Abstract

Using a 10 nm thick molybdenum oxide (MoO3−x) layer as a transparent and low barrier contact to p-CdTe, we demonstrate nanowire CdS-CdTe solar cells with a power conversion efficiency of 11% under front side illumination. Annealing the as-deposited MoO3 film in N2 resulted in a reduction of the cell’s series resistance, from 9.97 Ω/cm2 to 7.69 Ω/cm2 and increase in efficiency from 9.9% to 11%. Under illumination from the back, the MoO3−x/Au side, the nanowire solar cells yielded Jsc of 21 mA/cm2 and efficiency of 8.67%. Our results demonstrate use of a thin layer transition metal oxide as a potential way for a transparent back contact to nanowire CdS-CdTe solar cells. This work has implications toward enabling a novel superstrate structure nanowire CdS-CdTe solar cell on Al foil substrate by a low cost roll-to roll fabrication process.

Similar content being viewed by others

Introduction

CdTe1, Cu(In,Ga)Se22, Cu2ZnSn(S,Se)43, silicon4 and perovskites5 are among the leading photovoltaic technologies being developed to generate low-cost solar electricity. In particular, CdTe photovoltaics have energy return investment exceeding that of traditional fossil fuels and provide the shortest energy payback time among all photovoltaic technologies for terrestrial applications6. In addition, CdTe photovoltaics have superior tolerance to high energy irradiation and are more suitable for space applications7.

Development of a transparent and stable contact to the CdTe absorber layer has remained challenging and is of great interest because it can further advance the technology where CdTe solar cells are fabricated on flexible foils of metals in a superstrate device structure. The metal foil-based CdTe solar cells can be implemented by a high-throughput roll-to-roll manufacturing process, resulting in significant cost reduction, high material utilization and fabrication scalability7. Traditionally, CdTe solar cells on metal foils are configured with an inverted substrate structure6,7. However, CdTe solar cells using the substrate structure yield lower efficiency values than their superstrate counterparts7. The substrate structure imposes many restriction on process optimization, for example, the rather difficult etching process on the CdTe layer prior to contact formation, diffusion of impurities to the contact of CdTe and CdCl2 treatment effect on CdS and CdTe layer6,7. Hence, formation of superstrate structured CdTe solar cells on metal foils is one of the most promising options for low cost and high efficiency photovoltaic technologies.

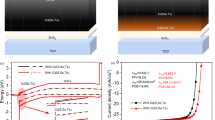

Recently, we have developed nanowire CdS-CdTe solar cells to address light absorption loss and interface recombination issues8,9,10,11 , where CdS nanowires embedded in a transparent anodic aluminum oxide (AAO) membrane replace planar CdS as the window layer and CdTe is deposited on the top of the CdS nanowires (Fig. 1a)12. Such nanowire CdS-CdTe solar cells reduced light absorption loss in the low wavelength region by confinement effects of nanostructures8,9,10,11 and exhibited a nearly ideal spectral response of quantum efficiency from 335 nm to 850 nm, which is the cut-off wavelength corresponding to the bandgap of the CdTe absorber. Next, it was thought that the development of a transparent back contact for CdTe film would lead to a nanowire CdS-CdTe solar cells that would allow the shining of sunlight through the back contact and thus realize the superstrate configuration (Fig. 1b). Because AAO is formed by anodizing aluminum, the nanowire CdS-CdTe solar cells can be grown on aluminum foil; this makes the roll-to-roll manufacturing process feasible and greatly reduces the complexity of fabrication (Fig. 1c).

(a) Schematic of a CdS nanowire window layer-CdTe absorber solar cell on TCO substrate illuminated from front side. (b) Schematic of a CdS nanowire window layer-CdTe absorber solar cell on TCO substrate with almost transparent back contacts which can be illuminated from front and back side. (c) Schematic of a CdS nanowire window layer-CdTe absorber solar cell on Al foil with almost transparent back contacts which can be illuminated from back side.

Several types of metal oxides have been investigated as buffer layer to low barrier back contacts13. In this work, molybdenum oxide (MoO3) is studied as a transparent back contact to the CdTe absorber layer, due to its high transparency (higher than 80%) in the visible and near IR range and its behavior is like that of a high work function metal14,15,16. In addition, its electrical and optical properties can be tuned by controlling the oxygen stoichiometry during processing. Several groups have applied MoO3/Ni and MoO3/Au back contacts into CdS/CdTe solar cells and reported 12.2–14.1% values for power conversion efficiency17,18,19. Here, we investigate the effects of a thin MoO3/Au layer as the transparent back contact on the nanowire solar cells through front and back side illuminations. We further investigate possibility of reducing resistance of MoO3 back contacts due to its insulation property by post-processing annealing. In the following sections, the effects of the MoO3/Au back contact layer on the structural and device properties of the nanowire CdS-CdTe solar cells are demonstrated and their loss mechanism and further improvement are discussed.

Experimental procedures

The nanowire CdS/CdTe solar cells are prepared by our previously established methods12. The solar cells were fabricated on ITO coated soda-lime glass substrates with sheet resistance of 23–28 Ω/square. The fabrication processes include formation of AAO membrane by anodizing aluminum film, electro-deposition of CdS nanowires with 100 nm height, close-space sublimation of CdTe to a thickness of 10 μm and CdCl2 treatments at 400 °C. Without NP etch, MoO3 thin films with a thickness of 10 nm were thermally evaporated on clean CdTe surfaces from stoichiometric MoO3 powder (Alfa Aesar, 99.9%), where the pressure was less than 1*10−5 Torr and the deposition rate was maintained as 0.5 Å/s. Samples were masked and then annealed at 200 °C in N2 for 10 mins. In the last step, 15 nm Au was deposited by sputtering process. For a comparative study, after thermal evaporation of molybdenum oxide, samples were directly coated with 15 nm of Au without the intervening annealing step. After depositing Au layer, all of the samples were annealed at 200 °C in Argon for 10 mins. Structures of CdS nanowires embedded in AAO templates were characterized via scanning electron microscopy (S-900-SEM). Current–voltage (I –V) was measured by a solar simulator set at 100 mW/cm2, calibrated by a power meter.

Results and Discussion

Materials Characterization

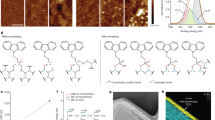

CdS nanwires are characterized by scanning electron microscopy (SEM). Figure 2a shows free standing CdS nanowires where AAO membrane has been completely removed by a highly selective NaOH solution. Figure 2b shows cross-sectional view of CdS nanowires. As seen in Fig. 2b, CdS nanowires are embedded in AAO nanopores; often, a few nanopores are seen to be missing their CdS nanowires; these, very likely, were knocked off from the AAO nanopores during the sample preparation steps for the SEM viewing. The sample preparation for cross section requires scoring the film hard so that from the shock, a fracture exposing the cross section is achieved.

On the other hand, in the SEM sample preparation for the top view (Fig. 2a), no such fracturing shock is required. In the top views of our films, all the AAO pores are in fact filled by the CdS nanowires.

Overall, CdS nanowires form uniform and dense arrays; values of the average length of nanowires, the average diameter and the average distance between the centers of neighboring nanowires are 100 nm, 60 nm and 106 nm respectively. Based on the CdS nanowires features, porosity is approximately 32% and area density of CdS nanowires is calculated as approximately 1.14*1010 nanowires/cm2. This high density CdS nanowire array was grown perpendicular to the glass-ITO substrate, but can also be directly grown on aluminum foil and other flexible substrates. These embedded CdS nanowires function as the window layer and are configured into the CdS nanowire window layer-CdTe absorber layer solar cells.

Figure 2c,d show the surface morphologies of CdTe film and cross-section view of CdTe film. It is obvious that CdTe film have a compact morphology, consisting of crystallites with grain size between average 6 μm to 7 μm. Observed from cross section SEM images of the CdTe film, it is estimated that thickness of CdTe is the 10 μm–15 μm. Figure 2e shows the AFM image of the top view of CdTe. For 6*6 μm2 CdTe area, the roughness and roughness rms values are 195 nm and 239 nm.

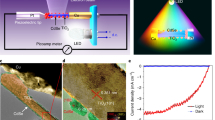

Quantum Efficiency of the Nanowire CdS-CdTe Solar Cells

Quantum efficiency characterization is especially interesting in exploring how the CdS nanowires embedded in the AAO membrane as the window layer effectively improve light transmission and how the nanowire CdS-CdTe solar cells effectively absorb light and generate and collect carriers by confinement effects of nanostructures8,9,10,11. The normalized external quantum efficiency (EQE) of a typical nanowire solar cell is shown in Fig. 3. These nanowire solar cells were fabricated on intrinsic SnO2/commercially available ITO-soda lime glass substrate with low transparency and high resistivity.

As shown in Fig. 3, the nanowire CdS-CdTe solar cells exhibit relatively strong quantum efficiency response from 345 nm to 845 nm, which is the bandgap edge of CdTe absorber. Such EQE response indicates that a very wide spectral range of incident photons is almost completely absorbed and photogenerated carriers are effectively collected. It is clear that CdS nanowires embedded in transparent AAO membrane effectively enhance transmission of the window layer. As a result, the wide spectrum of sunlight above 345 nm can be directed into the CdTe absorber where photons are absorbed and converted into charge carriers. Thus by using the embedded CdS nanowires as the window layer, abilities of carrier generation and collection in the CdS-CdTe solar cells are effectively enhanced.

Photovoltaic Characteristics of Nanowire CdS-CdTe-MoO3−x-Au solar cells

The performance of the nanowire CdS-CdTe solar cells with MoO3/Au back contacts was characterized. Figure 4 shows the J-V characteristics of the nanowire solar cells with MoO3/Au contacts with N2 annealing under dark, 1-Sun front side illumination and 1-Sun back side illumination, as well as the cells with MoO3/Au contacts without N2 annealing under 1-Sun front side illumination. There is no roll-over effect observed in any of the light J-V curves. Hence, incorporation of MoO3/Au as a back contact to CdTe film eliminates the commonly observed blockage to hole transport across the interface between the CdTe layer and the “traditional” back contact. It has been reported that MoO3 has high work function of 5.5 eV–6.86 eV and has a behavior like that of a metal15,16. This high work function of MoO3 is thought to form a well-aligned buffer layer and to reduce the effective barrier height, thus facilitating the formation of quasi- ohmic back contacts to CdTe.

The optimal thickness of the MoO3 layer is observed to be in the 5 nm–10 nm range., while the thickness of CdTe by closed-space sublimation is about 10 μm–12 μm. Thinner MoO3 layer, less than 5 nm, is not enough to guarantee a continuous coverage and efficient contacts for hole transport due to surface roughness of CdTe. Thicker MoO3 layer, more than 10 nm, leads to decrease of short current density (Jsc) and fill factor (FF) due to high resistivity of the MoO3 layer. To reduce resistance and guarantee a continuous layer, we deposited the 10 nm MoO3 layer as the buffer layer of back contacts for CdTe absorber in this work. Table 1 summarizes cell performance parameters.

The 195 nm roughness value of the surface of the CdTe absorber layer is small enough that a conformal covering of the MoOx electrode layer over CdTe is obtained when the thickness of MoOx is more than 5 nm. When the thickness of the MoOx buffer layer was smaller than 5 nm, the current-voltage characteristics of the completed NW-CdS/CdTe cell exhibited the “roll-over effect”, which is associated with a non-conducting, Schottky diode behavior at the CdTe-eletrode interface. This would be expected to happen when the CdTe was not fully covered by the MoOx buffer layer; then, there would be patches of CdTe surface in direct contact with the Au electrode, which forms a Schottky diode with p-CdTe. To avoid this undesirable outcome, in our experiments, the thickness of the MoOx buffer layer was set at 10 nm.

The reported cell performance was achieved on intrinsic SnO2/ITO-soda-lime glass substrates and without antireflective coating.

The new Table 1 lists the variability range for each parameter for a statistical sample of 3; the average value for each parameter is listed in the new Table 2. Comparing the first two rows of the Efficiency column in these Tables, it is seen that the annealing step improved the average efficiency value by 1.03% (from 9.97% to 11%); this increase is much larger than the variability range values of 0.23% and 0.22% and, therefore, of practical significance.

Similarly, comparing the last two rows of the Efficiency column in these Tables, it is seen that under back side illumination, the average efficiency value decreased by 2.33% (from 11% to 8.67%); this reduction is much larger in magnitude than the variability range values of 0.29% and 0.22% and, therefore, of practical significance.

As comparison, these solar cell parameter values are lower than the Voc of 770 mV, Jsc of 26 mA/cm2, fill factor of 60% s and power conversion efficiency of 12% seen in the best nanowire CdS-CdTe solar cell with Cu/graphite back contacts18,19. Hence there is room for further optimization and performance improvement. Low shunt resistance might have been caused by contribution from the incomplete isolation of cells and less than satisfactory scribing of intrinsic SnO2. Lower fill factor and Jsc are attributed to high series resistance, which is higher than the series resistance of planar CdS-CdTe solar cells. Fully stoichiometric MoO3 with only Mo6+ is insulating and has a rather high resistivity of 103–104 Ωcm18,19. Although J-V curves show that the incorporation of thin MoO3 layer does not lead to the roll-over behavior, still, high resistivity attribute of MoO3 may lead to some blockage of hole transport. This would show up as a high effective series resistance, leading to lower values fill factor and Jsc.

When MoO3 is exposed to N2 annealing before depositing Au as back contact, the performance of the nanowire solar cells is improved. The average Jsc and fill factor are improved to 25.6 mA/cm2 and 57.1% respectively and the average series resistance is reduced from 9.97 Ω/cm2 to 7.69 Ω/cm2 and shunt resistance is increased to 332.2 Ω/cm2, leading to power conversion efficiency of approximately 11%. The measured error of the efficiency is 1%. It has been reported earlier that after annealing in N2, a small amount of MoO2 as well as Mo4+ ions are present in the MoO3 film and MoO2 is metallic15,16. Consequently, it is thought that after annealing at 200 °C in N2 for 10 minutes, evaporated MoO3 film has in it the mixed oxidation states of Mo, mainly attributed to MoO3 and MoO2 phases14,15,16. These mixed oxidation states of Mo (MoO3−x) can sustain the dominant high work function behavior arising from MoO3 and also reduce resistivity due to metallic behavior of MoO2 phase. Hence, series resistance of the nanowire solar cells is significantly reduced and fill factor and power conversion efficiency are improved. An increase in Jsc for the annealing MoO3 (MoO3−x) back contact case is attributed to reduced barrier height due to lower resistivity of MoO3−x/Au back contacts.

To illustrate the feasibility of a relatively transparent MoO3−x/Au hole selective contact to p-CdTe, we illuminated the nanowire solar cells from back-contact side (MoO3−x/Au side rather than SnO2/ITO/Soda-lime glass side). The resulting J-V characteristics and the photovoltaic performance are shown in Fig. 4 and Table 1. Under back side illumination, the nanowire CdS-CdTe solar cell with MoO3−x/Au back contact exhibits average Jsc of 21 mA/cm2, Voc of 749 mV, fill factor of 55.1%, corresponding to an average power conversion efficiency of 8.67%; this is much higher than the 5.8% value reported for the nanopillor CdS-CdTe solar cells with Cu/Au (1 nm/13 nm) back contacts from back side illumination20.

When comparing with front-side illumination, thicker MoO3−x (10 nm) and Au (15 nm) are responsible for low optical transmission. Although MoO3−x has bandgap of 3.0–3.8 eV and high transparency of more than 80% from 400 nm to near IR range, still, Au of 15 nm thickness could cause relatively strong transmission losses. Hence, obvious decrease in efficiency is on account of lower Jsc based on low transmission from back side illumination. By further exploring transparent back contacts of CdTe, for example, transparent metal at nanoscale in the future, the superstrate structured nanowire CdS-CdTe solar cells on Al substrate can become a low complexity and high efficiency solar technique.

Considering that MoO3−x behaves like a high work function metal with a low density of states at the Fermi level and has transparent properties in the visible and near IR range14,15, it is chosen as a transparent back contact candidate for nanowire CdS-CdTe solar cells. For a better understanding of the MoO3−x back contacts, the energy band diagram of the junction between CdTe and MoO3−x/Au is illustrated in Fig. 5 below. A work function of 5.7 eV and energy bandgap of 3.2 eV are assumed for MoO3−x and the electron affinity of 4.4 eV and energy band of 1.5 eV are assumed for CdTe14. Figure 5 illustrates the energy band discontinuities between CdTe and MoO3−x/Au . It is noted that Au, when placed directly next to p-CdTe, would form a blocking, Schottky diode contact with a barrier height of 0.8 eV. This would prevent hole transport from CdTe to Au contact and reduce cell performance. Introducing the thin MoO3−x interlayer between CdTe and Au removes the Schottky diode problem. Now, a valance band offset of approximately 0.2 eV occurs between the CdTe and the MoO3−x layers. Thus, MoO3−x layer functions as a well-aligned buffer layer to reduce barrier height relative to CdTe. Hence it plays an important role to ensure hole extraction and transport to the electrode. As a result, the nanowire CdS-CdTe solar cells yield enhanced performance. In addition, due to its transparent properties, MoO3−x layer, as a back contact to CdTe provides a potency to achieve superstrate structured nanowire solar cells on flexible metal foil substrate.

Our nanowire CdS-CdTe cell design with MoO3−x/Au back contacts has demonstrated the performance comparable to that of planar counterpart with MoO3−x/metal back contacts under front side illumination17,18,19. For back side illumination, it has exhibited performance much better than that of nanopillar CdS-CdTe solar cells with Cu/Au contact20 and its performance is comparable to that of planar CdS-CdTe solar cells with substrate structure7,21. It clearly illustrates the concept of MoO3−x as a transparent hole selective contact to p-CdTe due to its well-aligned band structure.

Conclusions and Future Work

We have fabricated nanowire CdS-CdTe solar cells and introduced MoO3−x as a transparent, low barrier back contact. The MoO3 layer reduces the valence band offset relative to the CdTe and creates improved cell performance. Annealing as-deposited MoO3 in N2 reduces series resistance from 9.97 Ω/cm2 to 7.69 Ω/cm2 and hence efficiency of the nanowire solar cell is improved from 9.9% to 11%. When the nanowire solar cell is illuminated from MoO3−x/Au side, it yields an efficiency of 8.67%. This reduction in efficiency is attributed to decrease in Jsc from 25.6 mA/cm2 to 21 mA/cm2 due to light transmission loss in the MoO3−x/Au electrode. Even though these nanowire solar cells, when illuminated from back side exhibit better performance than that of nanopillar CdS-CdTe solar cells structure7,21, further development of transparent back contacts of CdTe could enable a low-cost roll-to-roll fabrication process for the superstrate structure-nanowire solar cells on Al foil substrate.

Various potential improvements of our nanowire solar cell design with MoO3−x/metal back contacts can be envisioned including optimization of MoO3−x layer to further reduce resistance and optimization of CdS nanowires and CdTe layer to further improve Voc and Jsc. The FF could be improved by replacement or ideal scribing of intrinsic SnO2 to increase shunt resistance and optimization of MoO3−x layer for low series resistance. Development of a transparent metal layer on the MoO3−x will improve light transmission loss and significantly enhance Jsc under back-side illumination. Furthermore, MoO3−x with the transparent metal as the back contacts of CdTe could make the nanowire solar cells on Al foil with superstrate structure promising and facilitate a roll-to-roll fabrication process application on such solar cells, thus providing a route toward a scalable, low-cost solar cell architecture.

Additional Information

How to cite this article: Dang, H. and Singh, V. P. Nanowire CdS-CdTe Solar Cells with Molybdenum Oxide as Contact. Sci. Rep. 5, 14859; doi: 10.1038/srep14859 (2015).

References

Wu, X. High-efficiency polycrystalline CdTe thin-film solar cells. Solar energy 77, 803–814 (2004).

Jackson, P. et al. New world record efficiency for Cu (In, Ga) Se2 thin‐film solar cells beyond 20%. Progress in Photovoltaics: Research and Applications 19, 894–897 (2011).

Wang, W. et al. Device Characteristics of CZTSSe Thin-Film Solar Cells with 12.6% Efficiency. Advanced Energy Materials 4, n/a-n/a 10.1002/aenm.201301465 (2014).

Green, M. A., Emery, K., Hishikawa, Y., Warta, W. & Dunlop, E. D. Solar cell efficiency tables (version 39). Progress in photovoltaics: research and applications 20, 12–20 (2012).

Liu, M., Johnston, M. B. & Snaith, H. J. Efficient planar heterojunction perovskite solar cells by vapour deposition. Nature 501, 395–398 (2013).

Kranz, L. et al. Doping of polycrystalline CdTe for high-efficiency solar cells on flexible metal foil. Nature communications 4 (2013).

Aliyu, M. et al. Recent developments of flexible CdTe solar cells on metallic substrates: issues and prospects. International Journal of Photoenergy 2012, 10.1155/2012/351381 (2012).

Chen, D., Zhao, W. & Russell, T. P. P3HT nanopillars for organic photovoltaic devices nanoimprinted by AAO templates. ACS nano 6, 1479–1485 (2012).

Tepavcevic, S., Darling, S. B., Dimitrijevic, N. M., Rajh, T. & Sibener, S. J. Improved hybrid solar cells via in situ UV polymerization. Small 5, 1776–1783 (2009).

Ramanathan, M., S Michael Kilbey, I., Ji, Q., Hill, J. P. & Ariga, K. Materials self-assembly and fabrication in confined spaces. Journal of Materials Chemistry 22, 10389–10405 (2012).

Ramanathan, M., Tseng, Y.-C., Ariga, K. & Darling, S. B. Emerging trends in metal-containing block copolymers: synthesis, self-assembly and nanomanufacturing applications. Journal of Materials Chemistry C 1, 2080–2091 (2013).

Dang, H., Rajaputra, S., Guduru, S. & Singh, V. Cadmium Sulfide Nanowire Arrays for Window Layer Applications in Solar Cells. Solar Energy Materials and Solar Cells 126, 184–191 (2014).

Alonzo, J. et al. Assembly and organization of poly (3-hexylthiophene) brushes and their potential use as novel anode buffer layers for organic photovoltaics. Nanoscale 5, 9357–9364 (2013).

Simchi, H., McCandless, B. E., Meng, T. & Shafarman, W. N. Structure and interface chemistry of MoO3 back contacts in Cu (In, Ga) Se2 thin film solar cells. Journal of Applied Physics 115, 033514 (2014).

Battaglia, C. et al. Silicon heterojunction solar cell with passivated hole selective MoOx contact. Applied Physics Letters 104, 113902 (2014).

Battaglia, C. et al. Hole Selective MoO x Contact for Silicon Solar Cells. Nano letters 14, 967–971 (2014).

Lin, H., Xia, W., Wu, H. N. & Tang, C. CdS/CdTe solar cells with MoO x as back contact buffers. Applied Physics Letters 97, 123504–123504-123503 (2010).

Paudel, N. R., Compaan, A. D. & Yan, Y. Ultrathin CdTe Solar Cells with MoO3− x/Au Back Contacts. Journal of Electronic Materials 43, 2783–2787 (2014).

Paudel, N., Compaan, A. & Yan, Y. Sputtered CdS/CdTe solar cells with MoO3− x/Au back contacts. Solar Energy Materials and Solar Cells 113, 26–30 (2013).

Fan, Z. et al. Three-dimensional nanopillar-array photovoltaics on low-cost and flexible substrates. Nature materials 8, 648–653 (2009).

Romeo, A. et al. Development of thin‐film Cu (In, Ga) Se2 and CdTe solar cells. Progress in Photovoltaics: Research and Applications 12, 93–111 (2004).

Acknowledgements

This work was supported in part by grants from the National Science Foundation, (NSF-NIRT-ECS-0609064) and (NSF-EPCOR EPS-0447479), Department of Energy/Kentucky Renewable Energy Consortium (DE-FG36-05G085013/ULRF 05-1231G, (NSF-EPS-0447479) and by grants from the Kentucky Science and Engineering Foundation, (KSEF–148-502-02-27, KSEF- 148-502-03-68). The authors would like to thank PV measurements, Inc for quantum efficiency measurement, Dr. Suresh Rajaputra for SEM images and fabrication processes.

Author information

Authors and Affiliations

Contributions

H.D. designed and conducted the experiments, fabricated the solar cells, performed characterizations and analyzed data. V.S. conceived the idea and the overall project of the embedded nanowire layers in solar cells with MoOx contacts and analyzed the results of experimental measurements. H.D. and V.S. co-wrote the paper. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Dang, H., Singh, V. Nanowire CdS-CdTe Solar Cells with Molybdenum Oxide as Contact. Sci Rep 5, 14859 (2015). https://doi.org/10.1038/srep14859

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep14859

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.