Abstract

The gel to carbonate precipitate route has been used for the synthesis of Ni1−xZnxFe2O4 (x = 0, 0.25, 0.5 and 0.75) bulk inverse spinel ferrite powder samples. The optimal zinc (50%) substitution has shown the maximum saturation magnetic moment and resulted into the maximum magnetic loss tangent (tanδm) > −1.2 over the entire 2–10 GHz frequency range with an optimum value ~−1.75 at 6 GHz. Ni0.5Zn0.5Fe2O4- Acrylo-Nitrile Butadiene Rubber (NBR) composite samples are prepared at different weight percentage (wt%) of ferrite loading fractions in rubber for microwave absorption evaluation. The 80 wt% loaded Ni0.5Zn0.5Fe2O4/NBR composite (FMAR80) sample has shown two reflection loss (RL) peaks at 5 and 10 GHz. Interestingly, a single peak at 10 GHz for 3.25 mm thickness, can be scaled down to 5 GHz by increasing the thickness up to 4.6 mm. The onset of such twin matching frequencies in FMAR80 composite sample is attributed to the spin resonance relaxation at ~5 GHz (fm1) and destructive interference at λm/4 matched thickness near ~10 GHz (fm2) in these composite systems. These studies suggest the potential of tuning the twin frequencies in Ni0.5Zn0.5Fe2O4/NBR composite samples for possible microwave absorption applications.

Similar content being viewed by others

Introduction

Microwave absorbing materials are important in the present war scenario to reduce the Radar Cross Section (RCS) for strategic airborne objects1. These materials also important for applications in civil sector viz. communication interference between electronic devices, antenna background clutters etc. Various dielectric, magnetic and carbonaceous materials, such as barium titanate2, core-shell materials3, carbon black4, carbonyl iron5,6, carbon nanotubes (CNTs)7, iron oxide8 and ferrites9,10 etc. are being investigated as the functional filler materials for microwave absorption applications. There are continuous efforts to achieve the enhanced wide band MW absorption properties by converting the materials in different geometries viz. ferrite nanofibers11, porous hollow microrods12, nested structure13 etc. Further, among these, ferrite materials provide several advantages such as relatively smaller values of absorber thickness, particularly for lower frequencies in the MW region, tunability of ferromagnetic resonance (FMR)14, excellent environmental stability, etc. in comparison to the dielectric materials. Ni1−xZnxFe2O4 inverse spinel ferrite system attracted special attention because of possible tunable electrical15,16, magnetic17,18, and microwave absorption properties19,20,21,22 by modulating the magnetic interaction at magnetic ion sites. Ni1−xZnxFe2O4 (at x = 0) having the inverse spinel structure of (Fe3+)tet[Ni2+, Fe3+]octO4 with cation’s antiparallel spin arrangements at tetragonal (A) and orthogonal (B) sites gives rise to the magnetic properties due to the superexchange interaction between A and B sites mediated through O2− ions. The net magnetization (MT) in Ni-Zn ferrite system is the result of the difference of magnetization at octahedral (MB) and tetrahedral sites (MA) giving rise to the ferrimagnetism. The spin arrangement in Ni-Zn system can be altered by substituting Zn2+ ions, replacing Fe+ 3 ions at the tetragonal sites (ZnxFe1−x3+)tet[Ni1−x2+, Fe1+x3+]octO4. This substitution results in the significant change of magnetic interaction and thus magnetic properties23,24. The absorption frequencies of these ferrite materials depend on the electron spin arrangement and also on the domain spin orientations. The incident microwave radiation can be absorbed in ferrite materials by exciting spin relaxation process, which may be transferred to host lattice due to spin-lattice coupling. The spin-lattice interaction25 in spinel ferrites, which strongly affects MW absorption characteristics, depends on the distribution of cations in the crystal structure, which is not only decided by the chemical composition and synthetic route but also by the other parameters including pH of chemical reactions26, annealing temperature, the rate of heating/cooling, etc.

The ferrite materials need to be dispersed in suitable binder resin matrix to realize the practical microwave absorbing products. Therefore, studies on MW absorbing composites with dispersed magnetic ferrite materials in polymer/resin matrix has always been a subject of interest27. Dispersion of ferrite granules has been attempted in different host matrices viz. epoxy resin28,29, polyvinylchloride (PVC)30, wax31,32 etc., wherein the studies have been focused on understanding the variation of electromagnetic characteristics of composites with a loading percentage of filler materials as well as their dispersion behavior. Further, the filler-host matrix interactions facilitate multiple scattering of MW radiation via suspended filler granules which may significantly enhance the MW absorption properties in the composites33. Yet, there are numerous challenges in the synthesis of homogeneous composite system e.g. dispersion/suspension of the high-density ferrite powder in liquid resin/wax medium leading to the inhomogeneities in the composites. The elastomeric matrix may provide a relatively better host for uniform dispersion of high-density filler due to the entrapment of heavy ferrite granules in cross-linked rubber structure during mixing and vulcanization process34. In spite of these advantages, there are very few studies on ferrite-elastomeric composites, directing to microwave absorption. Considering these advantages, in this report, we have focused our studies on the microwave absorbing properties of Ni1−xZnxFe2O4 ferrite as filler in Acrylo-Nitrile Butadiene Rubber (NBR) elastomeric matrix due to its light weight, flexible nature, high elongation, resistance to the corrosion, good high/low temperature stability (−20 °C to +125 °C) and high values of tensile strength. Ni1−xZnxFe2O4 (x = 0, 0.25, 0.50 and 0.75) ferrite powders have been prepared using simple, scalable and energy efficient wet chemical method. As synthesized powders have been annealed at different temperatures to study their size-dependent physical and microwave absorption properties. Flexible sheets were fabricated in NBR host matrix with different loadings fractions in the range of 50–80 weight percent (wt%) of the Ni-Zn ferrite material with optimal Zn concentration showing maximum saturation magnetization and investigated for their reflection loss characteristics in the microwave frequency range of 2–12.4 GHz.

Results and Discussion

The representative XRD spectra are shown in Fig. 1a for Ni1−xZnxFe2O4 (x = 0.50) ferrite powder sample, annealed at 650 °C, 950 °C and 1250 °C temperatures. International Centre for Diffraction Data (ICDD) powder diffraction file (PDF) # 22–106 has been used as a reference for phase identification and all the observed diffraction peaks could be indexed with this reference. The appearance of characteristics spinel phase peaks due to (220), (311), (222), (400), (422), (511) and (440) planes, marked in Fig. 1a, confirm the formation of pure spinel phase of Ni0.5Zn0.5Fe2O4 annealed at 650 °C. The broadening of XRD peaks for 650 °C annealed powder suggests the formation of ultrafine particles. Further, enhancement of intensities and decrease of respective broadening for these diffraction peaks have been observed with the increase in sequential annealing temperatures at 950 °C and 1250 °C, respectively. The other compositions of Ni1−xZnxFe2O4 (x = 0, 0.25 and 0.75) ferrite powders showed similar XRD spectra (Fig. 1b). However, the diffraction peaks are relatively shifted ~0.26° in 2ϴ towards lower angle with an increase in Zn2+ ion concentration from NiFe2O4 to Ni0.25Zn0.75Fe2O4 as shown in Fig. 1c, attributed to the enlargement of cubic lattice parameter ‘a’ for these inverse spinel compounds from 8.321A° for pure Ni ferrite (x = 0) to 8.385A° for Ni0.25Zn0.75Fe2O4ferrite (x = 0.75) composition, as shown in Fig. 1d. The increased ‘a’ with Zn2+ ion concentration is caused by the replacement of Ni2+ ion (ionic radii ~0.78A°) to the large sized Zn2+ ion (ionic radii ~0.83A°) in the crystal lattice of cubic NiFe2O4 structure35,36,37.

(a) XRD pattern of Ni0.5Zn0.5Fe2O4 ferrite powders annealed at different elevated temperatures of 650 °C, 950 °C and 1250 °C. (b) XRD pattern of Ni0.5Zn0.5Fe2O4 ferrite powders with Zn2+ ion concentration (c) Shifting in (311) plane XRD peak with Zn2+ ion concentration (d) Variation in lattice parameter with Zn content in compositions.

Scanning electron microscope (SEM) micrographs are shown in Fig. 2a,b, for Ni1−xZnxFe2O4 powders (x = 0 and 0.5), annealed at 650 °C, 950 °C and 1250 °C. Ferrite powder samples, annealed at 650 °C, show fine microstructure with spherical particle morphology, Fig. 2a(i). The grain growth has been observed with annealing temperature, resulted into the distorted spherical morphology observed for the powder samples, annealed at 1250 °C, Fig. 2a(iii). Ni1−xZnxFe2O4 (x = 0.50) showed larger grain size with fused particles, as shown in Fig. 2b (iii). This observation indicates that the addition of Zn promotes the grain growth in Ni1−xZnxFe2O4 ferrite composition. The results are consistent with the reported literature38.

The room temperature field dependent magnetic measurements are summarized in Fig. 3a–d for Ni1−xZnxFe2O4 (x = 0, 0.25, 0.50 and 0.75) ferrite powders annealed at 650 °C, 950 °C and 1250 °C. All these compositions show ferrimagnetic behavior with different saturation magnetization (Ms) and coercive field (Hc) values. The variation of Ms and Hc with respect to annealing temperature and Zn2+ ion concentration and composition are plotted in Fig. 3e and f respectively. The saturation magnetization increases with increasing the annealing temperature for all these compositions except for the Ni0.25Zn0.75Fe2O4 ferrite powder. The marginal decrease in saturation magnetization has been observed for this composition (x = 0.75) while annealed at 950 °C and then a small increase in value for annealing at a higher temperature ~1250 °C. Similarly, the coercive field values were found to decrease with increase in annealing temperature for all the compositions except for ferrite powder with high Zn content (x = 0.75). The distribution of ions in tetrahedral and octahedral sites takes place during the thermal treatment for the formation of inverse spinel crystallographic phase. The cation ordering increases with increasing the temperature, resulting in the higher saturation magnetization, as observed in samples annealed at 1250 °C25,39. Further, saturation magnetization increases initially with an increase in Zn2+ ion concentration and a significant decrease in value has been observed beyond x = 0.5 for ferrite composition as shown in Fig. 3f. At low concentration of Zn2+ ions, spin site occupancy reduces at A (tetrahedral) sites due to the presence of non-magnetic Zn2+ ions, however, net magnetization increases due to the shift of Fe3+ ions from A site to B (octahedral) sites. The increase in Zn2+ substitution beyond x = 0.5 resulted in the reduced effective spin A site contributions due to the non-availability of the minimum number of spins sites for the oxygen mediated super-exchange interaction between A and B cation sites, leading to decrease in magnetization value, as observed in the present study17,37. Moreover, the annealing temperature has favored grain growth, resulting in the enhanced number of domain walls or even larger domains within the grains. The contribution of a domain wall in magnetization/demagnetization process dominates against domain rotation, as domain wall movement is less energetic than the domain wall rotation18. Therefore, such energy competition between domain rotation and domain wall movement in larger grains has led to the lower coercive field values for compositions annealed at high temperature i.e. 1250 °C. The decrease in coercive field values is attributed to the decrease in magneto-crystalline anisotropy with Zn substitution, as substantiated in our experimental observations40.

The complex permittivity (εr* = εr′ − jεr″) and permeability (μr* = μr′ − jμr″) values were computed by Nicolson and Ross algorithm using S-parameters measured through waveguide transmission line technique over MW frequency range (2–12.4 GHz)41. The imaginary values of complex EM parameters (εr″, μr″) represent the MW attenuation/absorption characteristics of material and are depicted on the negative scale, following the standard convention for representing the loss factor. All the Ni1−xZnxFe2O4 samples annealed at 1250 °C show similar values of εr′~6.3 ± 0.1 over the measured frequency range 2–12.4 GHz. The imaginary permittivity values exhibit non-dispersive behavior with a constant value nearly ~0.005 for all Ni1−xZnxFe2O4 samples over the entire frequency range. These measurements suggest that Ni1−xZnxFe2O4 samples do not show any dielectric loss tanδe (=εr″/εr′) over the frequency range 2–12.4 GHz due to negligible imaginary permittivity. The measured real relative permeability (μr′) values are decreasing from ~2.5 to ~1 for Ni1−xZnxFe2O4 (x = 0, 0.25, 0.50 and 0.75) ferrite compositions annealed at different temperatures over the 2–12.4 GHz frequency range, as shown in Fig. 4a–d. The imaginary relative permeability (μr″) values also change from ~−3.12 to −0.11 simultaneously with an increase in annealing temperature for Ni1−xZnxFe2O4 (x = 0, 0.25 and 0.50) ferrite compositions with a dispersive behavior as shown in Fig. 4a–c for the 2–12.4 GHz frequency range. Further, μr″ values increase relatively in the 2–8 GHz low-frequency region and the effect is more prominent for Ni0.5Zn0.5Fe2O4. The values are negligible ~−0.02 for all different temperature annealed Ni0.25Zn0.75Fe2O4 samples, as shown in Fig. 4d. These measurements suggest that both annealing temperature and Zn2+ ion concentration in Ni1−xZnxFe2O4, affect μr″ dispersive behavior over the frequency range 2–12.4 GHz. The imaginary permeability, which is responsible for MW energy loss, depends on saturation magnetization (Ms) and coercive field (Hc) as given in equation (1) 42

where Ms is saturation magnetization, K1 is anisotropic constant, α is Gilbert constant, Hc is a coercive field and μ0 is intrinsic permeability. The μr″ values show an increasing trend from −1.90 to −3.2 at 2 GHz with an increase in annealing temperature from 650 °C to 1250 °C. This is in accordance with the observed increase in saturation magnetization Ms and the decrease in coercive field Hc for the samples (x = 0 to x = 0.5). The magnetic loss tangent (tanδm = μr″/μr′) for Ni1−xZnxFe2O4 (x = 0, 0.25, 0.50 and 0.75) ferrite powder samples, annealed at different temperatures viz. 650 °C, 950 °C and 1250 °C, are plotted in Fig. 5a–d. An increase in the loss tangent values has been observed for Ni1−xZnxFe2O4 ferrite samples for both (i) increase in x from 0 to 0.5 and (ii) annealing temperature from 650 °C to 1250 °C. The 1250 °C annealed Ni1−xZnxFe2O4 sample showed tanδm > −0.8 for x = 0 and 0.25 over the 2–8 GHz and 2–10 GHz frequency bands with the maximum tanδm ~−1.27 (x = 0) and ~−1.65 (x = 0.25) at ~6 GHz frequency. The sample with x = 0.5 has shown even enhanced tanδm > −1.2 over 2–10 GHz with maximum value ~−1.75 at 6 GHz. These measurements suggest that the maxima of loss tangent (tanδm)max values increase with Zn2+ ion concentration up to x = 0.50 and beyond that at x = 0.75 reduced sharply to the negligible loss tangent ~−0.05 as shown in Fig. 5e. These observations are consistent with the behavior of saturation magnetization and coercive field values as described earlier in the text. Further, it is interesting to note that the (tanδm)max for all compositions (x = 0, 0.25, 0.50 and 0.75) is found at 6 GHz, nearly independent of the frequency. The Ni0.5Zn0.5Fe2O4 ferrite powder annealed at 1250 °C shows maximum loss tangent values among all other compositions and therefore, has been considered for preparation of rubber composites for microwave absorption applications.

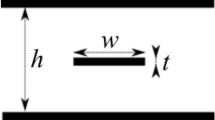

A 50 wt% loaded ferrite-NBR sample, FMAR50, showed the real permittivity (εr′) ~2.8 ± 0.1 over the entire 2–12.4 GHz frequency range. With the increase in Ni0.5Zn0.5Fe2O4 ferrite filler loading, εr′ value has increased to ~4.2 ± 0.2 at 60 wt% loading in sample FMAR60, ~4.7 ± 0.1 at 70 wt% in sample FMAR70 and ~5.9 at 80 wt% loading in sample FMAR80 as shown in Fig. 6a. The values of the imaginary component of the permittivity are found negligible between ~−0.0015 and ~−0.002 for all the different ferrite loaded rubber composites over the entire frequency range of 2–12.4 GHz. This small value of complex permittivity suggests the absence of dielectric loss contribution for microwave absorption in these rubber composites. The real component of the permeability values (μr′) in rubber composite samples has shown a decrease with increase in frequency as shown in Fig. 6b and μr′ values lie in the range of 1.14 to 0.90, 1.25 to 0.80, 1.26 to 0.83 and 1.37 to 0.70, for FMAR50, FMAR60, FMAR70, and FMAR80 samples respectively. The imaginary permeability (μr″) components for FMAR50 sample is found to be in the range of ~−0.33 to −0.03 with reducing trend towards the higher frequency range. Further, enhancement of μr″ values has been observed with increase in loading fraction of Ni0.5Zn0.5Fe2O4 ferrite powder in composite samples. In FMAR60 sample, the μr″ shows wider dispersion characteristics with values in the range of ~−0.65 to −0.10 over the entire frequency range. The similar trend has been observed for FMAR70 and FMAR80 samples where μr″ values fall in the range ~−0.82 to −0.17 and ~−1.03 to −0.20 respectively as shown in Fig. 6c. The magnetic loss tangent (tanδm) values show wide dispersion and values range from ~−0.28 to −0.03, −0.50 to −0.11, ~−0.63 to −0.20 and ~−0.80 to −0.30 in the entire 2–12.4 GHz frequency range for FMAR50, FMAR60, FMAR70 and FMAR80 samples respectively, as summarized in Fig. 6d. Thus, we observed that the magnetic loss tangent values have increased with Ni0.5Zn0.5Fe2O4 loading fraction in these rubber composite samples with decreasing trend towards higher frequency range. The observed enhancement in loss tangent values has been attributed to the increasing loading fraction of ferrite in NBR by 1.50, 2.33 and 4.00 times in comparison to sample FMAR50 (Table 1). The MW reflection losses (R.L.) have been computed for Ni0.5Zn0.5Fe2O4 ferrite loaded composite samples (FMAR50 - FMAR80) by using the following equation (2) 43:

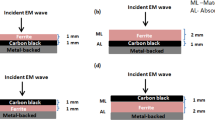

where, λ is the wavelength, μr* is the complex relative permeability, εr* is the complex relative permittivity and d is the absorber thickness. Further, the impedance of absorber’s top layer should be comparable to the free space impedance Z0 (377 Ω) to enter the microwaves inside the absorber for its effective attenuation as explained schematically in Fig. 7. Considering the close approximation of matched wave impedance criterion, the reflection loss of absorber should have matched values for absorber thickness (dm) at λm/4, to satisfy the destructive interference criterion among surface reflected and metal back-reflected wave with the following dependence, as explained by eqs (3) and (4) (Fig. 7)32,44

The calculated reflection loss values for different Ni0.5Zn0.5Fe2O4 ferrite loaded samples are shown in Fig. 8a–d. FMAR50 sample shows the maximum possible reflection loss value (R.L.)max ~−4dB at ~8 GHz for 5 mm absorber thickness, which has increased up to ~−10 dB at ~7 GHz for FMAR60 sample for the same thickness. Similarly, with further increase of ferrite loading (FMAR70), the (R.L.)max value has further increased to ~−15 dB at 10 GHz, ~20 dB at 8.3 GHz and ~24 dB at 7 GHz for absorber thickness values of ~3.5 mm, 4.0 mm, and 4.6 mm, respectively. It is interesting to note that the absorption peak is shifting towards the lower frequency with increasing the absorber thickness for this composition. The observed shifting in reflection loss, towards lower frequency for FMAR70 composite can be explained using eqs (3 and 4). These relations suggest that absorber thickness will effectively reduce with increasing εr′ and tanδm. The insignificant values of reflection loss observed for FMAR50 and FMAR60 are mainly because of the relatively lower tanδm, for these composite samples as shown in Fig. 6d. Interestingly, the onset of twin match frequencies (fm1/fm2) has been observed at two different matched thicknesses (tm1 and tm2), Fig. 8d, for FMAR80 composite sample. At absorber thickness tm1 = 4.6 mm, the first matched (R.L.)max value is ~−43 dB at the first matching frequency fm1~5 GHz. With the decrease in absorber thickness, R.L profile has shifted towards higher frequency side with lower (R.L.)max values ~−22 dB and ~−26 dB for absorber thicknesses ~4 mm and 3.5 mm, respectively. On further reduction in the absorber thickness at tm2 = 3.25 mm, the second matched (R.L.)max value ~−43 dB has been observed at the second matching frequency fm2 ~10 GHz.

Optimal Reflection Loss (R.L.) over frequency range 2–12.4 GHz and matching thicknesses of ferrite loaded rubber composites (a) FMAR50 (b) FMAR60 (c) FMAR70 (d) FMAR80 (e) variation of maximum reflection loss with ferrite powder loading fraction in composite (f) optimal R.L. bandwidth profile with composite absorber thickness.

The existence of such two matching frequencies has been observed earlier in pure ferrite powders, however, in rubber-ferrite composite samples only a single matching frequency has been reported37,45. The two possible MW absorption loss mechanism are generally attributed in ferrite materials: (i) relaxation mechanism due to the domain wall motion and (ii) the spin rotational resonance. The domain wall resonance mechanism usually dominates at lower MW frequency range (<1 GHz), as the relaxation of domain motion does not follow the higher MW frequency beyond 1 GHz, whereas relaxation of spin resonance or ferromagnetic resonance (FMR) dominates at the higher MW frequencies. The maximum loss tangent values observed at ~6 GHz for 1250 °C annealed Ni0.5Zn0.5Fe2O4 ferrites, is close to the first matching frequency (fm1) observed at ~5 GHz for 4.6 mm thick FMAR80 sample as shown in Fig. 8d, and is attributed to the spin resonance relaxation mechanism in these samples46. As discussed earlier, the FMR frequencies and thus, MW absorption of Ni-Zn ferrite system depends strongly on chemical composition, synthetic route and post processing conditions. Shi et al. tuned the resonance frequency ~2.54 GHz for Ni spinel ferrite nanoparticles prepared using sol-gel process47 whereas Zhao et al. adjusted the matching absorption frequencies for Ni-Zn spinel ferrite in the range of ~1–12 GHz by substitution of Cu2+/Co2+ ions48. The second matching frequency (fm2) has been observed at ~10 GHz for 3.25 mm FMAR80 absorber thickness. The fm2 is independent of resonance frequency and is observed because of matched absorber thickness (λm/4 ~ 3.25 mm) as given by eq. (4). The R.L. profile associated to fm1 at absorber thickness ~4.6 mm may extend towards the higher frequency side with a decrease in thickness up to 3.5 mm. Whereas, the R.L. profile associated with fm2 may contribute towards lower frequency side with an increase in thickness up to 4 mm. It has been observed that R.L. profiles have both the components of matching frequencies (x.fm1 + y.fm2) at these thicknesses, where x and y are the fractional contribution from individual matching frequencies fm1 and fm2, respectively. At the intermediate absorber thickness of 3.5 mm and 4.0 mm the matching frequency (fM) behavior follows the trend as given in eqs (5 and 6)

The matching frequencies (fm ) for d = 3.5 mm and 4.0 mm thick FMAR80 samples are 9 and 6 GHz respectively, as shown in Fig. 8d. The fractional contributions (x and y) for d = 3.5 mm thick FMAR80 sample are x = 0.2 and y = 0.8 corresponding to fm1 (5 GHz) and fm2 (10 GHz) respectively. For d = 4.0 mm thick FMAR80 sample, the fractional contributions are x = 0.8 and y = 0.2, corresponding to fm1 (5 GHz) and fm2 (10 GHz) respectively, substantiating the proposed mechanism of twin matching frequencies contribution for microwave absorption in these ferrite-rubber composite samples.

Conclusions

The maximum reflection loss (R.L.)max values increase with loading fraction of Ni0.5Zn0.5Fe2O4 ferrite powder in these rubber composites, as shown in Fig. 8e. Interestingly, for FMAR80 the desired frequency bandwidth (where R.L. ≥ 10 dB or at least 90% attenuation of MW signal) decreases with absorber thickness as shown in Fig. 8f. The MW absorber at 3.25 mm thickness (corresponding to fm2) has the widest bandwidth of ~7 GHz, whereas, at absorber thickness of 4.6 mm, frequency bandwidth window reduced to ~4.2 GHz. In the intermediate thicknesses, the bandwidth lies between this ranges. These studies suggest that the FMAR80 absorber can be used as a tunable MW frequency absorber using the thickness as a controlling parameter for strategic applications such as microwave stealth over the different frequency bands.

Methods

Experimental details

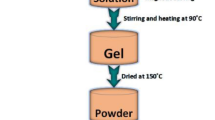

The ferrite powders are prepared using gel to carbonate precipitation method, where the co-precipitations of divalent cations (Ni2+, Zn2+) as fine particles of carbonates within hydrated gels of ferric hydroxide has been carried out by adding the alkali solution into the mixed metal salt ions. 1 M solution of FeCl3 (Merck CAS No. 7705-08-0), NiCl2 (Merck CAS No. 7718-54-9), ZnCl2 (Merck CAS No. 7646-85-7) were mixed stoichiometrically, followed by adding dropwise 1 M Na2CO3 solution (Merck CAS No. 497-19-8) while maintaining pH ~9, to realize the co-precipitation. The obtained precipitate was washed and dried in an oven at ~90 °C for 2 hours in the air ambient. The resultant composite powder consists of sub-micron crystalline particles of carbonates, embedded within the amorphous medium of Fe2O3.xH2O (70< x <110). The composite powder was annealed sequentially at 650 °C, 950 °C and 1250 °C for 3 hours each to obtain final sample, which was used for detailed characterization of the physical and microwave absorption properties. The similar process has been followed to prepare a series of Ni1−xZnxFe2O4 spinel ferrites with x = 0, 0.25, 0.50 and 0.75, to understand the effect of Zn substitution on the physical and microwave absorption properties.

Rubber based microwave absorbing sheets are fabricated using mechanical milling followed by high-temperature compression moulding (HTCM), to get the desired shape and size of composite samples. Initially, 30 g of NBR was thoroughly mixed in two roll mixing mill (TRMM) and Ni0.5Zn0.5Fe2O4 powder was added in different filler ratio in wt%, as listed in the Table -I. Different additives were mixed in quantity of parts per hundred (PHR) of rubber for vulcanization and curing of the rubber compound. The additives include sulphur (02 PHR) as vulcanizing agent, mercaptobenzothiazole disulphide (MBTS) (1.5 PHR) as accelerator for curing of rubber-filler compound, ZnO (05 PHR), Steric Acid (02 PHR) as activator to enhance the effect of accelerator and Trimethyl-Di-Quinoline TDQ (01 PHR) as antioxidant for rubber to prevent it from environmental degradation29. After homogeneous mixing, the compounds were transferred into 200 mm × 200 mm × 2 mm (L × B × D) size mould and hydraulically pressed at 150 °C with 30 Ton pressure for 30 minutes. The mould was then allowed to cool down to the ambient temperature and rubber sheet was collected for MW characterization. The loading of ferrite powder (>80 wt%) in NBR matrix was not possible due to the enhanced brittleness, making difficult to handle the composite materials.

X-ray diffraction measurements (Philips X’Pert Pro) were carried out with CuKα (λ = 1.514 A°) radiation as incident X-ray in 20° to 80° 2θ range, to identify the Ni1−xZnxFe2O4 crystallographic phase. Infrared (IR) spectroscopic studies were carried out using FTIR system (Model: Bruker Vertex 70 V). Shape and morphology of Ni1−xZnxFe2O4 powders were analyzed using Oxford EVO5 Scanning Electron Microscope (SEM) system. The room temperature magnetic hysteresis studies (M-H plots) were carried out using Vibrating Sample Magnetometer (VSM) Model ADE EV-5 for −2kOe to +2 kOe magnetic field. Electromagnetic parameters i.e. complex permittivity and permeability values were measured in 2–12.4 GHz MW frequency bands using Vector Network Analyzer model ZVM from Rohde and Schwarz for both pristine Ni1−xZnxFe2O4 ferrite powders and Ni1−xZnxFe2O4/NBR composite samples loaded with different concentrations of ferrite powder.

Additional Information

How to cite this article: Saini, L. et al. Tunable Twin Matching Frequency (fm2 /fm2 ) Behavior of Ni1−xZnxFe2O4/NBR Composites over 2–12.4 GHz: A Strategic Material System for Stealth Applications. Sci. Rep. 7, 44457; doi: 10.1038/srep44457 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Vinoy, K. J. & Jha, R. M. Radar Absorbing Materials: From Theory to Design and Characterization (Kluwer Academic Publishers, Norwell, Boston, USA, 1996).

Zhu, Y. F., Zhang, L., Natsuki, T., Fu, Y. Q. & Ni, Q. Q. Facile synthesis of BaTiO3 nanotubes and their microwave absorption properties. ACS Appl. Mater. Inter. 4, 2101–2106 (2012).

Gupta, V. et al. Synthesis and investigations on microwave absorption properties of core–shell FeCo(C) alloy nanoparticles. Sci. Adv. Mat. 6, 1–7 (2014).

Oh, J. H., Oh, K. S., Kim, C. G. & Hong, C. S. Design of radar absorbing structures using glass/epoxy composite containing carbon black in X-band frequency ranges. Compos. Part B 35, 49–56 (2004).

Meng, W., Yuping, D., Shunhua, L., Xiaogang, L. & Zhijiang, J. Absorption properties of carbonyl-iron/carbon black double-layer microwave absorbers. J. Magn. Magn. Mater. 321, 3442–3446 (2009).

Duan, Y., Li, G., Liu, L. & Liu, S. Electromagnetic properties of carbonyl iron and their microwave absorbing characterization as filler in silicone rubber. Bull. Mater. Sci. 33 (5), 633–636 (2010).

Zhao, D. L., Li, X. & Shen, Z. M. Microwave absorbing property and complex permittivity and permeability of epoxy composites containing Ni-coated and Ag filled carbon nanotubes. Compos. Sci Tech. 68, 2902–2908 (2008).

Huang, X. et al. Fabrication and electromagnetic loss properties of Fe3O4 nanofibers. J Mater Sci: Mater. Electron. 26, 3474–3478 (2015).

Zou, H. et al. Determining factors for high performance silicone rubber microwave absorbing materials. J. Magn. Magn. Mater. 323, 1643–1651 (2011).

Abbas, S. M., Dixit, A. K., Chatterjee, R. & Goel, T. C. Complex permittivity, complex permeability and microwave absorption properties of ferrite–polymer composites. J. Magn. Magn. Mater. 309, 20–24 (2007).

Huang, X., Zhang, J., Xiao, S., Sang, T. & Chen, G. Unique electromagnetic properties of the zinc ferrite nanofiber. Mat. Lett. 124, 126–128 (2014).

Huang, X. et al. Facile preparation and microwave absorption properties of porous hollow BaFe12O19/CoFe2O4 composite microrods. J. Alloy. Compound. 648, 1072–1075 (2015).

Zhao, J. et al. Lanthanum and neodymium doped barium ferrite-TiO2/MCNTs/poly(3-methyl- thiophene) composites with nest structures: preparation, characterization and electromagnetic microwave absorption properties. Sci. Rep. 6, 20496 (2016).

Li, N. et al. Electrostatic tuning of ferromagnetic resonance and magneto electric interactions in ferrite-piezoelectric heterostructures grown by chemical vapor deposition. Appl. Phys. Lett. 99, 192502 1–3 (2011).

Dzunuzovic, A. S. et al. Structure and properties of Ni–Zn ferrite obtained by auto-combustion method. J. Magn. Magn. Mater. 374, 245–251 (2015).

Razzitte, A. C., Fano, W. G. & Jacobo, S. E. Electrical permittivity of Ni and Ni-Zn ferrite polymer composites. Phys. B. 354, 228–231 (2004).

Krishna, K. R., Kumar, K. V., Ravindernathgupta, C. & Ravinder, D. Magnetic properties of Ni- Zn ferrites by citrate gel method. Adv. Mat. Phys. Chem. 2, 149–154 (2012).

Costa, A. C. F. M., Tortella, E., Morelli, M. R. & Kiminami, R. H. G. A. Synthesis, microstructure and magnetic properties of Ni–Zn ferrites J. Magn. Magn. Mater. 256, 174–182 (2003).

Amiri, G. R. et al. Magnetic properties and microwave absorption in Ni–Zn and Mn–Zn ferrite nanoparticles synthesized by low-temperature solid-state reaction. J. Magn. Magn. Mater. 323, 730–734 (2011).

Huang, X., Zhang, J., Lai, M. & Sang, T. Preparation and microwave absorption mechanisms of the Ni-Zn ferrite nanofibers. J. Alloy. Compound. 627, 367–373 (2015).

Kakirde, A., Sinha, B. & Sinha, S. N. Development and characterization of nickel–zinc spinel ferrite for microwave absorption at 2⋅4 GHz. Bull. Mater. Sci. 31 (5), 767–770 (2008).

Kim, S. S., Han, D. H. & Cho, S. B. Microwave absorbing properties of sintered Ni –Zn ferrite. IEEE Trans. Magn. 30 (6), 4554–4556 (1994).

Fawzi, A. S., Sheikh, A. D. & Mathe, V. L. Structural, dielectric properties and AC conductivity of Ni(1−x)ZnxFe2O4 spinel ferrites. J. Alloy. Compound. 502, 231–237 (2010).

Moulson, A. J. & Herbert, J. M. Electroceramics (Chapman and Hall, London, 1990).

Hench, L. L. & West, J. K. Principles of Electronic Ceramics (A Wiley–Inter Science Publication, Singapore, 1989).

Huang, X. et al. Effect of pH value on electromagnetic loss properties of Co–Zn ferrite prepared via coprecipitation method. J. Magn. Magn. Mater. 405, 36–41 (2016).

Kong, I. et al. Magnetic and microwave absorbing properties of magnetite–thermoplastic natural rubber nanocomposites. J. Magn. Magn. Mater. 322, 3401–3409 (2010).

Lima, U. R., Nasar, M. C., Nasar, R. S., Rezende, M. C. & Araujo, J. H. Ni–Zn nanoferrite for radar-absorbing material. J. Magn. Magn. Mater. 320, 1666–1670 (2008).

Verma, A., Saxena, A. K. & Dube, D. C. Microwave permittivity and permeability of ferrite–polymer thick films. J. Magn. Magn. Mater. 263, 228–234 (2003).

Dosoudil, R., Usakova, M., Franek, J., Slama, J. & Olah, V. RF electromagnetic wave absorbing properties of ferrite polymer composite materials. J. Magn. Magn. Mater. 304, e755–e757 (2008).

Zhu, L. et al. Electromagnetic and microwave-absorbing properties of magnetic nickel ferrite nanocrystals. Nanoscale 3, 2862–2864 (2011).

Bueno, A. R., Gregori, M. L. & Nobrega, M. C. S. Microwave-absorbing properties of Ni0.50–xZn0.50−xMe2xFe2O4 (Me=Cu, Mn, Mg) ferrite–wax composite in X-band frequencies. J. Magn. Magn. Mater. 320, 864–870 (2008).

Singh, V. K. et al. Microwave absorbing properties of a thermally reduced graphene oxide/nitrile butadiene rubber composite. Carbon 50 (6), 2202–2208 (2012).

Barlow, F. W. Rubber Compounding (Marcel Dekker Inc., New York, 1993).

Hwang, C. C., Tsai, J. S. & Huang, T. H. Combustion synthesis of Ni-Zn ferrite by using glycine and metal nitrates- investigations of precursor homogeneity, product reproducibility and reaction mechanism. Mater. Chem. Phys. 93(2–3), 330–336 (2005).

Jalaly, M., Enayati, M. H., Kameli, P. & Karimzadeh, F. Effect of composition on structural and magnetic properties of nanocrystalline ball milled Ni1−xZnxFe2O4 ferrite. Phys. B 405, 507–512 (2010).

Zhang, M. et al. Magnetic and microwave absorption properties of Ni1−xZnxFe2O4 nanocrystalline synthesized by sol-gel method. Sci. China Tech. Sci. 56 (1), 13–19 (2013).

Smith, J. & Wijn, H. P. J. Ferrites (Philips Technical Library, Netherlands, 1959).

Peelamedu, R., Grimes, C., Agrawal, D. & Roy, R. Ultralow dielectric constant nickel-zinc ferrites using microwave sintering. J. Mater. Res. 18 (10), 2292–2295 (2003).

Verma, A., Goel, T. C., Mendiratta, R. G. & Kishan, P. Magnetic properties of nickel-zinc ferrites prepared by the citrate precursor method. J. Magn. Magn. Mater. 208 (1–2), 13–19 (2000).

Nicolson, A. M. & Ross, G. F. Measurement of the intrinsic properties of materials by time-domain techniques. IEEE Trans. Instru. Meas. 19 (4), 377–382 (1970).

Chen, N. & Gu, M. Microstructure and microwave absorption properties of Y-substituted Ni-Zn ferrites. Op. J. Mat. 2, 37–41 (2012).

Michielssen, E., Sajer, J., Ranjithan, S. & Mittra, R. Design of lightweight, broad-band microwave absorbers using genetic algorithms. IEEE Trans. Microw. Theo. Tech. 41 (6), 1024–1031 (1993).

Petrov, V. M. & Gagulin, V. V. Microwave absorbing materials. Inorg. Mater. 37 (2), 93–98 (2001).

Kim, S. S. et al. Complex permeability and permittivity and microwave absorption of ferrite-rubber composite in X-band frequencies. IEEE Trans. Magn. 27 (6), 5462–5464 (1991).

Shin, J. Y. & Oh, J. H. The microwave absorbing phenomena of ferrite microwave absorbers. IEEE Trans. Magn. 29 (6), 3437–3439 (1993).

Shi, Z. et al. Magnetic resonance of the NiFe2O4 nanoparticles in the gigahertz range. Nanoscale Reas. Lett. 8, 404–408 (2013).

Zhao, D. L., Ly, Q. & Shen, Z. M. Fabrication and microwave absorbing properties of Ni-Zn spinel ferrite. J. Alloy. Compound. 480, 634–638 (2009).

Acknowledgements

Authors acknowledge Prof. C. V. R. Murty, Director, IIT Jodhpur for extending his support for the use of characterization facilities at the institute.

Author information

Authors and Affiliations

Contributions

Lokesh Saini, Manoj Kumar Patra, Ambesh Dixit and Sampat Raj Vadera coined the problem and planned experiments. Lokesh Saini, Raj Kumar Jani, and Goutam Kumar Gupta carried out experimental work. The data and results are discussed by all authors. Lokesh Saini, Ambesh Dixit, and S.R. Vadera wrote the manuscript and all authors have approved the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Saini, L., Patra, M., Jani, R. et al. Tunable Twin Matching Frequency (fm1/fm2) Behavior of Ni1−xZnxFe2O4/NBR Composites over 2–12.4 GHz: A Strategic Material System for Stealth Applications. Sci Rep 7, 44457 (2017). https://doi.org/10.1038/srep44457

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep44457

This article is cited by

-

Grain Size Effect on the Electric Properties of Gd/Nb Substituted Barium Titanate-Lithium Ferrite at High Frequency Region

Transactions on Electrical and Electronic Materials (2023)

-

Electromagnetic wave absorption properties of Ni-doped Dy2Co17 alloy

Journal of Materials Science: Materials in Electronics (2023)

-

Preparation and characterization of a flexible microwave absorber based on MnNiZn ferrite (Mn0.1Ni0.45Zn0.45Fe2O4) in a thermoset polyurethane matrix

SN Applied Sciences (2020)

-

Applications of Microwave Materials: A Review

Journal of Electronic Materials (2019)

-

Synthesis of hollow Fe3O4 particles via one-step solvothermal approach for microwave absorption materials: effect of reactant concentration, reaction temperature and reaction time

Journal of Materials Science: Materials in Electronics (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.