Abstract

Germanium Tin (GeSn) films have drawn great interest for their visible and near-infrared optoelectronics properties. Here, we demonstrate large area Germanium Tin nanometer thin films grown on highly flexible aluminum foil substrates using low-temperature molecular beam epitaxy (MBE). Ultra-thin (10–180 nm) GeSn film-coated aluminum foils display a wide color spectra with an absorption wavelength ranging from 400–1800 nm due to its strong optical interference effect. The light absorption ratio for nanometer GeSn/Al foil heterostructures can be enhanced up to 85%. Moreover, the structure exhibits excellent mechanical flexibility and can be cut or bent into many shapes, which facilitates a wide range of flexible photonics. Micro-Raman studies reveal a large tensile strain change with GeSn thickness, which arises from lattice deformations. In particular, nano-sized Sn-enriched GeSn dots appeared in the GeSn coatings that had a thickness greater than 50 nm, which induced an additional light absorption depression around 13.89 μm wavelength. These findings are promising for practical flexible photovoltaic and photodetector applications ranging from the visible to near-infrared wavelengths.

Similar content being viewed by others

Introduction

Flexible photonics have been developed to meet the demands for wearable electronic devices among other applications. To meet the needs of high efficiency photovoltaic ultrathin silicon solar cells, new forms of Si (nano/microwires, surface patterning and hybrid heterojunctions) films have emerged to enhance the light absorption1,2,3,4. Wang et al. in 2013 fabricated 10.7 to 1.6 μm flexible single crystal silicon wafers by KOH solution etching5. They showed that light absorption significantly depended on the silicon thickness, which varied from 552 nm to 790 nm. Li Zhu et al. in 2015 experimentally demonstrated brilliant colors tunable from green to red on a silicon film embedded on a flexible membrane6. The results were attractive for flexible optical applications. However, Si is an indirect band gap semiconductor with low carrier mobility, which is not suitable for high efficiency photovoltaic applications.

Germanium Tin (GeSn) is one of the most important tunable band gap material systems for visible and near/mid-infrared optoelectronic applications7,8,9,10. GeSn exhibits a direct band gap for Sn concentrations above 6.5 atomic percent, which is very promising for on-chip integrated optical detectors and modulators11. Additionally, the lattice constant of GeSn can be tuned by varying the Sn composition to allow for heteroepitial growth of multifunctitonal heterostructures12,13. Since the solubility limit of Sn in Ge is relatively low, i.e., ~1%, low temperature molecular beam epitaxy (MBE) and chemical vapor deposition (CVD) techniques have been developed to realize the growth of GeSn films with high Sn composition14,15. Recently, K. Toko deposited polycrystalline GeSn with Sn composition exceeding 25% on flexible plastic substrates at a extremely low temperature of 70 °C 16. In order to achieve ultrathin and highly absorbing optical films, F. Capasso et al. proposed to deposit a few tens of nanometers thick high dielectric Ge films on a metallic Au layer17. The Ge films require a minimum amount of absorbing material that can be as thin as 5–20 nm for visible light (400–850 nm). The findings open a new route for the ultrathin photodetector and solar cells applications.

In this work, we fabricated nanometer thick GeSn optical thin films on highly flexible aluminum (Al) foil substrates using low temperature MBE technique. The GeSn thickness dependent of optical absorption cutoff wavelength was realized. Color spectrum shows that its color gradually changes from bright yellow, to dark blue due to insufficient light absorption. The obtained absorption cutoff wavelength can be tuned from 400 nm to 1800 nm. However, the films thickness is much smaller than a quarter-wave thickness due to strong light interference. The size of the ultrathin GeSn optical coating can be larger than 4 inch diameter, which is very promising for practical flexible photovoltaic and photodetector applications ranging from visible to near-infrared wavelengths.

Results and Discussions

Figure 1(a) shows the schematic of the GeSn film with thickness t on flexible Al foil. Inset graph describes the behavior of light (red arrow) incident from air into the highly absorptive GeSn nanometer thin film as an optical coatings, which was deposited on a metallic Al foil substrate. We assume that there is no transmission through the Al foil substrate, the absorption of the structure can be written as A = 1 − R, where A is light absorption and R is the light reflection. For a metal Al foil substrate in the perfect electric conductor limit, its’ complex refractive index  Al = nAl + ikAl, nAl → ∞ and kAl → ∞. The incident light is completely reflected at the Al-GeSn interface with a phase shift of π, which makes the GeSn thickness much lower than the wavelength with h ≈ λ/4nGeSn (nGeSn is the refractive index of the GeSn). Figure 1(b–g) presents a photograph of samples of Al foil coated GeSn from 0 to 180 nm in thickness, which creates a spectrum of colors including silver, golden, dark blue and light blue. Although the surface of the Al foil substrates are unpolished, the various colors still clearly appear. It should be mentioned that the Al foil is polycrystalline with a thickness of ~200 μm. The grain distribution changes from 102 nm to 238 nm, which has been checked using an atomic force microscopy. The findings agree well with a previous report18. The wide optical absorption band comes from the remarkable reflectivity change of the aluminum foil by coating it with nanometer thick GeSn films. GeSn was selected because it is highly absorbing at visible/near-infrared wavelengths. Moreover, its indirect band gap can be tuned to a direct band gap with the application of tensile strain, which is very important for its photovoltaic and photodetector applications. The samples exhibit excellent mechanical flexibility and do not crack even after repeated bending. It can be cut into any shapes by shears, which facilitate flexible photonics fabrication.

Al = nAl + ikAl, nAl → ∞ and kAl → ∞. The incident light is completely reflected at the Al-GeSn interface with a phase shift of π, which makes the GeSn thickness much lower than the wavelength with h ≈ λ/4nGeSn (nGeSn is the refractive index of the GeSn). Figure 1(b–g) presents a photograph of samples of Al foil coated GeSn from 0 to 180 nm in thickness, which creates a spectrum of colors including silver, golden, dark blue and light blue. Although the surface of the Al foil substrates are unpolished, the various colors still clearly appear. It should be mentioned that the Al foil is polycrystalline with a thickness of ~200 μm. The grain distribution changes from 102 nm to 238 nm, which has been checked using an atomic force microscopy. The findings agree well with a previous report18. The wide optical absorption band comes from the remarkable reflectivity change of the aluminum foil by coating it with nanometer thick GeSn films. GeSn was selected because it is highly absorbing at visible/near-infrared wavelengths. Moreover, its indirect band gap can be tuned to a direct band gap with the application of tensile strain, which is very important for its photovoltaic and photodetector applications. The samples exhibit excellent mechanical flexibility and do not crack even after repeated bending. It can be cut into any shapes by shears, which facilitate flexible photonics fabrication.

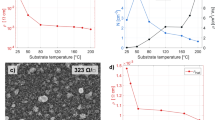

Room temperature micro-Raman spectroscopy for GeSn nanometer thin film coatings on Al foil with different thicknesses are shown in Fig. 2(a). A HeNe 532 nm laser was used as an excitation source. The exact wavenumber position of the peaks reflects the influence of chemical composition and strain. All Raman spectra present a strong Ge-Ge 1st peak located at ~292 cm−1. While, Ge-Ge 2nd peak locates at ~544 cm−1. It compares well with previous results of GeSn epitaxial growth on Si and SiO219,20,21. The typical Ge-Sn peak always displays at lower wavenumber 250-260 cm−1. Actually, the shoulder on the left side of the Ge-Ge 1st peak is due to the Ge-Sn peak at ~285 cm−1 22. The typical Ge-Al peak is at ~370 cm−1 23, however, in this work the Al implanted GeSn can be excluded from the Raman spectra.

Figure 2(b) shows the enlarged Ge-Ge 1st peak, from which a clear peak shift towards higher wavenumber with increasing GeSn thickness is observed. Comparing the Ge-Ge 1st peak at 292.7 cm−1 for 10 nm GeSn, a wavenumber shift of 3.1 cm−1 was achieved for 180 nm GeSn coated Al foils. It indicates that lattice strain changes much with changing GeSn coating thicknesses. The change in residual strain in epitaxial films was proven arising from lattice deformation24. We assume that the lattice deformation becomes larger for thicker GeSn films grown on the Al foil substrates. Ishikawa et al. demonstrated both the growth temperature and the thickness might affect the strain in the GeSi system25.

In order to describe the lattice deformation, we study the microstructure of the GeSn nanometer coatings on Al foil using XRD. The XRD patterns are shown in Fig. 3(a), most visible are the Al peaks from the substrate. With GeSn thickness t increasing up to 50 nm, GeSn (111) phase and GeSn (220) phase gradually appear. β-Sn (200) and (101) phases also appear corresponding to samples of high relative thickness. Raman analysis proved that the lattice strain changes considerably for different thicknesses of GeSn films. Here, as shown in Fig. 3(b), a large GeSn (220) peak shift is observed in the enlarged XRD patterns. The higher diffraction angle indicates a change to smaller lattice constants, which means the lattice constant of GeSn decreases for t larger than 50 nm. It has been shown that the epitaxial breakdown would change the surface morphology from a 2D growth mode to a 3D growth mode with large islands26. It is conjectured that Sn-rich precipitates will form on the GeSn thin films with t larger than 50 nm. The composition of the GeSn film changes with epitaxial breakdown, which can explain the decrease of GeSn lattice constant and the concomitant appearance of the β-Sn phase.

To better understand the nanoscale structure of GeSn thin film coated Al foils, high-resolution SEM images were measured. Figure 4(a–d) show the SEM images of GeSn thin films grown on Al foil with t = 20, 50, 100 and 180 nm, respectively. The GeSn thin film coatings present a smooth surface even grown upon normal Al foil substrate that were largely untreated from their commercial state. However, it is clear that nano-sized islands gradually atop the GeSn coatings that are thicker than 50 nm, as shown in Fig. 4(b–d). The XRD results suggest there probably exists Sn-rich islands. Here, we indeed observe these nano islands from the SEM images. To identify the elemental makeup of these nano-sized islands, we performed elemental mapping of GeSn films with a thickness of 180 nm grown on Al foil. As shown in Fig. 5(b), the Al element distributes uniformly with several light areas (in circled dash lines). Comparing this with the Sn element mapping as illustrated in Fig. 5(d), the nano islands appear Sn-rich as GeSn blotches. The results indicate an epitaxial breakdown exists in MBE grown GeSn thin films on Al foil substrate for thicknesses greater than 50 nm, which changes the surface morphology from a 2D growth mode to a 3D growth mode with relatively larger nm islands.

The visible/infrared reflection spectra were obtained using a Vis/NIR spectrophotometer (Lambda750). The incident light was unpolarized with an incident angle of ~5° with respect to the Al foil’s normal. An integrating sphere is used to collect the light back scattered in all directions. The reflectivity of a bare Al foil was employed as a reference. Figure 6(a) shows the measured reflection spectra of Al foil coated with various thicknesses of GeSn thin films (where t = 10, 20, 30, 40, 50, 60, 100 and 180 nm) over a wavelength range of 400–2400 nm. It is noticed that the change in reflectivity for different t samples is remarkable. With an increase of GeSn coating thickness, the response wavelength (the light reflectivity <50%) can be tailored for a range of wavelengths from 400 nm to 1800 nm. From the discussion above, without considering the Al transmission, the optical absorption of GeSn films can be obtained as A = 1 − R. The maximum light absorption ratio is as high as 85%, while a dip in reflectance is around 15% at t = 100 nm. The reflectivity spectra have the same shape and tend to a red shift with increasing GeSn coating thickness on Al foil substrate. The results agree well with the evolution of the GeSn/Al foil color as presented in Fig. 1(b). The enhanced light absorption comes from the light interference effect in GeSn/Al foil structure, which has great potential to be employed in highly efficient photovoltaic and photodetector applications. However, the epitaxial breakdown for thick GeSn films will reduce the efficiency of photovoltaics due to the Sn segregation induced poor layer quality. Especially, the epitaxial breakdown will cause a large surface roughness and a crystalline structure degradation. In order to suppress the Sn segregation, a minimum growth rate is preferred27. Figure 6(b) shows the reflection spectra in the range of 5–18 μm measured by FTIR. The reflection spectrum of bare Al foil has a uniform reflectance of ~60% (as shown as the black curve). The reflectance is boosted ~20 to 35% with coatings of GeSn nanometer films. In addition, there is an additional absorption dip around 13.89 μm. The relation between the wavelength of absorption light and the energy band gap Eg is given by λabs = 1.24/Eg 25. So, Eg is extracted as 0.089 eV. This agrees well with the band gap of Tin (~0.08 eV).

Conclusions

In summary, nanometer thick GeSn thin film coatings were deposited on highly flexible aluminum foil substrates using a low-temperature MBE approach. The optical absorption wavelength can be greatly tuned from 400 nm to 1800 nm with a film thickness much smaller than the quarter-wavelength thickness due to strong light interference effects. Various colors (silver, golden, dark blue and light blue) were obtained for the GeSn coated foils. Raman and XRD studies indicate that lattice strain changes considerably with different GeSn coating thicknesses. Nano-sized Sn-enriched GeSn islands gradually appeared on the GeSn coatings of thickness greater than 50 nm, which induced an additional absorption depression around 13.89 μm wavelength. The light absorption ratio in the nanometer GeSn/Al foil structures can be enhanced up to 85%, which has great potential to be used in highly efficient photovoltaic applications. Most importantly, the samples exhibit excellent mechanical flexibility with no apparent effects experienced by repeated bending, which facilitates their use in flexible photonics device technology.

Methods

The GeSn films of the present study were deposited on Al foils using a MBE system with a base pressure lower than 2 × 10−10 torr. The growth temperature was fixed at 250 °C. The crucible temperature for the Ge source was 1200 °C, while the crucible temperature for Sn source was 1000 °C. The thickness of the GeSn films were controlled by controlling the duration of deposition and knowing the growth rate was 1 nm/min.

Aluminum block in 99.99% purity has been squeezed to reduce its thickness to less than 200 μm with several passes through rolling mills. Lubrication has been used to facilitate the rolling process and smoothen the foil surface. In the final pass, two sheets are packed together and rolled simultaneously, which creates bright sides in contact with rolls and matte sides in contact with the other sheet. The aluminum foil is appropriately annealed during the rolling process to maintain its workability.

X-ray photoelectron spectroscopy (XPS) was carried out to quantitatively analyze the elemental composition and chemical ionic state of the elements. Micro-Raman analysis revealed evidence of interfacial strain for the GeSn film. The microstructure of GeSn coatings was examined using X-ray diffraction (XRD). High resolution scanning electron microscopy (HRSEM) was used to investigate the surface morphology of the films. Elemental mapping has been carried out using energy dispersive x-ray spectroscopy. Visible and near infrared range (400–2400 nm) reflectivity spectra of the GeSn optical coatings were measured using a Vis/NIR Spectrophotometer (Lambda750) at room temperature. Far-infrared range (4–18 μm) reflection spectra were measured using Fourier transform infrared spectroscopy (FTIR) with a Bruker-Tensor 27.

Additional Information

How to cite this article: Jin, L. et al. Large area Germanium Tin nanometer optical film coatings on highly flexible aluminum substrates. Sci. Rep. 6, 34030; doi: 10.1038/srep34030 (2016).

References

Li, G. J. et al. Nanopyramid Structure for Ultrathin c-Si Tandem Solar Cells. Nano Lett . 14, 2563− 22568 (2014).

Wang, K. X. et al. Absorption enhancement in ultrathin crystalline silicon solar cells with antireflection and light-trapping nanocone gratings. Nano Lett . 12, 1616− 11619 (2012).

Kim, I. et al. Silicon nanodisk array design for effective light trapping in ultrathin c-Si. Optics Express 22, 1431−1439 (2014).

He, J. et al. Realization of 13.6% Efficiency on 20 μm Thick Si/Organic Hybrid Heterojunction Solar Cells via Advanced Nanotexturing and Surface Recombination Suppression. ACS Nano . 9, 6522–6531 (2015).

Wang, S. et al. Large-Area Free-Standing Ultrathin Single-Crystal Silicon as Processable Materials. Nano Lett . 13, 4393−4398 (2013).

Zhu, L., Kapraun, J., Ferrara, J. & Chang-Hasnain, C. J. Flexible photonic metastructures for tunable coloration. Optica 2, 255−258 (2015).

Wirths, S. et al. Lasing in direct-bandgap GeSn alloy grown on Si. Nat. Photon . 9, 88−92 (2015).

Zhang, L., Agarwal, A. M., Kimerling, L. C. & Michel, J. Nonlinear Group IV photonics based on silicon and germanium: from near-infrared to mid-infrared. Nanophotonics 3, 247−268 (2014).

Cheng, T. H. et al. Strain-enhanced photoluminesence from Ge direct transition. Appl. Phys. Lett. 96, 211108 (2010).

Oehme, M. et al. GeSn/Ge multiquantum well photodetectors on Si substrates. Opt. Lett. 39, 4711−4724 (2014).

Gupta, S., Magyari-Köpe, B., Nishi, Y. & Saraswat, K. C. Achieving direct band gap in germanium through integration of Sn alloying and external strain. J. Appl. Phys. 113, 073707 (2013).

Wirths, S. et al. Band engineering and growth of tensile strained Ge/(Si)GeSn heterostructures for tunnel field effect transistors. Appl. Phys. Lett. 102, 192103 (2013).

Kato, K. et al. Formation of high-quality oxide/Ge1−xSnx interface with high surface Sn content by controlling Sn migration. Appl. Phys. Lett. 105, 122103 (2014).

D’Costa, V. R. et al. Towards simultaneous achievement of carrier activation and crystallinity in Ge and GeSn with heated phosphorus ion implantation: An optical study. Appl. Phys. Lett. 105, 122108 (2014).

Grzybowski, G. et al. Next generation of Ge1−y Sny (y = 0.01–0.09) alloys grown on Si(100) via Ge3H8 and SnD4: Reaction kinetics and tunable emission. Appl. Phys. Lett. 101, 072105 (2012).

Toko, K. et al. 70 °C synthesis of high-Sn content (25%) GeSn on insulator by Sn-induced crystallization of amorphous Ge. Appl. Phys. Lett. 106, 082109 (2015).

Kats, M. A., Blanchard, R., Genevet, P. & Capasso, F. Nanometre optical coatings based on strong interference effects in highly absorbing media. Nat. Mater. 12, 20−24 (2012).

Kats, M. A. & Capasso, F. Ultra-thin optical interference coatings on rough and flexible substrates. Appl. Phys. Lett. 105, 131108 (2014).

Takeuchi, W. et al. High hole mobility tin-doped polycrystalline germanium layers formed on insulating substrates by low-temperature solid-phase crystallization. Appl. Phys. Lett. 107, 022103 (2015).

Uchida, N. et al. Carrier and heat transport properties of polycrystalline GeSn films on SiO2 . Appl. Phys. Lett. 107, 232105 (2015).

Fournier-Lupien, J. H. et al. Strain and composition effects on Raman vibrational modes of silicon-germanium-tin ternary alloys. Appl. Phys. Lett. 103, 263103 (2013).

D’Costa, V. R. et al. Raman scattering in Ge1−ySny alloys. Solid State Commun . 144, 240 (2007).

Sanson, A. et al. Study of carrier concentration profiles in Al-implanted Ge by micro-Raman spectroscopy under different excitation wavelengths. J. Raman Spectrosc. 44, 665–669 (2013).

Terai, Y. et al. Effect of lattice deformations on Raman spectra in β-FeSi2 epitaxial films. JJAP Conf. Proc. 3, 011109 (2015).

Ishikawa, Y. et al. Strain-induced enhancement of near-infrared absorption in Ge epitaxial layers grown on Si substrate. J. Appl. Phys. 98, 013501 (2005).

Oehme, M. et al. Epitaxial growth of strained and unstrained GeSn alloys up to 25% Sn. Thin Solid Films 557, 169−172 (2014).

Von den Driesch, N. et al. Direct Bandgap Group IV Epitaxy on Si for Laser Applications. Chem. Mater. 27, 4693−4702 (2015).

Acknowledgements

This work was supported by the National Key Research and Development Plan (No. 2016YFA0300801), the National Natural Science Foundation of China (Grant Nos 61571079, 61021061 and 51472046) and the International Cooperation Projects 2013HH0003 and 111 Project No. B13042.

Author information

Authors and Affiliations

Contributions

L.J. conducted the experiments and wrote the manuscript. H.Z. conceived and supervised the research. D.Z., J.F., Y.L., C.L., Z.Z. and V.G.H. made the theoretical analysis. All the authors discussed the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Jin, L., Zhang, D., Zhang, H. et al. Large area Germanium Tin nanometer optical film coatings on highly flexible aluminum substrates. Sci Rep 6, 34030 (2016). https://doi.org/10.1038/srep34030

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep34030

This article is cited by

-

Polycrystalline GeSn thin films fabricated by simultaneous laser sintering and recrystallization

Journal of Materials Science: Materials in Electronics (2023)

-

Ge1−xSnx alloys: Consequences of band mixing effects for the evolution of the band gap Γ-character with Sn concentration

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.