Abstract

Anaerobic sludge digestion is the main technology for sludge reduction and stabilization prior to sludge disposal. Nevertheless, methane production from anaerobic digestion of waste activated sludge (WAS) is often restricted by the poor biochemical methane potential and slow hydrolysis rate of WAS. This work systematically investigated the effect of PHA levels of WAS on anaerobic methane production, using both experimental and mathematical modeling approaches. Biochemical methane potential tests showed that methane production increased with increased PHA levels in WAS. Model-based analysis suggested that the PHA-based method enhanced methane production by improving biochemical methane potential of WAS, with the highest enhancement being around 40% (from 192 to 274 L CH4/kg VS added; VS: volatile solid) when the PHA levels increased from 21 to 143 mg/g VS. In contrast, the hydrolysis rate (approximately 0.10 d−1) was not significantly affected by the PHA levels. Economic analysis suggested that the PHA-based method could save $1.2/PE/y (PE: population equivalent) in a typical wastewater treatment plant (WWTP). The PHA-based method can be easily integrated into the current WWTP to enhance methane production, thereby providing a strong support to the on-going paradigm shift in wastewater management from pollutant removal to resource recovery.

Similar content being viewed by others

Introduction

Activated sludge processes produce plenty of waste activated sludge (WAS), the treatment and disposal of which require substantial costs1,2,3. Anaerobic digestion has been extensively used for WAS treatment due to its ability to achieve methane production and reduce sludge volume simultaneously. However, anaerobic methane production is often restricted by the poor biochemical methane potential and slow hydrolysis rate of the WAS4,5,6. As a result, plenty of pre-treatment approaches including chemical, mechanical and thermal pre-treatment have been proposed to increase methane production by enhancing hydrolysis rate and/or biochemical methane potential5,6,7,8,9,10,11. For example, Park et al.11 reported that methane production from the microwave-treated WAS was 79% higher than that without pre-treatment. However, these methods are mostly cost intensive because of large chemical and/or energy requirements10. Also, all of these approaches only focused on the WAS pre-treatment and little attention has been paid to the WAS characteristic itself.

Polyhydroxyalkanoates (PHA), which are carbon and energy storage materials, can be easily accumulated in heterotrophic organisms in wastewater treatment processes12,13,14,15,16,17. PHA accumulation takes place in the presence of excess carbon source. It has been demonstrated that PHA-rich WAS could be produced from the wastewater treatment plants (WWTPs) through wastewater treatment process adjustment and/or operation optimization12,13,14,15,16,17. For instance, Takabatake et al.17 showed that up to 30% of PHA (on a dry cell weight basis) could be accumulated in the activated sludge biomass of the four real WWTPs. The increase in the PHA level of WAS would lead to the change of WAS characteristics, which might affect methane production in the subsequent anaerobic digestion. Indeed, Huda et al.18 recently found that methane production from WAS with PHA at 50 mg/g VS (VS: volatile solid) was 25% higher compared with that at 10 mg/g VS. This PHA-based method opens a new door for enhancing anaerobic methane production. However, only one PHA level (i.e. 50 mg/g VS, 10 mg/g VS was used as control) was investigated in the study of Huda et al.18. Also, the mechanisms responsible for the enhanced methane production are still unknown.

In this work, the effect of PHA levels (i.e. 21, 82, 114 and 143 mg/g VS) of WAS on methane production in anaerobic digestion was assessed systematically using both experimental and mathematical modeling approaches. Anaerobic methane production from WAS with varying PHA levels was experimentally evaluated by biochemical methane potential tests. A model-based analysis was carried out to explore the mechanisms of the PHA-driven improvement in anaerobic methane production. Economic analysis was performed to assess the economic benefit of the PHA-based method. An economically attractive and environmentally friendly integrated PHA-based anaerobic WAS digestion process was also proposed.

Results

Effect of PHA levels on biochemical methane production

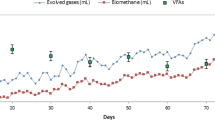

Measured methane production from WASs with varying PHA levels throughout the BMP test time is demonstrated in Fig. 1. In general, WASs with higher PHA levels have higher methane production than those with lower PHA levels. For example, the cumulative methane productions were 148, 183, 203 and 225 L CH4/g VS added at a digestion time of 20 day when the PHA levels were 21, 82, 114 and 143 mg/g VS, respectively. This reveals that the PHA-based method is capable of enhancing anaerobic methane production.

Effect of PHA levels on biochemical methane potential and hydrolysis rate

The biochemical methane potential and hydrolysis rate were predicted using a modified first-order kinetic model. The simulated methane production curves are demonstrated in Fig. 1, which suggests that the model can well capture the methane production data (R2 > 0.99 in all cases). Table 1 shows the estimated k1, k2, B0, Y and tlag at different PHA levels. In general, there is no significant changes (p > 0.05) in k1 (0.03 ± 0.01 d−1) and k2 (0.10 ± 0.01 d−1) in the studied PHA levels (21–143 mg/g VS). This indicates that hydrolysis rate was not significantly affected by the PHA levels. In contrast, B0 increased (p < 0.05) with increasing PHA levels, from 192 to 274 L CH4/kg VS (increased by 43%) when the PHA levels increased from 21 to 143 mg/g VS. This suggests that PHA-based method could enhance biochemical methane potential of WAS. Correspondingly, the calculated Y increased (p < 0.05) from 0.42 to 0.59 while the PHA levels increased from 21 to 143 mg/g VS, revealing that WAS degradation was improved by 43%. tlag (7 ± 1 d) was similar (p > 0.05) in all PHA levels, indicating that PHA levels applied would not affect lag time.

95% confidence regions of k1 and k2, k1 and B0 and k2 and B0, were determined to assess their identifiability. The linear confidence intervals (error bars) exceeded the non-linear regions (ellipses) due to the fact that the former was the estimates via four-parameter prediction while the latter was predicted via two-parameter prediction by fixing the other two parameters. The higher degree of freedom and increased localized error function in four-parameter estimation might lead to the over-estimation of the linear confidence intervals19. Nevertheless, the overall 95% confidence regions for the three pairs shown in Fig. 2 are small, with mean values lying at the center. This indicates that the parameters are well identifiable and the estimated values are reliable. Figure 2 shows that the 95% confidence regions of k1 and k2 almost fully overlapped in the studied PHA levels, suggesting that PHA levels would not significantly affect hydrolysis rate. In contrast, the 95% confidence regions of k1 and B0 and k2 and B0, moved rightward to the higher B0 direction with the increasing PHA levels, revealing that the higher biochemical methane potential can be achieved at the higher PHA levels.

Discussion

PHA-based method enhances biochemical methane potential instead of hydrolysis rate

There are two key parameters related to anaerobic methane production, biochemical methane potential (B0) and first order hydrolysis rate (k), which represent the extent and speed of anaerobic methane production, respectively. This study showed that the PHA-based method enhances anaerobic methane production through improving B0 instead of k. Indeed, a linear relationship between PHA levels and B0 was observed (see Fig. 3). This is for the first time that the mechanisms for the PHA improved methane production were revealed. Although Huda et al.18 demonstrated that the PHA-based method could enhance anaerobic methane production, their study was not systematic and only one PHA level was used. Also, the underlying mechanisms were not revealed in their study. However, it should be highlighted that microbiological analyses will be required in the future to further reveal the mechanisms.

In general, the waste activated sludge (WAS) mainly consisted of protein and carbohydrate. During anaerobic digestion, 1 g of protein (C4H6.1O1.2N, equivalent to 1.53 g of COD) and carbohydrate (C6H10O5, equivalent to 1.18 g of COD) can theoretically produce methane at 0.59 and 0.45 L CH4, respectively20. In contrast, 1 g of PHA (C4H6O2, equivalent to 1.67 g of COD) can theoretically generate more CH4 (0.65 L CH4/g PHA) in comparison with protein and carbohydrate21. Therefore, if WAS contains more PHA, higher biochemical methane potential would be achieved. This might account for the PHA improved biochemical methane potential of WAS.

The unchanged k revealed in this work indicates that the performance improvement would be impossible or very limited in hydraulically limited anaerobic digesters. However, for anaerobic digesters with a long hydraulic retention time (HRT), the increased B0 would drive the enhancement of methane production in the anaerobic digesters.

It has been widely reported that PHA can be accumulated in the main-stream wastewater treatment process by ordinary heterotrophic organisms, polyphosphate-accumulating organisms and glycogen-accumulating organisms12,13,14,15,16,17. The PHA-rich organisms/sludge would then be subject to anaerobic digestion. However, PHA degradation is not taken into account in the current Anaerobic Digestion Model No. 1 (ADM1)22. This might lead to an underestimation of methane generation especially for the anaerobic digester receiving PHA-rich sludge. Therefore, the current ADM1 should be modified to include PHA degradation in the future.

Potential economic benefit of PHA-based method to enhance anaerobic methane production

The results of laboratory BMP tests have been shown to be more conservative or comparable to those of full-scale trials23. Consequently, the experimental results attained in this work via the lab-scale BMP tests could be used conservatively for predicting the economic potential of the proposed PHA-based method. This was conducted via a desktop scaling-up study in a WWTP with a population equivalent (PE) of 400,000 and with an anaerobic digester at an HRT of 20 d. Figure 1 shows that WAS with PHA at 143 mg/g VS obtained the largest methane production at a digestion time of 20 d. As a result, this case was chosen for the subsequent economic evaluation. With a 52% increase in methane production at 143 mg PHA/g VS compared with that at 21 mg PHA/g VS (see Fig. 1, 225 versus 148 L CH4/kg VS added at a digestion time of 20 d) as demonstrated in this work, the economic benefit is predicted to be approximately $1.2/PE/y compared to the WWTP without PHA-based method (see Table 2). The benefit comes from the improved methane production associated benefit (i.e. its conversion to heat and power) ($0.8/PE/y) and reduced WAS disposal and transport costs ($0.4/PE/y). Therefore, the PHA-based method is potentially economically favorable. Nevertheless, it should be pointed out that the economic analysis results shown here should be regarded indicative only. Particularly, they may change in different regions and/or countries, depending on the local conditions.

An integrated PHA-based method to enhance anaerobic methane production in wastewater treatment plants

From an integrated economic and environmental perspective, the pollutants (e.g. carbon source) in the wastewater of a WWTP should be managed so that resource recovery from wastewater can be maximized24. Based on the findings of this work, an integrated PHA-based method to enhance carbon source recovery in the form of methane in the typical anaerobic/anoxic-aerobic wastewater treatment plants is proposed. The essence of the PHA-based method is to encourage the practitioners to increase PHA content in WAS by process optimization, thereby enhancing anaerobic methane production from WAS.

As shown in Fig. 4, wastewater first entered the anaerobic/anoxic bioreactor, where PHA can be accumulated utilizing the carbon source in the wastewater. In the subsequent aerobic bioreactor, process optimization can be performed to minimize PHA consumption15,16,25. Afterwards, the PHA-rich WAS is fed to the anaerobic digester, in which the enhanced methane production and reduced sludge production can be achieved. This PHA-based method provides a strong support to the on-going paradigm shift in wastewater management from pollutant removal to resource recovery. Also, this method would represent a significant cost reduction in the operation of the WWTPs due to enhanced methane production and reduced sludge production (see previous section). In addition, there is a strong environmental incentive for the PHA-based method, as it avoids external chemical and energy input.

Proposed integrated PHA-based method to enhance methane production in a typical anaerobic/anoxic-aerobic wastewater treatment plant.

PHA can be accumulated in the anaerobic/anoxic bioreactor when the carbon source is in excess. Process optimization can reduce PHA consumption in the aerobic bioreactor. The PHA-rich WAS in the anaerobic digester can enhance methane production and reduce sludge production, thereby forming an economically attractive and environmentally friendly method to enable maximized resource recovery in the form of methane. WAS: waste activated sludge.

In conclusion, the effect of PHA levels of WAS on anaerobic methane production was evaluated systematically using both experimental and mathematical modeling approaches in this work. It was demonstrated that PHA in WAS enhances anaerobic methane production and higher PHA levels lead to higher methane production in anaerobic digestion. The PHA-based method enhances methane production by improving biochemical methane potential of WAS, whereas the hydrolysis rate of WAS is not affected by the PHA levels. The PHA-based method is potentially environmentally friendly and economically attractive and can be integrated into the current WWTP to enhance methane production, thereby providing a strong support to the on-going paradigm shift in wastewater management from pollutant removal to resource recovery.

Methods

Sludge sources

WASs with different PHA levels (defined as WAS-I, WAS-II, WAS-III and WAS-IV, see Table 3) were harvested from four bioreactors with a sludge retention time of 7 day. Seed sludge for the four bioreactors was harvested from a full-scale WWTP in Shanghai, China. All the bioreactors were operated in six hours per cycle, consisting of 240 min aeration, 55 min settling, 5 min decanting and 60 min idle period. These four bioreactors were fed with synthetic wastewaters containing 200, 400, 600 and 800 mg COD/L (COD: chemical oxygen demand), respectively, with acetate as the sole organic carbon source. The other composition of the synthetic wastewaters was described in Wang et al.26.

The inoculum was collected from a lab-scale anaerobic sludge digester fed with WAS wasted from a full-scale WWTP in Shanghai, China. It will be used in the biochemical methane potential (BMP) tests to be detailed below. The main characteristics of the inoculum were shown in Table 3.

Anaerobic biochemical methane potential (BMP) tests

BMP tests were used to evaluate methane production from WAS with PHA levels. BMP tests were conducted in 1 L serum bottles (working volume of 600 mL). Every BMP test bottle contained 60 mL inoculum and 540 mL WAS. The bottles were flushed with nitrogen gas for 30 s to remove oxygen. Thereafter, all the serum bottles were capped with rubber stoppers, sealed and placed in an air-bath shaker at 37 ± 1 °C. Blank containing 60 mL inoculum and 540 mL MilliQ water in the absence of WAS was also set up. pH in all serum bottles was controlled at 7.0 ± 0.1 throughout the digestion period using 4 M HCl or 4 M NaOH with an automatic titrator. All tests were carried out in triplicates. The BMP tests sustained for 30 days, when biogas production decreased to negligible levels. Biogas (CH4, H2) production was monitored every day in the first two weeks and every 2-3 days thereafter. Biogas production from WAS was calculated by subtracting measured biogas production in an experimental bottle from that measured in the blank bottle. The methane production was recorded as the volume of methane produced divided by the organic dry weight of the WAS added (L CH4/kg VS added).

Model-based analysis

The biochemical methane potential (B0) and hydrolysis rate (k), two key parameters relevant to methane production, were adopted to assess and compare methane production potential and kinetics of the WAS with varying PHA levels4,5. According to the results of BMP tests, a lag period of methane production was observed. Therefore, a modified first-order kinetic model was used to estimate k and B0 via fitting the methane production results from BMP tests to the model using a modified version of Aquasim 2.1d23,27. It should be noted that only methane production results were used to estimate k and B0 using the model. This is the commonly used method and is widely used by different groups28,29,30. All parameters were simultaneously predicted using the gradient search method in Aquasim 2.1 d23, using the following equations:

When t < tlag,

When t > tlag,

where B(t) = cumulative methane production at time t (L CH4/kg VS added); B0 = biochemical methane potential (L CH4/kg VS added); t = time (d); tlag = lag time of methane production (d); k1 = hydrolysis rate during the lag period (d−1); k2 = hydrolysis rate after the lag period (d−1).

The Aquasim 2.1d was also used to estimate the uncertainty surfaces of k1, k2 and B0, based on a model-validity F-test with 95% confidence levels23.

The degradation extent (Y) of WAS was determined using the following equation:

where 380 = theoretical biochemical methane potential of WAS under standard conditions (25 °C, 1 atm) (L CH4/kg TCOD)31; RWAS = measured ratio of VS to TCOD in the studied WAS.

Analytical mhethods

The TS and VS levels were determined based on the standard methods32. PHA was determined according to the method of Randall and Liu33. Protein concentration was measured by the bicinchoninic acid assay method with bovine serum albumin as standard34. Carbohydrate concentration was determined by the Anthrone method with glucose as standard35. The gas volume was determined through releasing the pressure of the serum bottle using a 300 mL glass syringe to equilibrate with the room pressure based on the method reported previously36. The cumulative volume of methane was calculated by the following equation:

where VM,c and VM,p = cumulative volumes of methane in the current (c) and previous (p) time intervals, respectively. VT,c and VT,p = total gas volumes in the current and previous time intervals, respectively. PM,c and PM,p = percentages of methane measured by gas chromatography in the current and previous time intervals, respectively.

Biogas composition in the collected gas was determined using a gastight syringe with 0.2 mL injection volume and a gas chromatograph (GC112A). The details can be found in Wang et al.26,37.

Additional Information

How to cite this article: Wang, Q. et al. Polyhydroxyalkanoates in waste activated sludge enhances anaerobic methane production through improving biochemical methane potential instead of hydrolysis rate. Sci. Rep. 6, 19713; doi: 10.1038/srep19713 (2016).

References

Wang, J., Li, S. Y., Jiang, F., Wu, K., Liu, G. L., Lu, H. & Chen, G. H. A modified oxic-settling anaerobic activated sludge process using gravity thickening for excess sludge reduction. Sci Rep 5, 13972 (2015).

Hao, X., Wang, Q., Cao, Y. & van Loosdrecht, M. C. M. Evaluating sludge minimization caused by predation and viral infection based on the extended activated sludge model No. 2d. Water Res 45, 5130–5140 (2011).

Campos, J. L., Otero, L., Franco, A., Mosquera-Corral, A. & Roca, E. Ozonation strategies to reduce sludge production of a seafood industry WWTP. Bioresour Technol 100, 1069–1073 (2009).

Wang, Q., Ye, L., Jiang, G., Jensen, P., Batstone, D. & Yuan, Z. Free nitrous acid (FNA)-based pre-treatment enhances methane production from waste activated sludge. Environ Sci Technol 47, 11897–11904 (2013).

Wang, Q., Jiang, G., Ye, L. & Yuan, Z. Enhancing methane production from waste activated sludge using combined free nitrous acid and heat pre-treatment. Water Res 63, 71–80 (2014).

Appels, L., Baeyens, J., Degreve, J. & Dewil, R. Principles and potential of the anaerobic digestion of waste- activated sludge. Prog Energy Combust Sci 34, 755–781 (2008).

Zhang, D., Chen, Y., Zhao, Y. & Ye, Z. A new process for efficiently producing methane from waste activated sludge: alkaline pretreatment of sludge followed treatment of fermentation liquid in an EGSB reactor. Environ Sci Technol 45, 803–808 (2011).

Carrere, H., Dumas, C., Battimelli, A., Batstone, D. J., Delgenes, J. P., Steyer, J. P. & Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: a review. J Hazard Mater 183, 1–15 (2010).

Eskicioglu, C., Prorot, A., Marin, J., Droste, R. L. & Kennedy, K. J. Synergetic pretreatment of sewage sludge by microwave irradiation in presence of H2O2 for enhanced anaerobic digestion. Water Res 42, 4674–4682 (2008).

Foladori, P., Andreottola, G. & Ziglio, G. Sludge reduction technologies in wastewater treatment plants. IWA Publishing London, UK (2010).

Park, B., Ahn, J-H., Kim, J. & Hwang, S. Use of microwave pretreatment for enhanced anaerobiosis of secondary sludge. Water Sci Technol 50, 17–23 (2004).

Wang, D., Li, X., Yang, Q., Zheng, W., Wu, Y., Zeng, T. & Zeng, G. Improved biological phosphorus removal performance driven by the aerobic/extended-idle regime with propionate as the sole carbon source. Water Res 46, 3868–3878 (2012).

Lopez-Vazquez, C. M., Oehmen, A., Hooijmans, C. M., Brdjanovic, D., Gijen, H. J., Yuan, Z. & van Loosdrecht, M. C. M. Modeling the PAO-GAO competition: Effects of carbon source, pH and temperature. Water Res 43, 450–462 (2009).

Coats, E. R., Loge, F. J., Wolcott, M. P., Englund, K. & McDonald, A.G. Synthesis of polyhydroxyalkanoates in municipal wastewater treatment. Water Environ Res 79, 2396–2403 (2007).

Kleerebezem, R. & van Loosdrecht, M. C. M. Mixed culture biotechnology for bioenergy production. Curr Opin Biotech 18, 207–212 (2007).

Reis, M. A. M., Serafim, L. S., Lemos, P. C., Ramos, A. M., Aguiar, F. R. & van Loosdrecht, M. C. M. Production of polyhydroxyalkanoates by mixed microbial cultures. Bioprocess Biosyst Eng 25, 377–385 (2003).

Takabatake, H., Satoh, H., Mino, T. & Matsuo, T. PHA (polyhydroxyalkanoate) production potential of activated sludge treating wastewater. Water Sci Technol 45, 119–126 (2002).

Huda, S. M. S., Satoh, H. & Mino, T. Anaerobic digestion of polyhydroxybutyrate accumulated in excess activated sludge. J Water Environ Technol 11, 429–438 (2013).

Zhang, T., Wang, Q., Ye, L., Batstone, D. & Yuan, Z. Combined free nitrous acid and hydrogen peroxide pre- tretament of waste activated sludge enhances methane production via organic molecule breakdown. Sci Rep 5, 16631 (2015).

Huete, E., de Gracia, M., Ayesa, E. & Garcia-Heras, J. L. ADM1-based methodology for the characterisation of the influent sludge in anaerobic reactors. Water Sci Technol 54, 157–166 (2006).

Smolders, G. J. F., van der Meij, J., van Loosdrecht, M. C. M. & Heijnen, J. J. A structured metabolic model for the anaerobic and aerobic stoichiometry and kinetics of the biological phosphorus removal process. Biotechnol Bioeng 47, 277–287 (1995).

Batstone, D. J., Keller, J., Angelidaki, I., Kalyuzhnyi, S. V., Pavlostathis, S. G., Rozzi, A., Sanders, W. T. M., Siegrist, H. & Vavilin, V. A. The IWA anaerobic digestion model No. 1 (ADM1). Water Sci Technol 45, 65–73 (2002).

Batstone, D. J., Tait, S. & Starrenburg, D. Estimation of hydrolysis parameters in full-scale anaerobic digesters. Biotechnol Bioeng 102, 1513–1520 (2009).

Van Loosdrecht, M. C. M. & Brdjanovic, D. Anticipating the next century of wastewater treatment. Science 344, 1452–1453 (2014).

Wang, D., Chen, Y., Zheng, X., Li, X. & Feng, L. Short-chain fatty acid production from different biological removal sludges: the influences of PHA and gram-staining bacteria. Environ Sci Technol 47, 2688–2695 (2013).

Wang, D., Zeng, G., Chen, Y. & Li, X. Effect of polyhydroxyalkanoates on dark fermentative hydrogen production from waste activated sludge. Water Res. 73, 311–322 (2015).

Rao, M. S., Singh, S. P., Singh, A. K. & Sodha, M. S. Bioenergy conversion studies of the organic fraction of MSW: assessment of ultimate bioenergy production potential of municipal garbage. Appl Energy 66, 75–87 (2000).

Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos, J. L., Guwy, A. J., Kalyuzhnyi, S., Jenicek, P. & van Lier, J. B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 59, 927–934 (2009).

Appels, L., Lauwers, J., Gins, G., Degreve, J., Van Impe, J. & Dewil, R. Parameter identification and modelling of the biochemical methane potential of waste activated sludge. Environ Sci Technol 45, 4173–4178 (2011).

Donoso-Bravo, A., Perez-Elvira, S. I. & Fdz-Polanco, F. Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem Eng J 160, 607–614 (2010).

Metcalf and Eddy. Wastewater Engineering: Treatment and Reuse. (McGraw-Hill Inc, 2003).

Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association (APHA), American Water Works Association and Water Environment Federation: Washington, DC (1998).

Randall, A. A. & Liu, Y. H. Polyhydroxyalkanoates form potentially a key aspect of aerobic phosphorus uptake in enhanced biological phosphorus removal. Water Res. 36, 3473–3478 (2002).

Smith, P. K., Krohn, R. I., Hermanson, G. T., Mallia, A. K., Gartner, F. H., Provenzano, M. D., Fujimoto, E. K., Goeke, N. M., Olson, B. J. & Klenk, D. C. Measurement of protein using bicinchoninic acid. Anal Biochem 150, 76–85 (1985).

Raunkjaer, K., Hvitved-Jacobsen, T. & Nielsen, P. H. Measurement of pools of protein, carbohydrate and lipid in domestic wastewater. Water Res 28, 251–262 (1994).

Owen, W. F., Stuckey, D. C., Healy, J. B., Young, L. Y. & McCarty, P. L. Bioassay for monitoring biochemical methane potential and anaerobic toxicity. Water Res 13, 485–492 (1979).

Carballa, M., Duran, C. & Hospido, A. Should we pretreat solid waste prior to anaerobic digestion ? an assessment of its environmental cost. Environ Sci Technol 45, 10306–10314 (2011).

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (61403142), the funding support from The University of Queensland Early Career Research Grant (ECR040) awarded to Dr. Qilin Wang, the project of NSFC (Grants 51508178, 51521006 and 51408551) and Planned Science and Technology Project of Zhejiang Province, China (2015C33012). Dr Dongbo Wang appreciates the International Postdoctoral Exchange Fellowship Program (China) for partly financial support of this work.

Author information

Authors and Affiliations

Contributions

All authors contributed intellectually via scientific discussions during the work and have read and approved the final manuscript. Q.W. developed the methodology, performed data analysis, prepared all figures and drafted the manuscript. J.S., C.Z., G.X. and X.Z. contributed to the methodology development. J.Q., G.Y. and G.Z. assisted with the analysis and discussed the results. Y.L. and D.W. critically reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wang, Q., Sun, J., Zhang, C. et al. Polyhydroxyalkanoates in waste activated sludge enhances anaerobic methane production through improving biochemical methane potential instead of hydrolysis rate. Sci Rep 6, 19713 (2016). https://doi.org/10.1038/srep19713

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep19713

This article is cited by

-

The A-stage process to promote bioflocculation and microbial storage for carbon redirection: current perspectives and future research directions

Reviews in Environmental Science and Bio/Technology (2023)

-

Research on the experiment of the enhancement removal of fine sand by hydrocyclone in sewage treatment plant

Environmental Science and Pollution Research (2021)

-

Assessment of Heterotrophic Growth Supported by Soluble Microbial Products in Anammox Biofilm using Multidimensional Modeling

Scientific Reports (2016)

-

Nitrite addition to acidified sludge significantly improves digestibility, toxic metal removal, dewaterability and pathogen reduction

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.