Abstract

A series of β-NaLuF4 crystals were synthesized via a hydrothermal method. Hexagonal phase microdisks, microprisms, and microtubes were achieved by simply changing the amount of citric acid in the initial reaction solution. Pure red upconversion (UC) luminescence can be observed in β-NaLuF4:Yb3+, Tm3+, Er3+ and Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+. Based on the rate equations, we report the theoretical model about the pure red UC mechanism in Yb3+/Tm3+/Er3+ doped system. It is proposed that the pure red UC luminescence is mainly ascribed to the energy transfer UC from Tm3+:3F4 → 3H6 to Er3+:4I11/2 → 4F9/2 and the cross-relaxation (CR) effect [Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2] rather than the long-accepted mechanism [CR process among Er3+:4F7/2 + 4I11/2 → 4F9/2 + 4F9/2]. In addition, compared to the Li+-free counterpart, the pure red UC luminescence in β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ with 15 mol% Li+ doping is enhanced by 13.7 times. This study provides a general and effective approach to obtain intense pure red UC luminescence, which can be applied to other synthetic strategies.

Similar content being viewed by others

Introduction

Recently, lanthanide (Ln) doped upconversion (UC) materials have aroused extensive attention because of their potential applications in fields such as flat-panel displays, therapeutics, photovoltaics, and biological imaging1,2,3,4,5,6,7,8,9. Their advantages include long luminescence lifetimes, low toxicity and high photochemical stability10,11,12,13,14, which make them more desirable than conventional fluorescent materials. As an important fluoride, β-NaLuF4 has excellent UC luminescence due to its high refractive index, low phonon energy, and high thermal stability, which has attracted significant interest15,16,17,18. In contrast to green and blue light, red light (600–700 nm) can deeply penetrate biotissues owing to the lack of efficient endogenous absorbers19,20,21. Consequently, a strategy to achieve high purity of red UC luminescence will be useful for UC applications, especially for biological imaging. As is known, UC materials usually display multipeak emissions due to Ln ions have more than one metastable excited state19. Thus, avoiding the blue and green emissions and boosting the red emission are needed to obtain high pure red UC luminescence. For instance, Tan et al. reported the pure red UC emission in NaYbF4 nanocrystals doping with high Er3+ content22. Chan et al. revealed a UC mechanism in which energy transfer (ET) from Tm3+:3F4 → 3H6 to Er3+:4I11/2 → 4F9/2, leading to the population of red-emitting manifold (Er3+:4F9/2)23. Therefore, it can be concluded that high-content doping of Er3+ and low-content doping of Tm3+ can induce a tremendous increase in the red to green ratio (RGR) and ultimately pure red UC luminescence. There are three common cross-relaxation (CR) processes among Er3+ that account for the enhancement of RGR in Yb3+/Er3+ codoped system. The first CR effect is the long-accepted and most popular mechanism22,24,25,26. According to Capobianco et al.’s report26, the enhanced red UC emission was obtained owing to a CR process [Er3+:4F7/2 + 4I11/2 → 4F9/2 + 4F9/2], which directly populates the 4F9/2 state. The second CR effect was proposed by Gao et al.27, which was derived from Er3+:4S3/2 + 4I13/2 → 4F9/2 + 4I11/2, resulting in the promotion of red emission and quenching of green emission. The third CR effect was proposed by Salas et al.28, they reported that the increased red UC luminescence mainly comes from the CR process [Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2], and subsequently energy transfer UC (ETU) process [I13/2 (Er3+) + 2F5/2 (Yb3+) → 4F9/2 (Er3+) + 2F7/2 (Yb3+)]. However, there is no theoretical model about the pure red UC mechanism in Yb3+/Tm3+/Er3+ doped system. Besides, compared to traditional phosphors, the main drawback of UC materials is their low UC luminescence efficiency. It is still a challenge to obtain the intense pure red UC luminescence, and an effective method to enhance the pure red UC emission is urgently needed. It has been proved that the doping of Li+ can greatly increase the UC luminescence intensity29,30,31. As is known, Li+ can be easily doped into the host lattice substitutionally or interstitially owing to its small ionic radius, which would reduce the symmetry of crystal field around Ln ions, inducing the enhancement of UC emission intensity. However, there is no report on the increase of pure red UC luminescence by introducing Li+ in β-NaLuF4:Yb3+, Tm3+, Er3+.

As a typical solution-based approach, the hydrothermal method has been widely applied to synthesize inorganic materials with controllable structures and morphologies32,33. During the hydrothermal treatment, a series of external parameters such as the pH value, citrate ions (Cit3−) content, NaF content, reaction time and temperature may have significant effects on the morphology evolution of particles18,34,35,36. In particular, the addition of chelating agent has a great impact on the kinetics of crystal growth37,38. Cit3− as a shape modifier plays a critical role in the shape evolution of the final products due to its high thermal stability and ability to form complexes with other metal ions39,40,41.

In this article, a series of β-NaLuF4 crystals were prepared via a hydrothermal method using citric acid as a chelating agent, and their pure red UC luminescence were studied. Hexagonal phase microdisks, microprisms, and microtubes were achieved by simply changing the amount of citric acid in the initial reaction solution. Importantly, pure red UC luminescence can be observed in β-NaLuF4:Yb3+, Tm3+, Er3+ and Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+. Based on the rate equations, the theoretical model about the pure red UC mechanism in Yb3+/Tm3+/Er3+ doped system is presented. The red UC emission of 660 nm in Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ is greatly increased compared to the Li+-free sample under 980 nm excitation at room temperature.

Results and Discussion

Morphology evolution of β-NaLuF4 crystals

Citric acid has been regarded as one of the most effective chelating agents because of its ability to regulate the morphology and dimension of the samples in the hydrothermal process42. In the present system, citric acid also plays a critical role in the morphology evolution of β-NaLuF4 crystals. Figure 1 shows the XRD patterns of the as-prepared β-NaLuF4 samples with different citric acid contents from 2 to 8 mmol. As can be seen, all the diffraction peaks can be well indexed to pure β-NaLuF4, which is consistent with the standard card (JCPDS 27-0726). No other impurity peaks are detected, indicating the high purity of β-NaLuF4 samples. It is worth to note that the relative intensities of (100), (110), (101) and (201) peaks display some differences from each other, implying the existence of oriented growth under different Cit3− contents. The above XRD results are supported by the corresponding SEM images, as exhibited in Fig. 2. When the adding citric acid is 2 mmol (Fig. 2a), regular hexagonal phase microdisks with an average size of 0.79 μm in height and 7.58 μm in diameter are obtained. As the citric acid content increases to 3 mmol (Fig. 2b), short hexagonal phase microprisms with uniformity and smooth surfaces are achieved. The mean height and diameter of the prisms are 2.12 μm and 8.51 μm, respectively. Further increasing the citric acid content to 8 mmol, hexagonal phase microtubes with hollow structure are presented in Fig. 2c. The tubes have an average height of 9.47 μm and an average diameter of 1.88 μm. The ratios of height to diameter (H/D ratios) are calculated to be about 0.10, 0.25, and 5.04 when the adding citric acid is 2, 3, and 8 mmol. From the above analysis, it can be concluded that the H/D ratio is increased as the citric acid content increases from 2 to 8 mmol. Based on the high anisotropic structure of β-NaLuF443, when the adding citric acid increases from 2 to 8 mmol, Cit3− absorbs onto the {0001} facets more strongly than the  facets. Thus, the growth rate along [0001] direction is faster than that along

facets. Thus, the growth rate along [0001] direction is faster than that along  direction, resulting in the morphology evolution from disks to tubes and the enhancement of H/D ratio. The hollow structure of the tubes is generated owing to the growth rate at the center is lower than that at the edges44. The corresponding schematic diagrams of β-NaLuF4 crystals under different citric acid contents are displayed in Fig. 2(d–f).

direction, resulting in the morphology evolution from disks to tubes and the enhancement of H/D ratio. The hollow structure of the tubes is generated owing to the growth rate at the center is lower than that at the edges44. The corresponding schematic diagrams of β-NaLuF4 crystals under different citric acid contents are displayed in Fig. 2(d–f).

Pure red UC mechanism of β-NaLuF4:Yb3+, Tm3+, Er3+ crystals

A series of β-NaLuF4:Yb3+, Tm3+, Er3+ crystals were synthesized by adding 3 mmol citric acid. Figure 3 shows the UC emission spectra (normalized to Er3+ 540 nm emission) of (a) β-NaLuF4:20% Yb/xEr, (b) β-NaLuF4:20% Yb/0.5% Tm/xEr, and (c) β-NaLuF4:20% Yb/1% Tm/xEr (x = 0.5, 2, 5, 10, 20%) under 980 nm excitation at room temperature. Green emissions at around 520/540 nm correspond to the transitions of Er3+:2H11/2/4S3/2 → 4I15/2. Red emissions at approximately 660 nm and 696 nm are attributed to the transition of Er3+:4F9/2 → 4I15/2 and the transition of Tm3+:3F3 → 3H6, respectively. As can be seen, compared with Tm3+-free group [Fig. 3(a)], the RGR is greatly increased in 0.5% Tm3+-group [Fig. 3(b)] and 1% Tm3+-group [Fig. 3(c)]. The maximum RGR is observed in 0.5% Tm3+ and 1% Tm3+-groups doped with 20 mol% Er3+. From the insets of Fig. 3(a–c) and Table 1, it can be clearly seen that the RGR is almost unchanged in Tm3+-free group while dramatically enhanced in 0.5% Tm3+ and 1% Tm3+-groups with the increase of Er3+ dopant content. The RGR in 0.5% Tm3+ (R/G = 43.7) and 1% Tm3+ (R/G = 49.3)-groups with 20% Er3+ doping are increased by 26 and 19 times compared to their 0.5% Er3+ doping (R/G = 1.66, 2.57). Consequently, low-content doping of Tm3+ and high-content doping of Er3+ induce great enhancement in the RGR. Figure 4 shows the pump power dependence of green and red UC emissions in 0.5% Tm3+ and 1% Tm3+-groups with 0.5%, 5% and 20% Er3+ doping under 980 nm excitation. According to the formula45: Iuc ∝ Pn, where Iuc is the output UC emission intensity, P is the infrared excitation power, n is the absorbed laser photon number when emitting an UC photon. As shown in Fig. 4(a,c), the slopes of green emission (Er3+:2H11/2/4S3/2 → 4I15/2) are 1.23, 1.40, and 1.72 in β-NaLuF4:20% Yb/0.5% Tm/xEr; 1.15, 1.53, and 1.61 in β-NaLuF4:20% Yb/1% Tm/xEr (x = 0.5, 5, 20%). The slopes of red emission (Er3+:4F9/2 → 4I15/2) are 1.22, 1.10, and 0.64 in 0.5% Tm3+-group; 1.27, 1.16, and 1.08 in 1% Tm3+-group with 0.5%, 5% and 20% Er3+ doping. On the basis of the above analysis, it can be concluded that green emission varies from one-photon process to two-photon processes, and red emission (660 nm) keeps one-photon process in 0.5% Tm3+ and 1% Tm3+-groups.

In this paper, we built a theoretical model to have a deep understanding of the ET process in Yb3+/Tm3+/Er3+ doped system. We supposed 4F7/2, 2H11/2, and 4S3/2 energy levels as a same level. When the Yb3+/Tm3+/Er3+ system doped with low Er3+ content, CR effect between Er3+ can be neglected. The corresponding rate equations are as follows:

N0, N1, N2, N2′, N3, N4, M0, M1, NYb0 and NYb1 are the population densities of the Er3+ 4I15/2, 4I13/2, 4I11/2, 4I9/2, 4F9/2, 4S3/2/2H11/2/4F7/2, Tm3+ 3H6, 3F4, Yb3+ 2F7/2 and 2F5/2 levels, respectively. ω0, ω1, ω2, ω3, and ω4 correspond to the ET rates of 2F5/2 + 4I15/2 → 2F7/2 + 4I11/2 (ET1), 2F5/2 + 4I13/2 → 2F7/2 + 4F9/2 (ET2), 2F5/2 + 4I11/2 → 2F7/2 + 4F7/2 (ET3), 4S3/2 + 3H6 → 4I9/2 + 3F4 (ET4), and 3F4 + 4I11/2 → 3H6 + 4F9/2 (ET5), respectively. ω21, ω2′2, and ω43 are multiphonon relaxation (MPR) rates from Er3+:4I11/2 → 4I13/2, 4I9/2 → 4I11/2, and 4F7/2 → 4F9/2, respectively. A3 and A4 are the spontaneous radiative probabilities of Er3+ 4F9/2 and 4S3/2/2H11/2 levels, respectively. As presented in Fig. 5, the Er3+ 4F7/2 level is populated through the ET1 + ET3 processes. Then green UC emission is generated by the MPR processes of Er3+:4F7/2 → 4S3/2/2H11/2 levels. For red UC emission (660 nm), the Er3+ 4F9/2 level is populated in two ways: (a) the MPR from Er3+ 4F7/2 level, (b) the ET4+ET5 processes. In consideration of the high Yb3+ content, many radiative and nonradiative processes can be ignored, such as the back ET process from Er3+ to Yb3+ (4I11/2 + 2F7/2 → 4I15/2 + 2F5/2), MPR processes, N1, N2 radiative emissions and so on. Under steady-state condition, the rate equations can be acquired as follows:

The mechanism involves the ETU from Tm3+ to Er3+23.

The population density of Yb3+ 2F5/2 can be described as follows46:

where σ is the absorption cross-section of Yb3+ 2F5/2 level, ρ is the pump rate of near-infrared (NIR) laser. Under steady-state condition, we get

By solving the above equations, we have

As can be seen from Equations (1) and (2), both red-emitting manifold N3 and green-emitting manifold N4 have linear relationships with pump power at low Er3+ dose, which are in good agreement with the experimental results shown in Fig. 4.

When the Yb3+/Tm3+/Er3+ system doped with high Er3+ dose, pure red UC luminescence can be obtained. As is known, CR is dependent on the distance among activators46. The average distance between Er3+ reduces with the increase of Er3+ dopant dose, which would result in the enhancement of CR effect. Thus, the CR process among Er3+ plays an important role in the achievement of pure red UC luminescence. There are generally three CR processes between Er3+ that account for the increase of RGR (has been described in the section of “Introduction”), as displayed in Fig. 6. Additionally, the ET4+ET5 processes between Tm3+ and Er3+ also make a significant contribution to the high RGR. In the following sections, the above three CR effects are discussed systematically. As the Yb3+/Tm3+/Er3+ system doped with high Er3+ content, green UC emission can be neglected, and red UC emission (660 nm) mainly comes from two ways: (a) the CR effect among Er3+; (b) the ETU from Tm3+ to Er3+.

Theoretical model for the first CR effect

The corresponding rate equations are as follows:

ωC1 is the CR rate for [Er3+:4F7/2 + 4I11/2 → 4F9/2 + 4F9/2 (CR1)]. CR1 is the long-accepted and most popular mechanism to account for the enhancement of RGR in Yb3+/Er3+ codoped system22,24,25,26. By solving the equations under steady-state excitation, we get

As can be seen from Equation (5), the green-emitting level N4 does not have quasi-quadratic relationship with pump power, which is not corresponding to Fig. 4(a,c) where n are 1.72 and 1.61 in 0.5% Tm3+ and 1% Tm3+-groups at high content (20 mol%) of Er3+ doping, indicating CR1 is not suitable for explaining the experimental results. Consequently, CR1 has nothing to do with the increase of red emission (660 nm) at high Er3+ content in Yb3+/Tm3+/Er3+ doped system.

Theoretical model for the second CR effect

The corresponding rate equations are as follows:

ωC2 is the CR rate for [Er3+:4S3/2 + 4I13/2 → 4F9/2 + 4I11/2 (CR2)]. By solving the equations under steady-state condition, we have

As can be seen from Equations (7) and (8), red-emitting manifold N3 and green-emitting manifold N4 have linear and quasi-quadratic relationships with pump power at high Er3+ content, which correspond to the relevant results in Fig. 4. The power dependence of RGR for β-NaLuF4:20% Yb/1% Tm/20% Er is exhibited in Fig. 7(a). It can be clearly seen that the RGR is decreased with the increase of pump power. The ratio of N3 to N4 shows the inverse proportional relationship to pump power [Equation (9)], which is in accordance with the result in Fig. 7(a). From the above analysis, it can be deduced that CR2 maybe makes a contribution to the high RGR when the Yb3+/Tm3+/Er3+ system doped with high Er3+ dose.

Theoretical model for the third CR effect

The corresponding rate equations are as follows:

ωC3 is the CR rate for [Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2 (CR3)], and red UC emission (660 nm) is obtained by the subsequent ETU process [I13/2 (Er3+) + 2F5/2 (Yb3+) → 4F9/2 (Er3+) + 2F7/2 (Yb3+)]. By solving the equations under steady-state condition, we get

As can be seen from Equation (10), red-emitting level N3 ~ aρ + bρ2, which is corresponding to the relevant results in Fig. 4(b,d) when we suppose the parameter “b” is close to zero. Equations (11) and (12) show the green-emitting manifold N4 and ratio of N3 to N4 have quasi-quadratic and inverse proportional relationships with pump power, which are in good agreement with the results shown in Figs 4(a,c) and 7(a), respectively. Thus, CR3 can be used to explain the experimental results.

On the basis of the above analysis, it can be concluded that both CR2 and CR3 maybe are the appropriate ET mechanisms for the achievement of pure red UC luminescence at high Er3+ content in Yb3+/Tm3+/Er3+ doped system. According to our experimental results, there are three reasons to prove that CR3 (Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2) is the main CR effect for the population process of 4F9/2 manifold. First, the ratio of NIR to green (NGR) is enhanced with the increase of Er3+ content in β-NaLuF4:20% Yb/1% Tm/xEr (NIR emission corresponds to the 4I13/2 → 4I15/2 transition of Er3+), as presented in Fig. 7(b). The increasing NGR indicates that the population of Er3+ 4I13/2 level becomes larger and larger compared to Er3+ 4S3/2/2H11/2 levels. As is known, the probability of MPR from 4I11/2 to 4I13/2 is quite low due to the low phonon energy in our system. Thus, the increasing NGR is mainly ascribed to CR3. Second, the decay curves of the 4I13/2 → 4I15/2 transition of Er3+ in β-NaLuF4:20% Yb/1% Tm/0.5% Er and β-NaLuF4:20% Yb/1% Tm/20% Er are shown in Fig. 8. The decay lifetime was calculated based on the function:  , where I(t) is the emission intensity at time t, and IP is the peak intensity in the decay curve. The calculation results show that τ0.5% Er = 1.40 ms and τ20% Er = 0.55 ms. The energy transfer efficiency (ETE) can be evaluated by the following expression: ηETE = 1 − τ20% Er/τ0.5% Er, the calculation result shows that ηETE = 60.71%. With the increase of Er3+ dose, the enhanced red UC emission (660 nm) mainly comes from the enhancement of CR effect between Er3+ in Yb3+/Tm3+/Er3+ doped system. Thus, it is reasonable to consider that the probability of CR3 is 60.71%. Third, the ET process of CR2 (Er3+:4S3/2 + 4I13/2 → 4F9/2 + 4I11/2) needs the population process of Er3+ 4I13/2 manifold, which is mainly dependent on the ET process of CR3 (Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2). Therefore, the CR3 process is required before the CR2 process, resulting in the leading role of CR3 in the CR effects.

, where I(t) is the emission intensity at time t, and IP is the peak intensity in the decay curve. The calculation results show that τ0.5% Er = 1.40 ms and τ20% Er = 0.55 ms. The energy transfer efficiency (ETE) can be evaluated by the following expression: ηETE = 1 − τ20% Er/τ0.5% Er, the calculation result shows that ηETE = 60.71%. With the increase of Er3+ dose, the enhanced red UC emission (660 nm) mainly comes from the enhancement of CR effect between Er3+ in Yb3+/Tm3+/Er3+ doped system. Thus, it is reasonable to consider that the probability of CR3 is 60.71%. Third, the ET process of CR2 (Er3+:4S3/2 + 4I13/2 → 4F9/2 + 4I11/2) needs the population process of Er3+ 4I13/2 manifold, which is mainly dependent on the ET process of CR3 (Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2). Therefore, the CR3 process is required before the CR2 process, resulting in the leading role of CR3 in the CR effects.

It can be concluded that the pure red UC luminescence is mainly ascribed to the ETU from Tm3+:3F4 → 3H6 to Er3+:4I11/2 → 4F9/2 and the CR effect [Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2 (CR3)] rather than the long-accepted and most popular mechanism (CR1 process among Er3+:4F7/2 + 4I11/2 → 4F9/2 + 4F9/2).

Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ crystals

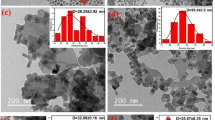

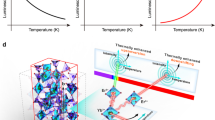

A series of Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ crystals were synthesized by adding 3 mmol citric acid. Figure 9 presents the XRD patterns (a) and the main diffraction peak (b) of different Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ crystals. As shown in Fig. 9(a), all the diffraction peaks of the products can be indexed as pure β-NaLuF4 (JCPDS 27-0726) even the Li+ concentration increases up to 20 mol%, indicating that Li+ doping has no influence on the crystal structure of the products. The corresponding UC emission spectra of the products under 980 nm excitation are shown in Fig. 10. As can be seen, the pure red UC luminescence is greatly enhanced after Li+ doping. Compared to the Li+-free sample, the pure red UC luminescence in β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ with 15 mol% Li+ doping is increased by 13.7 times. This phenomenon is mainly caused by the asymmetric surrounding environment around Ln ions after Li+ doping. Figure 9(b) exhibits that the main diffraction peak moves to the larger angles when the Li+ concentration is from 0 to 15 mol%, whereas shifts in reverse as the Li+ concentration increases up to 20 mol%. According to Bragg’s law 2dsinθ = nλ, where d represents the interplanar distance, θ represents the diffraction angle, and λ represents the diffraction wavelength. When d decreases, θ increases; when d increases, θ decreases. As is displayed in Fig. 11(a), Na+ and Ln3+ occupy the same lattice site in β-NaLuF4 lattice. When the Li+ is introduced into the host lattice, it can replace Na+ (d decreases, θ increases, 0 < Li+ concentration ≤15 mol%) [Fig. 11(b)] or occupy the interstitial site (d increases, θ decreases, 15 < Li+ concentration ≤20 mol%) [Fig. 11(c)] due to its small ionic radius, leading to the contraction or expansion of unit cell. Both the contraction and expansion of unit cell would reduce the symmetry of crystal field around Ln ions, inducing the sharp increase of pure red UC luminescence intensity29,30,31. The strongest UC luminescence intensity is acquired in β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ with 15 mol% Li+ doping, which is attributed to the most asymmetric surrounding environment around Ln ions, as shown in Fig. 9(b).

Conclusion

In summary, hexagonal phase microdisks, microprisms, and microtubes were achieved by simply changing the amount of citric acid in the initial reaction solution. Pure red UC luminescence can be observed in β-NaLuF4:Yb3+, Tm3+, Er3+ and Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+. We prove that the low-content doping of Tm3+ and high-content doping of Er3+ induce great enhancement in the RGR. The RGR in 0.5% Tm3+ (R/G = 43.7) and 1% Tm3+ (R/G = 49.3)-groups with 20% Er3+ doping are increased by 26 and 19 times compared to their 0.5% Er3+ doping (R/G = 1.66, 2.57). Green emission varies from one-photon process to two-photon processes, and red emission (660 nm) keeps one-photon process in 0.5% Tm3+ and 1% Tm3+-groups. Based on the rate equations, we report the theoretical model about the pure red UC mechanism in Yb3+/Tm3+/Er3+ doped system. It is proposed that the pure red UC luminescence is mainly ascribed to the ETU from Tm3+:3F4 → 3H6 to Er3+:4I11/2 → 4F9/2 and the CR effect [Er3+:4S3/2 + 4I15/2 → 4I9/2 + 4I13/2 (CR3)] rather than the long-accepted and most popular mechanism (CR1 process among Er3+:4F7/2 + 4I11/2 → 4F9/2 + 4F9/2). Additionally, compared to the Li+-free sample, the pure red UC luminescence in β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ with 15 mol% Li+ doping is enhanced by 13.7 times. The results suggest that the enhanced pure red UC luminescence in Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ may have potential applications in flat-panel displays, solid-state lasers and light-emitting diodes. Besides, this study provides a general and effective approach to obtain intense pure red UC luminescence, which can be applied to other synthetic strategies to prepare many types of nanocrystals with high purity of red UC luminescence, making it suitable for the future bioapplications.

Methods

Chemicals

All of the chemicals are of analytical grade and used as received without further purification. 1 M of Lu(NO3)3, 0.5 M of Yb(NO3)3, 0.1 M of Er(NO3)3, and 0.1 M of Tm(NO3)3 stock solutions were prepared by dissolving the corresponding rare earth oxide (99.99%) in dilute nitric acid (30%) at elevated temperature.

Preparation

A series of β-NaLuF4 crystals with different morphologies were synthesized via a hydrothermal method using citric acid as a chelating agent. In a typical procedure, (2 mmol/3 mmol/8 mmol) of citric acid (2 M, 1 mL/1.5 mL/4 mL), 5 mmol of NaOH (4 M, 1.25 mL) and 10 mL of deionized water were mixed and stirred for 10 min. Then 1 mmol of Ln(NO3)3 [1 mmol of Lu(NO3)3 (1 M, 1 mL)] was added to the above mixture and then stirred for 30 min to form the RE-Cit3− complex. Subsequently, an aqueous solution containing 8 mmol of NaF (1 M, 8 mL) and (9 mL/8.5 mL/6 mL) of deionized water was added into the chelated RE-Cit3- complex to form a colloidal suspension and kept stirring for another 30 min. Finally, the suspension was transferred into a 50 mL-Teflon vessel, sealed in an autoclave and maintained at 200 °C for 10 h before cooling down naturally. The final products were separated by centrifugation, washed several times with ethanol and deionized water, then dried in air at 60 °C for 12 h. β-NaLuF4: 20% Yb3+, (0%/0.5%/1%)Tm3+, (0.5%/2%/5%/10%/20%)Er3+ crystals and (8%/15%/20%)Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ crystals were prepared by a similar process (Cit3− = 3 mmol) under the same experimental conditions. In particular, as for (8%/15%/20%)Li+ doped β-NaLuF4:20% Yb3+, 1% Tm3+, 20% Er3+ crystals, after the formation of RE-Cit3− complex, a mixture containing (0.64 mmol/1.2 mmol/1.6 mmol) of LiNO3 (1 M, 0.64 mL/1.2 mL/1.6 mL), (7.36 mmol/6.8 mmol/6.4 mmol) of NaF (1 M, 7.36 mL/6.8 mL/6.4 mL), (0.32 mmol/0.6 mmol/0.8 mmol) of NH4HF2 (1 M, 0.32 mL/0.6 mL/0.8 mL) and (6 mL/5.5 mL/5.5 mL) of deionized water were added into the chelated RE-Cit3− complex to form the colloidal suspension.

Characterization

The phase and structure of the as-prepared products were confirmed by powder X-ray diffraction (XRD) patterns using the D-Max 2200VPC XRD from Rigaku Company. Morphologies and grain sizes were verified by using an Oxford Quanta 400F Thermal Field Emission environmental Scanning Electronic Microscope (SEM). UC photoluminescence spectra were acquired on the Edinburgh Instrument FLSP920 steady-state fluorescence spectrometer equipped with a 2 W 980 nm laser diode. The spot size of the 980 nm laser on the samples is about 0.05 cm2.

Additional Information

How to cite this article: Lin, H. et al. Morphology evolution and pure red upconversion mechanism of β-NaLuF4 crystals. Sci. Rep. 6, 28051; doi: 10.1038/srep28051 (2016).

References

Shalav, A., Richards, B. S., Trupke, T., Krämer, K. W. & Güdel, H. U. Application of NaYF4:Er3+ up-converting phosphors for enhanced near-infrared silicon solar cell response. Appl Phys Lett 86, 013505–3 (2005).

Das, G. K. et al. Gadolinium oxide ultranarrow nanorods as multimodal contrast agents for optical and magnetic resonance imaging. Langmuir 26, 8959–8965 (2010).

Wang, F. & Liu, X. G. Recent advances in the chemistry of lanthanide-doped upconversion nanocrystals. Chem Soc Rev 38, 976–989 (2009).

Idris, N. M. et al. Tracking transplanted cells in live animal using upconversion fluorescent nanoparticles. Biomaterials 30, 5104–5113 (2009).

Ding, M. et al. Simultaneous morphology manipulation and upconversion luminescence enhancement of β-NaYF4:Yb3+/Er3+ microcrystals by simply tuning the KF dosage. Sci Rep 5, 12745, doi: 10.1038/srep12745 (2015).

Wang, C. Y. & Cheng, X. H. Controlled hydrothermal growth and tunable luminescence properties of β-NaYF4:Yb3+/Er3+ microcrystals. J Alloys Compd 617, 807–815 (2014).

Liao, J. et al. Preparation and upconversion emission modification of crystalline colloidal arrays and rare earth fluoride microcrystal composites. Sci Rep 5, 7636, doi: 10.1038/srep07636 (2015).

Han, S. Y., Deng, R. R., Xie, X. J. & Liu, X. G. Enhancing luminescence in lanthanide-doped upconversion nanoparticles. Angew Chem Int Ed 53, 2–16 (2014).

Huang, F. et al. Origin of near to middle infrared luminescence and energy transfer process of Er3+/Yb3+ co-doped fluorotellurite glasses under different excitations. Sci Rep 5, 8233, doi: 10.1038/srep08233 (2015).

Zhang, F. et al. Fabrication of Ag@SiO2@Y2O3:Er nanostructures for bioimaging: tuning of the upconversion fluorescence with silver nanoparticles. J Am Chem Soc 132, 2850–2851 (2010).

Zhang, F. & Wong, S. S. Ambient large-scale template-mediated synthesis of high-aspect ratio single-crystalline, chemically doped rare-earth phosphate nanowires for bioimaging. ACS Nano 4, 99–112 (2010).

Li, Z. Q. & Zhang, Y. Monodisperse silica-coated polyvinylpyrrolidone/NaYF4 nanocrystals with multicolor upconversion fluorescence emission. Angew Chem Int Ed 45, 7732–7735 (2006).

Cheng, L. et al. Facile preparation of multifunctional upconversion nanoprobes for multimodal imaging and dual-targeted photothermal therapy. Angew Chem 123, 7523–7528 (2011).

Yi, G. S. & Chow, G. M. Water-soluble NaYF4:Yb, Er(Tm)/NaYF4/polymer core/shell/shell nanoparticles with significant enhancement of upconversion fluorescence. Chem Mater 19, 341–343 (2007).

Niu, N. et al. Hierarchical bundles structure of β-NaLuF4: facile synthesis, shape evolution, and luminescent properties. RSC Adv 2, 10337–10344 (2012).

He, F. et al. Morphology-controllable synthesis and enhanced luminescence properties of β-NaLuF4: Ln (Ln = Eu, Tb and Ce/Tb) microcrystals by solvothermal process. RSC Adv 2, 7569–7577 (2012).

Desiraju, G. R. Polymorphism: the same and not quite the same. Cryst Growth Des 8, 3–5 (2008).

Gao, Y., Zhao, Q., Xu, Z. H. & Sun, Y. G. Hydrothermally derived NaLuF4:Yb3+, Ln3+ (Ln3+ = Er3+, Tm3+ and Ho3+) microstructures with controllable synthesis, morphology evolution and multicolor luminescence properties. New J Chem 38, 2629–2638 (2014).

Wang, J., Wang, F., Wang, C., Liu, Z. & Liu, X. G. Single-band upconversion emission in lanthanide-doped KMnF3 nanocrystals. Angew Chem Int Ed 50, 10369–10372 (2011).

Tian, G. et al. Mn2+ dopant-controlled synthesis of NaYF4:Yb/Er upconversion nanoparticles for in vivo imaging and drug delivery. Adv Mater 24, 1226–1231 (2012).

Zeng, S. J. et al. Simultaneous realization of phase/size manipulation, upconversion luminescence enhancement, and blood vessel imaging in multifunctional nanoprobes through transition metal Mn2+ doping. Adv Funct Mater 24, 4051–4059 (2014).

Wei, W. et al. Cross relaxation induced pure red upconversion in activator- and sensitizer-rich lanthanide nanoparticles. Chem Mater 26, 5183–5186 (2014).

Chan, E. M., Gargas, D. J., Schuck, P. J. & Milliron, D. J. Concentrating and recycling energy in lanthanide codopants for efficient and spectrally pure emission: the case of NaYF4:Er3+/Tm3+ upconverting nanocrystals. J Phys Chem B 116, 10561–10570 (2012).

Su, J. et al. Phonon-assisted mechanisms and concentration dependence of Tm3+ blue upconversion luminescence in codoped NaY(WO4)2 crystals. J Phys D: Appl Phys 39, 2094–2099 (2006).

Wang, H. B., Yi, Z. G., Rao, L., Liu, H. R. & Zeng, S. J. High quality multi-functional NaErF4 nanocrystals: structure-controlled synthesis, phase-induced multi-color emissions and tunable magnetic properties. J Mater Chem C 1, 5520–5526 (2013).

Vetrone, F., Boyer, J. C., Capobianco, J. A., Speghini, A. & Bettinelli, M. Significance of Yb3+ concentration on the upconversion mechanisms in codoped Y2O3:Er3+, Yb3+ nanocrystals. J Appl Phys 96, 661–667 (2004).

Gao, D., Zhang, X., Zheng, H., Gao, W. & He, E. Yb3+/Er3+ codoped β-NaYF4 microrods: synthesis and tuning of multicolor upconversion. J Alloys Compd 554, 395–399 (2013).

Salas, P. et al. Synthesis, characterization and luminescence properties of ZrO2:Yb3+-Er3+ nanophosphor. Opt Mater 27, 1295–1300 (2005).

Zhao, C. Z. et al. Li+ ion doping: an approach for improving the crystallinity and upconversion emissions of NaYF4:Yb3+, Tm3+ nanoparticles. Nanoscale 5, 8084–8089 (2013).

Yin, W. et al. Enhanced red emission from GdF3:Yb3+, Er3+ upconversion nanocrystals by Li+ doping and their application for bioimaging. Chem Eur J 18, 9239–9245 (2012).

Cheng, Q., Sui, J. H. & Cai, W. Enhanced upconversion emission in Yb3+ and Er3+ codoped NaGdF4 nanocrystals by introducing Li+ ions. Nanoscale 4, 779–784 (2012).

Li, C. X. et al. Different microstructures of β-NaYF4 fabricated by hydrothermal process: effects of pH values and fluoride sources. Chem Mater 19, 4933–4942 (2007).

Li, C. X. et al. Shape-Controllable Synthesis and upconversion properties of lutetium fluoride (doped with Yb3+/Er3+) microcrystals by hydrothermal process. J Phys Chem C 112, 13395–13404 (2008).

Lin, H. et al. Tuning of structure and enhancement of upconversion luminescence in NaLuF4:Yb3+, Ho3+ crystals. Phys Chem Chem Phys 17, 19515–19526 (2015).

Lin, H. et al. Simultaneous realization of structure manipulation and emission enhancement in NaLuF4 upconversion crystals. J Mater Chem C 3, 11754–11765 (2015).

Lin, H. et al. Shape-controllable synthesis and enhanced upconversion luminescence of Li+ doped β-NaLuF4:Yb3+, Ln3+ (Ln = Tm, Ho) microcrystals. New J Chem 39, 2565–2572 (2015).

Sun, Y. G. & Xia, Y. N. Large-scale synthesis of uniform silver nanowires through a soft, self-seeding, polyol process. Adv Mater 14, 833–837 (2002).

Jiang, D. L. et al. Shape-controlled synthesis of F-substituted hydroxyapatite microcrystals in the presence of Na2EDTA and citric acid. J Colloid Interface Sci 350, 30–38 (2010).

Sun, Y. J., Liu, H. J., Wang, X., Kong, X. G. & Zhang, H. Optical spectroscopy and visible upconversion studies of YVO4:Er3+ nanocrystals synthesized by a hydrothermal process. Chem Mater 18, 2726–2732 (2006).

Hao, Q., Xu, L. Q., Li, G. D. & Qian, Y. T. Hydrothermal synthesis of microscaled Cu@C polyhedral composites and their sensitivity to convergent electron beams. Langmuir 25, 6363–6367 (2009).

Kim, T. U., Kim, J. A., Pawar, S. M., Moon, J. H. & Kim, J. H. Creation of nanoscale two-dimensional patterns of ZnO nanorods using laser interference lithography followed by hydrothermal synthesis at 90 °C. Cryst Growth Des 10, 4256–4261 (2010).

Chen, S. et al. Chelation-controlled compound transition of luminescent fluoride crystals. Mater Lett 106, 326–331 (2013).

Niu, N. et al. Tunable multicolor and bright white emission of one-dimensional NaLuF4:Yb3+, Ln3+ (Ln = Er, Tm, Ho, Er/Tm, Tm/Ho) microstructures. J Mater Chem 22, 10889–10899 (2012).

Wang, Y., Gai, S. L., Niu, N., He, F. & Yang, P. P. Synthesis of NaYF4 microcrystals with different morphologies and enhanced up-conversion luminescence properties. Phys Chem Chem Phys 15, 16795–16805 (2013).

Wang, F. X. et al. Upconversion and pump saturation mechanisms in Er3+/Yb3+ co-doped Y2Ti2O7 nanocrystals. J Appl Phys 115, 134310–7 (2014).

Xu, D. K., Liu, C. F., Yan, J. W., Yang, S. H. & Zhang, Y. L. Understanding energy transfer mechanisms for tunable emission of Yb3+-Er3+ codoped GdF3 nanoparticles: concentration-dependent luminescence by near-infrared and violet excitation. J Phys Chem C 119, 6852–6860 (2015).

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant No. 61176010 and No. 61172027, Guangdong Natural Science Foundation under Grant No. 2014A030311049, and the Research Foundation of IARC-SYSU under Grant No. IARC 2014-09.

Author information

Authors and Affiliations

Contributions

H.L. performed the experiments and wrote the manuscript; H.L. carried out the optical and structural characterizations of the as-synthesized samples; D.X. participated in experiment design and helpful recommendations; D.X., A.L., S.Y. and Y.Z. participated in the analysis of experimental data; All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Lin, H., Xu, D., Li, A. et al. Morphology evolution and pure red upconversion mechanism of β-NaLuF4 crystals. Sci Rep 6, 28051 (2016). https://doi.org/10.1038/srep28051

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep28051

This article is cited by

-

Assessing the reproducibility and up-scaling of the synthesis of Er,Yb-doped NaYF4-based upconverting nanoparticles and control of size, morphology, and optical properties

Scientific Reports (2023)

-

Near infrared emission properties of Er doped cubic sesquioxides in the second/third biological windows

Scientific Reports (2018)

-

Improving Optical Temperature Sensing Performance of Er3+ Doped Y2O3 Microtubes via Co-doping and Controlling Excitation Power

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.