Abstract

The general form of interfacial contact resistance was derived for organic thin-film transistors (OTFTs) covering various injection mechanisms. Devices with a broad range of materials for contacts, semiconductors, and dielectrics were investigated and the charge injections in staggered OTFTs was found to universally follow the proposed form in the diffusion-limited case, which is signified by the mobility-dependent injection at the metal-semiconductor interfaces. Hence, real ohmic contact can hardly ever be achieved in OTFTs with low carrier concentrations and mobility, and the injection mechanisms include thermionic emission, diffusion, and surface recombination. The non-ohmic injection in OTFTs is manifested by the generally observed hook shape of the output conductance as a function of the drain field. The combined theoretical and experimental results show that interfacial contact resistance generally decreases with carrier mobility, and the injection current is probably determined by the surface recombination rate, which can be promoted by bulk-doping, contact modifications with charge injection layers and dopant layers, and dielectric engineering with high-k dielectric materials.

Similar content being viewed by others

Introduction

The charge injection at the metal–semiconductor interface is one of the main limiting factors of many non-silicon-based electronic devices, especially those with organic semiconductors1. The energy barriers and/or interface states at the heterojunction contacts considerably consume voltage drop2,3, generate Joule heating4, and decrease injection efficiency. Especially, a large contact resistance seriously suppresses the performance of thin-film transistors (TFTs) used for the back panel of displays5, sensors, memories, and other facile electronics, which call for a low driving voltage and a high on–off ratio6. Such limitations raise the demand for ohmic-contact injection7,8, which has not been achieved in most organic TFTs (OTFTs), or organic field-effect transistors (OFETs). To solve the problem, we need to understand what procedure carriers experience at the injection, as well as how contact resistance is determined by the materials, interfaces, device, and operational conditions.

Injection barriers generally exist at the contacts of OTFTs and are caused by mismatched work functions of metals with respect to the injection levels in organic semiconductors9, or interfacial states with charge-transfer and dipole moments1,10. The injection barrier leads to a depletion region11 where carriers are depleted and need to diffuse through the region after a number of collisions. The depletion width (Wd) can be estimated by knowing the effective barrier height (~0.5 eV), band-gap (~2 eV), and Fermi-level of organic semiconductors (OSCs) (near the mid-gap). Using common parameters of intrinsic OSCs in the literature, Wd is estimated to be over 1 μm in OTFTs12. This value is much larger than the mean free path (lfree) of a carrier in OSCs that is only at the order of intermolecular distance (several Å to nm) owing to structural disorders and localized polarons13,14. Moreover, the estimated Wd is much larger than the usual thickness of active layers (10 nm < t < 100 nm), pointing to the possibility of diffusion-limited injection. However, there is still a lack of direct evidence in OTFTs that charge injection is diffusion-limited, as well as a need for quantitative studies to understand how this limitation affects charge injection and contact resistance in OTFTs.

In this work, we analyzed different injection mechanisms and derived a general form of interfacial contact resistance (Rc,int), which is expressed as a function of the effective injection barrier, carrier mobility, and drain voltage in staggered OTFTs. We propose that, in OTFTs with non-ohmic injection, a hook shape would appear in conductance-drain voltage (G-Vd) relations, and we experimentally observed such an effect in OTFTs made with a broad range of materials. The hook effect indicates that as the drain field increases, OTFTs experience a transition from the injection-limited to the field-effect transport regime. By analyzing various OTFTs with our developed tool, we reveal that the interfacial contact resistance (readily excluding the bulk resistance) is closely related to carrier mobility and the charge injection in OTFTs is universally diffusion-limited. Importantly, the values of Rc,int followed our proposed general form in the case of surface recombination process, i.e., carriers recombine with the image charges at the metal-semiconductor interface in OTFTs. Thus, the semiconductor mobility plays a critical role in the injection, probably by determining the surface recombination velocity and rate.

Results

Materials and structures of OTFTs

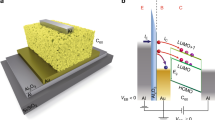

To investigate the contact properties of OTFTs, we fabricated a wide range of OTFTs covering a variety of materials. The basic structures are bottom-gate/top-contact (BG/TC) and top-gate/bottom-contact (TG/BC) with gold source and drain electrodes, unless stated otherwise (see Fig. 1). For organic semiconductors, we used: (1) p-type small molecule dioctylbenzothienobenzothiophene (C8-BTBT) and polymer poly(3-hexylthiophene) (P3HT); (2) n-type small molecule [6,6]-phenyl-C61-butyric acid methyl ester (PCBM, small molecule) and polymer poly [[N,N′-bis(2-octyldodecyl)-1,4,5,8-naphthalene-dicarboximide-2,6-diyl]-alt-5,5′-(2,2′-bithiophene)] [P(NDI2OD-T2) or N2200]; and (3) ambipolar poly[[2,5-bis(2-octyldodecyl)-2,3,5,6-tetrahydro-3,6-dioxopyrrolo[3,4-c]pyrrole-1,4-diyl]-alt-[[2,2′-(2,5-thiophene) bis-thieno(3,2-b)thiophene]-5,5′-diyl]] (DPPT-TT). The materials include the commonly used thieno-thiophene-based, thiophene-based, C60-based, perylene-based, and diketopyrrolopyrrole (DPP)-based organic semiconductors. To modify the contacts, different types of contact engineering methods and materials were used, including selectively inserting a doping layer (FeCl3), inserting a charge injection layer [MoO3, V2O5, BaCl2, Ba(OH)2], and doping the bulk semiconductor with dopants (CoCp2, CsF). For the dielectrics, we selected commonly used low-k polymer dielectrics [parylene, poly(methyl methacrylate) (PMMA), polystyrene (PS)], and a high-k dielectric poly(vinylidene fluoride-ter-trifluoroethylene-ter-chlorotrifluoroethylene) [P(VDF-TrFE-CtFE)]. The semiconducting and dielectric layers of the devices were all solution-processed by spin coating, except the device with the C8-BTBT layer, which was vacuum evaporated, and the device with the parylene layer, which was chemical-vapor deposited.

Interfacial contact resistance in OTFTs

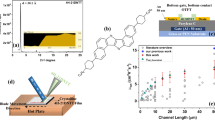

The injection barriers cause the injection current to increase non-linearly with the applied voltage Va because injections may occur with the mechanisms illustrated in Fig. 2. When depletion width Wd is smaller than the mean free path lfree, only thermionic emission (denoted as “e”) or tunneling processes (denoted as “t”) dominate (Fig. 2a,b) and the current follows15:

Schematic representations of charge injection mechanisms (take electron injections for an example): (a) thermionic emission; (b) tunneling; (c) thermionic diffusion; and (d) thermionic emission with surface recombination. The injections via thermal activation or tunneling are indicated with dark blue arrows and the mean free paths are indicated with red arrows. The characteristic lengths mentioned in the main text are also illustrated.

Here A* is the Richardson constant, T is the temperature, k is the Boltzmann constant, S is the injection area, φeff is the effective Schottky barrier height that takes into account the density of states distributions16, E00 is related to doping concentrations in semiconductors, and Va is the applied voltage across the metal–semiconductor junction, which is assumed to follow drain voltage Vd in OTFT as Va ∝ (Vd)α. The image-force-induced lowering of the injection barrier (Schottky effect) is not considered here for simplicity and the forms of Rc,int are:

Here the parameters B are the constant of Vd (this also applies to the following equations).

However, when depletion width Wd is much larger than the mean free path lfree, which is usually the case in OTFTs, carriers experience many collisions across the depletion region (Fig. 2c) and the injection becomes diffusion-limited. The thermionic emission–diffusion model (denoted as “ed”) predicts the injection current as15:

Assuming that the interfacial electric field  and the interfacial mobility follows the channel mobility μint ∝ μγ, Rc,int is:

and the interfacial mobility follows the channel mobility μint ∝ μγ, Rc,int is:

Here q is the elementary charge and Nc is the effective density of states in the conduction band. Especially, Emtage et al. showed that, at the metal–organic interface, carriers recombine with their image charges when thermal energy kT reaches the carrier–image binding energy17,18, and the recombination can occur with unipolar carriers. The critical distance for the recombination xC for common OSCs (~5 nm)18 is larger than or comparable with lfree (several Å to a few nm) (Fig. 2d). The recombination current is opposite to the thermionic injected current and Scott et al. calculated the detailed balance between the two to derive the net injection current18:

Here the subscript “r” denotes surface recombination, ψ is a function slowly varying with electric field ϵ, N0 is the total hopping sites in the organic semiconductor (similar to the above Nc in inorganic semiconductors), and rC is the Coulomb radius (rC ~ 4xC). The mobility appears because it determines the surface recombination velocity near the interface. This form was supported by experiments in a metal–organic semiconductor diode by Shen et al.19 and so Rc,int should follow:

From the above models, we can summarize Eqs 2, 4, 6, and 8 to give a general form as:

Here φ0 ideally equals  except in the tunneling model where φ0 = E00, and the parameter B generally decreases with thermal energy

except in the tunneling model where φ0 = E00, and the parameter B generally decreases with thermal energy  . In the non-diffusion-limited cases, including thermionic emission and the tunneling models, γ = 0 and a = b; in the diffusion-limited case, including thermionic emission-diffusion and the surface recombination models, γ > 0 and usually a ≠ b. We expect a diffusion-limited injection in OTFTs because lfree << Wd and it is probably accompanied by a surface recombination process as lfree ≤ xC.

. In the non-diffusion-limited cases, including thermionic emission and the tunneling models, γ = 0 and a = b; in the diffusion-limited case, including thermionic emission-diffusion and the surface recombination models, γ > 0 and usually a ≠ b. We expect a diffusion-limited injection in OTFTs because lfree << Wd and it is probably accompanied by a surface recombination process as lfree ≤ xC.

Extraction of interfacial contact resistance

In the following we will examine if Rc,int in OTFTs generally follows Eq. 9, whether charge injection in OTFTs is diffusion-limited, and, if so, to what extent the charge injection is limited by diffusion. To extract Rc,int, we have derived a series of functions using the Id–Vd relations as listed in Table 1, because conventional extraction methods (e.g., transfer-length method, TLM)20 are not applicable as they cannot exclude the bulk injection resistance (Rc,bulk). Among these functions, the G-function has been introduced21 and other functions are derived in the supplementary information (SI, part 1). The key point is that as Vd increases, Rc,int will dramatically decrease according to Eq. 9, but Rc,bulk and Rch will gradually increase21; then, the conductance of the OTFT increases first and then starts to decrease at a critical drain voltage Vd’. Thus, for both static output conductance  and dynamic output conductance

and dynamic output conductance  , a hook shape appears near Vd’ in the G–Vd and Gdif –Vd relation (referred to as the “hook effect” in the following).

, a hook shape appears near Vd’ in the G–Vd and Gdif –Vd relation (referred to as the “hook effect” in the following).

The hook effect and the application to extract Rc,int are shown in Fig. 3, which depicts numerical simulations on the charge injection in OTFTs. To cover general injection behaviors, we simulated Rc,int in the forms of  (referred to as “Exp-1”),

(referred to as “Exp-1”),  (“Exp-2”),

(“Exp-2”),  (“Power”), or a constant P4 (“Const.”) (see simulation details in experimental and SI, Part 2). The simulated Id–Vd curves are depicted in Fig. 3a and the extracted G, Gdif, and G* are shown in Fig. 3b–d. Clearly, the hook effect appears in non-linear injections but does not appear in the linear injection (i.e., Rc = 0, dashed lines). In Fig. 3e–h, Rc,int is extracted (in lines) by Table 1 and compared with the set values Rc,set in the simulations (open squares). G- and Gdif-functions give accurate estimations when Rc,int is strongly Vd-dependent, while the G*-function does so when Rc,int is Vd-independent. For comparison, values of Rch are depicted as dashed curves and they crosses the Rc,set curves at the critical Vd’. Furthermore, the G- and Gdif-functions were examined using commercial TFT simulation tools (Silvaco Atlas) with Schottky barriers as presented in the SI (Part 3), which proves good accuracy. Importantly, the extracted resistance readily excludes the main part of the bulk resistance (Rc,bulk), and therefore is mainly the interfacial contact resistance (Rc,int), as discussed in the SI (part 4). In the following, we apply the method to analyze the experimental results of various OTFTs.

(“Power”), or a constant P4 (“Const.”) (see simulation details in experimental and SI, Part 2). The simulated Id–Vd curves are depicted in Fig. 3a and the extracted G, Gdif, and G* are shown in Fig. 3b–d. Clearly, the hook effect appears in non-linear injections but does not appear in the linear injection (i.e., Rc = 0, dashed lines). In Fig. 3e–h, Rc,int is extracted (in lines) by Table 1 and compared with the set values Rc,set in the simulations (open squares). G- and Gdif-functions give accurate estimations when Rc,int is strongly Vd-dependent, while the G*-function does so when Rc,int is Vd-independent. For comparison, values of Rch are depicted as dashed curves and they crosses the Rc,set curves at the critical Vd’. Furthermore, the G- and Gdif-functions were examined using commercial TFT simulation tools (Silvaco Atlas) with Schottky barriers as presented in the SI (Part 3), which proves good accuracy. Importantly, the extracted resistance readily excludes the main part of the bulk resistance (Rc,bulk), and therefore is mainly the interfacial contact resistance (Rc,int), as discussed in the SI (part 4). In the following, we apply the method to analyze the experimental results of various OTFTs.

(a) The simulated Id–Vd characteristics for various contact properties. The extracted static output conductance G, dynamic output conductance Gdif, and G* are depicted in (b–d), respectively. Comparison between the set values (open squares) and calculated values (lines) of Rc,int for various contact properties: (e) “Exp-1”, (f) “Exp-2”, (g) “Power”, and (h) “Constant”. The set values of Rch (dashed lines) are also shown for reference.

Experimental results of OTFTs

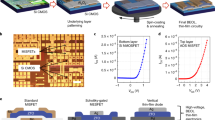

The measurement and investigation of output characteristics of all OTFTs is shown in Fig. 4 (n-type) and Fig. 5 (p-type), and the results are summarized in Table 2. In the analysis, we intentionally skip the data next to Vd = 0 V to reduce the error induced by Vd-dependent mobility, because the above methods assume that mobility is weakly dependent on Vd. In all OTFTs, we observed the universal hook effect, which is manifested as follows: G and Gdif start from zero, raise to a maximum and then decrease linearly in all the OTFTs, regardless of the fabrication process and material of contacts, semiconductors, and dielectrics. This is the first important finding of our study.

(a–d) N2200 transistors without dopant; (e–h) N2200 transistors with CoCp2 as bulk dopants; (i–l) N2200 transistors with CsF as bulk dopants; (m–p) PCBM transistors without charge injection layers (CILs); (q–t) PCBM transistors with BaCl2 as CILs; (u–x) PCBM transistors with Ba(OH)2 as CILs. The dotted lines in the G and Gdif figures illustrate the linear part. The dashed lines in the R figures denote the extracted channel resistance (Rch) for the corresponding voltage.

(a–d) P3HT transistors with pure Mo electrodes; (e–h) P3HT transistors with Mo electrodes covered by MoO3 CILs; (i–l) P3HT transistors with Mo electrodes covered by V2O5 CILs; (m–p) DPPT-TT transistors PMMA dielectric; (q–t) DPPT-TT transistors PVDF-TrFE-CtFE dielectric. The dotted lines in the G and Gdif figures illustrate the linear part. The dashed lines in the R figures denote the extracted channel resistance (Rch) for the corresponding voltage.

The hook effect is alleviated by using bulk dopants, inserting charge injection layers (CILs), or even by changing dielectrics. We take the n-type, BC/TG OTFTs based on N2200 semiconductors for the first example (see Id, G, and Gdif in Fig. 4a–d). Both G and Gdif exhibit typical hook features followed by a linear relationship with Vd (see the dashed red lines). With organic dopant CoCp2 or inorganic dopant CsF in the bulk N2200, the OTFTs exhibit larger conductance (G and Gdif above 2 μΩ−1) as compared to the pristine device (below 0.6 μΩ−1). We use G-function to calculate Rc,int and Rch and quantitatively determine Vd’ (Rc,int = Rch) for each type of device in Fig. 4a–c, which signifies the transition from the injection-dominated regime to transport-dominated regime. The critical Vd’ is above 15 V with pristine semiconductors, while Vd’ is below 6 V with bulk dopants. As the dopants CoCp2 and CsF increase the carrier concentration22, the conductivity adjacent to the contact is enhanced, the depletion region is narrowed12, and the Rc,int is lowered by over 100 times.

Such improvements are also observed in OTFTs with CILs. In n-type OTFTs with PCBM (Fig. 4m–x), the Ba(OH)2 CIL reduced Rc,int as significantly as three orders of magnitude (values at 2 V). In p-type OTFTs with P3HT/Mo contacts (Fig. 5a–l), the solution-processed MoO3 and V2O5 CILs reduced Rc,int by up to two orders of magnitude, and reduced |Vd’| to below −2 V. The improvement comes from reducing the energy barrier according to spectroscopic observations23,24. In addition, CILs that are strong dopants also help in p-type OTFTs with C8-BTBT semiconductor (SI, part 4). The FeCl3 CIL at the contact region increases free carriers and reduces the unoccupied traps, so that it reduced Rc,int by about 10 times and reduced Vd’ to be unobservable. For reference, the extracted Rc,int for C8-BTBT OTFTs with FeCl3 is 6.8 kΩ·cm (Vd = −2 V) which is close to the value (8.8 kΩ·cm) extracted from TLM25, showing that our methods are reasonable estimations.

Besides bulk dopants and CILs, interesting results were also found in OTFTs with various dielectrics. In OTFTs with the DPPT-TT/Au contacts (Fig. 5m–t), the devices with the low-k PMMA dielectric (k = 3.5) exhibited Rc,int values of more than 1000 kΩ·cm (at Vd = −2 V) and critical Vd’ in the range of −8 to −10 V, while the devices with the high-k PVDF-TrFE-CtFE (k = 10.4) featured Rc,int values two orders lower (about 20 kΩ·cm) and a much smaller critical Vd’ (~−3 V). The large bulk capacitance and interfacial negative dipoles of PVDF-TrFE-CtFE induced strong electrostatic coupling to increase the carrier concentration and lowered the Fermi level towards the highest occupied molecular orbital (HOMO)26. The magnitude of enhancement is exceptional, considering that carrier concentration only increased about six times. The above results indicate that the hook effect generally exist as a sign of non-ohmic contact injection in OTFTs and can be used to qualitatively characterize charge injections.

Whether the charge injection is diffusion-limited or not was firstly examined by depicting the relations between Vd’, Rc,int’ (Rc,int at Vd’), and μ of OTFTs (Fig. 6a–h). The critical electric field is calculated by Fc = Vd’/L, and for those cases where Vd’ does not appear within the measurement window, we conservatively use the minimum Vd and the corresponding channel resistance as Rc,int’. The calculated mobility values are lower than those reported before calculated from the saturation regime, as the values here were extracted from Table 1, whose values are close to those calculated from the linear regime. We depict normalized Fc and Rc,int’ as a function of normalized μ for all solution-processed OTFTs (Fig. 6i,j). Here in OTFTs, it is clear that, regardless of materials, device configurations, and processing, a higher μ is related to a lower Fc and a lower Rc,int. In detail, a three to four times higher μ corresponds to a three to four times lower critical field, and a 102 to 103 times lower Rc,int. Previous studies on the relation between mobility and injection are mainly based on diodes19. Firstly, it indicates that tuning (or optimizing) contact injection efficiency and semiconductor mobility is always synergetic, i.e., one interacts as both cause and effect with the other. Secondly, as Rc,int’ decreases as the carrier mobility increases, the results imply that charge injections in OTFTs are diffusion-limited, as Fig. 6e–h suggest a universal relation that Rc,int’ decreases with μ.

The critical field Fc (a–d) and corresponding interfacial contact resistance Rc,int’ (e–h) plotted against channel mobility. The values are extracted from OTFTs (shown in Figs 4 and 5) made with P3HT (a,e), DPPT-TT (b,f), PCBM (c,g), and N2200 (d,h). In (a–d), types of devices are given by texts, and the detailed structures are shown in Figs 4 and 5. The values of Fc and Rc,int’ are normalized and plotted in the (I,j) for comparison. In (i), grey and yellow squares are used to visualize different types of devices, comparing pristine devices and those with CIL, high-k dielectrics, or dopants. In (e–h,j), the lines are guides for the eye.

Diffusion-limited injection with surface recombination

In diffusion-limited injection, we especially examine Eq. 8 because the recombination process is regarded to take place in OSCs where carriers transport mainly via hopping. At the metal–organic interface, the recombination can occur between the carriers and their image charges18, where thermionically injected carriers within xC return to the metal surface to form the organic-to-metal current opposite to the metal-to-organic current (illustrated in Fig. 7a). This process can occur with unipolar carriers, in contrast to the recombination in the bulk of OSCs where Langevin’s recombination occurs in the form of electron–hole recombination27,28, as well as trap-assisted recombination29. In this scenario, the total number of charge recombination events per unit time and per unit area, i.e., the surface recombination rate rrec (unit in cm−2 s−1), is determined by the carrier mobility together with the injection barrier. The surface recombination rate at zero field rrec,0 is (see derivation in the SI, Part 5):

(a) Schematic diagram of surface recombination at the metal–organic interface (take electron current as an example). (b–d) Calculated Rc,int as a function of Vd for different injection barriers according to Eq. 8. (e) Calculated relation between Rc,int and recombination rate rrec in various electric field for different injection barriers.

For example, when φeff = 0.1 eV, μint = 0.1 cm2/Vs, N0 = 106, and ε = 3.5, the rate rrec,0 is 1.4 × 108 cm−2 s−1 at 300 K, which is independent of Vd and well characterizes the interfacial conditions. When OTFT is operated at non-zero field, the rate rrec is proportional to rrec,0 and will increase with Vd, and the exact form of rrec can be found in the SI (Part 5). Importantly, Rc,int in OTFTs will decrease with increasing rrec. The calculated rrec and Rc,int as a function of Vd are shown in Fig. 7b–d and the correlation between rrec and Rc,int are shown in Fig. 7e (see the SI, Part 5, for calculation details). The main features of the calculated curves are similar to the experimental results mentioned above, and hence we will use the Eq. 8 to fit the experimental data in the following.

Based on Eq. 8, for the simplicity of fitting, we assume the parameters α and β to be unity and obtain (see derivation in the SI, Part 6):

Here,  is the most important constant related to the effective Schottky barrier φeff, carrier mobility μ, and number of charge hopping sites N0; B is related to the local electric field and the image potential; R0 is much smaller than the first term and it should also increase exponentially with the Schottky barrier (see the SI, Part 5). The Mo/V2O5/P3HT transistors (device structure is shown in Fig. 5) were examined as in those OTFTs the work-function of contact electrode was continuously tuned by changing the thickness of the V2O5 layers. For fitting, the values of φeff are simply estimated by the measured injection barrier φB, which is calculated by using the difference between the work function measured from Mo/V2O5 surface and the HOMO levels of P3HT. Reasonable fittings of Eq. 11 were obtained for the extracted Rc,int with different V2O5 layer thickness, as shown in Fig. 8a–e and Table 3. Note that when discussing injection barrier, devices spin-coated with 0 wt% to 0.5 wt% V2O5 solution were compared as the interlayers are thin and flat, except the 0.8 wt% device, which had a thick and rough insulating interlayer and the resulting extra access resistance23. In addition, according to Eq. 11, the fitting parameters should follow:

is the most important constant related to the effective Schottky barrier φeff, carrier mobility μ, and number of charge hopping sites N0; B is related to the local electric field and the image potential; R0 is much smaller than the first term and it should also increase exponentially with the Schottky barrier (see the SI, Part 5). The Mo/V2O5/P3HT transistors (device structure is shown in Fig. 5) were examined as in those OTFTs the work-function of contact electrode was continuously tuned by changing the thickness of the V2O5 layers. For fitting, the values of φeff are simply estimated by the measured injection barrier φB, which is calculated by using the difference between the work function measured from Mo/V2O5 surface and the HOMO levels of P3HT. Reasonable fittings of Eq. 11 were obtained for the extracted Rc,int with different V2O5 layer thickness, as shown in Fig. 8a–e and Table 3. Note that when discussing injection barrier, devices spin-coated with 0 wt% to 0.5 wt% V2O5 solution were compared as the interlayers are thin and flat, except the 0.8 wt% device, which had a thick and rough insulating interlayer and the resulting extra access resistance23. In addition, according to Eq. 11, the fitting parameters should follow:

(a–e) Fitting the extracted values of Rc,int to Eq. 11. The extracted Rc,int are shown in black solid curves and the fitted curves are shown in red dashes. (f,g) Relationships between the parameter A and the measured injection barrier φB and μ. (h,i) Relationships between the parameter R0 and the measured injection barrier φB and μ, confirming Eqs 11, 12, 13. The measured injection barrier φB is calculated the difference between the work function measured from Mo/V2O5 surface and the HOMO level of P3HT.

Here C1, C2, C3, and C4 are constants for Vd. Importantly, Fig. 8f–i correspond well to Eqs 12 and 13 and indicate good consistency between the theoretical derivations and the experimental results, suggesting the surface recombination scenario in OTFT injections. In fact, Eq. 10 indicates that the recombination rates can be promoted by lowering the injection barrier or/and enhancing the interfacial mobility, which has been achieved in the experimental methods mentioned above, including bulk-doping, charge injection layers, and dielectric engineering.

To further examine the general applicability of the relation between Rc,int and carrier mobility, we analyzed the devices with n-type N2200 transistors with CsF dopants. By doping organic semiconducting layers (N2200) with dopants (CsF) in different concentrations (or weight ratios, device structure is shown in Fig. 4), the mobility of the semiconductor is tuned without changing the injection barrier and the impact of mobility on Rc,int can be solely studied. The results are shown in Fig. 9, depicting values of Rc,int of devices with different doping weight ratios of CsF (in wt%). Generally, Rc,int decreases with mobility in a power law and it is in good accordance with the theoretical prediction, which is given by the diffusion-limited injection (Eqs 6, 7, 8, 9):

N2200 transistors with CsF dopants: (a) Relation between interfacial contact resistance [in terms of ln(Rc,int)] and channel mobility [in terms of ln(μ)] for different doping concentrations (including various Vd); the dashed line is a guide for the eye, indicating ln(Rc,int) decreases linearly with ln(μ). (b) the parameter γ for fitting ln(Rc,int) ∝−γ ln (μ) at different lateral fields.

The power factor γ indicates how interfacial injection is affected by channel mobility, determined by the materials and device structure. Fittings of data from N2200 transistors in Fig. 9 to the above equation are generally good as the correlation coefficients for fitting are from 0.9006 to 0.9841. Moreover, the values of power factor γ are around 3.0 at different drain field determined by Vd values, indicating that the assumption that mobility is almost independent of lateral electric field in the studied region. The results again confirm the above theory on the diffusion-limited injection where Rc,int follows mobility.

Discussions

Charge injection of OTFTs with various semiconductors and contact materials was investigated systematically. According to our calculations, real ohmic contact can hardly be achieved in common OTFTs with their low carrier mobilities and low carrier concentrations. Consistently, the hook effect signifying non-ohmic contact was experimentally found to be universal in OTFTs. For different non-ohmic injection mechanisms, different forms of interfacial contact resistance have been theoretically derived, which can be summarized into a general applicable form. We also developed a series of functions to analyze the interfacial contact resistances and used them to study OTFTs with a broad range of materials.

The experimental results of TFTs confirm the proposed form of interfacial contact resistance, and strongly support that OTFTs universally suffer from diffusion-limited injection, where the interfacial contact resistance generally decreases with carrier mobility. The injection process is also probably accompanied by a surface recombination process at the metal-organic interfaces. The surface recombination rate determines the injection current and has been promoted by bulk-doping, contact engineering with charge injection layers and dopant layers, and even dielectric engineering with high-k dielectric materials. As a result, the critical voltage |Vd’|, signifying the transition from the injection-limited to the field-effect transport regime, has also been reduced from generally over 10 V towards zero.

Methods

Fabrication and characterizations of OTFTs

All the fabrication and characterization of OTFTs were carried out in an N2 atmosphere unless stated otherwise.

N2200 OTFTs

A top-gate/bottom-contact (TG/BC) structure was fabricated on a glass substrate. The bottom contact electrodes were Cr/Au (3/27 nm). The semiconductor is N2200 or N2200 with CoCp2 and CsF doping. The N2200 film deposited by spin casting from the p-xylene solution and dried at 110 °C (30 nm thick). The bulk dopants were mixed with N2200 solution in the weight ratio in 0.025%, 0.5%, 1.0%, and 2.0% before spin-coating. The gate dielectric is CYTOP (500 nm, deposited by spin casting and annealed at 130 °C for 1 hour). The top gate electrode is Al (50 nm, deposited by thermal evaporation in high vacuum). The channel length is 10 μm and the channel width is 1 mm.

PC61BM OTFTs

The TFTs in TG/BC structure was fabricated on a glass substrate. The contact electrodes are Ni/Au (3/12 nm) deposited by thermal evaporation and patterned by photolithography. For the interlayers, Ba(OH2) and Ba(Cl2) (from Sigma-Aldrich) were dissolved in methanol (2 mg/ml) and spin-coated onto the Au patterned electrodes (4000 rpm)24. The n-channel semiconductor PC61BM (from Nano-C) was dissolved in anhydrous chlorobenzene (10 mg/ml), spin-coated at 2000 rpm, and annealed at 110 °C for 20 min. The top-gate dielectric layer was deposited by spin-coating PMMA (MW = 120 kD, from Sigma-Aldrich) dissolved in n-butyl acetate (80 mg/ml) followed by annealing at 80 °C for 30 min. The top-gate electrodes were fabricated by the thermal deposition of aluminum (Al) via metallic shadow masks (50 nm thick). The channel length is 20 μm and the channel width is 1 mm.

P3HT OTFTs

A TG/BC structure was fabricated on a glass substrate. The bottom contact electrodes were fabricated by sputtering Ni/Mo (3/13 nm) and conventional photolithography process to define patterns for source and drain electrodes. For the MoO3 interlayers, the ammonium molybdate (NH4)2MoO4 in H2O solution (0.8 wt% of MoO3) was spin-coated and annealed at 150 °C for 10 min in air30. For V2O5 interlayers, the ammonium vanadate ((NH4)3VO4) solution of different concentration (0.1–0.5 wt% of V2O5) was spin-coated and then annealed at 150 °C for 20 min in air23. Then semiconducting polymer rr-P3HT (from Sigma-Aldrich) dissolved in anhydrous dichlorobenzene (DCB, 10 mg/ml) was spin-coated and annealed at 150 °C for 30 min. The top-gate dielectric layer PMMA and the top Al electrodes were deposited as described above. The channel length is 10 μm, and channel width W is 1 mm.

C8-BTBT OTFTs

The bottom-gate electrodes are Ti/Au (3/37 nm, formed by vacuum evaporation), the gate dielectric was parylene (290 nm, deposited by chemical vapor deposition), the semiconductor was C8-BTBT (40 nm film, evaporated at 0.01 nm/s, Nippon Kayaku), and the top contact electrodes were pristine Au (50 nm) or FeCl3/Au (0.3/40 nm, evaporated at 0.01 nm/s). The channel length is 350 μm and the channel width is 1000 μm.

DPPT-TT OTFTs

A TG/BC structure was fabricated on a glass substrate with the bottom contact electrodes Ni/Au (3/12 nm) deposited as stated above. The p-channel semiconductor DPPT-TT was spin-coated from anhydrous chlorobenzene solution (10 mg/ml) and annealed at 200 °C for 30 min. The gate dielectric layer is PMMA, PS, or PVDF-TrFE-CtFE (formed on top of the DPPT-TT layer by spin-coating). The capacitance per unit area is 6.2 nF/cm2 for PMMA, 4.6 nF/cm2 for PS, and 63.72 nF/cm2 for PVDF-TrFE-CtFE, respectively. The top gate electrode is Al (50 nm, by thermal deposition). The channel length is 10 μm and channel width W is 1 mm. In the figure for DPPT-TT (b,f), the data of OTFTs using polystyrene (PS) dielectrics are also included.

Characterizations

The electrical characteristics of OTFTs were measured with an Agilent 4156A Semiconductor Parameter Analyzer in an N2 atmosphere. L and W are channel length and width, respectively, μ is carrier mobility in channel, Vg is gate-voltage, and Vth is the threshold voltage.

Calculation and simulation of interfacial contact resistance

Data in Fig. 2 in the main text were calculated by simulating the Id-Vd characteristics in the linear regime using the equation (Fig. 2):

Here,  and

and  . The values of ΔL do not affect the extracted Rc,int. Then the values of Rc,int are set in the following forms:

. The values of ΔL do not affect the extracted Rc,int. Then the values of Rc,int are set in the following forms:  (referred to as “Exp-1”),

(referred to as “Exp-1”),  (“Exp-2”),

(“Exp-2”),  (“Power”), P4 (“Const”). In the calculation and simulation, Vd ranges from 0 V to −30 V with a step of −1 V. In Fig. 2, the set values of Rc,int and calculated Rc,int extracted by Table 1 are compared. The values of calculation and simulation parameters can be found in SI, Part 2.

(“Power”), P4 (“Const”). In the calculation and simulation, Vd ranges from 0 V to −30 V with a step of −1 V. In Fig. 2, the set values of Rc,int and calculated Rc,int extracted by Table 1 are compared. The values of calculation and simulation parameters can be found in SI, Part 2.

Calculation and simulation of surface recombination rate

The surface recombination rate rrec can be calculated as the product of the surface charge density n and the surface recombination velocity S. The voltage across the interface Va and local electric field ϵ at the interface and are affected by Vd. Assume the former is  and the latter is

and the latter is  , and charge mobility near the interface follows the field-effect mobility

, and charge mobility near the interface follows the field-effect mobility  . Then rrec can be expressed by (unit in cm−2s−1) (Fig. 7)

. Then rrec can be expressed by (unit in cm−2s−1) (Fig. 7)

Here ψ is a weak function of ϵ (see SI for details). The detailed derivation and values of parameters in calculations and simulations can be found in SI, Part 5.

Additional Information

How to cite this article: Liu, C. et al. Universal diffusion-limited injection and the hook effect in organic thin-film transistors. Sci. Rep. 6, 29811; doi: 10.1038/srep29811 (2016).

References

Natali, D. & Caironi, M. Charge Injection in Solution-Processed Organic Field-Effect Transistors: Physics, Models and Characterization Methods. Adv. Mater. 24, 1357–1387 (2012).

Ante, F. et al. Contact Resistance and Megahertz Operation of Aggressively Scaled Organic Transistors. Small 8, 73–79 (2012).

Greiner, M. T., Chai, L., Helander, M. G., Tang, W. M. & Lu, Z. H. Metal/Metal-Oxide Interfaces: How Metal Contacts Affect the Work Function and Band Structure of MoO3. Adv. Func. Mater. 23, 215–226 (2013).

Xu, Y. et al. Joule’s law for organic transistors exploration: Case of contact resistance. Journal of Applied Physics 113, 064507-064507-064505 (2013).

Gelinck, G., Heremans, P., Nomoto, K. & Anthopoulos, T. D. Organic Transistors in Optical Displays and Microelectronic Applications. Adv. Mater. 22, 3778–3798 (2010).

Guo, Y. L., Yu, G. & Liu, Y. Q. Functional Organic Field-Effect Transistors. Adv. Mater. 22, 4427–4447 (2010).

Dong, H. L., Jiang, L. & Hu, W. P. Interface engineering for high-performance organic field-effect transistors. Physical Chemistry Chemical Physics 14, 14165–14180 (2012).

Zhou, Y. H. et al. A Universal Method to Produce Low-Work Function Electrodes for Organic Electronics. Science 336, 327–332 (2012).

Greiner, M. T. et al. Universal energy-level alignment of molecules on metal oxides. Nature Materials 11, 76–81 (2012).

Marinkovic, M., Belaineh, D., Wagner, V. & Knipp, D. On the origin of contact resistances of organic thin film transistors. Adv Mater 24, 4005–4009 (2012).

Paasch, G. & Scheinert, S. Space charge layers in organic field-effect transistors with Gaussian or exponential semiconductor density of states. Journal of Applied Physics 101 (2007).

Khim, D. et al. Control of Ambipolar and Unipolar Transport in Organic Transistors by Selective Inkjet-Printed Chemical Doping for High Performance Complementary Circuits. Advacned Functional Materials 24, 6252–6261 (2014).

Zhao, N. et al. Polaron Localization at Interfaces in High-Mobility Microcrystalline Conjugated Polymers. Adv. Mater. 21, 3759–3763 (2009).

Troisi, A. & Orlandi, G. Charge-transport regime of crystalline organic semiconductors: Diffusion limited by thermal off-diagonal electronic disorder. Physical Review Letters 96, 086601 (2006).

Sze, S. M. Physics of Semiconductor Devices. 2nd Edition edn, (JOHN WILEY&SONS, Inc., 1981).

Ng, T. N., Silveira, W. R. & Marohn, J. A. Dependence of charge injection on temperature, electric field, and energetic disorder in an organic semiconductor. Physical Review Letters 98, 066101 (2007).

Emtage, P. & O’Dwyer, J. Richardson-Schottky effect in insulators. Physical review letters 16, 356 (1966).

Scott, J. C. & Malliaras, G. G. Charge injection and recombination at the metal-organic interface. Chem. Phys. Lett. 299, 115–119 (1999).

Shen, Y. L., Klein, M. W., Jacobs, D. B., Scott, J. C. & Malliaras, G. G. Mobility-Dependent Charge Injection into an Organic Semiconductor. Physical Review Letters 86, 3867–3870 (2001).

Imakawa, M., Sawabe, K., Yomogida, Y., Iwasa, Y. & Takenobu, T. Extraction of the contact resistance from the saturation region of rubrene single-crystal transistors. Appl. Phys. Lett. 99, 233301 (2011).

Liu, C. et al. Direct and quantitative understanding of the non-Ohmic contact resistance in organic and oxide thin-film transistors. Organic electronics 27, 253–258 (2015).

Liu, C. et al. Effect of Doping Concentration on Microstructure of Conjugated Polymers and Characteristics in N‐Type Polymer Field‐Effect Transistors. Adv. Func. Mater. 25, 758–767 (2015).

Long, D. X. et al. Solution processed vanadium pentoxide as charge injection layer in polymer field-effect transistor with Mo electrodes. Organic Electronics 17, 66–76 (2015).

Kim, N.-K. et al. Solution-Processed Barium Salts as Charge Injection Layers for High Performance N-Channel Organic Field-Effect Transistors. ACS applied materials & interfaces 6, 9614–9621 (2014).

Minari, T. et al. Highly Enhanced Charge Injection in Thienoacene-Based Organic Field-Effect Transistors with Chemically Doped Contact. Appl. Phys. Lett. 100, 093303 (2012).

Khim, D. et al. Large Enhancement of Carrier Transport in Solution‐Processed Field‐Effect Transistors by Fluorinated Dielectric Engineering. Adv. Mater. 28, 518–526 (2016).

Van der Holst, J., Van Oost, F., Coehoorn, R. & Bobbert, P. Electron-hole recombination in disordered organic semiconductors: Validity of the Langevin formula. Physical Review B 80, 235202 (2009).

Juška, G., Genevičius, K., Nekrašas, N., Sliaužys, G. & Österbacka, R. Two dimensional Langevin recombination in regioregular poly (3-hexylthiophe ne). Appl. Phys. Lett. 95, 013303 (2009).

Kuik, M., Koster, L., Wetzelaer, G. & Blom, P. Trap-assisted recombination in disordered organic semiconductors. Physical review letters 107, 256805 (2011).

Long, D. X., Xu, Y., Wei, H.-x., Liu, C. & Noh, Y.-Y. Controlling charge injection properties in polymer field-effect transistors by incorporation of solution processed molybdenum trioxide. Physical Chemistry Chemical Physics 17, 20160–20167 (2015).

Acknowledgements

The authors gratefully acknowledge the financial support of the project from National Natural Science Foundation of China (61504173), Guangdong Provincial Department of Science and Technology (2015B090924001), and Shunde Government (Contract No. 20140401), China. This work was also supported by the Center for Advanced Soft Electronics (2013M3A6A5073183) funded by the Ministry of Science, ICT, & Future Planning and a National Research Foundation of Korea (NRF) grant funded by the Korean Government (MSIP) (NRF-2014R1A2A2A01007159). CL & YYN thank to Nam-Koo Kim for supplying a few device results.

Author information

Authors and Affiliations

Contributions

C.L. and Y.Y.N. designed the research. C.L. performed theoretical calculations; C.L., G.H., Y.X., D.X.L., W.T.P., X.L. and T.M. performed experiments and analysed the results. C.L. and Y.Y.N. wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Liu, C., Huseynova, G., Xu, Y. et al. Universal diffusion-limited injection and the hook effect in organic thin-film transistors. Sci Rep 6, 29811 (2016). https://doi.org/10.1038/srep29811

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep29811

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.