Miniaturizing a simple photomechanical system could expand its range of applications.

Abstract

Polymer solutions and solids that contain light-sensitive molecules can undergo photo-contraction, whereby light energy is converted into mechanical energy1,2,3,4,5,6,7,8. Here we show that a single film of a liquid-crystal network containing an azobenzene chromophore can be repeatedly and precisely bent along any chosen direction by using linearly polarized light. This striking photomechanical effect results from a photoselective volume contraction and may be useful in the development of high-speed actuators for microscale or nanoscale applications, for example in microrobots in medicine or optical microtweezers.

Similar content being viewed by others

Main

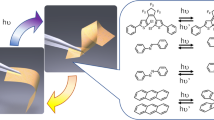

We prepared the films by thermal polymerization of a liquid-crystal monomer (molecule 1 in Fig. 1a) and a diacrylate crosslinker (molecule 2) (9:1, mol/mol), both of which possess azobenzene moieties. Figure 1b shows a sequence of frames indicating how such a film can be bent along a precisely controlled direction by irradiation with linearly polarized light (for movies, see supplementary information).

a, Chemical structures of the liquid-crystal monomer (molecule 1) and crosslinker (molecule 2) used for preparation of the film. On cooling from 95 °C, 1 changes from an isotropic to a nematic phase, and at 91 °C it becomes crystalline; molecule 2 undergoes a phase transition from crystalline to isotropic at 98 °C. b, Photographic frames of the film bending in different directions in response to irradiation by linearly polarized light of different angles of polarization (white arrows) at 366 nm, and being flattened again by visible light longer than 540 nm. The flat film (4.5 mm × 3 mm × 7 μm) lay on a copper stick fixed to a copper plate; a stage under the plate was set at 85 °C to control the temperature of the film, which was covered by a piece of blue paper. The bending time for the four different bending directions was within 10 s, when the light intensity of 366-nm linearly polarized light was 3.5 mW cm−2 after exposure to visible light longer than 540 nm (547 nm, 24.2 mW cm−2; 577 nm, 26.8 mW cm−2), the bent film reverted to the flat state in about 10 s.

The first frame in Fig. 1b shows the film before light irradiation; counting clockwise, the second shows how the film curls up after exposure to 366-nm light that has a polarization direction at zero degrees. The film is bent towards the direction of irradiation of the light, with the bending occurring parallel to the direction of light polarization (Fig. 1b, white arrows). When the bent film was exposed to visible light with a wavelength longer than 540 nm, it completely reverted to its initial flat state (third frame in Fig. 1b).

The effects on the film of altering the polarization direction of light at 366 nm to −45°, −90° and −135° are shown in the fourth, sixth and eighth frames, respectively, of Fig. 1b. It can be seen that the bending direction of the film moves anticlockwise by 45°, 90° and 135°, respectively, keeping parallel to the direction of light polarization. The film could be restored from each bent state to its initial flat form by irradiation with visible light at wavelengths longer than 540 nm (Fig. 1b). Moreover, the bending–unbending cycle of these four modes could be repeated without apparent fatigue. These results show that the bending direction of a single film can be precisely controlled by altering the direction of polarization of the irradiating light, and that such a film can be bent repeatedly.

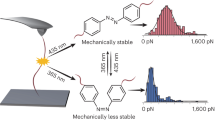

In the film used here, the incident light is mostly absorbed by the film surface because of the strong absorption by the azobenzene moieties of light at about 360 nm. The film is a polydomain liquid-crystal film that consists of many micro-sized domains of azobenzene liquid-crystal moieties aligned in one direction in each domain, although macroscopically the direction of alignment is random. On irradiation of the film with linearly polarized light, the selective absorption of light of a specific direction leads to a trans–cis isomerization of the azobenzene moieties in specific domains where the azobenzene moieties are aligned along the direction of light polarization.

As a result, the subtle reduction in microscopic size and ordering of the liquid-crystal components1,2,3,4,9,10 gives rise to a substantial macroscopic volume contraction5,6,7,8 at the film surface and a bending of the whole film as a result of the cooperative movement of the liquid-crystal moieties and polymer segments. Light energy is therefore efficiently converted into mechanical energy. It should be simple to miniaturize our system for potential application in driving micro-machines and nanomachines without the aid of batteries, motors and gears, using remote irradiation with laser beams.

References

Van der Veen, G. & Prins, W. Nature Phys. Sci. 230, 70–72 (1971).

Smets, G. & De Blauwe, F. Pure Appl. Chem. 39, 225–238 (1974).

Eisenbach, C. D. Polymer 21, 1175–1179 (1980).

Matejka, L., Ilavsky, M., Dusek, K. & Wichterle, O. Polymer 22, 1511–1515 (1981).

Finkelmann, H., Nishikawa, E., Pereira, G. G. & Warner, M. Phys. Rev. Lett. 87, 015501-1-4 (2001).

Hogan, P. M., Tajbakhsh A. R. & Terentjev, E. M. Phys. Rev. E 65, 041720-1-10 (2002).

Li, M.-H. et al. Adv. Mater. 15, 569–572 (2003).

Ikeda, T., Nakano, M., Yu, Y., Tsutsumi, O. & Kanazawa, A. Adv. Mater. 15, 201–205 (2003).

Ikeda, T. J. Mater. Chem. 13, 2037–2057 (2000).

Ikeda, T., & Tsutsumi, O. Science 268, 1873–1875 (1995).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

41586_2003_BF425145a_MOESM1_ESM.mov

Supplementary Movie: The polarization direction of 366-nm linearly polarized light (LPL; 3.5 mW/cm2) was set parallel to the long side of the film. When a normal irradiation was performed, the film bent toward the irradiation direction of the incident LPL in 10 s, and the bending direction was along the light polarization. (MOV 1169 kb)

41586_2003_BF425145a_MOESM2_ESM.mov

Supplementary Movie: The polarization direction of 366-nm LPL (3.5 mW/cm2) was anticlockwisely altered by 45 degrees compared with that of LPL in Movie 1, and the bending direction of the film was similarly turned by 45 degrees, still parallel to the light polarization. (MOV 1115 kb)

Rights and permissions

About this article

Cite this article

Yu, Y., Nakano, M. & Ikeda, T. Directed bending of a polymer film by light. Nature 425, 145 (2003). https://doi.org/10.1038/425145a

Issue Date:

DOI: https://doi.org/10.1038/425145a

This article is cited by

-

Integrating dual photoresponsive molecules via a cocrystal strategy: photosalient effects, negative photochromism, and fluorescence enhancement

Science China Materials (2024)

-

Light-driven peristaltic pumping by an actuating splay-bend strip

Nature Communications (2023)

-

Polarization-driven reversible actuation in a photo-responsive polymer composite

Nature Communications (2023)

-

Light-driven dandelion-inspired microfliers

Nature Communications (2023)

-

Light- and humidity-driven fluorescence changeable soft robot enabled by water-gated photoinduced electron transfer pathway

Science China Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.