou, S., Ulbricht, C., Egbe, D. A. M., Miron, M. C., Major, Z., Scharber, M. C., Sekitani, T., Someya, T., Bauer, S. & Sariciftci, N. S. Ultrathin, highly flexible and stretchable PLEDs. Nat. Photonics 7, 811–816 (2013).

Liang, J., Li, L., Niu, X., Yu, Z. & Pei, Q. Elastomeric polymer light-emitting devices and displays. Nat. Photonics 7, 817–824 (2013).

Someya, T., Sekitani, T., Iba, S., Kato, Y., Kawaguchi, H. & Sakurai, T. A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl Acad. Sci. USA 101, 9966–9970 (2004).

Yamada, T., Hayamizu, Y., Yamamoto, Y., Yomogida, Y., Izadi-Najafabadi, A., Futaba, D. N. & Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol 6, 296–301 (2011).

Park, M., Im, J., Shin, M., Min, Y., Park, J., Cho, H., Park, S., Shim, M. B., Jeon, S., Chung, D. Y., Bae, J., Park, J., Jeong, U. & Kim, K. Highly stretchable electric circuits from a composite material of silver nanoparticles and elastomeric fibres. Nat. Nanotechnol. 7, 803–809 (2012).

Lipomi, D. J., Tee, B. C. K., Vosgueritchian, M. & Bao, Z. Stretchable organic solar cells. Adv. Mater. 23, 1771–1775 (2011).

Kaltenbrunner, M., White, M. S., Głowacki, E. D., Sekitani, T., Someya, T., Sariciftci, N. S. & Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 3, 770 (2012).

Kaltenbrunner, M., Kettlgruber, G., Siket, C., Schwödiauer, R. & Bauer, S. Arrays of ultracompliant electrochemical dry gel cells for stretchable electronics. Adv. Mater. 22, 2065–2067 (2010).

Gaikwad, A. M., Zamarayeva, A. M., Rousseau, J., Chu, H., Derin, I. & Steingart, D. A. Highly stretchable alkaline batteries based on an embedded conductive fabric. Adv. Mater. 24, 5071–5076 (2012).

Sharma, A. K. Advanced Semiconductor Memories: Architectures, Designs, and Applications, Wiley-Interscience: Piscataway: NJ Hoboken, (2003).

Chang, T. C., Jian, F. Y., Chen, S. C. & Tsai, Y. T. Developments in nanocrystal memory. Mater. Today 14, 608–615 (2011).

Sekitani, T., Yokota, T., Zschieschang, U., Klauk, H., Bauer, S., Takeuchi, K., Takamiya, M., Sakurai, T. & Someya, T. Organic nonvolatile memory transistors for flexible sensor array. Science 326, 1516–1519 (2009).

Kaltenbrunner, M., Stadler, P., Schwödiauer, R., Hassel, A. W., Sariciftci, N. S. & Bauer, S. Anodized aluminum oxide thin films for room-temperature-processed, flexible, low-voltage organic non-volatile memory elements with excellent charge retention. Adv. Mater. 23, 4892–4896 (2011).

Yang, J. J., Strukov, D. B. & Stewart, D. R. Memristive devices for computing. Nat. Nanotechnol. 8, 13–24 (2012).

Ouyang, J., Chu, C. W., Szmanda, C. R., Ma, L. & Yang, Y. Programmable polymer thin film and non-volatile memory device. Nat. Mater. 3, 918–922 (2004).

Ling, Q. D., Liaw, D. J., Zhu, C., Chan, D. S. H., Kang, E. T. & Neoh, K. G. Polymer electronic memories: materials, devices and mechanisms. Prog. Polym. Sci. 33, 917–978 (2008).

International Technology Roadmap for Semiconductors, ITRS http://www.itrs.net/Links/2012ITRS/Home2012.htm. last accessed on June (2013).

Guo, R., Yu, Y., Xie, Z., Liu, X., Zhou, X., Gao, Y., Liu, Z., Zhou, F., Yang, Y. & Zheng, Z. Matrix-assisted catalytic printing for the fabrication of multiscale, flexible, foldable, and stretchable metal conductors. Adv. Mater. 25, 3343–3350 (2013).

Hadipour, A., De Boer, B., Wildeman, J., Kooistra, F. B., Hummelen, J. C., Turbiez, M. G., Wienk, M. M., Janssen, R. A. & Blom, P. W. Solution-processed organic tandem solar cells. Adv. Funct. Mater. 16, 1897–1903 (2006).

Geim, A. K. & Novoselov, K. S. The rise of graphene. Nat. Mater. 6, 183–191 (2007).

Yan, C., Lee, S. K., Jang, H. & Ahn, J. H. in Stretchable Electronics ed. Someya T., Ch. 3, 43–80 Wiley: Weinheim, (2012).

Bae, S., Kim, H., Lee, Y., Xu, X., Park, J. S., Zheng, Y., Balakrishnan, J., Lei, T., Kim, H. R., Song, Y. I., Kim, Y. J., Kim, K. S., Ozyilmaz, B., Ahn, J. H., Hong, B. H. & Iijima, S. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 5, 574–578 (2010).

Kim, K. S., Zhao, Y., Jang, H., Lee, S. Y., Kim, J. M., Kim, K. S., Ahn, J. H., Kim, P., Choi, J. Y. & Hong, B. H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457, 706–710 (2009).

Lee, C. G., Park, S., Ruoff, R. S. & Dodabalapur, A. Integration of reduced graphene oxide into organic field-effect transistors as conducting electrodes and as a metal modification layer. Appl. Phys. Lett. 95, 023304 (2009).

Koenig, S. P., Boddeti, N. G., Dunn, M. L. & Bunch, J. S. Ultrastrong adhesion of graphene membranes. Nat. Nanotechnol. 6, 543–546 (2011).

Wang, Y., Yang, R., Shi, Z., Zhang, L., Shi, D., Wang, E. & Zhang, G. Super-elastic graphene ripples for flexible strain sensors. ACS Nano 5, 3645–3650 (2011).

Guo, Y. & Guo, W. Electronic and field emission properties of wrinkled graphene. J. Phys. Chem. C 117, 692–696 (2013).

Zang, J., Ryu, S., Pugno, N., Wang, Q., Tu, Q., Buehler, M. J. & Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 12, 321–325 (2013).

Li, X., Cai, W., An, J., Kim, S., Nah, J., Yang, D., Piner, R., Velamakanni, A., Jung, I., Tutuc, E., Banerjee, S. K., Colombo, L. & Ruoff, R. S. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324, 1312–1314 (2009).

Khang, D. Y., Rogers, J. A. & Lee, H. H. Mechanical buckling: mechanics, metrology, and stretchable electronics. Adv. Func. Mater. 19, 1526–1536 (2009).

Lai, Y. C., Hsu, F. C., Chen, J. Y., He, J. H., Chang, T. C., Hsieh, Y. P., Lin, T. Y., Yang, Y. J. & Chen, Y. F. Transferable and flexible label-like macromolecular memory on arbitrary substrates with high performance and a facile methodology. Adv. Mater. 25, 2733–2739 (2013).

Li, X., Zhang, R., Yu, W., Wang, K., Wei, J., Wu, D., Cao, A., Li, Z., Cheng, Y., Zheng, Q., Ruoff, R. S. & Zhu, H. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep. 2, 870 (2012).

Park, K. K., Jung, J. H. & Kim, T. W. Memory effects and carrier transport mechanisms of write-once-read-many-times memory devices fabricated using poly(3-hexylthiophene) molecules embedded in a polymethylmethacrylate layer on a flexible substrate. Appl. Phys. Lett. 98, 193301 (2011).

Acknowledgements

This work was supported by grants from the National Science Council and the Ministry of Education of the Republic of China. We thank Jian-Yu Chen, Pin-Chieh Wu, Wei-Ting Chen, Yao-Wei Huang, Professor Din-Ping Tsai and Professor Fang-Chi Hsu for experimental assistance. Y.C.L thanks Dr Changhyun Pang of Sungkyunkwan University for the stimulating suggestion.

Author contributions

Y.C.L conceived the study. Y.C.L and Y.C.H designed the experiments. Y.C.H, Y.X.W, Y.C.L, Tzu-Yao Lin and B.W.Y performed the experiments and analyzed the data. C.Y.C assisted in taking the SEM images. Y.L assisted with the stress simulation. Y.F.C, T.Y.L, Y.P.H, W.F.S and Y.J.Y gave technical support and conceptual advice. Y.F.C and Tai-Yuan Lin supervised the project. Y.C.L and Y.F.C wrote the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Lai, YC., Huang, YC., Lin, TY. et al. Stretchable organic memory: toward learnable and digitized stretchable electronic applications. NPG Asia Mater 6, e87 (2014). https://doi.org/10.1038/am.2013.85

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2013.85

Keywords

This article is cited by

-

Selective noble-metal deposition modulation on photocurable polydimethylsiloxane films for electronics device applications

Applied Physics A (2021)

-

A Universal Strategy for Stretchable Polymer Nonvolatile Memory via Tailoring Nanostructured Surfaces

Scientific Reports (2019)

-

High-performance stretchable resistive memories using donor–acceptor block copolymers with fluorene rods and pendent isoindigo coils

NPG Asia Materials (2016)

-

Facile fabrication of stretchable Ag nanowire/polyurethane electrodes using high intensity pulsed light

Nano Research (2016)

-

Cost-Effective and Highly Photoresponsive Nanophosphor-P3HT Photoconductive Nanocomposite for Near-Infrared Detection

Scientific Reports (2015)