Abstract

For the first time, renewable and easy accessible pre-bleached spent coffee powder coated with polyethylenimine (PEI) and ferric ions (Coffee-PEI-Fe) was used for the successive adsorption of As(V), Cu(II) and P(V) ions from spiked water samples. Fully characterized coffee-PEI-Fe was employed for batch mode experiments. Kinetic regression analysis showed that the adsorption processes of As(V) and P(V) anions follows a pseudo-second-order model, while the adsorption of Cu(II) ions fit with a pseudo-first-order model. The maximum adsorption capacities estimated by Langmuir model for As(V), Cu(II) and P(V) ions were 83.3, 200.1, and 50.2 mg/g, respectively. The simulated results revealed that the internal diffusion is the rate-determining step for the adsorptions of As(V) and Cu(II) ions, while film diffusion is the mass transfer resistance for the adsorption of P(V) ions on the surface of coffee-PEI-Fe. The successive adsorptions of adsorbates were achieved through electrostatic attraction between adsorbent surface and adsorbates. The dynamic column adsorption behavior of the adsorbent was described by Thomas model, which showed a good agreement with the experimental values (qexp). The results presented in this paper could be used for developing efficient adsorbent from renewable materials for water purification.

Similar content being viewed by others

Introduction

Large quantities of coffee beans are processed every year to quench the thirst for coffee drinkers around the world. However, about 45–50% of the total coffee beans (i.e. a few million tons) are disposed every year as spent coffee grounds1. In recent years, renewable resources have been explored as potential adsorbents for the extraction of different contaminants from water2. Spent coffee grounds comprises of lignin, hemicelluloses, cellulose, pectin and small quantity of extractives3. The abundant functional groups (such as hydroxyl group, amino group, and carboxyl group) on the surface of spent coffee grounds makes it a potential low-cost renewable adsorbent for pollutant removal from water4. In this study, readily available spent coffee grounds were pretreated with bleaching solutions to extract the cellulose nanofibers as low-cost adsorbents for the removal of arsenate, copper and phosphate ions from aqueous solutions. Pretreatment with bleaching solution is a convenient method, which ensures the removal of hemicelluloses, lignin and other soluble compounds from spent coffee to obtain cellulosic fibers as adsorbent5. Cellulose nanofibers are interesting adsorbents owing to their high specific surface area, large number of hydroxyl groups on the surface and exceptional mechanical properties such as low density, renewability, low cost, and low thermal expansion6.

Arsenic (As) pollution in water is a worldwide problem and has been considered as one of the major pollutants in potable water7. The occurrences of arsenic at elevated concentrations in groundwater has been well documented in many countries such as Argentina, Bangladesh, China, India, Mexico and Vietnam8. Fe-based sorbents have been extensively developed and showed good extraction efficiency for arsenic removal from contaminated water9. The high concentration of heavy metals such as copper and lead in water cause health hazards to living organisms10,11. Similarly, presence of phosphate in large quantities is known to deteriorate natural ecosystems, water quality and responsible for eutrophication problem of surface water12. Among the techniques currently available for pollutants removal from water, the adsorption process using biomass derived adsorbents is considered as one of the most promising techniques owing to high efficiency, easy to operate, economic and environmental factors13.

In the current work, pretreated spent coffee powder is used as a renewable adsorbent and a new protocol of layer-by-layer adsorption is developed to enhance the efficiency of adsorption. The pretreated coffee powder was treated with PEI, cross-linked to reduce water solubility and adsorbed with Fe (III) cations for enhancing the affinity towards arsenic anions in water. We hypothesized that adsorption of arsenic ions on the surface of the adsorbent lead to the development of a net negative surface charge, which could be used for the extraction of cationic pollutants such as Cu(II) ions from water and such alternating adsorption process can continue for a few adsorbates with opposite charges, before regenerating the adsorbent. Such successive extractions could be used in industrial cities where the effluents from each industry varies in chemical nature and composition. As a proof of concept, the pretreated coffee based adsorbent was used for the extraction of arsenic anions, copper cations and phosphate anions, successively (Fig. 1). Full characterization of the adsorbent and analytical data are given in the paper to demonstrate the efficiency of the pretreated spent coffee powder as potential adsorbent for water purification. To the best of our knowledge, this kind of layer-by-layer adsorption was seldom applied for water purification. In this study, successive adsorption based purification of real water sample was not tested, because we need to understand the interactions and interference of different cations and anions towards the adsorption efficiency. There is no need to discard or regenerate the exhausted adsorbent (e.g. adsorbent with As(V) on the surface), but can be reused as such for the adsorption of oppositely charged pollutants from water. Therefore, this layer-by-layer adsorption of alternatively charged pollutants from water may offer potential for reducing the overall cost of water purification process.

Results and Discussion

Characterization of Coffee Cell-PEI

Pretreated and purified spent coffee powder was fully characterized using a range of techniques, before employing for extraction studies.

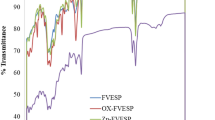

Analysis of FT-IR spectra of adsorbents

The changes in functional groups on the spent coffee powder before and after modification can be seen from FTIR spectra (Fig. 2). The broad absorption band at 3200–3600 cm−1 is characteristic of the stretching vibration of hydroxyl groups (from alcohols, phenols or carboxylic acid) and water adsorbed on the cellulosic fiber surface. The sharp peak at 2920 cm−1 was assigned to C-H asymmetric and symmetric stretch of the methylene groups (-CH2-) and methyl groups (-CH3)14,15. The band at 2853 cm−1 indicated aliphatic C-H stretching from the cellulose backbone14. The strong band at 1450 cm−1 of raw coffee grounds was assigned to -CH2 and -CH3 bending vibrations and/or the O-H bending peak due to the existence of phenols on the raw spent coffee powder surface15,16. The wide peak at 1100–1300 cm−1 may be assigned to the C-C vibration of the cellulose17. After PEI modification, all such bands were weakened and a new peak appeared at 1053 cm−1 is assigned to the C-N stretching vibration18.

Scanning electron microscopy and elemental analysis

Figure 3 depicts the SEM images of the raw coffee powder (Fig. 3A), pretreated spent coffee cellulose (Fig. 3B), Coffee-PEI (Fig. 3C) and Coffee-PEI-Fe after successive adsorption of As(V), Cu(II) and P(V) (Fig. 3D). The raw coffee powder surface is rough with a variety of flaky protuberances. After the bleaching pretreatment, a smooth surface was observed and the flaky protuberances disappeared. After coating with PEI and cross-linking with gluteraldehyde, the roughness of the adsorbent surface was reduced (Fig. 3C). The surface of Coffee-PEI-Fe was also rough and small lumps were observed after successive adsorption of As(V), Cu(II) and P(V) ions (Fig. 3D). As expected, the elemental analysis showed an increase in nitrogen content from 0.5% to 3% after coating the surface with PEI. No significant leaching of PEI from the adsorbent into water was observed during the washing or extraction experiments as nitrogen content in the aqueous fractions was non-detectable or insignificant. Elemental analysis of the coffee-PEI-Fe showed a Fe content of around 0.36%. After consecutive adsorption of As(V), Cu(II) and P(V) ions (using an initial concentration of each adsorbate solution of 5 mg/L), the elemental concentrations of As, Cu and P on the adsorbent surface were 0.14%, 0.76%, and 0.49%, respectively. Elemental analysis data of the adsorbents are given in Table 1.

Batch adsorption of As(V), Cu(II) and P(V) ions using coffee-PEI-Fe adsorbent

As(V) anion adsorption on coffee-PEI-Fe adsorbent

The comparison of As(V) adsorption on spent coffee powder, coffee-PEI and coffee-PEI-Fe are shown in Fig. 4. The initial concentration of As(V) anion used was 1, 2, 5, 10, 50, 100 mg/L and the raw spent coffee showed a maximum adsorption capacity of 0.2 mg/g for As(V) ions. However, the adsorption ability was significantly enhanced after treatment with PEI, followed by iron loading processes. The adsorption capacity of As(V) ions on coffee-PEI and coffee-PEI-Fe is increased significantly with an increase of initial concentrations. The maximum adsorption capacity of coffee-PEI was 63.1 mg/g while that of coffee-PEI-Fe was 85.1 mg/g at the initial As(V) ion concentration of 100 mg/L. The protonated amine groups of PEI were responsible for the increased As(V) anion extraction by coffee-PEI via electrostatic attraction. Similarly, the loading of Fe(III) cations on coffee-PEI-Fe surface significantly enhanced As(V) anion adsorption to 85.1 mg/g through the formation of Fe-As complex19. A comparison of three adsorbents, raw coffee, coffee-PEI and coffee-PEI-Fe, demonstrated that the incorporation of PEI and Fe on the surface contributed to the enhancement of As(V) anion extraction by the pretreated spent coffee powder (Fig. 4). A comparison of adsorbents reported in the literature is given in the Supplementary Information (Table S1).

Successive extraction of As(V), Cu(II) and P(V) ions on coffee-PEI-Fe adsorbent

Figure 5 shows the successive extraction of As(V), Cu(II) and P(V) ions on coffee-FEI-Fe adsorbent. It can be seen that As(V) ion extraction on coffee-PEI-Fe increased from 1 to 85 mg/g with an increase in initial concentration of arsenate from 5 to 100 mg/L. Meanwhile, Cu(II) ion extraction capacity was also increased with an increasing initial concentrations, and the maximum extraction capacity was reached to 161 mg/g. After As(V) anion adsorption, the effective negative charges on the surface of coffee-PEI-Fe favors the adsorption of Cu(II) cations from solution. Similarly, adsorption of Cu(II) cations enhances the net positive charges on the surface and facilitate the adsorption of P(V) anions with an adsorption capacity of about 48 mg/g, when the initial concentration of P(V) anion used was 100 mg/L. Thus, layer-by-layer adsorption of oppositely charged ions was achieved through the maximization of electrostatic attraction between the ions. We hope that such successive removal of pollutant will be useful for treating effluents from various industries, in which the chemical nature of the pollutants is well established.

In order to estimate the change of surface charge during the consecutive adsorption, the zeta potentials of all adsorbents such as raw coffee cellulose, coffee-PEI, coffee-PEI-Fe, after As(V) anion adsorption (coffee-PEI-Fe-As), after Cu(II) cation adsorption (coffee-PEI-Fe-As-Cu) and after adsorption of P(V) anions (coffee-PEI-Fe-As-Cu-P), were measured and summarized in Table 2. The raw coffee cellulose after bleaching showed a zeta potential of −29.8 mV, indicating a negatively charged surface. After modification with PEI, the negative zeta potential was decreased to −3.92 mV owing to the presence of protonated amine groups on the surface. The zeta potential was increased to +41.6 mV after adsorption of Fe (III) ions on the surface, which facilitates the adsorption of negatively charged arsenate ions from solution. As expected, the adsorption of As(V) ions resulted in the reduction of positive zeta potential to +1.1 mV, which was again increased to +41 mV after Cu(II) cation adsorption. Similarly, adsorption of P(V) anion on the surface reduced the zeta potential to +21.1 mV. The consecutive increase and decrease in Zeta potentials indicated the layer-by-layer adsorption of cations and anions from solution.

Langmuir and Freundlich isotherm models were used to describe the adsorption isotherms as shown in Fig. 5, the fitting parameters were summarized in Table 3. For As(V) and P(V) adsorption, the Langmuir model showed a better fit with the adsorption isotherms (R2 > 0.99) than Freundlich model (R2 between 0.97~0.98). For Cu(II), the Freundlich model fitted much better than Langmuir model. The maximum adsorption capacities of As(V), Cu(II) and P(V) ions estimated by Langmuir model are 83.3, 50.2 and 200.1 mg/g, respectively. A comparison of Langmuir constant19 indicated that the adsorption affinity towards Cu(II) was stronger than As(V) and P(V) ions, owing to the presence of amine functional groups on the surface which enhances the affinity towards Cu(II) ions.

Adsorption kinetics

For the adsorption of As(V) and P(V) anions on the adsorbent surface (as shown in Fig. 6), the initial adsorption rates within the first 25 min are relatively fast, followed by a slower reaction rate, and the adsorption equilibrium was achieved within 100 min. For Cu(II) ions, the adsorption rate is much faster owing to strong interaction between copper ions and amines on the surface, and the rate remain constant for the period of up to 250 min and then shows a plateau. It is conceivable that two different mechanisms may be involved for the adsorption of As(V), P(V) and Cu(II) on the surface of adsorbent. To understand the kinetics of arsenate adsorption onto coffee-PEI-Fe surfaces, the data were analyzed using both pseudo-first-order and pseudo-second-order kinetic models. The parameters of these two models were summarized in Table 4.

As can be seen from Table 4, the kinetics involved in the adsorption of As(V) and P(V) anions can be well described by pseudo-second-order model, implying a chemical adsorption with strong affinity to the surface. The correlation coefficient R2 is 0.992 and 0.845 for As(V) and P(V), respectively. The k2 value of 0.22 for P(V) ions is much higher than that of 0.07 for As(V) anions, indicating that coffee-PEI-Fe exhibited a stronger affinity towards P(V) than As(V) anions. Moreover, the observed leaching of adsorbed As(V) anion into the solution during P(V) adsorption could be due to a competitive adsorption between As(V) and P(V) anions from solution. As can be seen from Fig. 6, the adsorption curve of P(V) anions is similar in shape with that of the leaching curve of arsenic anions. At the same time, leaching of Fe(III) ions during the Cu(II) adsorption was not observed (Fig. 7). For the adsorption of Cu(II) cations, the kinetic data fitted much better to the pseudo-first-order model with a R2 value of 0.986 and strong electrostatic interaction between the adsorbent and adsorbate is the dominant adsorption mechanism. Moreover, Cu(II) ions form a blue color copper-amine complex with the grafted PEI molecule.

In order to further investigate the different affinity of coffee-PEI-Fe surface towards adsorption of As(V), Cu(II) and P(V) ions, a kinetic study was conducted with all three ions mixed together (the initial concentrations for the three ions were 5 mg/L). As can be seen from Fig. 8, the kinetic curves are similar to that given in Fig. 6, but the adsorption capacities for As(V), Cu(II) and P(V) ions are decreased, suggesting a competitive adsorption on the adsorbent surface. Some of the amine groups on the surface of Coffee-PEI-Fe powders can be neutral, while some are cationic in nature. The neutral electron rich amino groups bind to Cu(II) cations while the cationic groups interact strongly with As(V) and P(V) anions. Unlike systematic adsorption performed one ion after the other, the mixed ions may compete for the surface functional groups, which leads to a decrease in adsorption capacities for each ion.

Dynamic column study

Batch experiments were performed to evaluate the equilibrium capacity of adsorbent for adsorbate present in water. But in practical industrial water treatment processes, the experimental data obtained from the laboratory scale fixed bed column experiments are helpful for checking the potential applicability at the industrial scale. Column adsorption offers a more realistic simulation by replicating the batch treatment. Therefore, a dynamic column adsorption experiment was conducted to determine the mass transfer mechanism and various types of column parameters. As shown in Fig. 9, the duration to reach the breakthrough point for 1 mg/L for As(V) ions, needs 110 min at a flow velocity of 10 mL/min, while it needs 60 min to reach the breakthrough point for 1 mg/L for P(V) ions at the same flow velocity. For Cu(II) ions, it needs a much longer time of 540 min to reach the breakthrough point.

It is generally believed that the process of mass transfer is controlled by four independent processes20, which include bulk transport, film diffusion (mass transfer across the external boundary), intra-particle diffusion (diffusion within the pores of the adsorbent), and chemical reaction (adsorption at a special site on the surface). In order to further investigate the mechanism of mass transfer, the kinetic data was simulated using the models discussed in detail by Fulazzaky21. It is briefly introduced as follows:

where C0 is the initial concentration of adsorbate (in mg/L), Cs is the concentration of adsorbate in the eluent at time t (in mg/L), [kLa]f is the external mass transfer factor (or film mass transfer factor) (in 1/h), t is the reaction time (in h). Monitoring Cs at outlet of the column after the breakthrough point is important for modeling.

where [kLa]g is the global mass transfer factor in 1/h.

By substituting Eq. (1) into Eq. (2) yields a continuous equation valid in determining the variation of mass transfer factor.

A deduction of Eq. (3) mathematically gives a linear expression below:

where q is the cumulative quantity of solute on adsorbent (in mg/g), β is the adsorbate-adsorbent affinity parameter (in g h/mg).

where [kLa]d is the internal mass transfer factor (in 1/h).

A plot (Fig. 10) of ln(q) versus ln(t) gives a straight line with an intercept at B and 1/β as slope with the correlation coefficient of 0.928, indicating that the use of parameter B and β is reasonable for investigating mass transfer potential and adsorbate-adsorbent affinity for As(V), Cu(II) and P(V) ions on coffee-PEI-Fe adsorbent.

The variations of global, external and internal mass transfer factors are shown in Fig. 11. The curves of [kLa]g, [kLa]f, [kLa]d for these three ions descended progressively with increase in running time and the values of both [kLa]f and [kLa]d approached to zero when the coffee-PEI-Fe surface was saturated through adsorption.

For As(V) and Cu(II) ions, the internal mass transfer [kLa]d constituted a larger proportion of the global mass transfer [kLa]g, indicating that the resistance of mass transfer is dependent on the internal mass transfer. The chemical interactions between As(V) anions and the Fe(III) cations on the surface are relatively important for enhancing the As(V) ion adsorption. Arsenic tends to form inner-sphere complex with iron oxyhydroxide through mechanism of ligand exchange. Such chemisorption is also indicated by the simulation with the pseudo-second-order model. Cu(II) ions form the expected copper-amine complex on the coffee-PEI-Fe surface. For P(V) anions, the external mass transfer [kLa]d constituted a larger proportion of the global mass transfer [kLa]g, indicating the film transfer is the main resistance for P(V) anion adsorption on the surface of coffee-PEI-Fe adsorbent. Thomas model was used to fit the data from tests of column adsorption (R2 > 0.92) (Fig. 12, Table 5). The results of column adsorption capacity indicated a good agreement between the values (q0) generated using Thomas model and the experimental values (qexp).

Recycling of the adsorbents

In the practical application, the stability and reuse of the adsorbents are usually important factors because of the economic necessity. However, adsorbent based on biomass are readily available at a low cost and may not be recycled. Desorption of As(V), Cu(II) and P(V) from coffee-PEI-Fe surface were carried out by washing with 5% NaOH solution (100 mL) or 5% H2SO4 solution (100 mL), respectively. The desorption process occurred via ionization of surface functional groups and replacement of the adsorbed As(V) and P(V) anions by OH−, and replacement of Cu(II) ions by H+ ions. Data from desorption studies are shown in Fig. 13. The adsorption efficiency decreased with an increasing number of cycles, i.e., over 70% of efficiency for As(V) and Cu(II) and over 60% of efficiency for P(V) were obtained in the third adsorption-desorption cycles. This indicates that the adsorption of As(V), Cu(II) and P(V)on coffee-PEI-Fe was reversible and the adsorbent could be recycled after proper treatments.

Conclusion

In summary, renewable low-cost spent coffee powder was used as an effective adsorbent for the removal of As(V), Cu(II) and P(V)ions from water. The raw spent coffee grounds were bleached thoroughly to remove lignin, hemicellulose and maximize the cellulose content. Iron was adsorbed on the PEI coated spent coffee cellulose surface to facilitate successive adsorption of As(V), Cu(II) and P(V) ions using the changes in net surface charges after adsorption of each ions. The maximum experimental adsorption capacities of coffee-PEI-Fe were 83.3, 200.1, and 50.2 mg/g for As(V), Cu(II) and P(V) ions, respectively. The kinetic study using the mixture of three ions in the same solution suggested coffee-PEI-Fe exhibited the strongest affinity towards Cu(II) ions through electrostatic attraction and metal coordination, followed by P(V) and As(V) anions. The rate-limiting step in the adsorption of As(V) and Cu(II) ions depends on the internal mass transfer resistance, while the film mass transfer mainly hinder the adsorption of P(V) ions on coffee-PEI-Fe surface. The column data showed a good fit with Thomas model and a good agreement between the simulated and experimental data. Our study concludes that the treated spent coffee ground is an interesting renewable adsorbent for the removal of various pollutants from contaminated water. Besides the As(V), Cu(II) and P(V) ions, coffee-PEI-Fe adsorbent can be used as a potential adsorbent for the removal of other dissolved pollutants.

Methods

Synthesis of modified coffee grounds adsorbents

The spent coffee materials were collected from local coffee shops and washed several times with water to remove soluble compounds. The pretreatment of the spent coffee (~1000 g) was conducted repeatedly using commercial bleach solution (5%, 200 mL) for several times until the color of the spent coffee powder changed from black to white. The floating cellulose fibers were separated (~100 g) and stirred with 10% polyethyleneimine (PEI, 100 mL) solution for 2 hrs, followed by crosslinking with aqueous solution of glutaraldehyde (0.5 mL, 25%). The product was washed with deionized water to remove excess reagents, dried in air and named as coffee-PEI. In order to increase the adsorption affinity towards arsenic anions, different batches of coffee-PEI (20 g) were stirred in aqueous Fe(NO3)3 solutions separately with different initial concentrations (100, 250, 500, 1000 mg/L) of Fe(NO3)3 solutions (250 mL) for 4 hr to adsorb of Fe (III) ions, filtered, washed with water and dried to obtain a series of coffee-PEI-Fe adsorbents. In order to establish the amount of iron loading, coffee-PEI-Fe (0.2 g) was digested with 50 ml of concentrated nitric acid and the solution was analyzed for iron concentration using elemental analysis.

Successive adsorption of As(V), Cu(II) and P(V) on the adsorbent

Batch adsorption experiments

The initial concentrations of 1, 5, 10, 50, 75, 100 mg/L As(V) solutions were used for arsenic adsorption experiments using coffee-PEI-Fe (0.5 g) suspended in water (100 ml). The deionized water was used for making all solutions without adjusting the initial pH of 7.1. The adsorption capacity for arsenic was determined using the equation below:

where q is the amount of As adsorbed per unit mass of the adsorbent (mg/g) at a given time t; C0 is the initial concentration of As (mg/L); Ct is the concentration of As (mg/L) at a given time t; madsorbent is the mass of the adsorbent (g/L).

After arsenic adsorption, the adsorbent (coffee-PEI-Fe-As) was filtered and collected for Cu(II) ion adsorption experiment. The Cu(NO3)2 solutions with initial concentrations of 1, 5, 10, 50, 75, 100 mg/L were used to study the adsorption of Cu(II) ions and extraction capacity was determined using the equation (6). After the extraction of Cu(II) ions, the adsorbent (designated as coffee-PEI-Fe-As-Cu) was filtered and collected for phosphate anion extraction. The NaH2PO4 solutions with concentrations of 1, 5, 10, 50, 75, 100 mg/L were used to study the adsorption capacities for P(V) ions. The final adsorbent was designated as coffee-PEI-Fe-As-Cu-P. The Langmuir and Freundlich models are frequently used to simulate the adsorptive isotherms data. The Langmuir equation (7) assumes that adsorbates form continuous monolayer on energetically equivalent sites on the adsorbent surface22.

where Qe (mg/g) is the equilibrium adsorption capacity, Qmax (mg/g) is the maximum adsorption capacity, Ce (mg/L) is the equilibrium arsenic concentration, KL is a constant related to the binding energy. The separation factor RL, as a characteristic parameter of this isotherm, is expressed as:

The Freundlich model is usually seen as an empirical equation (9), which is based on the assumption that multilayer adsorption on an energetically heterogeneous surface23.

where Qe (mg/g) is the amount of adsorbed arsenic per unit mass of the adsorbent at equilibrium, Ce (mg/L) is the equilibrium arsenic concentration, Kf, n are parameters related to the adsorption capacity and the intensity of adsorption.

Kinetic studies

Coffee-PEI-Fe (1.0 g) was dispersed in As(V) solution (1000 ml, 5 mg/L) to determine adsorption capacity at different time intervals. The initial solution pH was around 7.0 and no changes were done during the adsorption experiments. The kinetics study was carried out using an orbital shaker operating at 250 rpm. Time point collections of samples (5 mL) were done at 5, 10, 15, 20, 30, 40, 60, 90, 120, 180, 240, 360, 1440 mins. Arsenic concentrations were detected by an Inductively Coupled Plasma- Optical Emission Spectroscopy (ICP-OES). The As-laden coffee-PEI-Fe adsorbent was collected by filtration for the kinetic experiment with Cu(II) ions. The initial concentration of Cu(NO3)2 solution was kept at 5 mg/L and the experimental procedure was repeated. After that, the Cu-As-laden coffee-PEI-Fe was collected by filtration and used for the extraction of P(V) ions from aqueous solution (1000 ml, 5 mg/L). In all cases, three consecutive runs were conducted and the solution samples and saturated adsorbents were collected for elemental analysis (EA). The average of the three values are reported as the final results.

The pseudo-first-order and pseudo-second-order kinetic models are commonly used to simulate As adsorption kinetics on various adsorbent surfaces24. The first pseudo-first order equation used is,

where qt is the quantity of arsenic adsorbed at a time t (mg/g), qe the quantity of arsenic adsorbed at equilibrium (mg/g), k2 (g· mg−1·min−1) is the rate constant.

The pseudo-second-order kinetic model24 is expressed as follows:

where qt is the quantity of arsenic adsorbed at time t (mg/g), qe the quantity of arsenic adsorbed at equilibrium (mg/g), k2 (g·mg−1·min−1) is the rate constant and v0 (mg·g−1·min−1) is the initial adsorption rate.

Column test

Dynamic adsorption experiments were conducted using a polyethylene column with10 cm in height and 2.0 cm inner diameter. Cotton was placed at the bottom of column to prevent discharge of adsorbents from the tubes. Coffee-PEI-Fe (1 g) was filled into the column (5 cm) and As(V) solution (1 mg/L) was added dropwise into the column. The flow velocity was kept at 10 mL/min and samples were collected at regular time intervals to determine the concentration of arsenic ions present in the filtered solution. After about 700 min run of As(V) adsorption, the feed solution was changed to Cu(II) (1 mg/L) and procedure was repeated. Effluent was collected at regular time intervals to determine the concentration of copper remained in solution. After about 1000 min run of Cu(II) adsorption, the feed solution of phosphate (1 mg/L) was added into the column, the procedure was repeated again and the effluents were collected for analyses.

Several models such as Thomas20, Yoon-Nelson20, Wolborska21 and Adams–Bohart models25 were used in the literature to simulate the column tests data. In this study, Thomas model was used to simulate the column test data, assuming the second order reversible reaction kinetics and the data follows the Langmuir isotherm model. The Thomas model was described as the following equation:

where, C0 and Ct are the influent and effluent concentrations (mg/L), q0 is the adsorption capacity (mg/g), kT is the Thomas model constant (mL/mg · min), and t stands for total flow time (min). Q is the volumetric flow rate (mL/min). Values of kT and q0 are determined from the linear plot of ln[(C0/Ct) − 1] against t.

Analytical determinations

FTIR spectra of the coffee cellulose before and after functionalization were recorded within the range of450~4000 cm−1 using a Bruker ALPHA FT-IR spectrophotometer using KBr as matrix. Scanning Electron Microscope (SEM, JEOL JSM-6701F field emission scanning electron microscope) was used to observe the changes in morphology of spent coffee powder before and after modification. Concentrations of As, Cu, P, and Fe ions in solution were determined using Inductively Coupled Plasma-Optical Emission Spectroscopy (Dual-view Optima5300 DV). Elemental analyses were done using an Elementar Vario Micro Cube instrument. Zeta potential measurements were done using Malvern Zetasizer Nano-ZS90 instrument.

Additional Information

How to cite this article: Hao, L. et al. Successive extraction of As(V), Cu(II) and P(V) ions from water using spent coffee powder as renewable bioadsorbents. Sci. Rep. 7, 42881; doi: 10.1038/srep42881 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Campos-Vega, R., Loarca-Piña, G., Vergara-Castañeda, H. & Oomah, B. D. Spent coffee grounds: A review on current research and future prospects. Trend Food Sci Tech 45, 24–36 (2015).

Liu, L. et al. Adsorption removal of dyes from single and binary solutions using a cellulose-based bioadsorbent. ACS Sustain Chem Eng 3, 432–442 (2015).

Nuruddin, M. et al. A novel approach for extracting cellulose nanofibers from lignocellulosic biomass by ball milling combined with chemical treatment. J Appl Polym Sci 133, 42990–50000 (2016).

Wang, L.-Y. & Wang, M.-J. Removal of Heavy Metal Ions by Poly (vinyl alcohol) and Carboxymethyl Cellulose Composite Hydrogels Prepared by a Freeze–Thaw Method. ACS Sustain Chem Eng 4, 2830–2837 (2016).

Xiao, S., Gao, R., Gao, L. & Li, J. Poly (vinyl alcohol) films reinforced with nanofibrillated cellulose (NFC) isolated from corn husk by high intensity ultrasonication. Carbohyd Polym 136, 1027–1034 (2016).

Caes, B. R., Teixeira, R. E., Knapp, K. G. & Raines, R. T. Biomass to furanics: Renewable routes to chemicals and fuels. ACS Sustain Chem Eng 3, 2591–2605 (2015).

Malakar, A. et al. Efficient artificial mineralization route to decontaminate Arsenic (III) polluted water-the Tooeleite Way. Sci Rep 6, 26031–26041 (2016).

Smedley, P. & Kinniburgh, D. A review of the source, behaviour and distribution of arsenic in natural waters. Appl Geochem 17, 517–568 (2002).

Cantu, J. et al. Removal of arsenic from water using synthetic Fe7S8 nanoparticles. Chem Eng J 290, 428–437 (2016).

Kong, X. P. & Wang, J. Copper(II) adsorption on the kaolinite(001) surface: Insights from first-principles calculations and molecular dynamics simulations. Appl Surf Sci 389, 316–323 (2016).

Mushtaq, M. et al. Eriobotrya japonica seed biocomposite efficiency for copper adsorption: Isotherms, kinetics, thermodynamic and desorption studies. J Environ Manage 176, 21–33 (2016).

Conley, D. J. et al. Controlling eutrophication: nitrogen and phosphorus. Science, 123, 1014–1015 (2009).

Awual, M. R. et al. Evaluating of arsenic (V) removal from water by weak-base anion exchange adsorbents. Environ Sci Pollut Res 20, 421–430 (2013).

Mona, S., Kaushik, A. & Kaushik, C. Prolonged hydrogen production by Nostoc in photobioreactor and multi-stage use of the biological waste for column biosorption of some dyes and metals. Biomass Bioenerg 54, 27–35 (2013).

Azouaou, N., Sadaoui, Z., Djaafri, A. & Mokaddem, H. Adsorption of cadmium from aqueous solution onto untreated coffee grounds: Equilibrium, kinetics and thermodynamics. J Hazard Mater 184, 126–134 (2010).

Franca, A. S., Oliveira, L. S. & Ferreira, M. E. Kinetics and equilibrium studies of methylene blue adsorption by spent coffee grounds. Desalination 249, 267–272 (2009).

Pavlović, M. D. et al. Rapid cationic dye adsorption on polyphenol-extracted coffee grounds—A response surface methodology approach. J Taiwan Inst Chem Eng 45, 1691–1699 (2014).

Setyono, D. & Valiyaveettil, S. Functionalized paper—A readily accessible adsorbent for removal of dissolved heavy metal salts and nanoparticles from water. J Hazard Mater 302, 120–128 (2016).

Hao, L. et al. Temperature effects on arsenate adsorption onto goethite and its preliminary application to arsenate removal from simulative geothermal water. RSC Adv 4, 51984–51990 (2014).

Shukla, S. R. & Pai, R. S. Adsorption of Cu(II), Ni(II) and Zn(II) on modified jute fibres. Bioresour Technol 96, 1430–1438 (2005).

Fulazzaky, M. A., Khamidun, M. H., Din, M. F. M. & Yusoff, A. R. M. Adsorption of phosphate from domestic wastewater treatment plant effluent onto the laterites in a hydrodynamic column. Chem Eng J 258, 10–17 (2014).

Chauhan, D., Dwivedi, J. & Sankararamakrishnan, N. Novel chitosan/PVA/zerovalent iron biopolymeric nanofibers with enhanced arsenic removal applications. Environ Sci Pollut Res 21, 9430–9442 (2014).

Agrawal, P. R. et al. Novel 3D lightweight carbon foam as an effective adsorbent for arsenic(v) removal from contaminated water. RSC Adv 6, 29899–29908 (2016).

Liu, Q. S. et al. Adsorption isotherm, kinetic and mechanism studies of some substituted phenols on activated carbon fibers. Chem Eng J 157, 348–356 (2010).

Chowdhury, S. & Saha, P. D. Artificial neural network (ANN) modeling of adsorption of methylene blue by NaOH-modified rice husk in a fixed-bed column system. Environ Sci Pollut R 20, 1050–1058 (2013).

Acknowledgements

The authors thank the financial and technical support from the Department of Chemistry and National University of Singapore. HL thank China Scholarship Council for financial support for the joint PhD programme.

Author information

Authors and Affiliations

Contributions

S.V. designed the synthesis of coffee-PEI-Fe and proposed the idea of layer-by-layer adsorption achieved by electrostatic attraction. H.L. synthesized the adsorbent and carried out the experimental plans. W.P. helped to analyze the experimental data and studied the mass transfer mechanism of dynamic column tests.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Hao, L., Wang, P. & Valiyaveettil, S. Successive extraction of As(V), Cu(II) and P(V) ions from water using spent coffee powder as renewable bioadsorbents. Sci Rep 7, 42881 (2017). https://doi.org/10.1038/srep42881

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep42881

This article is cited by

-

Coffee pulp characterization and treatment as adsorbent material for heavy metal removal from landfill leachates

International Journal of Environmental Science and Technology (2023)

-

Pollutant decontamination by polyethyleneimine-engineered agricultural waste materials: a review

Environmental Chemistry Letters (2022)

-

Extending the geographic reach of the water hyacinth plant in removal of heavy metals from a temperate Northern Hemisphere river

Scientific Reports (2018)

-

Converting environmental risks to benefits by using spent coffee grounds (SCG) as a valuable resource

Environmental Science and Pollution Research (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.