Abstract

Decarboxylation of fatty acids over non-noble metal catalysts without added hydrogen was studied. Ni/C catalysts were prepared and exhibited excellent activity and maintenance for decarboxylation. Thereafter, the effects of nickel loading, catalyst loading, temperature and carbon number on the decarboxylation of fatty acids were investigated. The results indicate that the products of cracking increased with high nickel loading or catalyst loading. Temperature significantly impacted the conversion of stearic acid but did not influence the selectivity. The fatty acids with large carbon numbers tend to be cracked in this reaction system. Stearic acid can be completely converted at 370 °C for 5 h and the selectivity to heptadecane was around 80%.

Similar content being viewed by others

Introduction

Biofuel production research has been encouraged by the desire to displace fossil fuels and to mitigate CO2 emissions. Statistically, energy-related CO2 emissions from the transportation system has represented about 23% of the worldwide total1,2. The airline industry contributes about 2~3% of the global CO2 emissions and receives considerable attention3,4. Concern for the environment has promoted a strong incentive for the aviation industry to shift to the use of alternative fuel sources. The carbon of renewable feedstock comes from CO2 in the atmosphere by photosynthesis, which can equalize the CO2 emission from the use of renewable aviation fuels. Therefore, renewable aviation fuel was a long-term sustainable alternative for fossil fuels.

Aviation fuel is a special kind of liquid fuel that has a higher heating value and greater energy density than conventional fuels. It consists of C8–C16 alkanes, alkenes and aromatic hydrocarbons3,5. Although bio-fuels such as bio-ethanol and bio-diesel have demonstrated their compatibility with vehicles, they cannot be added into aviation fuels since the components of aviation fuels have strict requirements.

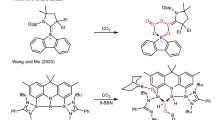

Triglycerides, the main components of vegetable oils, animal fats, waste cooking oils and microalgae lipids, can produce straight chain alkanes, ranging from C8 to C18, that can be used for the production of aviation fuel6,7. At present, hydrodeoxygenation of triglycerides or free fatty acids is the main approach to producing aviation fuel from biomass8,9,10,11. The use of refined oil as the starting material and the high cost of hydrogen in the hydrodeoxygenation process, however, increase the cost of production12. Recently, decarboxylation of fatty acids and their derivatives without additional hydrogen was reported as a new approach for producing aviation fuel at a lower cost13,14,15. In our previous studies15,16,17, the decarboxylation behaviors, kinetics and mechanisms of saturated and unsaturated fatty acids to alkanes over heterogeneous noble metal catalysts were determined. Noble metals such as Pd and Pt have been proved to be effective in catalyzing the decarboxylation of fatty acids and their derivatives13,15,16,18, but the high cost and low abundance of noble metal catalysts are serious constraints for large scale applications. Therefore, finding an inexpensive catalyst showing similar performance and durability is of great interest from an industrial standpoint.

Crocker and co-workers reported deoxygenation of triglycerides and fatty acids over supported nickel catalysts, triglycerides can be effectively into fuel-like hydrocarbon over Ni catalysts19,20,21,22 and the primary results are shown in Table 1 21,22. Ni/C afforded good yields of hydrocarbons in catalytic deoxygenation of stearic acid and triglycerides even in the absence of hydrogen. The selectivity to light hydrocarbons increases with the increase of unsaturation of the triglycerides, reflecting the greater reactivity of the unsaturated fatty acids towards cracking. Although Ni/C exhibited a promising activity for decarboxylation, the decarboxylation behaviors of saturated fatty acids over Ni/C catalysts, however, was not systematically studied.

In this article, several non-noble metal catalysts were prepared and the catalytic activities for decarboxylation of stearic acid over non-noble catalysts were evaluated. The maintenance of 20% Ni/C and the products distribution were also studied. Thereafter, the effects of nickel loading, catalyst loading, temperature and carbon number were investigated. The reaction regularity on the decarboxylation of stearic acid over Ni/C at different reaction conditions was discussed.

Experimental Section

Materials

Nickel nitrate hexahydrate (98%), aluminium nitrate hydrate(98%), cobalt nitrate hydrate(99%), cupric nitrate hydrate(99%) and zirconyl nitrate hydrate (99%) were purchased from Aladdin Industrial Corporation, Shanghai, China. 5% Pt/C and activated carbon were obtained from Sigma–Aldrich, USA, 40% Ni/SiO2 were purchased from Gansu Zhongkeyaoyuan Biological Engineering Co., Ltd, China. 20% Ni/Al2O3, 20% Cu/ZrO2, 20% Co/ZrO2 and 20% Ni/ZrO2 were synthesized in lab by the co-precipitation method. 10% Ni/C, 20% Ni/C and 30% Ni/C were synthesized in lab by the impregnation method. Stearic acid (>99%), lauric acid (>99%), myristic acid (>99%), palmitic acid (>99%), arachidic acid (>99%) and behenic acid (>99%) were all purchased from Sigma-Aldrich, USA. Acetone (analytic reagent grade) was obtained from Hangzhou Chemical Reagent Co., Ltd, China. The XRD results for all the catalysts were presented in Figure S1 or the section of “effects of nickel loadings on decarboxylation”.

Catalyst characterization

N2 physisorption measurements

Surface areas and pore-size distribution were measured using nitrogen as a sorbate at 77 K in a static volumetric apparatus (Micromeritics ASAP2020). Samples were degassed prior to the measurements at 300 °C for 16 h. Specific surface areas were calculated using the Brunauer-Emmett-Teller (BET) equation and calculation of pore sizes and pore volumes followed the method of Barret-Joyner-Halenda (BJH). According to implemented software routines, the Halsey thickness equation was used for relating the thickness of the adsorbed layer to the relative pressure. All calculations were based on the adsorption model.

X-Ray diffraction (XRD)

X-Ray diffraction technique was used for identifying the phases present in the synthesized samples and calculating the crystallite size of Ni by the Scherrer equation. XRD patterns were recorded on a PANalytical Empyrean 200895, using Ni filtered Cu Kα radiation (λ = 0.154 nm) as a source (current intensity, 30 mA; voltage, 40 kV) and X-celerator detector. The samples were scanned in the 2θ range of 10–80°.

The elemental composition of the reduced nickel supported catalysts was determined by inductively coupled plasma atomic emission spectroscopy (ICP-AES) using Leeman Labs Inc, USA (Model: PS 3000 UV) ICP-AES analyzer.

Experimental procedure

The decarboxylation of fatty acids was carried out in a micro batch reactor (1.67 mL volume), which was assembled from one 3/8-inch tube and two 3/8-inch caps purchased from Swagelok, USA. The photo of the micro batch reactor and its parts is shown in Fig. 1. A certain amount of reactant and catalyst were added to the reactor. Thereafter, the sealed reactor was placed in a fluidized sand bath (Techne SBL-2) which was heated to the desired reaction temperature. After the desired reaction time had elapsed, the reactor was put into water to quench the reaction. The reaction mixture in the reactor was rinsed and diluted in a 10 mL volumetric flask with acetone. Then the diluted solution was filtered for analysis.

Product analysis

The samples were analyzed with a gas chromatograph (GC, Agilent 7890A) equipped with a 30 m × 0.25 mm × 0.33 mm HP-5 capillary column and a flameionization detector. 1 μL sample was injected into the GC with a split ratio of 10:1 and the carrier gas (nitrogen) flow rate was 11 mL/min. The temperature of the injector and detector were 280 and 300 °C, respectively. The oven temperature program consisted of a 4 min soak at 40 °C followed by a 10 °C/min ramp up to 280 °C, which was held for 5 min. The reaction products were identified by fragmentation patterns from an Agilent 5970 Mass Spectrometric(MS) detector and by matching gas chromatograph retention times with known standards. Quantitative analysis was performed using calibration curves for each compound of interest.

Reactant molar conversions were calculated as the number of moles of reactant consumed divided by the initial number of moles of reactant loaded into the reactor. Selectivity was calculated as the number of moles of product recovered divided by the number of moles of reactant that had reacted (i.e., yield/conversion). Uncertainties reported are standard deviations, which were determined by replicating experiments. Each data point represents the mean result from at least three independent experiments.

Results and Discussion

Catalytic activity and maintenance

The catalytic activities for decarboxylation of stearic acid over different non-noble catalysts were evaluated, shown in Fig. 2. The reaction was carried out at 330 °C for 5 h. The loading of stearic acid was 0.176 mmol and the loading of catalyst was 30 mg. The error bars represent standard deviations of three replicate experiments. The conversions of stearic acid over Cu/ZrO2, Co/ZrO2 and Ni/ZrO2 were 36.3%, 74.8% and 37.4% respectively and the selectivities of heptadecane were 22.9%, 8.9% and 79.4% respectively. Although the conversion of stearic acid over Co/ZrO2 was the highest, the selectivity of heptadecane over Co/ZrO2 was the lowest, leading a very low yield of heptadecane (6.7%), which was lower than those over Cu/ZrO2 (8.3%) and Ni/ZrO2 (29.7%). Synthetically, the catalytic performance of nickel was superior to copper and cobalt for decarboxylation. The conversions of stearic acid over Ni/C, Ni/SiO2 and Ni/ZrO2 were 37.1%, 54.1% and 37.4% respectively and the selectivities of heptadecane were 89.1%, 51.2% and 79.4% respectively. Although the conversion of stearic acid over Ni/SiO2 was higher than those over Ni/C and Ni/ZrO2, the selectivity of heptadecane over Ni/SO2 was much lower than those over Ni/C and Ni/ZrO2, leading to lower yield. The conversions of stearic acid over Ni/C and Ni/ZrO2 were very close, but the selectivity of heptadecane over Ni/C was higher than that over Ni/ZrO2. Synthetically, activated carbon was better as a support than ZrO2 and SiO2. Stearic acid could be completely converted over 5% Pt/C within 2 h at 330 °C and the selectivity of heptadecane was 91%. The conversion efficiency of stearic acid over Ni/C was 7.4% per hour, while that of stearic acid over Pt/C was 49.7% per hour. Although the conversion efficiency of Ni/C for decarboxylation was not as good as Pt/C, the selectivities to heptadecane over Ni/C and Pt/C were quite close, meaning that heptadecane can be selectively obtained over Ni/C by longer time or higher temperature. The critical point for the potential use of nickel as a catalyst is that the price of nickel is much cheaper than platinum, which would significantly lower the cost of production although higher temperature or longer reaction time are required.

Effects of nickel loadings on decarboxylation

The decarboxylation of stearic acid was examined over three Ni/C catalysts with different nickel loadings (10%, 20% and 30%) under the same experimental conditions (Temperature = 330 °C, time = 5 h, catalyst loading = 30 mg, stearic acid loading = 0.176 mmol). The effect of nickel loading on the conversion of stearic acid and the selectivity to heptadecane was shown in Fig. 3. As observed from the figure, the conversion of stearic acid increased with increasing nickel loading on activated carbon. The selectivity to heptadecane over 20% Ni/C was much higher than 10% Ni/C and 30% Ni/C.

The products from the decarboxylation of stearic acid over 20% Ni/C and 30% Ni/C were identified by GC/MS. Except heptadecane, other products such as decane, undecane, dodecane, tridecane, tetradecane, pentadecane, hexadecane, heptadecene, octadecane and octadecanol were also detected. We defined the total areas of the detected peaks as 100% and obtained the relative percentage (area of peak/total area of peaks) of each product and the product distribution is shown in Table 2. The product distribution indicates that cracking and hydrodeoxygenation occurred during the decarboxylation. Compared to the sample catalyzed by 20% Ni/C, more alkanes with small carbon number were detected in the sample catalyzed by 30% Ni/C (decane: 0.8%; undecane: 1.2%; dodecane: 1.6%). Moreover, the overall yield of cracking products (alkanes with smaller carbon numbers than heptadecane) over 30% Ni/C and 20% Ni/C was 21.3% and 10.4% respectively, indicating that 30% Ni/C tends to catalyze cracking compared to 20% Ni/C.

To study the reusability of Ni/C catalyst, spent catalysts of previous experiments were first separated by filtration under vacuum and then washed thoroughly with acetone followed by water multiple times. The filtered catalyst was then dried in a forced air oven at 110 °C overnight and then calcined at 500 °C for 4 h under the flow of nitrogen in a tubular furnace. The activity maintenance of 20% Ni/C was evaluated at 330 °C for 5 h with a catalyst loading of 30 mg and 0.176 mmol of reactant, shown in Fig. 4. The conversions of stearic acid, yields and selectivities to heptadecane over fresh Ni/C (1st use), catalyst used once previously (2nd use) and catalyst used twice previously (3rd use) were almost the same. The selectivity remained around 90%, keeping stable in a solvent free system.

The N2 adsorption-desorption isotherms of 10% Ni/C, 20% Ni/C, 30% Ni/C and 20% Ni/C (used) were shown in Fig. 5. The isotherms of these catalysts exhibited similar sharps, indicating that the structure of these catalysts were not different, even after used. The surface area and the porosity structure of Ni/C samples were summarized in Table 3. The TEM results of Ni/C at low magnification, high magnification and the distribution of Ni particle size are shown in Figure S2. The average pore sizes of these catalysts were around 3.5 nm and the mean Ni particle size was 11.7 nm from the TEM results (Figure S2c), while the mean Ni particle size was 13.7 nm from the XRD results. The surface areas and pore volumes decreased as the nickel loadings increased, indicating excessive Ni particles might block a certain amount of pores of activated carbon and decrease the pore volume. The average pore sizes for the catalysts were almost the same. X-ray diffraction (XRD) further investigated the crystalline Ni particles supported on activated carbon (Fig. 6). The prominent peak at 26° was recorded and ascribed to the reflection of amorphous carbon support. Apart from the characteristic peaks of carbon support, the peaks at 44.5°, 51.8° and 76.4° can be assigned to Ni (JCPDS 04–0850). According to the XRD data, the peak signals of Ni-based particles gradually enhanced with increased Ni loadings, indicating the fluctuation of Ni particles.

Effects of catalyst loading

The effects of catalyst loading on conversion of stearic acid and the selectivity for heptadecane were studied for five different 20% Ni/C catalyst loadings at 330 °C for 5 h, as shown in Fig. 7. The error bars represent standard deviations of three replicate experiments. The decarboxylation reaction of stearic acid was carried out without any catalyst and no conversion of stearic acid was observed after 5 h. In Fig. 5, the conversion of stearic acid increased continuously from 17.6% to 57.8% as the catalyst loading increased from 10 to 50 mg. The selectivity of heptadecane remained around 90% as the catalyst loading increased from 10 to 30 mg. When the loading amount of 20% Ni/C was higher than 30 mg, the selectivity of heptadecane decreased, suggesting excess amount of catalysts was not favorable for the decarboxylation.

Effects of temperature

Figure 8 shows the time course of the decarboxylation of stearic acid over 20% Ni/C at three different temperatures, 330, 350, 370 °C. It was found that the conversion of stearic acid increased with prolonged reaction time and continuously increased with increasing reaction temperature. At 370 °C, complete conversion of stearic acid was achieved in 5 h. The selectivity for heptadecane at these temperatures and reaction times ranged around 90%. These results indicate that the 20% Ni/C in the decarboxylation of stearic acid has a high selectivity for heptadecane, even at high temperatures.

Decarboxylation of fatty acids with varying carbon numbers

The decarboxylation of different fatty acids (lauric acid, myristic acid, palmitic acid, stearic acid, arachidic acid and behenic acid) with the same molar ratio of reactant loading to catalyst loading were studied at 350 °C for 4 h as shown in Fig. 9. These results suggested that different fatty acids with varying carbon numbers also underwent decarboxylation over Ni/C. The conversions of lauric acid, myristic acid, palmitic acid, stearic acid, arachidic acid and behenic acid were 79.1%, 76.4%, 67.9%, 61.5%, 60.2% and 66.3% respectively and the selectivities to the corresponding alkanes were 88.5%, 87.2%, 83.5%, 85.4%, 73.1% and 64.3% respectively. The conversions of the fatty acids with smaller carbon numbers were higher than those with larger carbon numbers at the same reaction condition. The acidity decreased in the sequence of lauric acid, myristic acid, palmitic acid and stearic acid23, consistent with the decrease sequence of fatty acid conversion. It indicates that the acidity of fatty acids might facilitate the decarboxylation. Moreover, the fatty acids with large carbon numbers had lower selectivity to the corresponding alkane than those with small carbon numbers, indicating the fatty acids with large carbon numbers tend to be cracked in this reaction system.

Conclusion

Ni/C catalysts were prepared and exhibited excellent activity and maintenance for decarboxylation. Stearic acid can be completely converted at 370 °C for 5 h and the selectivity to heptadecane was around 80%. Excessive Ni particles might block a certain amount of pores of activated carbon and decrease the pore volume. The products of cracking increased with high nickel loading or catalyst loading. Temperature significantly impacted the conversion of stearic acid but did not influence the selectivity. The fatty acids with large carbon numbers tend to be cracked in this reaction system.

Additional Information

How to cite this article: Wu, J. et al. Catalytic Decarboxylation of Fatty Acids to Aviation Fuels over Nickel Supported on Activated Carbon. Sci. Rep. 6, 27820; doi: 10.1038/srep27820 (2016).

References

Chavez-Rodriguez, M. F. & Nebra, S. A. Assessing GHG emissions, ecological footprint and water linkage for different fuels. Environ Sci Technol. 44(24), 9252–9257 (2010).

Liu, G., Yan, B. & Chen, G. Technical review on jet fuel production. Renew Sust Energy Rev. 25, 59–70 (2013).

Blakey, S., Rye, L. & Wilson, C. W. Aviation gas turbine alternative fuels: A review. P Combust Inst. 33(2), 2863–2885 (2011).

Stratton, R. W., Wolfe, P. J. & Hileman, J. I. Impact of aviation non-CO(2) combustion effects on the environmental feasibility of alternative jet fuels. Environ Sci Technol. 45(24), 10736–10743 (2011).

Hong, T. D. et al. A study on developing aviation biofuel for the Tropics: Production process—Experimental and theoretical evaluation of their blends with fossil kerosene. Chem Eng Process. 74, 124–130 (2013).

Wang, W.-C., Thapaliya, N., Campos, A., Stikeleather, L. F. & Roberts, W. L. Hydrocarbon fuels from vegetable oils via hydrolysis and thermo-catalytic decarboxylation. Fuel. 95, 622–629 (2012).

Zhao, C., Brück, T. & Lercher, J. A. Catalytic deoxygenation of microalgae oil to green hydrocarbons. Green Chem. 15(7), 1720–1739 (2013).

Deliy, I. V., Vlasova, E. N., Nuzhdin, A. L., Gerasimov, E. Y. & Bukhtiyarova, G. A. Hydrodeoxygenation of methyl palmitate over sulfided Mo/Al2O3, CoMo/Al2O3and NiMo/Al2O3catalysts. RSC Adv. 4(5), 2242–2250 (2014).

Hollak, S. A. W., Gosselink, R. W., van Es, D. S. & Bitter, J. H. Comparison of Tungsten and Molybdenum Carbide Catalysts for the Hydrodeoxygenation of Oleic Acid. ACS Catal. 3(12), 2837–2844 (2013).

Ayodele, O. B., Togunwa, O. S., Abbas, H. F. & Daud, W. M. A. W. Preparation and characterization of alumina supported nickel-oxalate catalyst for the hydrodeoxygenation of oleic acid into normal and iso-octadecane biofuel. Energy Convers and Manage. 88, 1104–1110 (2014).

Kumar, P., Yenumala, S. R., Maity, S. K. & Shee, D. Kinetics of hydrodeoxygenation of stearic acid using supported nickel catalysts: Effects of supports. Appl Catal A:Gen. 471, 28–38 (2014).

Yang, C., Nie, R., Fu, J., Hou, Z. & Lu, X. Production of aviation fuel via catalytic hydrothermal decarboxylation of fatty acids in microalgae oil. Bioresource Technol. 146, 569–573 (2013).

Duan, P. et al. Catalytic upgrading of crude algal oil using platinum/gamma alumina in supercritical water. Fuel. 109, 225–233 (2013).

Duan, P. & Savage, P. E. Upgrading of crude algal bio-oil in supercritical water. Bioresource Technol. 102(2), 1899–1906 (2011).

Fu, J., Lu, X. & Savage, P. E. Catalytic hydrothermal deoxygenation of palmitic acid. Energy Environ Sci. 3(3), 311–317 (2010).

Fu, J., Lu, X. & Savage, P. E. Hydrothermal decarboxylation and hydrogenation of fatty acids over Pt/C. ChemSusChem. 4(4), 481–486 (2011).

Fu, J., Shi, F., Thompson, L. T., Lu, X. & Savage, P. E. Activated Carbons for Hydrothermal Decarboxylation of Fatty Acids. ACS Catal. 1(3), 227–231 (2011).

Madsen, A. T., Ahmed, E. H., Christensen, C. H., Fehrmann, R. & Riisager, A. Hydrodeoxygenation of waste fat for diesel production: Study on model feed with Pt/alumina catalyst. Fuel. 90(11), 3433–3438 (2011).

Morgan, T. et al. Conversion of triglycerides to hydrocarbons over supported metal catalysts. Top Catal. 53, 820–829 (2010).

Morgan, T. et al. Catalytic deoxygenation of triglycerides to hydrocarbons over supported nickel catalysts. Chem Eng J. 189, 346–355 (2012).

Santillan-Jimenez, E., Morgan, T., Lacny, J., Mohapatra, S. & Crocker, M. Catalytic deoxygenation of triglycerides and fatty acids to hydrocarbons over carbon-supported nickel. Fuel. 103, 1010–1017 (2013).

Santillan-Jimenez, E., Morgan, T., Shoup, J., Harman-Ware, A. E. & Crocker M. Catalytic deoxygenation of triglycerides and fatty acids to hydrocarbons over Ni–Al layered double hydroxide. Catal Today. 237, 136–144 (2014).

Rahman, M. A., Ghosh, A. K. & Bose, R. N. Dissociation constants of long chain fatty acids in methanol-water and ethanol-water mixtures. J. Chem. Tech. Biotechnol. 29, 158–162 (1979).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 21476204, 21436007) and Zhejiang Provincial Natural Science Foundation of China (No. LZ14B060002, LQ13B060001).

Author information

Authors and Affiliations

Contributions

X.L. and Z.H. suggested and supervised the work. J.F. and J.L. wrote the main manuscript with input from all authors. J.W. did most of the experiments and prepared all the figures and tables. J.S. assisted to prepare the catalysts. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wu, J., Shi, J., Fu, J. et al. Catalytic Decarboxylation of Fatty Acids to Aviation Fuels over Nickel Supported on Activated Carbon. Sci Rep 6, 27820 (2016). https://doi.org/10.1038/srep27820

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep27820

This article is cited by

-

A Comprehensive Review of Experimental Parameters in Bio-oil Upgrading from Pyrolysis of Biomass to Biofuel Through Catalytic Hydrodeoxygenation

BioEnergy Research (2023)

-

Photoenzymatic Decarboxylation to Produce Hydrocarbon Fuels: A Critical Review

Molecular Biotechnology (2023)

-

Influence of oxalate ligand functionalization on Co/ZSM-5 activity in Fischer Tropsch synthesis and hydrodeoxygenation of oleic acid into hydrocarbon fuels

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.