Abstract

Oxypnictide thin film growth by pulsed laser deposition (PLD) is one of many insufficiently resolved issues in the research of iron-based superconductors. Here we report on the successful realization of superconducting SmO1−xFxFeAs oxypnictide thin film growth by in-situ PLD on CaF2 (fluorite) substrates. CaF2 acts as fluorine supplier by diffusion and thus enables superconducting oxypnictide thin film growth by PLD. Films are grown heteroepitaxially and characteristically have a broad resistive normal-to-superconducting transition. Best films have onset transition temperatures around 40 K. The proposed in-situ PLD film growth offers an alternative and cheap route for the fabrication of iron oxypnictides. PLD becomes now an additional option for iron oxypnictide synthesis.

Similar content being viewed by others

Introduction

Discovery of high-temperature superconductivity in iron oxypnictides1 that crystallize in the ZrCuSiAs-structure2 (so-called 1111) led to surprises, provoked expectations, and keeps on exerting fascination. Their high critical temperatures up to Tc ≈ 55 K and their high upper critical fields μ0Hc2 > 50 T create an attractive goal for synthesis, engineering and science of oxypnictide thin films, however, their growth has been a challenge ever since 20083. In contrast to the high-temperature superconductor YBa2Cu3O7−δ, where film growth by in-situ PLD succeeded promptly after its discovery in 19874, in-situ PLD of iron oxypnictides has been an unresolved issue and this fact severely impedes the development of iron oxypnictide thin film applications. The furthermore difficult and expensive high-pressure single crystal synthesis of oxypnictides strongly motivates the search for complementary, faster, more feasible and cheaper fabrication techniques5.

The main challenge for an in-situ PLD growth of superconducting iron oxypnictides is, in first instance, to balance the loss of stoichiometric transfer of high vapor pressure (volatile) elements such as F that is essential for doping and, thus, inevitable for inducing superconductivity in the parent compound. In general, PLD is a powerful tool for growing thin films from a stoichiometric source (target)6. However, it becomes arbitrarily complicated for volatile species. Off-stoichiometric transfer in PLD7 is commonly defeated by an enrichment of the target with the volatile element or by deposition under reactive conditions. For achieving F-doping in the as-grown films we propose here another method where F-doping is obtained via diffusion from the substrate. This approach enables the first successful growth of superconducting iron oxypnictide thin films by in-situ PLD.

From ex-situ to in-situ PLD

The first film growth attempts of F-doped LaOFeAs by PLD in ultra-high vacuum (UHV) in 2008 succeeded in heteroepitaxy of LaOFeAs on oxide substrates8. Unfortunately, the resulting films were undoped and non-superconducting as a result of the volatility of fluorine. Because of the lack of stoichiometric transfer PLD of oxypnictides is sharply constrained. Furthermore, oxypnictide phase formation from the vapor phase is always in contest with the formation of impurity phases such as pure iron, arsenic oxides, iron arsenides, and rare-earth oxides9.

An approach based on room-temperature deposition of ROFeAs (R = La, Sm) and a subsequent ex-situ heat treatment of the as-grown films in an evacuated silica-glass tube, that contains an additional RO1−xFxFeAs pellet, resulted in superconducting films, however with less control over epitaxy10,11,12. Epitaxial RO1−xFxFeAs thin films were finally grown by fine tuning the parameters of the heat treatment and due to a rather accidentally formed rare-earth oxyfluoride impurity layer that acts as a seed13. The investigation of critical current densities and the upper critical field anisotropy of an epitaxially grown LaO1−xFxFeAs thin film with a thickness of 100 nm can thus be viewed as an early milestone14. Nevertheless, PLD is used for the creation of nucleation centers on the substrate but the two-step route clearly deviates from a typical PLD film growth and suffers from insufficient control of F-doping level15.

In the last five years advances in the growth of oxypnictide thin films were made by means of molecular beam epitaxy (MBE) which should be able to master film growth with volatile elements16,17,18. However, also in MBE F-doping has first been introduced via diffusion from a fluorine containing capping layer or from a fluorine containing substrate. Other thin film growth methods such as chemical vapor deposition have not yet found their breakthrough in producing F-doped oxypnictides19.

For an advance in PLD of oxypnictide thin films and application-oriented research all above summarized experiences suggest a reactive all in-situ PLD process, i.e. under tunable fluorine gas supply. This reactive process can only be performed under severe safety regulations, because fluorine gas is highly toxic. In order to tackle the challenge of oxypnictide thin film growth by an all in-situ PLD process, we have re-investigated oxypnictide thin film growth on different substrates (and templates) and found, alternatively, a fluorine supplier in CaF2 substrates. Our results are directive for future oxypnictide thin film growth efforts.

Methods

Thin film deposition

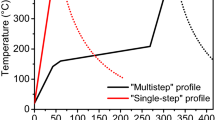

Thin film deposition was carried out in a UHV chamber (base pressure 5 × 10−9 mbar) using a Spectra Physics Quanta-Ray INDI pulsed Nd:YAG laser (2ω) with a fixed laser repetition rate setting of 10 Hz and a wave-length of 532 nm. Measurements of the pulsed beam energy were performed in front of the entrance window of the UHV chamber before each deposition. Energies of 20–25 mJ used for film deposition result in energy densities on the target surface of approximately 0.9–1.7 Jcm−2.

Deposition was performed on different single crystalline oxide substrates, MgO(100) (a = 4.21 Å), LaAlO3 (100) (a = 3.79 Å), and on single crystalline alkaline earth halide CaF2 (100) (a = 5.46 Å). Furthermore, film growth on Fe and BaFe2As2 buffered MgO substrates was investigated since the excellent in-plane lattice parameter matching is expected to facilitate epitaxial film growth of the 1111 oxypnictide phase. In the following this excursion on buffer layers is only shortly summarized and our focus will be on the results obtained for F-doped SmOFeAs on CaF2 (100) substrates.

Commercially available CaF2 substrates (10 × 10 × 0.5 mm3) from Furuuchi Chemical Corporation were heated within the vacuum chamber by a high power diode laser system to the deposition temperature and were kept 5 min at this temperature prior to deposition. No special pre-treatment of the substrates was undertaken. The substrate temperature inside the vacuum chamber was monitored by a pyrometer and by a thermocouple. Optimal deposition temperatures are around 860 °C. The target-substrate distance was set to 25–30 mm.

Target preparation

The polycrystalline SmO0.9F0.1FeAs target used in the experiments was synthesized by a two-step solid state reaction. All processes except heating were performed in an argon-filled glove box. First, the precursor materials SmAs, Fe2As and FeAs were synthesized by mixing elements of Sm, Fe, and As. They were mixed in the chemical composition of Sm:Fe:As = 1:3:3 and heated at 900 °C for 12 h in an evacuated silica tube. The resultant SmFe3As3 powder was then mixed with dehydrated Sm2O3 powder, where 10% of Sm2O3 was replaced by a 1:1 mixture of SmF3 and Sm metal for F substitution, following the chemical reaction of SmFe3As3 + 0.9 Sm2O3 + 0.1 SmF3 + 0.1 Sm → 3 Sm(O0.9F0.1)FeAs. The mixture compound Sm(O0.9F0.1)FeAs was pressed and heated in an evacuated silica-tube at 1300 °C for 40 h to obtain a sintered pellet. Phase purity of the resulting PLD target was examined by X-ray diffraction, indicating a small amount of FeAs impurity.

Thin film characterization

Standard characterization of the grown thin films was carried out by X-ray diffraction on a Rigaku SmartLab and on a Bruker AXS D8 Advance diffractometer, both equipped with Cu Kα radiation. High resolution X-ray diffractometry (XRD) and reflectivity (XRR) analysis were performed using a Ge 2-bounce monochromator for the incident beam (Rigaku SmartLab). Film thicknesses were determined from Kiessig fringes in XRR. For surface characterization a Bruker AXS MultiMode8 Atomic Force Microscope (AFM) was used in tapping mode with conventional silicon tips on nitride cantilevers (f0 = 130 ± 30 kHz, k = 0.4 Nm−1). Images were processed and analyzed with WSxM software20.

Surface analysis was also carried out on a JEOL Scanning Electron Microscope (SEM) at working distance of 8 mm and operating with a high voltage of 15 kV.

Electrical resistance measurements were carried out in a Quantum Design Physical Property Measurement System (PPMS) typically in a temperature range between T = 2–300 K and up to applied magnetic fields of μ0H = 9 T. Cu wires of diameter below 100 μm were attached with Ag paste as electrical contacts.

Results

Film growth on stable oxide substrates

Iron oxypnictide thin film growth on stable oxide substrates - as already reported in refs 8 and 9 - is characterized by impurity phase formation such as Fe2As and Sm2O3 that strongly compete with the 1111 oxypnictide phase formation. In-situ PLD of iron oxypnictides is thus characterized by a constrained window of deposition parameters such as temperature, energy density on the target surface and target-substrate distance. The lack of superconductivity in the films is mainly attributed to the F-loss during deposition but a crucial O- and As-deficiency cannot be excluded.

Whereas oxypnictide films can be grown epitaxially on BaFe2As2/MgO templates, films on Fe/MgO always contained a larger fraction of impurity phases. These results contradict the conjecture made by Thersleff that Fe could be a generic seed layer for the epitaxial growth of Fe-based superconductors in general22. For both templates the absence of a superconducting transition in SmO1−xFx FeAs deposited films can be again explained primarily due to F-losses. Results of the apparently undoped SmOFeAs film are shown in Fig. 1.

(a) High resolution XRD (2θ/ω-scan) of SmOFeAs/BaFe2As2/MgO. 00l reflections of each phase are indexed. The BaFe2As2 layer (Ba-122) has a thickness of about 16 nm (c122 = 12.97 Å). The SmOFeAs layer (Sm-1111) was deposited at 860 °C and is about 36 nm thin (c1111 = 8.53 Å). (b) No superconducting transition is detected in the electrical resistance measured down to 2 K.

Film growth on CaF2

The lack in stoichiometric transfer during PLD for the growth of F-doped iron oxypnictides can be balanced by the use of CaF2 substrates that serve as a fluorine supplier during deposition by diffusion. With this working hypothesis superconducting SmO1−xFx FeAs thin films were fabricated on CaF2(001) substrates at temperatures around 860 °C. CaF2 substrates were used in PLD of iron-based superconducting films with the basic idea of tuning epitaxial strain23, but never with the aim of F doping. In contrast, a possible chemical influence of CaF2 substrates on the superconducting properties was primarily neglected3. Only a few exceptional studies like ref. 24 reported a possible chemical reaction of the CaF2 substrate even for iron chalcogenide thin films, where deposition temperatures are typically below 400 °C. Chemical reactions have to be considered at higher deposition temperatures used in our case and in the case of BaFe2As2 thin film growth.

In the following we demonstrate that thin film growth of superconducting iron oxypnictides is realized on CaF2. No impurity phases except a small amount of Fe were detected by XRD (Fig. 2a). The best film has an onset transition temperature, Tc,on near 40 K. The c-axis lattice parameters of the PLD grown films (8.63–8.66 Å) are comparable to the reported c-axis lattice parameters for MBE grown films (8.55–8.65 Å)18 but generally larger than 8.495 Å (x = 0), 8.428 Å (x = 0.1)25, or 8.488–8.498 Å (x = 0.2)26, in sintered polycrystalline powder samples and also larger than the c-axis in a single crystal (8.468 Å for x = 0.14)5.

(a) High resolution XRD (2θ/ω-scan) of SmO1−xFx FeAs/CaF2. 00l reflections of the 1111 phase and the substrate are indexed. The obtained lattice parameter is c1111 = 8.66 Å. Small amount of Fe impurity is found as indicated by the Fe 110 reflection. (b) A total film thickness of 58.4 nm was evaluated from a fit of the normalized XRR intensity in the range of 2θ = 0.6°–1.8°. (c) 008 Bragg reflection with total maximum at 2θ ≈ 90.95° as a superposition of two extremal profiles p1 (with maximum at 2θ ≈ 90.9°) and p2 (with maximum at 2θ ≈ 92.1°). (d) Pole figure (ψ, ϕ) for 2θ = 47.0° ± 1.0° with CaF2 202 and SmO1−xFxFeAs 104 reflections. (e) Pole figure (ψ, ϕ) for 2θ = 30.0° ± 1.2° with CaF2 111 and SmO1−xFxFeAs 102 reflections.

Asymmetric Bragg reflections indicate the presence of diffusion layers or gradients. The lattice parameter change with film thickness can be estimated by a fit of the reflection intensity composed of a superposition of several peak profiles. The asymmetry intensifies with higher order, exemplarily the 008 reflection is shown (Fig. 2c). According to a simple fit the estimated relative change in the c-axis lattice parameter is slightly less than 1%.

Heteroepitaxial growth of SmO1−xFxFeAs on CaF2 was confirmed by pole figure measurements (Fig. 2d,e) and is characterized by the following orientation relationship: (001)[100]SmO1−xFxFeAs||(001)[110]CaF2. SmO1−xFxFeAs grows with the c-axis perpendicular to the substrate surface and its basal plane a × a is rotated by 45° in-plane versus the unit cell of CaF2.

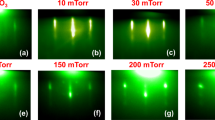

Apart from droplets, i.e. particles of larger size typically observed on the surface of PLD grown films, the global surface topography is characterized by defects that evolve along the crystallographic [100] and [010] directions of the SmO1−xFxFeAs film (Fig. 3a–d). These line-shaped defects appear in films grown on CaF2 substrates and originate very likely from cracks. Such cracks are also observed to appear during scanning electron microscopy (SEM) where whole crack networks are induced under the scanning electron beam obviously by local heat generation in the CaF2 substrate. SEM characterization of the films is thus a destructive procedure. Two consecutive scans demonstrate the appearance of defects within a short time (Fig. 3g,h). It is therefore plausible that the observed defect structure in the surface topography is caused by the bursting of the film surface. These defects increase the surface roughness (global rms ≈ 10 nm in a 10 × 10 μm2 scan including droplets vs. local rms ≈ 1 nm in a in a 1 × 1 μm2 scan), and also deteriorate the current flow (and critical currents) in the films leading most likely to current percolation.

(a) AFM image (10 × 10 μm2) of the film surface (film deposition time = 10 min) scanned with a rate of 0.5 Hz and 512 samples/line along the crystallographic [100] direction of the SmO1−xFxFeAs film. Apart from (1) droplets the film surface topography is characterized by (2) a line-shaped defect structure oriented along the crystallographic [100] and [010] direction of SmO1−xFxFeAs. The root-mean-squared roughness (rms) is 8.5 nm. (b) Profile of a vertical line scan (3) across the defect structure. The estimated size of the defects is about 500 × 150 × 50 nm3. (c) AFM image (1 × 1 μm2) of a thinner film (deposition time = 5 min) scanned with a rate of 1.5 Hz and 512 samples/line along the crystallographic [100] direction of the SmO1−xFxFeAs film. Line-shaped defects do not appear here but holes (4) are still present in the microstructure after island coalescence. The rms roughness of the film surface within this scan is 0.8 nm. (d) Profile of a vertical line scan (5) across the defect structure. (e) AFM image with scan area of 500 × 500 nm2 (compare Fig. 3c). The rms roughness is 0.74 nm. (f) Selected profiles of terraces with step sizes of approximately 1 and 2 unit cells. (g) SEM image of a film surface with initial cracks and (h) induced cracks during scanning of the electron beam on the same magnified area of the film. The cracks (white contrast) appear quickly within several seconds.

The growth mode distinguishes from a layer-by-layer and resembles an island (Volmer-Weber) growth, where terrace-like structures with step sizes of approximately 1 and 2 unit cells can be identified (Fig. 3e,f).

Because of low film growth rates (≤ 1 Å s−1) deposition times of 5–10 min are required for film thicknesses of 20–50 nm. With increasing deposition time (>5 min) at elevated temperatures crack formation in the as-grown films is observed by AFM imaging that might be a result of outgassing fluorine leading to a bursting of the film layer along its crystallographic a-axis. CaF2 substrates are not yet perfectly suitable for technological applications.

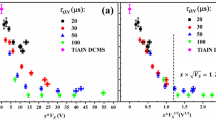

Electrical resistance of the films measured in van-der-Pauw geometry for applied magnetic fields parallel and perpendicular to the film c-axis (Fig. 4a). Qualitatively, the resistive transitions are very broad. The usually applied resistance criteria for 90%, 50%, and 10% of the normal resistance result in Tc,90 ≈ 35 K, Tc,50 ≈ 28 K, and Tc,10 ≈ 24 K. The broad transitions and the changes in the slope of R(T) within the normal-to-superconducting transition are characteristic for an inhomogeneous film due to F-doping gradients. Current percolation caused by the observed defects can have additional effects on broadening. The upper critical field (Fig. 4b) extracted from data of the 10% criterion has moderate slopes of dHc2/dT ≈ −2.7 TK−1 (−1.3 TK−1) for μ0Hc2||ab (μ0Hc2||c). The maximum slope of dHc2/dT ≈ −5.5 TK−1 estimated from the 90% criterion for μ0Hc2||ab corresponds to reported values in sintered powders22.

(a) Resistive transitions R(T) for zero field and magnetic fields (0.5, 2, 4, 6, 8 T) applied parallel to the c-axis and perpendicular to the c-axis. The criteria of 90%, 50% and 10% of normal resistance above the transition are indicated by dashed lines. (b) Magnetic phase diagram μ0Hc2(T) evaluated for different criteria.

Discussion and Conclusion

The experiments have confirmed that superconductivity in iron oxypnictides depends sensitively on the stoichiometry of the rare earth oxide layer in the 1111 unit-cell. O-deficiency turns out to be an additional drawback for the in-situ PLD process of oxypnictides. Successful growth of superconducting iron oxypnictides by PLD must, therefore, supply enough oxygen and fluorine during film growth. These results are in accordance with investigations of O-deficient oxypnictides, RO1−δFeAs, that are not superconducting21. A precise stoichiometric control stays still a technological challenge for these materials and might be realizable only after optimization or in a reactive fabrication process. The essential supply of fluorine during film growth for doping and stabilizing the rare earth oxide layers is enabled by a diffusion process. This new solution deviates from the usual PLD philosophy that relies on the stoichiometric transfer of material from the target to the substrate. In using F-diffusion provoked by the substrate, latter becomes an additional source of material in the described in-situ PLD process.

The choice of brittle CaF2 substrates is not yet optimal for applications of Fe-based superconductor thin films, a fact that has been widely neglected in the thin film growth of Fe-based superconductors in general. In future CaF2 should be replaced by other materials that act as F-suppliers and, simultaneously, have better mechanical properties. As a remark: The observed enhancement in critical temperatures in Co-doped BaFe2As2 thin films grown on CaF2 is very likely a result of a fluorine interdiffusion from the substrate to the film followed by a change in stoichiometry and lattice parameters. Similar defects (cracks) as described above appear in the surface morphology of Ba(Fe1−xCox)2As2 films, too. Considering the difficult and rare synthesis of iron oxypnictide single crystals or thin films in general the importance of having a standard fabrication process for oxypnictides is evident. Our results indicate once more the requirement of a highly advanced process for machining iron oxypnictides into competitive superconducting applications. The above presented iron oxypnictide film fabrication route by in-situ PLD allows film growth and further development. With an in-situ PLD process for SmO1−xFxFeAs the already developed concepts of coated conductor technology can be adapted as it was demonstrated by a first proof-of-concept for FeSe1−xTex27 and Co-doped BaFe2As228 superconductors already. Since film growth by MBE is still expensive and difficult to upscale towards an industrial level, a suitable PLD fabrication process represents a substantial step towards a reliable application-oriented research on iron-oxypnictides.

To summarize, the here reported successful in-situ growth of superconducting oxypnictide thin films by PLD on CaF2 substrates represents a significant progress in the fabrication of F-doped oxypnictide thin films. In-situ PLD of superconducting iron oxypnictides seemed to be impossible due to a lack in stoichiometric transfer and the loss of fluorine as a dopant. Fluorine supply by diffusion from the CaF2 substrate is, however, able to introduce sufficient doping. We have demonstrated that the use of the substrate as additional material source represents a methodological advance in PLD against material loss due to volatile components. Furthermore, the diffusion process offers at present a cheap solution to the problem of F-doping during film growth and circumvents chemical hazards of a fully reactive process.

Additional Information

How to cite this article: Haindl, S. et al. In-situ growth of superconducting SmO1−xFxFeAs thin films by pulsed laser deposition. Sci. Rep. 6, 35797; doi: 10.1038/srep35797 (2016).

References

Y. Kamihara, T. Watanabe, M. Hirano & H. Hosono . Iron-Based Layered Superconductor La[O1−xFx]FeAs (x = 0.05–0.12) with Tc = 26 K. J. Am. Chem. Soc. 130, 3296 (2008).

V. Johnson & W. Jeitschko . ZrCuSiAs: A ‘filled’ PbFCl type. J. Solid State Chem. 11, 161 (1974).

S. Haindl et al. Thin film growth of Fe-based superconductors: from fundamental properties to functional devices. A comparative review. Rep. Prog. Phys. 77, 046502 (2014).

D. Dijkkamp et al. Preparation of Y-Ba-Cu oxide superconductor thin films using pulsed laser evaporation from high Tc bulk material. Appl. Phys. Lett. 51, 619 (1987).

N. D. Zhigadlo et al. Single crystals of superconducting SmFeAsO1−xFy grown at high pressure. J. Phys.: Condens. Matter 20, 342202 (2008).

D. B. Chrisey, G. K. Hubler (eds). Pulsed Laser Deposition of Thin Films. Wiley, New York (1994).

J. Schou . Physical aspects of the pulsed laser deposition technique: The stoichiometric transfer of material from target to film. Appl. Surf. Sci. 255, 5191 (2009).

H. Hiramatsu, T. Katase, T. Kamiya, M. Hirano & H. Hosono . Heteroepitaxial growth and optoelectronic properties of layered iron oxyarsenide, LaFeAsO. Appl. Phys. Lett. 93, 162504 (2008).

H. Hiramatsu, T. Kamiya, M. Hirano & H. Hosono . Heteroepitaxial film growth of layered compounds with the ZrCuSiAs-type and ThCr2Si2-type structures: From Cu-based semiconductors to Fe-based superconductors. Physica C 469, 657 (2009).

E. Backen et al. Growth and anisotropy of La(O,F)FeAs thin films deposited by pulsed laserdeposition. Supercond. Sci. Technol. 21, 122001 (2008).

S. Haindl et al. High Upper Critical Fields and Evidence of Weak-Link Behavior in Superconducting LaFeAsO1−xFx Thin Films. Phys. Rev. Lett. 104, 077001 (2010).

M. Kidszun et al. Fabrication of superconducting oxypnictide thin films. EPL 90, 57005 (2010).

M. Kidszun et al. Epitaxial LaFeAsO1−xFx thin films grown by pulsed laser deposition. Supercond. Sci. Technol. 23, 022002 (2010).

M. Kidszun et al. Critical Current Scaling and Anisotropy in Oxypnictide Superconductors. Phys. Rev. Lett. 106, 137001 (2011).

S. Haindl, M. Kidszun, F. Onken, A. Mietke & T. Thersleff . Lessons from Oxypnictide Thin Films. Int. J. Mod. Phys. B 27, 1330001 (2013).

T. Kawaguchi et al. In situ growth of superconducting NdFeAs(O,F) thin films by molecular beam epitaxy. Appl. Phys. Lett. 97, 042509 (2010).

S. Ueda, S. Takeda, S. Takano, A. Yamamoto & M. Naito . High-Tc and high-Jc SmFeAs(O,F) films on fluoride substrates grown by molecular beam epitaxy. Appl. Phys. Lett. 99, 232505 (2011).

H. Sugawara et al. One-step growth of SmFeAs(O,F) films by molecular beam epitaxy using FeF2 as a fluorine source. Supercond. Sci. Technol. 28, 015005 (2015).

I. Corrales-Mendoza, A. Conde-Gallardo & V. M. Sánchez-Reséndiz . Nd1−xFexOF Thin Films Deposited by Chemical Vapor Deposition and Their Arsenic Diffusion. IEEE Trans. Appl. Supercond. 21, 2849 (2011).

I. Horcas, R. Fernández, J. M. Gómez-Rodríguez, J. Colchero, J. Gómez-Herrero & A. M. Baro . WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 78, 013705 (2007).

Y. Muraba, S. Iimura, S. Matsuishi & H. Hosono . Hydrogen-Substituted Superconductors SmFeAsO1−xHx Misidentified As Oxygen-Deficient SmFeAsO1−x . Inorg. Chem. 54, 11567 (2015).

T. Thersleff et al. Coherent interfacial bonding on the FeAs tetrahedron in Fe/Ba(Fe1−xCox)2As2 bilayers. Appl. Phys. Lett. 97, 022506 (2010).

I. Tsukada et al. Epitaxial Growth of FeSe0.5Te0.5 Thin Films on CaF2 Substrates with High Critical Current Density. Appl. Phys. Express 4, 053101 (2011).

A. Ichinose et al. Microscopic analysis of the chemical reaction between Fe(Te,Se) thin films and underlying CaF2 . Supercond. Sci. Technol. 26, 075002 (2013).

Z.-A. Ren et al. Superconductivity at 55 K in Iron-Based F-Doped Layered Quaternary Compound Sm[O1−xFx]FeAs. Chin. Phys. Lett. 25, 2215 (2008).

C. Wang et al. Low-temperature synthesis of SmO0.8F0.2FeAs superconductor with Tc = 56.1 K. Supercond. Sci. Technol. 23, 055002 (2010).

W. Si et al. Iron-chalcogenide FeSe0.5Te0.5 coated superconducting tapes for high field applications. Appl. Phys. Lett. 98, 262509 (2011).

T. Katase et al. Biaxially textured cobalt-doped BaFe2As2 films with high critical current density over 1 MA/cm2 on MgO-buffered metal-tape flexible substrates. Appl. Phys. Lett. 98, 242510 (2011).

Acknowledgements

The work at Tokyo Institute of Technology was supported by the Ministry of Education, Culture, Sports, Science and Technology (MEXT) through Element Strategy Initiative to Form Core Research Center. All authors thank Dr. Takayoshi Katase for synthesizing the polycrystalline PLD target disks. S.H. and H.Hi. acknowledge financial support by German Research Foundation (DFG HA5934/5-1). H. Hi. was also supported by the Japan Society for the Promotion of Science (JSPS) Challenging Exploratory Research (Grant Number 26630305), the JSPS Grant-in-Aid for Scientific Research on Innovative Areas Nano Informatics (Grant Number 25106007), and Support for Tokyotech Advanced Research (STAR).

Author information

Authors and Affiliations

Contributions

S.H., H.Hi. and H.Ho. supervised the project, S.H. has designed the study and carried out the experiments with help of K.H., H.S. and H.Hi. S.H. and H.Hi. wrote the manuscript. All authors have analysed the results and reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Haindl, S., Hanzawa, K., Sato, H. et al. In-situ growth of superconducting SmO1−xFxFeAs thin films by pulsed laser deposition. Sci Rep 6, 35797 (2016). https://doi.org/10.1038/srep35797

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep35797

This article is cited by

-

Engineering of Fe-pnictide heterointerfaces by electrostatic principles

NPG Asia Materials (2021)

-

Second Harmonic Generation Response in Thermally reconstructed Multiferroic β′- Gd2(MoO4)3 Thin Films

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.