Abstract

In this approach, the VO2 nanoparticles have been successfully fabricated via combusting the low-cost precursor solution consisted of NH4VO3, C2H6O2 and C2H5OH. By the XRD, TEM and XPS analysis, it can be found that the synthetic monoclinic VO2 is single crystal and no impurity is defined. After dispersing the VO2 nanoparticles into the polymer, the solar modulation of VO2-based composite film is up to 12.5% with luminous transmission and haze around 62.2% and 0.5%, respectively. In other words, the composite films show high performance of thermochromic properties. This could open an efficient way to fabricate low-cost and large-scale VO2 (M) nanoparticles and thermochromic films.

Similar content being viewed by others

Introduction

Monoclinic vanadium dioxide VO2 (M) which was reported firstly by Morin in 19591, has attracted significant attention due to its superior physico-chemical property. The reversible and abrupt semiconductor-metal transition could be associated with the change of crystallographic structure from the monoclinic (M-phase, P21/c, semiconductor) to the tetragonal (R-phase, P42/mnm, mental) phase at 68 °C. And dramatic changes in IR region transmission and electrical resistance also occurred simultaneously. By these advantages, VO2 (M) is believed to be a potential functional material for various industrial and technological applications such as electrical devices2,3 and energy-efficient smart windows4,5.

In the past several decades, different methods including sputting deposition6, chemical vapour deposition(CVD)7, sol-gol8,9,10, pyrolysis11,12 and hydro/solvothermal13,14,15,16,17 have been developed for preparing VO2 (M). However, these methods suffer from some limitations such as harsh gas atmosphere with exactly controlled flow, time consuming or post-treatment with high-temperature. In order to enable a practical process for the application of VO2 (M) in industrial fields, developing simple and efficient methods are highly desired.

Recently, there are several groups which report some accessable methods to prepare VO2 (M). Y. Xie18 et al. have studied in detail that the several different precursors to prepare VO2 by the combustion method. VO(acac)2 and Bis (α-furylacrylic acid) oxovanadium (IV) complex is considered as the V source, which could fabricate VO2 nanoparticles. However, the Bis (α-furylacrylic acid) oxovanadium (IV) complex needs to be prepared by the time-consuming process, of which the yield rate is also low19. And the price of VO(acac)2 is more expensive. In 2013, G.T. Chandrappa20 et al. developed a solution consisted of NH4VO3 and DL-malic acid to prepare monoclinic VO2 by the combustion. The VO2 can be obtained in 5 min, which is quite fast to collect VO2 nanopowder. Unfortunately, the method needs 470 ± 10 °C in muffle furnace to guarantee enough energy to form VO2. In addition, at the smouldering stage, the air partial pressure is not easy to be controlled exactly, which is not helpful for the formation of the pure VO2 (M). J. Zou and co-workers21 have reported the thermolysis of VEG (vanadyl ethylene glycolate) for synthesizing VO2 (M) in air. Nevertheless, the multi-step operation and time-consuming process would limit its practical application. By contrast, further works should be made for providing a facile route to prepare VO2 (M), especially the production of VO2 (M) nanoparticles in a large scale and promotion of thermochromic smart window in a low cost.

As part of an ongoing interest on preparation of VO2 (M), we herein propose a simple and low-cost method for preparing VO2 (M) nanoparticles with high purity and thermochromic performance. This process only involves the combustion of a mixture of EG (ethylene glycol), NH4VO3 and EtOH (ethyl alcohol) in several minutes. Compared with the previous methods, the VO2 (M) could be obtained with high cost performance. The thermochromic performance of VO2-based composite film shows 12.5% for the solar transmittance modulation with luminous transmission and haze around 62.2% and 0.5%, respectively. These privileges make it be possible for the production of VO2 (M) and thermochromic films in a large-scale with low cost.

Results and Discussion

Fabrication mechanism of the VO2 (M)

In this approach, VO2 (M) can be formed via a solution combustion process as illustrated in Fig. 1, followed by all-around characterization. In order to explore reaction mechanism, the temperature evolution of position A, B in Fig. 1 directly measured by the thermocouple are shown in Fig. 2. The position A is located at the interface of the flame and solution. The position B is located at the interface of the flame, solution and inner wall of the container. The temperature measurement at position A is to prove the formation of VEG. The temperature at position B is variable on account of dynamic change of flame, whereas the change trend of temperature could be used to analyze the temperature scale of position B in a full reaction process.

From the temperature evolution in Fig. 2, it can be found that at 6 minutes, the temperature of position A is up to 120 °C and kept at the above 120 °C over a period of time, which ensures the formation of VEG by reaction between NH4VO3 and C2H6O221. And at the same time, the colour of the solution changes from bright yellow to brown and a little precipitates appear on the inner wall of container as shown in Fig. 1b. The temperature at position A is increased to 171 °C at 9 minutes, and a black reaction solution is observed (in Fig. 1c). In order to clarify this change, the reaction was interrupted at the time and the resulting precipitates were collected.

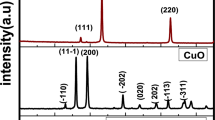

The XRD pattern of the precipitate is shown in Fig. 3a. It can be found that the XRD pattern of the precipitate matches well with that of the standard JCPDS card (No. 49-2497) corresponding to VEG. No peaks of other phases and impurities are observed, which indicates that pure VEG could be produced in the reaction as the following equation Eq. (1).

The morphology and microstructure determined by SEM are shown in Fig. 3b. It can be found that the VEG product is composed of dispersed microspheres with different sizes, which is similar with the previous results22. The surface structure of spherical VEG presents the aggregation of chain-like VEG as shown in the magnified SEM.

In order to explore the conversion process of the VEG, the thermal behavior of VEG in air is investigated subsequently. The TG and DSC curves of the VEG are shown in Fig. 3c. From the DSC curve, it can be found that there is an obvious exothermic peak around 253 °C, indicating that the decomposed temperature of the VEG is around 253 °C. The corresponding sharp mass loss can be found in TG curve. The total mass loss between 180 and 300 °C is 32.3%, which is approximate to the theoretical value of 34.6% calculated from the equation below23.

Hence, according to the TG and DSC curves, the heat treatment of the VEG at 300 °C can be sufficient for the complete decomposition. With the decreasing of solvent in the combustion process, more and more precipitates appear on the inner wall of the dish. The temperature of the position B is always above 300 °C in Fig. 2b. Therefore, the formation of VO2 proceeds at position B, resulting from the adequate energy and oxygen accessed. After reaction completion, the precipitates are fully converted into the black-blue powder.

The XRD pattern and SEM images of the black-blue powder are shown in Fig. 3d–f. It can be found that all diffraction peaks in XRD pattern are well in agreement with that of the standard JCPDS card (No. 43-1051) corresponding to VO2 (M). It means that after reaction the black-blue powder is VO2 (M). According to SEM image (Fig. 3e), the black-blue powder generated is the well-defined hierarchical spherical shape with diameters typically ranging from 3 to 8 μm. However, it can be observed that the microstructure consists of large quantities of nanoparticles from the magnified SEM image (Fig. 3f). The size of the nanoparticles is estimated to be 100–300 nm.

As is well known, the molecular structure of VEG is a long chain24. Based on the reaction process and result obtained, it can be found that during the combustion, the chain-like VEG is formed and rapidly aggregate into spherical microparticles to reduce the total energy of the system as schematically illustrated in Fig. 4a–c. As the reaction proceeds, the formed VEG aggregates deposit on the inner wall. In addition, the temperature of position B is always above 300 °C, far higher than the decomposition temperature of VEG with 253 °C. The interface between flame and solution gradually drops with the solvent consumption. The deposited VEG on the inner wall can be decomposed directly at position B. Therefore, after combustion completion, the VEG precursor is decomposed in-situ and converted into VO2, which has been proved in our previous work as shown in the above equation (2)23. At the same time, the aggregated VO2 nanoparticles continue to grow to form big particles (in Fig. 4d) as a result of the evolution of CO2 gas, H2O vapor and structural rearrangement of VO2 units during the decomposition process, of which the result is similar with that of the literature21. Hence, the fabrication mechanism of VO2 (M) nanoparticles could be proposed as “precursor formation – self-assemble – pyrolysis” process (in Fig. 4).

Taking into account the reaction performed in air, the curvature of the container could influence the reaction process. Thus, the containers with different curvature are investigated. The curvature radius and corresponding curvature of these containers can be seen from Table 1. The volume of reaction solution is kept at 100 mL. The XRD patterns of the products obtained from different containers are shown in Fig. 5. It can be found that with the change of curvature from 0.23 to 0 cm−1, the diffraction peak of VEG at 2θ = 13.6° shows the corresponding intensity and then disappears at curvature of 0.17 cm−1, and finally appears again (shown in the inset of Fig. 5). However, when the curvature is 0.17 cm−1, the diffraction peak for VO2 (M) at 2θ = 27.8° shows the strongest intensity and all diffraction peaks are ascribed to that of JCPDS 43–1051, with the lattice parameters a = 5.7529 Å, b = 4.5263 Å, c = 5.3825 Å, and β = 122.6°. No peaks of other phases or impurities are observed, indicating that the high purity of the VO2 (M) is obtained.

The possible reasons for the above results are hinted in Fig. 6. Due to the difference of curvature, the VEG precipitate layer in container (a) is thicker than (c). The VEG at the bottom could not be pyrolyzed sufficiently in the lack of oxygen and heat energy even though the reaction is exothermic. When the flame is quenched, therefore, little VEG is still existent at the bottom of the container (a) as shown in Fig. 6. Whereas the VEG precipitate layer in the container (e) is thinner than container (c), and the VEG can access to oxygen in air. The VEG can be partially decomposed due to the lack of heat energy because the little heat from exothermic reaction after the disappearance of the flame. Finally, the container (c) with the curvature 0.17 cm−1 is suitable for the formation of precipitate and adequate oxygen and proper heat energy, which can ensure the sufficient pyrolysis of VEG to form VO2 (M).

Except for curvature, the volume of reaction solution is another factor to influence the pyrolysis. Thus, the experiments of the reaction solution with different volumes in the container (c) are carried out. The corresponding XRD patterns are shown in Fig. 7. It can be found that there is a diffraction peak of VEG at 2θ = 13.6° when the solution volume is at 40 mL and the appearance of diffraction peak of VEG could result from the lack of heat energy for VEG thin layer as the above mentioned. Whereas the solution volume is increased to 200 mL, a thick precipitate layer is observed. Similarly, the incomplete pyrolysis of VEG results in the appearance of diffraction peak of VEG, which is the same as that of the 100 ml reaction solution in container (a). As for diffraction peak at 2θ = 27.8° for VO2 (M), whether or not the volume of reaction solution is increasing or decreasing, the intensity become apparently weak compared with the solution of 100 mL in container (c). As a result, the crystallinity of VO2 (M) is optimal under the conditions of 100 mL solution in container (c). The VO2 powder obtained at the optimal condition is used for the subsequent tests and analyses.

Analysis of TEM images for the obtained VO2

The size of the nanoparticles are measured by TEM images (Fig. 8a), which is close to the result shown in the SEM image (Fig. 3 (f)). Figure 8b shows the representative HRTEM image of individual nanoparticles. The interplanar distances of 0.483 nm and 0.226 nm matches well with the d(100) and d(020) spacings of monoclinic VO2 (M) structure, respectively. Furthermore, the measured lattice-plane angle is 90°, which is consistent with the result calculated from VO2 (M) crystallographic parameters, providing the microscopic evidence for the formation of VO2 (M)13. According to the SAED pattern (Fig. 8c), the independent and bright diffraction spots indicate that the VO2 (M) nanoparticles present good crystallinity. The dots are indexed to (100), (020) planes of VO2 (M), which are consistent with the result of HRTEM image.

Analysis of the XPS spectrum for the obtained VO2

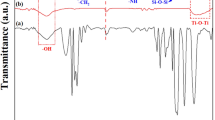

The XPS spectrum of the obtained products is presented in Fig. 9. The binding energies obtained in the XPS analysis were corrected for specimen charging by referencing the C1s line to 284.6 eV. There are only three elements containing carbon, vanadium and oxygen in the XPS survey spectrum (Fig. 9a), where the carbon peak is attributed to surface contamination. Two peaks at 516.4 and 523.9 eV in the high-resolution XPS spectra (Fig. 9b) are associated with the spin-orbit splitting of V2p3/2 and V2p1/2, which are well in agreement with V4+ in the literature25. In addition, it has been established that the oxidation state of vanadium oxides can be determined by the difference of binding energy (Δ) between the O1s and V2p3/2 level. The Δ(O1s -V2p3/2) value of as-obtained products is 13.6 eV that matches well with the result reported26. It indicates the vanadium of the sample is V4+ without other oxide state. Especially, the absence of V5+ may be attributed to the protection (such as H2 and CO2) generated in the combustion process18. Thus, XRD, TEM and XPS spectra confirm the high quality of the as-obtained VO2 (M) nanoparticles.

The optical properties of the VO2 composite film

The integral visible transmittance and solar transmittance of VO2-based composite film were obtained based on the measured spectra using the following equation:

where Tr (λ) denotes the transmittance at wavelength λ, i denotes ‘vis’ or ‘sol’ for the calculations, φvis is the standard luminous efficiency function for the photopic vision, and φsol is the solar irradiance spectrum for the air mass 1.5 (corresponding to the sun standing 37° above the horizon)27. The modulation ability of  is defined as the difference of Tsol between 25 and 100 °C.

is defined as the difference of Tsol between 25 and 100 °C.

There are several crucial factors including  ,

,  , Tc and haze for VO2-based smart thin film. The much higher

, Tc and haze for VO2-based smart thin film. The much higher  ,

,  , and lower Tc, haze are hopefully obtained. In the past few years, it has been calculated that the VO2 nanoparticles are randomly and uniformly dispersed into transparent medium, of which the films possess numerous specific advantages over VO2-based continuous films28. In the work, the VO2 nanoparticles present high purity and good crystallinity. Consequently, by dispersing the VO2 nanoparticles into transparent polymer and spinning coating, the film of VO2-based is fabricated. The transmission spectra and related haze of the obtained film are presented in Fig. 10a. It can be found that the VO2-based film obtained shows excellent optical and thermochromic properties. The luminous transmittance

, and lower Tc, haze are hopefully obtained. In the past few years, it has been calculated that the VO2 nanoparticles are randomly and uniformly dispersed into transparent medium, of which the films possess numerous specific advantages over VO2-based continuous films28. In the work, the VO2 nanoparticles present high purity and good crystallinity. Consequently, by dispersing the VO2 nanoparticles into transparent polymer and spinning coating, the film of VO2-based is fabricated. The transmission spectra and related haze of the obtained film are presented in Fig. 10a. It can be found that the VO2-based film obtained shows excellent optical and thermochromic properties. The luminous transmittance  is up to 62.2% and the solar transmittance modulation

is up to 62.2% and the solar transmittance modulation  keeps 12.5%, which is consistent with the calculated result of the work28. Hence, the film shows better thermochromic properties compared with the previous strategies such as solution method29, physical vapour deposition (PVD)30. Moreover, the haze is 0.5% at 550 nm of the film which verifies significantly the uniformity of the thin film.

keeps 12.5%, which is consistent with the calculated result of the work28. Hence, the film shows better thermochromic properties compared with the previous strategies such as solution method29, physical vapour deposition (PVD)30. Moreover, the haze is 0.5% at 550 nm of the film which verifies significantly the uniformity of the thin film.

The hysteresis loop of the composite film at the fixed wavelength of 1500 nm is shown in Fig. 10b with embedding plot of dTr/dT-T. The temperature corresponding to the maximum of dTr/dT is defined as the phase transition temperature of the branch; T1 and T2 represent the phase transition temperature of heating and cooling branches, respectively. The phase transition temperature is defined as Tc = (T1+T2)/231. In the past few years, it has been reported that the VO2 phase transition occurs through a nucleation and growth process affected by microstructure defects, particle sizes, grain boundaries32,33,34,35. From the Fig. 10b, it can be found that the phase transition temperature T1 = 58 °C and T2 = 86 °C. Hence, it can be calculated that Tc is equal to 72 °C, closing to 68 °C for the bulk of VO2 in the literature36. And a broad hysteresis loops widths in our paper is 28 °C, which is in line with the results that nanoparticles have fewer defects resulting in wide hysteresis loop in the literature reported by R. Lopez et al.32.

Conclusion

In summary, monoclinic vanadium dioxide with pretty crystallinity is successfully fabricated by means of a facile combustion of precursor solution in the evaporating dish. The raw materials: NH4VO3, C2H6O2 and C2H5OH are inexpensive and the period of the preparation is relatively short in air without the protection of the extra inert gas. The curvature of container and the volume of solution are proved to be of significant to the fully pyrolysis of VEG and the formation of pure VO2 (M). Moreover, the composite foils (haze 0.5%) made from VO2 (M) particles displays excellent visible transmittance (up to 62.2%) and solar modulation ability (up to 12.5%). The present strategy exhibits the promising potential for smart window film with low cost and large-scale production.

Methods

Synthesis of VO2 (M)

All reagents were analytical grade and used without further purification. Firstly, a mixture of 2.0 g powders of NH4VO3 (99.0%, Aladdin reagent) and 75 mL of ethylene glycol (C2H6O2, Guangzhou Chemistry Reagent) in beaker was heated to 30–70 °C for 30 minutes with vigorous stirring. The transparent yellow solution was obtained after cooling to room temperature. Then the equal volume of ethanol was added to the above solution and the mixture was stirred for additional 30 minutes at the room temperature. Subsequently, the forming solution was placed in evaporating dish, and combusted directly in air. After completion, the black-blue powder on the inner wall of the evaporating dish was collected.

Preparation of thermochronic films

To prepare VO2-based composite smart thermochronic film, VO2 (M) powder was mixed fully with the transparent polymer and stirred for several hours. The VO2 composite thin films were coated on the glass substrate by spinning with 2000 rpm.

Characterization

X-ray powder diffraction (XRD) patterns were recorded on X’Pert Pro MPD diffractometer with Cu kα radiation (λ = 0.154178 nm) using a current and voltage of 40 mA and 40 kV. Unless additional stated, all samples were measured at a scanning rate of 0.1°/2θs−1. For thermolysis analysis, the differential scanning calorimetry (DSC) experiments were performed using a NETZSCH thermal analyzer (DSC 204F1) under dry air flow in the range of 20–500 °C with a heating rate of 10 K min−1. A Hitachi S-4800 scanning electron microscope (SEM) at an acceleration voltage of 2 kV was used to acquire SEM and high-magnificent SEM images. X-ray photoelectron spectroscopy (XPS) measurements were performed on a Thermo Scientific ESCALAB 250 Xi X-ray phtotoelectron spectrometer. The morphology of the prepared particles was also observed by transmission electron microscopy (TEM, JEOL JEM-2010, Japan) operated at 200 kV. The attachment of selected area electron diffraction (SAED) of JEM-2010 was used to get the crystallographic information. To prepare the samples for TEM/HRTEM/SAED analysis, the nanostructures were dispersed in ethanol and then deposited onto 400 mesh carbon-coated Cu grids. The temperature evolution was detected by a thermocouple detector at various stages. Thermochromic properties of films were monitored on a Lambda 750 spectrophotometer equipped with a heating unit in the wavelength range of 380–2500 nm. Transmittance spectra before and after phase transition were recorded at 25 and 100 °C, respectively.

Additional Information

How to cite this article: Cao, Z. et al. A simple and low-cost combustion method to prepare monoclinic VO2 with superior thermochromic properties. Sci. Rep. 6, 39154; doi: 10.1038/srep39154 (2016).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Morin, F. J. Oxides which show mental-to-insulator transition at the neel temperature. Phys. Rev. Lett. 3, 34–36 (1959).

Lee, M. J. et al. Two series oxide resistors applicable to high speed and high density nonvolatile memory. Adv. Mater. 19, 3919–3923 (2007).

Liu, M. et al. Terahertz-field-induced insulator-to-metal transition in vanadium dioxide metamaterial. Nature 487, 345–348 (2012).

Ye, H. et al. The demonstration and simulation of the application performance of the vanadium dioxide single glazing. Sol. Energ. Mat. Sol. C. 117, 168–173 (2013).

Yang, J. et al. Performance analyses of building energy on phase transition processes of VO2 windows with an improved model. Appl. Energ. 159, 502–508 (2015).

Zhao, L. et al. A low cost preparation of VO2 thin films with improved thermochromic properties from a solution-based process. Thin Solid Films 543, 157–161 (2013).

Gaskell, J. M. et al. Optimised atmospheric pressure CVD of monoclinic VO2 thin films with picosecond phase transition. Surf. Coat. Tech. 287, 160–165 (2016).

Livage, J., Guzman, G., Beteille, F. & Davidson, P. Optical properties of sol-gel derived vanadium oxide films. J. Sol-Gel. Sci. Techn. 8, 857–865 (1997).

Huang, C., Chen, l., Xu, G. & Miao, L. Sol–gel template synthesis and characterization of VO2 nanotube arrays. J Sol-Gel Sci. Techn. 63, 103–107 (2012).

Yuan, N., Li, J. & Lin, C. Valence reduction process from Sol-Gel V2O5 to VO2 thin film. Appl. Surf. Sci. 191, 176–180 (2002).

Zheng, C., Zhang, J., Luo, G., Ye, J. & Wu, M. Preparation of vanadium dioxide powders by thermolysis of a precursor at low temperature. J. Mater. Sci-Mater. El. 35, 3425–3429 (2000).

Peng, Z., Jiang, W. & Liu, H. Synthesis and electrical properties of tungsten-doped vanadium dioxide nanopowders by thermolysis. J. Phys. Chem. C 111, 1119–1122 (2007).

Wu, C. et al. Direct hydrothermal synthesis of monoclinic VO2 (M) single-domain nanorods on large scale displaying magnetocaloric effect. J. Mater. Chem. 21, 4509–4517 (2011).

Chen, R. et al. One-step hydrothermal synthesis of V1−xWxO2 (M/R) nanorods with superior doping efficiency and thermochromic properties. J. Mater. Chem. A 3, 3726–3738 (2015).

Chen, Z., Cao, C., Chen, S., Luo, H. & Gao, Y. Crystallised mesoporous TiO2 (A)–VO2 (M/R) nanocomposite films with self-cleaning and excellent thermochromic properties. J. Mater. Chem. A 2, 11874–11884 (2014).

Zhang, L. et al. Phase and morphology evolution during the solvothermal synthesis of VO2 polymorphs. Inorg. Chem. Front. 3, 117–124 (2016).

Chen, R. et al. Shape-controlled synthesis and influence of W doping and oxygen nonstoichiometry on the phase transition of VO2 . Sci. Rep. 5, 14087, doi: 10.1038/srep14087 (2015).

Wu, C. et al. Direct confined-space combustion forming monoclinic vanadium dioxides. Angew. Chem. Int. Edit. 49, 134–137 (2010).

Li, J. & Sun, G. The synthesis bis (α-furylacrylic acid) oxovanadium (IV) complex. Chem. & Bioeng. 25, 10–11 (2008).

Nagabhushana, G. P. & Chandrappa, G. T. Facile solution combustion synthesis of monoclinic VO2: a unique and versatile approach. J. Mater. Chem. A 1, 11539–11542 (2013).

Zou, J., Peng, Y. & Lin, H. A low-temperature synthesis of monoclinic VO2 in an atmosphere of air. J. Mater. Chem. A 1, 4250–4254 (2013).

Wang, H. et al. Facile synthesis of hierarchical and porous V2O5 microspheres as cathode materials for lithium ion batteries. J. Colloid Interf. Sci. 418, 74–80 (2014).

Zhang, H. et al. A cost-effective method to fabricate VO2 (M) nanoparticles and films with excellent thermochromic properties. J. Alloy. Compd. 636, 106–112 (2015).

Weeks, C. et al. The one dimensional chain structures of vanadyl glycolate and vanadyl acetate. J. Mater. Chem. 13, 1420–1423 (2003).

Xu, C., Ma, L., Liu, X., Qiu, W. & Su, Z. A novel reduction–hydrolysis method of preparing VO2 nanopowders. Mater. Res. Bull. 39, 881–886 (2004).

Silversmit, G., Depla, D., Poelman, H., Marin, G. B. & De Gryse, R. Determination of the V2p XPS binding energies for different vanadium oxidation states (V5+ to V0+). J. Electron. Spectrosc. Relat. Phenom. 135, 167–175 (2004).

Chen, Z. et al. VO2-based double-layered films for smart windows: Optical design, all-solution preparation and improved properties. Sol. Energ. Mat. Sol. C. 95, 2677–2684 (2011).

Li, S. Y., Niklasson, G. A. & Granqvist, C. G. Nanothermochromics: Calculations for VO2 nanoparticles in dielectric hosts show much improved luminous transmittance and solar energy transmittance modulation. J. Appl. Phys. 108, 063525-1–063525-8 (2010).

Vernardou, D., Pemble, M. E. & Sheel, D. W. The growth of thermochromic VO2 films on glass by atmospheric-pressure CVD: A comparative study of precursors, CVD methodology, and substrates. Chem. Vapor. Depos. 12, 263–274 (2006).

Kakiuchida, H., Jin, P. & Tazawa, M. Control of thermochromic spectrum in vanadium dioxide by amorphous silicon suboxide layer. Sol. Energ. Mat. Sol. C. 92, 1279–1284 (2008).

Du, J. et al. Significant changes in phase-transition hysteresis for Ti-doped VO2 films prepared by polymer-assisted deposition. Sol. Energ. Mat. Sol. C. 95, 469–475 (2011).

Lopez, R., Haynes, T. E., Boatner, L. A., Feldman, L. C. & Haglund, R. F. Size effects in the structural phase transition of VO2 nanoparticles. Phys. Rev. B 65, 224113-1–224113-5 (2002).

Petit, C., Frigerio, J. M. & Goldmann, M. Hysteresis of the metal–insulator transition of VO2: evidence of the influence of microscopic texturation. J. Phys-Condens. Mat. 11, 3259–3264 (1999).

Narayan, J. & Bhosle, V. M. Phase transition and critical issues in structure-property correlations of vanadium oxide. J. Appl. Phys. 100, 103524 (2006).

Whittaker, L., Jaye, C., Fu, Z., Fischer, D. A. & Banerjee, S. Depressed Phase Transition in Solution-Grown VO2 Nanostructures. J. Am. Chem. Soc. 131, 8884–8894 (2009).

Qazilbash, M. M. et al. Mott transition in VO2 revealed by infrared spectroscopy and nano-imaging. Science 318, 1750–1753 (2007).

Acknowledgements

This study was supported by the Major Science and Technology Projects of Guangdong Province (No. 2013A011401011), Science and Technology Project of Guangdong Province (No. 2014A010106018), Pearl River Star of Science and Technology (No. 2014J2200078), CAS Key Laboratory of Renewable Energy Fund of GIEC (No. y507j41001), the National Natural Science Foundation of China (No. 51506205), Youth Innovation Promotion Association CAS, Special plan of Guangdong Province (2015TQ01N714).

Author information

Authors and Affiliations

Contributions

Z.Y.C. and X.D.X. conceived and designed the study, prepared all figures, and they all wrote the manuscript. Z.Y.C. performed the experiments mainly, and X.M.L., Y.J.Z., H.L.C., and G.X. helped to do the measurements and discussed the results. All authors reviewed and revised the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Cao, Z., Xiao, X., Lu, X. et al. A simple and low-cost combustion method to prepare monoclinic VO2 with superior thermochromic properties. Sci Rep 6, 39154 (2016). https://doi.org/10.1038/srep39154

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep39154

This article is cited by

-

Study on thermally stabilized vanadium dioxide nanoparticles solid–solid phase change thermal energy storage material

Journal of Materials Science: Materials in Electronics (2022)

-

One-step ball milling synthesis of VO2 (M) nanoparticles with exemplary thermochromic performance

SN Applied Sciences (2021)

-

Synthesis of Nano-Urchin Mo-Doped VO2 Particles by the Hydrothermal Method

Journal of Applied Spectroscopy (2020)

-

Pt-free, low-cost and efficient counter electrode with carbon wrapped VO2(M) nanofiber for dye-sensitized solar cells

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.