Abstract

Inspired by the multifunctionality of biological surfaces necessary for the survival of an organism in its specific environment, we developed an artificial special wetting nanofur surface which can be adapted to perform different functionalities necessary to efficiently separate oil and water for cleaning accidental oil spills or separating industrial oily wastewater. Initial superhydrophobic nanofur surface is fabricated using a hot pulling method, in which nano- and microhairs are drawn out of the polymer surface during separation from a heated sandblasted steel plate. By using a set of simple modification techniques, which include microperforation, plasma treatment and subsequent control of storage environment, we achieved selective separation of either water or oil, variable oil absorption and continuous gravity driven separation of oil/water mixtures by filtration. Furthermore, these functions can be performed using special wetting nanofur made from various thermoplastics, including biodegradable and recyclable polymers. Additionally, nanofur can be reused after washing it with organic solvents, thus, further helping to reduce the environmental impacts of oil/water separation processes.

Similar content being viewed by others

Introduction

Requirements of the developing world put a lot of strain on the planet, including environmental pollution and overuse of the resources. In recent decades accidental crude oil spills occurring during its transportation and extraction have resulted in devastating consequences for the environment, public health and economy1. During the infamous Deepwater Horizon oil spill in the Gulf of Mexico in 2010, caused by the explosion of the oil rig, 4.9 million barrels (780 million liters) of oil were released into the gulf waters1. The toxic crude oil devastated the coastal and marine ecosystems, and its long-term effects are still not fully understood2,3. The current technologies applied to oil spill cleaning include in-situ burning, adding chemical dispersants, and oily water collection followed by oil/water separation techniques such as floatation, coalescing and centrifuge4,5. Conventional techniques are limited by low efficiency, high costs and generation of secondary pollutants6. Besides oil spills, such industries as petrochemical, textile and metallurgy produce oily wastewater which has to be processed and separated according to strict specifications6.

The development of advanced materials with special wetting properties that can selectively remove water or oil during separation offers a great potential for handling future oil spill disasters and aiding the industries. Superhydrophobic materials are characterized by high apparent water contact angles (CA) above 150° and low roll-off angles, and their roughness-induced non-wettability is described by fundamental Wenzel and Cassie-Baxter models. They predict that superhydrophobicity can be achieved by adding roughness to hydrophobic surfaces (intrinsic CA > 90°), while adding it to the hydrophilic surfaces (CA < 90°) enhances wettability7,8. Understanding of the classical models has been greatly extended in the recent decades, and it was theoretically predicted and experimentally shown that surfaces non-wettable by water and low surface-tension liquids such as oils can be fabricated on materials with CA < 90° by controlling the local surface curvature of the roughness8,9. A term “superhygrophobic” (“hygro” is “liquid” in Greek) was suggested to describe superhydrophobic and superoleophiobic surfaces10. Moreover, based on theoretical and experimental results, the intrinsic CA = 65° was suggested as a boundary above which surface superhydrophobicity can be attained by adding nano- and microscale roughness11,12,13.

Selective separation of either oil or water from oil/water mixtures requires two different types of materials with special wetting properties: superhydrophobic/superoleophilic for oil removal, and underwater superoleophobic for water removal. Additionally, two material geometries exist to perform absorption or filtration of the selected fluid from the mixture: mesh-like porous structure as a filter, and sponge- or powder-like structure as an absorber14. As a result, multiple fabrication techniques and materials are used to realize seemingly similar oil/water separation tasks. For example, aerogels, powders, graphene oxide films, sponges modified with graphene, carbon nanotubes (CNT), nanoparticles or low-surface energy chemicals are used for oil absorption from water4,15,16,17,18,19,20,21,22,23,24; superhydrophobic CNT membranes, metal meshes or textiles chemically modified or coated with metal oxide nanoparticles and nanorods are utilized for oil filtration from oil/water mixtures25,26,27,28,29,30,31; and underwater superoleophobic porous nanotube membranes, meshes and textiles modified with palygorskite powders, zeolites, TiO2 nanostructures, nanoparticles, zwitterionic polymers or cellulose aerogels are used for filtrating water from oil/water mixtures32,33,34,35,36,37,38,39. To ensure a better control over the oil/water separation process, materials which switch their wetting properties in response to external stimuli such as changing electric or magnetic field, pH, temperature or light illumination, and pre-wetted materials were developed6,40,41,42,43,44.

Contrary to artificial surfaces, biological surfaces have evolved to perform various functions necessary for the survival of an organism in its specific environment. The top surface of the leaves of many floating plants is superhydrophobic in order to provide buoyant support on water and increase gas exchange through stomata pores, while the submerged bottom surface of the leaves is wettable by water45,46,47,48. For example, the Lotus leaf is superhydrophobic on top and underwater superoleophobic on the bottom side48. The surface wettability of the plant leaves is enhanced by a variety of nano- and microstructures such as hairs, waxes or cuticular folds47. Taking inspiration from the multifunctionality of plant surfaces into the global problem of oil/water separation, we developed an artificial surface, which by using a set of fabrication and modification techniques, can be adapted to perform different functionalities necessary for efficient oil/water separation: selective separation of water or oil by change of surface wettabilty; variable oil absorption capacity; continuous gravity driven separation of oil/water mixtures by filtration (Fig. 1). The presented techniques can be applied to a wide selection of polymeric materials, including biodegradable and recyclable polymers, and fabricated surface can be reused after washing with organic solvents. Bioinspired superhydrophobic nanofur surface is fabricated using a hot pulling method, in which nano- and microhairs are drawn out of the polymer surface due to adhesion to a heated sandblasted steel plate49,50. By combining the presented methods a custom oil/water separation platform in terms of material, filtration fluid and separation type can be created. For example, an oil absorber with high oil absorption capacity, a porous underwater superoleophobic membrane for water filtration or an oil filter, all made from the same biodegradable polymer can be realized.

Results and Discussion

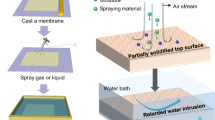

Bioinspired nanofur is a polymeric surface covered by a dense layer of nano- and microhairs fabricated using a hot pulling technique schematically shown in Fig. 2a49,50,51. Hot pulling is a modified hot embossing process, in which demolding forces occurring during polymer and mold insert separation are used to fabricate high aspect ratio polymeric nano- and microstructures52,53,54. A steel plate sandblasted with rough aluminum silicate abrasive and then with finer aluminum oxide sand serves as a mold insert in hot pulling. The mold plate is heated above the glass transition temperature of the polymer, and pressed into the flat polymer foil attached to the bottom plate. Softened polymer fills the microcavities of the sandblasted mold, and the subsequent mold retraction creates a topography consisting of microcavities surrounded by dense nano- and microhairs on the polymer surface. Step-by-step nanofur fabrication procedure and corresponding scanning electron microscopy (SEM) images of the fine sand used for sandblasting, sandblasted steel plate and polycarbonate (PC) nanofur are shown in Fig. 2a.

(a) SEM and schematic images of the nanofur fabrication steps. Hot pulling with a heated sandblasted steel plate is used to produce nanofur. SEM images of the sand, sandblasted plate and polycarbonate (PC) nanofur surface are taken at the same magnification for better comparison. (b) Photograph of a water droplet on the superhydrophobic PC nanofur surface with contact angle θ ≈163°. (c) Crude oil spill cleanup by PC nanofur submerged into crude oil spill in a Petri dish. Nanofur absorbed most of the oil within few seconds.

The nanofur is superhydrophobic with typical contact angles above 150° (Fig. 2b), as its hierarchical nano- and microhairs entrap the air and support the water in Cassie-Baxter wetting state. The nanofur superhydrophobicity is achieved solely by the micro- and nanoscale roughness created during hot pulling. The superhydrophobic nanofur is superoleophilic, and can be used for selective oil/water separation49. The as-prepared nanofur successfully cleans an imitated crude oil spill (EK 651, MiRO refinery, Germany) when submerged into contaminated water by absorbing most of the oil within seconds, as shown in Fig. 2c. The oil remains locked in the nanofur hairs even after its removal from water.

Biodegradable, recyclable and reusable nanofur

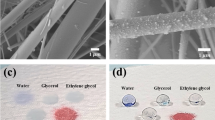

Replacing conventional polymers derived from fossil fuels with biodegradable polymers from renewable resources is essential for reducing the environmental impact of many industries and households. Using biodegradable materials to handle such environmental disasters as crude oil spills is of an increased significance. Therefore, a biodegradable nanofur was fabricated from polylactic acid (PLA). PLA is a biodegradable polymer derived from corn starch or sugarcane55. To fabricate PLA nanofur for oil spill cleanup the hot pulling method was used in a velocity and force-controlled mode with the following parameters: T = 155 °C, embossing velocity 20 mm/min, embossing force 5.5 kN, retraction velocity 100 mm/min. The surface of the fabricated PLA nanofur is covered in high aspect ratio microhairs, as shown in SEM image in Fig. 3a. High magnification SEM image in Fig. 3b reveals submicron grooves on the PLA microhairs. The biodegradable nanofur is superhydrophobic (inset in Fig. 3b) and superoleophilic, and can be used for environmentally friendly oil/water separation.

(a) PLA microhairs are hundreds of microns long. (b) Higher magnification SEM image reveals submicron structures on the hairs. Water contact angle (WCA) of 156° is in the inset. (c) PET nano- and microhairs form a mesh parallel to the surface. (d) The diameter of PET nanohairs is below 100 nm in some sections. WCA of 153° is in the inset.

Reusing recycled polymers for oil/water separation is another approach for reducing environmental impact of oil spills on the ecosystems and polymeric material accumulation in nature. To fabricate recyclable nanofur, we used films of polyethylene terephthalate (PET). PET is one of the most common fossil fuel-based polymers used for fabricating plastic bottles, textiles and packaging materials, and its recycling is widely established in the world. Using the hot pulling technique we fabricated recyclable PET nanofur. The parameters used for fabrication are: embossing temperature 275 °C, embossing velocity 10 mm/min, penetration depth 200 μm, retraction velocity 100 mm/min. SEM images of the PET nanofur are shown in Fig. 3c,d. PET nano- and microhairs have an average size of 470 ± 240 nm and minimal size below 100 nm. The recyclable nanofur is superhydrophobic, as can be seen in the inset in Fig. 3d. A unique characteristic of the PET nanofur topography compared to nanofur made from other polymers is that its hairs form a mesh parallel to the bulk polymer surface. Additionally, superhydrophobic/superoleophilic nanofur was successfully fabricated from such recyclable polymers as polypropylene (PP) and polyethylene (LDPE and HPDE).

Moreover, the oil-contaminated nanofur can be reused after washing it with organic solvents4,56. To investigate the nanofur reusability, polypropylene (PP) nanofur was contaminated with oil and subsequently cleaned with isopropanol (stirred twice at 200 rpm for 5 min, and dried), which removes the absorbed hydraulic oil. The oil absorption capacities of the original PP nanofur and nanofur after five absorption/washing cycles are, correspondingly, 310 ± 46 g/m2 and 288 ± 49 g/m2. Washing does not affect the wetting properties of the nanofur, as the water contact angles before and after five washing cycles are 151 ± 4°. Reusability, in addition to the possibility of nanofur fabrication from biodegradable and recyclable polymers, makes the nanofur especially attractive for large-scale environmentally friendly oil/water separation.

Variable oil absorption

The oil absorption capacity of the hair-covered superhydrophobic/superoleophilic surface depends on the hair length and morphology, as was recently shown in a study of oil absorption by different superhydrophobic plants57. Another important functionality of the nanofur is the ability to vary its hair morphology by using different materials and fabrication parameters. Hot pulling is a versatile technique which can be applied to various thermoplastic polymers as described above. Different molecular structures and physical properties of the polymers used for hot pulling result in specific micro- and nanostructures of the pulled hairs unique for each polymer. Different hair morphologies can be seen in the cross-sectional SEM images of PC and PLA nanofur shown in Fig. 4a,b. The length of hairs varies from tens of microns in PC nanofur to millimeters in PLA nanofur. Such difference in length greatly affects oil absorption. Oil absorption capacity of the nanofur was measured using hydraulic oil (Total Azolla ZS 10), and for the short-haired PC nanofur is up to 127 g/m249. In comparison, the long-haired PLA nanofur absorbs up to 479 g/m2 of oil.

(a) Short-haired polycarbonate (PC) nanofur is capable of absorbing up to 127 g/m2 of oil. (b) Long-haired polylactic acid (PLA) nanofur oil absorption capacity is up to 479 g/m2. (c) SEM images of PC nanofur fabricated using molds sandblasted with different size sands (53 ± 3 μm, 17 ± 1 μm) are taken at the same magnification. The sand size influences the mold roughness and, thus, the demolding forces occurring during polymer and mold separation, resulting in different nanofur hair densities and lengths.

The hair morphology of the polymeric nanofur can be further changed by varying the fabrication parameters such as embossing temperature and force, penetration depth, mold roughness, demolding temperature and velocity. Although a detailed analysis of the hair morphology over a wide parameter space is beyond the scope of this paper, one notable example is the effect of the mold roughness. The size of the sand used for mold sandblasting influences the roughness of the mold and, thus, the demolding forces occurring during polymer and mold separation, resulting in different nanofur hair densities and lengths, as shown in SEM images Fig. 4c.

Selective separation: oil-removing and water-removing nanofur

Selective separation of either oil or water from the oil/water mixtures requires materials with opposite wetting properties. Most of the materials fabricated using existing technologies can separate only one of the two fluids, and separating the other one requires a different technology15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38. The possibility to selectively separate both fluids using the same material offers flexibility for different oil/water separation applications. The as-prepared polymeric nanofur is superhydrophobic/superoleophilic and can be used to remove oil from oil/water mixtures. To modify the nanofur functionality from oil-removing to water-removing, the surface energy of the as-prepared material is changed using plasma treatment. Plasma treatment is widely used to increase the surface energy of polymeric and other surfaces, and as a result increases their hydrophilicity58,59,60. Modification of the polycarbonate (PC) nanofur surface was carried out by argon plasma treatment (0.2 mbar, 30 W, 120 s). SEM images of the nanofur before and after plasma treatment did not reveal any changes in the surface topographies. The PC nanofur water contact angle (WCA) in air is 165 ± 6° on unmodified nanofur, and ranges from 50° to 133° on plasma-treated nanofur surface (p-nanofur) (left column in Fig. 5a). For comparison, WCA of the flat PC surface before plasma treatment is 88 ± 2°, and 52 ± 1° after. In water, the surface of the untreated nanofur is superoleophilic with underwater oil contact angle (OCA) close to 0°. However, plasma treatment of the nanofur results in underwater superoleophobicity of the surface (OCA > 150°), as can be observed in Fig. 5a (right column). The underwater superoleophobicity of the p-nanofur surface is a result of minimized contact between oil and solid due to water trapped in between the nano- and microhairs, similarly to air trapped on the untreated superhydrophobic nanofur surface6.

(a) Photographs of water droplets in air and oil droplets in water on untreated superhydrophobic/superoleophilic PC nanofur surface and plasma-treated hydrophilic/underwater superoleophobic p-nanofur reveal the change in wetting properties induced by the treatment. (b) The C 1s XPS spectra of PC nanofur and p-nanofur indicate incorporation of hydrophilic carboxyl functional groups on the p-nanofur surface. (c) Average water contact angles vs. storage time of untreated PC nanofur stored in air and plasma-treated p-nanofur stored in air and in water demonstrate that hydrophobic recovery of the p-nanofur can be prevented by storing in water. Error bars correspond to the standard deviation of at least 7 measurements.

The surface chemistry of the as-prepared PC nanofur and nanofur treated with argon plasma was investigated by X-ray photoelectron spectroscopy (XPS). The core level C 1s XPS spectra of untreated and plasma-treated nanofur are shown in Fig. 5b. The C 1s envelope of the as-prepared PC nanofur can be decomposed into three peaks (285.0 eV peak corresponds to C-C and C-H bonds, 286.6 eV is due to C-O groups, and 291.0 eV is due to CO3)61. After Ar plasma treatment an additional peak at 289.0 eV representing O=C-O groups was obtained. The spectrum of plasma-treated sample indicates oxidation of carbon in atmospheric oxygen after plasma treatment. Incorporation of hydrophilic carboxyl functional groups on the surface renders the p-nanofur surface hydrophilic. The nanofur surface prior to plasma treatment contained 14.9% oxygen, compared to 24.6% oxygen at the p-nanofur surface after treatment.

Hydrophilization of the polymeric surfaces by plasma treatment necessary for separating water from oil/water mixtures is not permanent, which results in a so-called hydrophobic recovery or aging of the surface. Multiple mechanisms are responsible for the hydrophobic recovery, including reorientation of hydrophilic functional groups and diffusion59,62. However, the recovery rate can be greatly influenced by storage conditions, such as surrounding medium, temperature and humidity59,60,62. To study the hydrophobic recovery of the plasma-treated PC p-nanofur, we measured water contact angles of p-nanofur stored in ambient air and in deionized water for duration of 85 days, and compared them to contact angles of the as-prepared nanofur stored in air. The graph of average measured water contact angles as a function of storage time for these three groups of PC nanofur is shown in Fig. 5c. The results indicate the hydrophobic recovery of the p-nanofur stored in air, which recovers its high water contact angles (WCA = 154 ± 7°) approximately after three weeks of aging. The contact angles measured on p-nanofur stored in water, on the contrary, stay low. For example, the average WCA of p-nanofur samples is 100 ± 27° on the day of the treatment, and is 97 ± 4° after 30 days of storage in water. The consequent reduction of WCA of the p-nanofur stored in water for longer times could be attributed to water absorption by polycarbonate59. The results shown in Fig. 5c demonstrate that hydrophobic recovery of the p-nanofur can be prevented by storing it in water. These results are consistent with previously reported studies of hydrophobic recovery of plasma-treated polymer surfaces59,60,63. Therefore, the underwater superoleophobic properties of the p-nanofur, necessary for oil/water separation, can be retained by storing it in water. Nanofur and p-nanofur selectively remove oil or water, and cover the full range of oil/water separation applications which technical specifications require either one or the other fluid to be removed from the oil/water mixture.

Porous nanofur for continuous oil/water filtration

Special wetting materials with pores allow continuous separation of both fluids from the oil/water mixtures by filtration. Porous materials are especially attractive for oil/water separation because of the wide use of porous membrane-based filtration technology in various industries. To extend the nanofur capabilities to filtration of oil/water mixtures, we fabricated micropores in the PC nanofur surface by perforating it with microneedles (160 μm in diameter). SEM image of the resulting porous nanofur membrane is shown in Fig. 6a. Due to opposite wetting properties of nanofur and p-nanofur, porous membranes made from these materials are capable of selectively removing either oil or water from the mixtures. The differences between the filtration processes characteristic to each material are highlighted in Fig. 6b. An optical image of side-by-side nanofur/p-nanofur submerged underwater indicates the superhydrophobicity of the untreated nanofur (silvery layer indicates air trapped by the hairs) and hydrophilicity of the p-nanofur (opaque in water). With addition of pores into the superhydrophobic/superoleophilic nanofur, the oil is absorbed on the surface after replacing the air (Fig. 2c), and is drained through the pores, while water is retained above the surface (Fig. 6b). The situation is reversed in case of porous underwater superoleophobic p-nanofur, where water is filtered out by the membrane and oil stays on top.

(a) SEM image of porous nanofur fabricated by perforation with microneedles. (b) Schematic and optical image of combined side-by-side nanofur and p-nanofur underwater: air-retaining superhydrophobic nanofur is silvery due to light reflection from the air-water interface, and hydrophilic p-nanofur is opaque. Schematic of the filtration process by combined porous nanofur/p-nanofur filter: oil is drained though the pores in superhydrophobic/superoleophilic nanofur (water is retained above nanofur), and water is drained through the porous underwater superoleophobic p-nanofur. (c) Oil/water mixture separation by combined nanofur/p-nanofur filter: water (colored blue) penetrates through the p-nanofur (left), and cooking oil is filtered out through the nanofur (right).

To demonstrate oil and water separation from the oil/water mixture by nanofur, we produced a filter by gluing together nanofur and p-nanofur into one membrane shown in optical image and schematic in Fig. 6b, and perforated 100 microholes on each side. The porous membrane was inserted into a filtration device and oil/water mixture was added on top of it (Fig. 6c). Water used in this experiment was colored with blue ink for better visibility, while oil was uncolored. In the images shown in Fig. 6c, it can be seen that water penetrates thorough the p-nanofur half of the porous filter and is collected below, and oil penetrates thorough the untreated nanofur. There is no oil/water mixture left on top of the device after the separation is finished. Due to amphiphilicity of the unstructured filter backside droplets can spread to the opposite part of the filter resulting in cross-contamination (no oil droplets are observed in the separated water, but small water droplets are sometimes seen in oil). The presented results demonstrate that porous nanofur/p-nanofur filter can separate water and oil from the mixture.

Using nanofur for oil/water separation by filtration, together with controlling filtration fluid, absorption and fabrication material will help to simplify various oil/water separation tasks and satisfy requirements imposed by the specific operational conditions of industrial and environmental separations. For example, due to the variety of polymers available for nanofur fabrication, the oil/water separating material that can adhere to safety regulations of the food processing industry, or the material that possesses chemical resistance necessary for separating petroleum refinery oily wastewater can be fabricated. The control over filtration fluid will help to overcome efficiency limitations imposed by the oil properties. For example, the water-removing filter can be used for separation of high viscosity oil from mixtures without affecting the permeation flux and separation efficiency; and both oil- and water-removing filters can help to simplify the removal of oils with different densities, which will either float or sink underwater27,44. Moreover, depending on the technical requirements such as fluid recovery after separation, fouling prevention and material recycling, the suitable separation technique (filtration or absorption) can be selected64.

In conclusion, we presented an artificial nanofur surface, which similar to the multifunctional surfaces found in nature, can be adapted to perform different types of oil/water separation: selective separation of either oil or water, variable oil absorption and continuous filtration. The nanofur is fabricated from various polymers, including recyclable and biodegradable, using a scalable hot pulling technique in which nano- and microhairs are created on the polymer surface during polymer separation from the heated sandblasted steel plate. The polymeric nanofur is superhydrophobic and superoleophilic, and can efficiently absorb oil from oil/water mixtures and be reused after washing without losing its wetting properties. The nanofur surfaces made from different polymers vary in hair length and topography, resulting in different oil absorption capacities. The hair morphology of the nanofur can be further controlled by adjusting fabrication parameters such as roughness of the mold. Selective separation of either water or oil from the oil/water mixtures is achieved by reversing the wetting properties of the superhydrophobic nanofur (used for oil removal) to underwater superoleophobic (used for water removal) by argon plasma treatment. The hydrophobic recovery of the underwater superoleophobic plasma-treated nanofur is prevented by storing it in water. Porous nanofur filters fabricated by perforation with microneedles allow continuous gravity driven separation of both fluids from the oil/water mixtures by filtration. Using the described set of simple fabrication and modification techniques a custom oil/water separation platform in terms of material, filtration fluid and separation type can be created, thus, achieving more efficient and environmentally friendly oil/water separation.

Methods

Superhydrophobic nanofur fabrication

A hot embossing machine (Jenoptik, Germany) is used to fabricated nanofur by hot pulling. The mold insert is fabricated by sandblasting a steel plate with rough aluminum silicate abrasive, and then with finer aluminum oxide sand with size 53 ± 3 μm, 29 ± 12 μm or 17 ± 1 μm (Hasenfratz Sandstrahltechnik GmbH, Germany). To fabricate polycarbonate (PC) nanofur, the sandblasted plate is heated in the hot embossing machine above the glass transition temperature of PC (Tg = 144 °C), and pressed into the flat PC foil (thickness = 0.2–1 mm) attached to the bottom plate with T = 215 °C, embossing velocity 0.4 mm/min, penetration depth 200 μm. Subsequent mold retraction (0.3 mm/min) results in formation of dense nano- and microhairs. Samples used for oil/water filtration and hydrophobic recovery experiments were fabricated using a modified hot pulling technique in which initial PC films were attached to a sacrificial cyclo-olefin-copolymer layer51. Polymers used for nanofur fabrication include PC (Makrolon LED2045, Bayer, Germany); PLA (Uhde Inventa-Fischer GmbH, Germany); PET films (Hanita Coatings, Israel); PP, LDPE, HPDE films (Infiana, Germany).

Characterization and modification

The wetting behavior of the nanofur and hydrophobic recovery of a plasma-treated nanofur (p-nanofur) are characterized by contact angle measurements (OCA 40, DataPhysics Instruments GmbH, Germany), in which 3–4 μl deionized water droplets were dispensed on the surfaces. To measure underwater oil contact angles, 7 μl oil droplet (Total Azolla ZS 10) was dispensed on the p-nanofur placed upside down in a container filled with DI water54. Argon plasma treatment of the nanofur surface (0.2 mbar, 30 W, 120 s) was carried out using a reactive ion etching system (Sentech, GmbH, Germany). Porous nanofur was fabricated by perforating nanofur surface with microneedles. Needles with diameter of 160 μm and 25 mm length (Phoenix Medical Ltd., United Kingdom) were manually pushed into nanofur surface placed on a soft spacer material to guarantee puncturing and to minimize damage to the needles. Scanning electron microscopy (SEM) images were taken using Supra 55P microscope (Carl Zeiss, Germany). The nanofur and p-nanofur surface chemistry was investigated by X-ray photoelectron spectroscopy (XPS) using a K-Alpha XPS spectrometer (ThermoFisher Scientific, UK). Data acquisition and processing using the Thermo Avantage software are described elsewhere65,66. All spectra were referenced to the C 1s peak (C-C, C-H) at 285.0 eV binding energy61.

Additional Information

How to cite this article: Kavalenka, M. N. et al. Adaptable bioinspired special wetting surface for multifunctional oil/water separation. Sci. Rep. 7, 39970; doi: 10.1038/srep39970 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Deep water: the gulf oil disaster and the future of offshore drilling (Report to the President [of the USA] 2011).

Cornwall, W. Deepwater horizon: After the oil. Science 348, 22–29 (2015).

White, H. K. et al. Impact of the deepwater horizon oil spill on a deep-water coral community in the gulf of mexico. PNAS 109, 20303–20308 (2012).

Korhonen, J., Kettunen, M., Ras, R. & Ikkala, O. Hydrophobic nanocellulose aerogels as floating, sustainable, reusable, and recyclable oil absorbents. ACS Appl. Mater. Interfaces 3, 1813–1816 (2011).

Wang, B., Liang, W., Guo, Z. & Liu, W. Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature. Chem. Soc. Rev. 44, 336–361 (2015).

Xue, Z., Cao, Y., Liu, N., Feng, L. & Jiang, L. Special wettable materials for oil/water separation. J. Mater. Chem. A 2, 2445 (2014).

Marmur, A. From hygrophilic to superhygrophobic: theoretical conditions for making high-contact-angle surfaces from low-contact-angle materials. Langmuir 24, 7573–7579 (2008).

Tuteja, A. et al. Designing superoleophobic surfaces. Science 318, 1618–1622 (2007).

Marmur, A. Wetting on hydrophobic rough surfaces: to be heterogeneous or not to be? Langmuir 19, 8343–8348 (2003).

Marmur, A. Hydro-hygro-oleo-omni-phobic? Terminology of wettability classification. Soft Matter 8, 6867–6870 (2012).

Vogler, E. Structure and reactivity of water at biomaterial surfaces. Adv. Colloid Interface Sci. 74, 69–117 (1998).

Guo, C. et al. Wettability alteration of polymer surfaces producedby scraping. J. Adhes. Sci. Technol. 22, 395–402 (2008).

Tian, Y. & Jiang, L. Wetting: Intrinsically robust hydrophobicity. Nat. Mater. 12, 291–292 (2013).

Wang, Z., Elimelech, M. & Lin, S. Environmental applications of interfacial materials with special wettability. Environ. Sci. Technol. 50, 2132–2150 (2016).

Zhang, J., Li, B., Li, L. & Wang, A. Ultralight, compressible and multifunctional carbon aerogels based on natural tubular cellulose. J. Mater. Chem. A 4, 2069–2074 (2016).

Feng, C. et al. Superhydrophobic and superoleophilic micro-wrinkled reduced graphene oxide as a highly portable and recyclable oil sorbent. ACS Appl. Mater. Interfaces (2016).

Arbatan, T., Fang, X. & Shen, W. Superhydrophobic and oleophilic calcium carbonate powder as a selective oil sorbent with potential use in oil spill clean-ups. Chem. Eng. J 166, 787–791 (2011).

Wang, H. et al. A novel carbon nanotubes reinforced superhydrophobic and superoleophilic polyurethane sponge for selective oil-water separation through a chemical fabrication. J. Mater. Chem. A 3, 266–273 (2015).

An, Q. et al. A facile method to fabricate functionally integrated devices for oil/water separation. Nanoscale 7, 4553–4558 (2015).

Chu, Z., Feng, Y. & Seeger, S. Oil/water separation with selective superantiwetting/superwetting surface materials. Angew. Chem. Int. Ed. 54, 2328–2338 (2015).

Nguyen, D., Tai, N., Lee, S. & Kuo, W. Superhydrophobic and superoleophilic properties of graphene-based sponges fabricated using a facile dip coating method. Energy Environ. Sci. 5, 7908 (2012).

Pham, V. H. & Dickerson, J. H. Superhydrophobic silanized melamine sponges as high efficiency oil absorbent materials. ACS Appl. Mater. Interfaces 6, 14181–14188 (2014).

Zhu, Q. & Pan, Q. Mussel-inspired direct immobilization of nanoparticles and application for oil-water separation. ACS Nano 8, 1402–1409 (2014).

Zhang, L., Li, L. & Dang, Z.-M. Bio-inspired durable, superhydrophobic magnetic particles for oil/water separation. J. Colloid Interf. Sci. 463, 266–271 (2016).

Gu, J., Xiao, P., Huang, Y., Zhang, J. & Chen, T. Controlled functionalization of carbon nanotubes as superhydrophobic material for adjustable oil/water separation. J. Mater. Chem. A 3, 4124–4128 (2015).

Huang, J. et al. Robust superhydrophobic TiO2 fabrics for UV shielding, self-cleaning and oil-water separation. J. Mater. Chem. A 3, 2825–2832 (2015).

Zhang, F. et al. Nanowire-haired inorganic membranes with superhydrophilicity and underwater ultralow adhesive superoleophobicity for high efficiency oil/water separation. Adv. Mater. 25, 4192–4198 (2013).

Xue, C.-H. et al. Self-roughened superhydrophobic coatings for continuous oil-water separation. J. Mater. Chem. A 3, 10248–10253 (2015).

Kong, L.-H., Chen, X.-H., Yu, L.-G., Wu, Z.-S. & Zhang, P.-Y. Superhydrophobic cuprous oxide nanostructures on phosphor-copper meshes and their oil-water separation and oil spill cleanup. ACS Appl. Mater. Interfaces 7, 2616–2625 (2015).

Wang, Z., Xu, Y., Liu, Y. & Shao, L. A novel mussel-inspired strategy toward superhydrophobic surfaces for self-driven crude oil spill cleanup. J. Mater. Chem. A 3, 12171–12178 (2015).

Feng, L. et al. A super-hydrophobic and super-oleophilic coating mesh film for the separation of oil and water. Angew. Chem. Int. Ed. 43, 2012–2014 (2004).

Li, L. et al. Underwater superoleophobic porous membrane based on hierarchical TiO2 nanotubes: multifunctional integration of oil-water separation, flow-through photocatalysis and self-cleaning. J. Mater. Chem. A 3, 1279–1286 (2015).

Li, J. et al. Underwater superoleophobic palygorskite coated meshes for efficient oil/water separation. J. Mater. Chem. A 3, 14696–14702 (2015).

Wen, Q., Di, J. C., Jiang, L., Yu, J. H. & Xu, R. R. Zeolite-coated mesh film for efficient oil-water separation. Chem. Sci. 4, 591–595 (2013).

Zheng, X. et al. Underwater self-cleaning scaly fabric membrane for oily water separation. ACS Appl. Mater. Interfaces 7, 4336–4343 (2015).

Maguire-Boyle, S. J. & Barron, A. R. A new functionalization strategy for oil/water separation membranes. J. Membrane Sci. 382, 107–115 (2011).

He, K. et al. Cleaning of oil fouling with water enabled by zwitterionic polyelectrolyte coatings: overcoming the imperative challenge of oil-water separation membranes. ACS Nano 9, 9188–9198 (2015).

He, Z., Zhang, X. & Batchelor, W. Cellulose nanofibre aerogel filter with tuneable pore structure for oil/water separation and recovery. RSC Adv. 6, 21435–21438 (2016).

Zhang, L., Zhong, Y., Cha, D. & Wang, P. A self-cleaning underwater superoleophobic mesh for oil-water separation. Sci. Rep. 3, 2326 (2013).

Kwon, G. et al. On-demand separation of oil-water mixtures. Adv. Mater. 24, 3666–3671 (2012).

Wu, J., Wang, N., Zhao, Y. & Jiang, L. Simple synthesis of smart magnetically driven fibrous films for remote controllable oil removal. Nanoscale 7, 2625–2632 (2015).

Ou, R., Wei, J., Jiang, L., Simon, G. P. & Wang, H. Robust thermoresponsive polymer composite membrane with switchable superhydrophilicity and superhydrophobicity for efficient oil-water separation. Environ. Sci. Technol. 50, 906–914 (2016).

Cheng, Z. et al. ph-controllable on-demand oil/water separation on the switchable superhydrophobic/superhydrophilic and underwater low-adhesive superoleophobic copper mesh film. Langmuir 31, 1393–1399 (2015).

Li, J. et al. A prewetting induced underwater superoleophobic or underoil (super) hydrophobic waste potato residue-coated mesh for selective efficient oil/water separation. Green Chem. 18, 541–549 (2016).

Barthlott, W. et al. The Salvinia paradox: superhydrophobic surfaces with hydrophilic pins for air retention under water. Adv. Mater. 22, 2325–2328 (2010).

Koch, K. & Barthlott, W. Superhydrophobic and superhydrophilic plant surfaces: an inspiration for biomimetic materials. Phil. Trans. R. Soc. A 367, 1487–1509 (2009).

Koch, K., Bhushan, B. & Barthlott, W. Multifunctional surface structures of plants: an inspiration for biomimetics. Prog. Mater Sci. 54, 137–178 (2009).

Cheng, Q. et al. Janus interface materials: superhydrophobic air/solid interface and superoleophobic water/solid interface inspired by a lotus leaf. Soft Matter 7, 5948–5951 (2011).

Röhrig, M. et al. Nanofur for biomimetic applications. Adv. Mater. Interfaces 1, 1300083 (2014).

Kavalenka, M. N. et al. Bioinspired air-retaining nanofur for drag reduction. ACS Appl. Mater. Interfaces 7, 10651–10655 (2015).

Vüllers, F. et al. Bioinspired superhydrophobic highly transmissive films for optical applications. Small, doi: 10.1002/smll.201601443 (2016).

Worgull, M. Hot embossing - Theory and Technology of Micro Replication (William Andrew, Oxford, 2009).

Röhrig, M. et al. Hot pulling and embossing of hierarchical nano- and micro-structures. J. Micromech. Microeng. 23, 105014 (2013).

Kavalenka, M. N., Hopf, A., Schneider, M., Worgull, M. & Hölscher, H. Wood-based microhaired superhydrophobic and underwater superoleophobic surfaces for oil/water separation. RSC Adv. 4, 31079 (2014).

Mathew, A. P., Oksman, K. & Sain, M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J. Appl. Polym. Sci. 97, 2014–2025 (2005).

Zhu, Q. et al. Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material. J. Mater. Chem. A 1, 5386–5393 (2013).

Zeiger, C. et al. Superhydrophobic plant leaves as effective sorbent materials for oil spill cleanup. Bioinspir. Biomim. 11, 056003 (2016).

Song, W., Veiga, D. D., Custodio, C. A. & Mano, J. F. Bioinspired degradable substrates with extreme wettability properties. Adv. Mater. 21, 1830–1834 (2009).

Bormashenko, E., Chaniel, G. & R. Grynyov . Towards understanding hydrophobic recovery of plasma treated polymers: Storing in high polarity liquids suppresses hydrophobic recovery. Appl. Surf. Sci. 549–553 (2013).

Chen, F. et al. Stability of plasma treated superhydrophobic surfaces under different ambient conditions. J. Colloid Interface Sci. 470, 221–228 (2016).

Tischer, T. et al. Direct mapping of raft controlled macromolecular growth on surfaces via single molecule force spectroscopy. ACS Macro Lett. 5, 498–503 (2016).

Mortazavi, M. & Nosonovsky, M. A model for diffusion-driven hydrophobic recovery in plasma treated polymers. Appl. Surf. Sci. 6876–6883 (2012).

Jokinen, V., Suvanto, P. & Franssila, S. Oxygen and nitrogen plasma hydrophilization and hydrophobic recovery of polymers. Biomicrofluidics 6, 016501–10 (2012).

Pintor, A. M., Vilar, V. J., Botelho, C. M. & Boaventura, R. A. Oil and grease removal from wastewaters: Sorption treatment as an alternative to state-of-the-art technologies. a critical review. Chem. Eng. J. 297, 229–255 (2016).

Parry, K. L. et al. Arxps characterisation of plasma polymerised surfacechemical gradients. Surf. Interface Anal. 1497–1504 (2006).

Scofield, J. H. Hartree-slater subshell photoionization cross-sections at 1254 and 1487 eV. J. Electron Spectr. Relat. Phen. 129 (1976).

Acknowledgements

F. V. acknowledges a scholarship from the Landesgraduiertenförderung Baden-Württemberg. C. Z. acknowledges a scholarship from Carl Zeiss Foundation. The authors thank U. Köhler, M. Schneider, R. Thelen, P. Abaffy and A. Storz for their support with fabrication and characterization. This work was partly carried out with the support of the Karlsruhe Nano Micro Facility (KNMF, www.kit.edu/knmf), a Helmholtz Research Infrastructure at Karlsruhe Institute of Technology (KIT, www.kit.edu). We acknowledge support by Deutsche Forschungsgemeinschaft and Open Access Publishing Fund of Karlsruhe Institute of Technology.

Author information

Authors and Affiliations

Contributions

M.K., M.W. and H.H. designed the study. M.K., F.V., C.Z., J.K., V.T., S.S., T.T. and C.L. performed the experiments and analyzed the results. All authors discussed the results and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kavalenka, M., Vüllers, F., Kumberg, J. et al. Adaptable bioinspired special wetting surface for multifunctional oil/water separation. Sci Rep 7, 39970 (2017). https://doi.org/10.1038/srep39970

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep39970

This article is cited by

-

Thermally stable and durable superhydrophobic surfaces on stainless steel sheets with microholes via acid pretreatment and modification with self-assembled monolayers

Microfluidics and Nanofluidics (2021)

-

Fabrication of superrepellent microstructured polypropylene/graphene surfaces with enhanced wear resistance

Journal of Materials Science (2019)

-

Open surface multifunctional droplet manipulation platform fabricated by micromilling

Journal of Materials Science (2019)

-

One-step fabrication of robust superhydrophobic and superoleophilic surfaces with self-cleaning and oil/water separation function

Scientific Reports (2018)

-

Bioinspired Fabrication of one dimensional graphene fiber with collection of droplets application

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.