Abstract

A Ta/TaOx/Pt stacked capacitor-like device for resistive switching was fabricated and examined. The tested device demonstrated stable resistive switching characteristics including uniform distribution of resistive switching operational parameters, highly promising endurance and retention properties. To reveal the resistive switching mechanism of the device, micro structure analysis using high-resolution transmission electron microscope (HR-TEM) was performed. From the observation results, two different phases of Ta-metal clusters of cubic α-Ta and tetragonal β-Ta were founded in the amorphous TaOx mother-matrix after the device was switched from high resistance state (HRS) to low resistance state (LRS) by externally applied voltage bias. The observed Ta metal clusters unveiled the origin of the electric conduction paths in the TaOx thin film at the LRS.

Similar content being viewed by others

Introduction

Resistive switching (RS) phenomena in various transition metal oxides (TMO) have been considerably investigated for next-generation non-volatile memory application as conventional sub-micron device fabrication skill confronts its physical limitation1,2,3,4,5. Early stage of researches mostly focused on examining various material candidates for the RS itself. Afterward, the RS reliability issue for commercial device application led to mainly investigating a few candidate materials such as TaOx6,7, HfOx8,9 and TiOx10,11,12,13. Among these, TaOx has been highlighted for its excellent endurance performance and low power consumption in the RS operation6,7. Yang. et al. reported the highly promising endurance characteristic over ~1010 RS cycles of the TaOx thin film, which is attributed to simple thermodynamic equilibrium phases of Ta-O system in the range of conventional RS operation condition7. According to their report, the high endurance characteristic of the TaOx thin film can benefit by two thermodynamic equilibrium phases-insulating oxide mother-matrix and electrically conductive phase. These two stable phases can accommodate electrical conduction paths and oxygen reservoir alternatively during the RS. Later, the conductive phase was identified as amorphous Ta-rich Ta(O) surrounded by nano-crystalline Ta2O5 phase14,15. However, direct observation on the Ta-rich phase as the electrical conduction path in the TaOx thin film is not yet presented. In this work, the highly promising RS performance of the TaOx thin film is demonstrated and microscopic analyses by high-resolution transmission electron microscope (HR-TEM) provide direct observation on the origin of the RS in the TaOx thin film.

Results

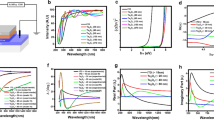

Figure 1(a) shows I–V hysteresis characteristic of a Ta/TaOx/Pt capacitor-like device. The electrical measurement was performed with applying voltage bias on top electrode (Ta) and maintaining electrical ground on bottom electrode (Pt), as schematically shown in Fig. 1(b). To avoid permanent dielectric break-down, compliance current (CC) was set to 10 mA during ‘SET’ (resistance change from high resistance state (HRS) to low resistance state (LRS) by external bias) measurement. Pristine state of the device went through the initial RS cycle remarked by the red line in Fig. 1(a), so called ‘forming’ process. Over 300 RS cycles, the tested device demonstrated highly uniform distribution of SET operation voltage at ~0.65 V and of RESET (resistance change from LRS to HRS) voltage at ~–0.6 V as denoted in Fig. 1(c). Standard deviations of the SET and the RESET voltages are respectively 0.025 V and 0.024 V and the ratio of the deviation to each operation voltage is less than 4%. The resistance distributions of each LRS and HRS are presented in Fig. 1(d). It is assumed that the resistance in each state should be statistically distributed obeying a normal distribution model. Based on this assumption, the peak-to-peak separation between the LRS and the HRS was estimated by difference between the mean resistance of the LRS and the HRS and was 6.27 (σHRS + σLRS), where the standard deviations of the HRS and the LRS resistance are σHRS and σLRS, respectively. This assures that the probability of the mutual overlap between the resistance states is less than approximately 0.0002 ppm, which can be interpreted that less than one out of 5 Giga bits may be identified as an error. In addition to the promising RS I–V characteristics of the device, severely damaged region in the top Ta electrode was microscopically observed after the RS measurement as shown in the inset of Fig. 1(a). The similar observation on TiOx thin films has already been reported by others12,16. It is attributed to sudden evolution of oxygen gas within the thin films during the RS to induce the rupture of the top electrode. This blown off region provides a useful site to observe the origin of the RS with unveiling the causality of the rupture. The detailed observation results will be discussed in the following.

(a) The I–V characteristic of Ta/TaOx/Pt device and the inset presenting the blown-off region during SET operation. (b) The schematic figure of Ta/TaOx/Pt device and measurement system (c) and (d) show cumulative probability of the operation voltage and LRS/HRS resistance distribution, respectively.

The reliability characteristics of the tested device were examined and the electrical endurance and the retention characteristic are shown in Fig. 2 (a), respectively. The current level of the device was read at reading voltage of 0.2 V for the endurance and the retention measurements and the tested device was kept at 125 °C for accelerated condition of the retention measurement. The device demonstrated the reliable electrical endurance of up to 105 RS cycles and the retention characteristic of 104 sec. The retention characteristic was also certified in various temperature conditions, data not shown here and the reliable retention characteristic had been confirmed. Although the electrical endurance performance of the tested device in this study was lower than one in the previous report by Yang et al. 7, the presented result is still competitive enough to satisfy a desirable criterion of 105 RS cycles for emerging memory application17.

The effect of active device area on the RS characteristics was investigated with a set of the samples patterned into 6 different sizes as shown in Fig. 2(C). The resistance of the HRS rapidly increased up to 65% more as the active area decreased by 35 times, whereas the LRS showed relatively insensitive dependency on the various active cell sizes. The size-independent characteristic of the LRS indicates that the electrical conduction paths must be locally confined within the TaOx matrix regardless of the cell size. The localized nature of the LRS will be correlated with its microscopic observation later.

The temperature dependency of the LRS and the HRS is shown in Fig. 2(d). In the LRS, the resistance level of the device rose up as the measurement temperature increased, which represents typical characteristic of current conduction in metals. On the other hand, the resistance of the HRS responded in the opposite way to the LRS. It indicates that the conduction paths formed in the LRS have metal-like characteristic and these metal-like conduction paths might weaken or diminish through the RESET operation. One possible model for this phenomenon is that the metal-like conductive phase was formed during the SET operation, similarly reported as oxygen deficient phase, Magnéli (TinO2n-1), in the TiOx case12,18. The other is that metallic clusters are generated and connected with each another to finally build up the conduction paths between the top and the bottom electrodes. The conduction paths of the metallic clusters are likely to arise in the TaOx based RS system because the thermodynamic equilibrium of the Ta-O system shows only two stable phases, oxide Ta2O5 and metal Ta, below 300 °C7,15,19,20. Moreover, two thermodynamic equilibrium phases (Ta2O5 and Ta) are not reactive with each other and the formed Ta phase can reside after the RS operation, resulting in the satisfactory LRS retention characteristic7,15. Although there are several metastable phases in Ta-O system, these oxide phases can only contribute to the circumstantial portion of the electrical conduction due to their insulating nature. Additionally, the electron conduction through those metastable phases has positive temperature dependency oppose to the metallic conduction.

To microscopically investigate the TaOx thin film, HR-TEM and AES analyses were performed on the samples. Figure 3(a) shows the AES depth profile of the pristine Ta/TaOx/Pt device. The relative atomic concentration of Ta and O was estimated to be approximately 3:7 within the TaOx layer. In addition, the top layer of Ta has negligible oxygen concentration to remain as a metal electrode. Figure 3(b) shows vertical structure of the Ta/TaOx/Pt device in the pristine state examined by HR-TEM. The inset of Fig. 3(b) provides the fast Fourier transformation (FFT) image of a smeared ring pattern in the TaOx region, which indicates that the whole TaOx thin film is composed of amorphous oxide phase homogeneously. The formation of the amorphous TaOx layer is reasonable because the TaOx thin film deposited at room temperature had insufficient activation energy to form any crystalline structure. The TaOx thin film has the electrical property of an insulator in the pristine state as shown in Fig. 1(a) due to the homogeneously dispersed oxygen atoms.

In contrast to the homogeneous amorphous TaOx thin film in the pristine state, some crystalline structures were observed after the SET operation as shown in Fig. 4(a). The most noticeable change is highlighted and marked as the dashed-yellow-square region ‘1’ in Fig. 4(a) and the related FFT image shown in Fig. 4(b). The electron diffraction pattern (DP) appearing as the spot pattern was observed in Fig. 4(b), which was not observed in the pristine state of the TaOx thin film. It should be noted that the amorphous phase was still observed as shown in the dashed-yellow-square region ‘2’ in Fig. 4(a) and the related FFT image presented in Fig. 4(c). It suggests that the observed local crystalline structure should be formed during the SET operation.

To figure out the crystalline structures, the electron DP shown in Fig. 4(d) was analysed and identified as Ta-metal phases and its equi-directional crystallographic planes. The representative DPs of the Ta-metal phases were marked with dashed yellow and red circles in Fig. 4(d). There are two well-known phases of the Ta-metal in crystallographic point of view21,22. One is called ‘alpha-Ta’ (α-Ta), a body-centered cubic structure with lattice parameters of a = b = c = 3.305 Å and the other is ‘beta-Ta’ (β-Ta), a primitive tetragonal structure with lattice parameters of a = b = 10.19 Å and c = 5.313 Å21,22. The representative planes of the alpha-Ta were found in the electron DP of the tested device in the LRS and indexed as (110) and (321) planes. In Fig. 4(d), the red and yellow dashed circles are related to the alpha-Ta and the beta-Ta, respectively. Based on the measured values from the electron DP image and the crystallographic equations described below, the extracted lattice parameters of (110) and (321) of the alpha-Ta planes were 3.29 Å and 3.35 Å, respectively.

Where dhkl is inter-planar spacing in real space, (h k l) is Miller indices and kis reciprocal vector when the Bragg condition is met. The lattice parameters extracted from each plane of the alpha-Ta have lattice strain less than 1% compared to the reference value. It seems comprehensible when the crystalline Ta-metal phases are surrounded by the amorphous TaOx. Moreover, the lattice mismatch can readily occur at the interfaces between the oxides and the metal phases. It is known that the lattice strain of less than 3% in the Ta metal phases is bearable to maintain their own crystalline structures even in thin film morphology23. Equivalent planes of (321) were also discovered to revalidate the crystalline structure as the alpha-Ta phase. Those planes undisputedly appeared at integer times of the reciprocal vector of (321) as supposed, simultaneously satisfying the symmetry of (321). It reassured that the lattice parameters obtained from the electron DP of the tested device in the LRS agree with ones of the alpha-Ta phase.

Similarly, the characteristic planes of the tetragonal beta-Ta were found to be identified as (312) and (313). The tetragonal structure of the beta-Ta requires more than two diffraction planes in order to extract each lattice parameters as shown in Eq. (2). The lattice parameters from those planes were a = b = 10.44 Å and c = 5.34 Å. Discrepancy between the reference and the extracted was respectively about 2% and 0.5% for ‘a’ and ‘c’, which is still laid in the elastic deformation range. Furthermore, equivalent planes of (312) of the beta-Ta phase were also observed and the symmetry of those planes was confirmed to reassure the crystalline structure as the beta-Ta phase. Although the beta-Ta phase known as a metastable phase is easily converted to the alpha-Ta above 750 °C, the beta-Ta phase can coexist with the alpha-Ta even in the thin film24. Thus the distinctive electron DP from two different metal-Ta phases illustrates that the alpha- and the beta-Ta phases coexist as a mixture within the TaOx matrix after the SET operation and these metal phases should mainly contribute to the electron conduction in the LRS.

Discussion

A series of the RS cycle is presented in Fig. 5 schematically. The RS cycle is initiated from the pristine state by forming process (Fig. 5(a)). The connection of the Ta metal phases is formed and the resistance of the device lowers to the LRS (Fig. 5(b)). Then the device transits to the HRS (Fig. 5(c)) through the RESET operation. The initial resistance of the pristine device, however, could not be fully recovered at the HRS as shown in Fig. 1(a) and the HRS showed the positive temperature dependency as an insulator or a semiconductor behaves. This indicates that some part of the Ta metal phase connection may disappear by recombination with oxygen during the RESET and the electrical conduction path may be shut conclusively. Further microscopic analysis on the device at the HRS is missing in this paper, which can explicitly confirm the Ta metal phases may be partially left after the RESET. Multiple trials were made on HR-TEM observation with the LRS TaOx film during in-situ RESET process to paradoxically disclose the origin of the conduction path in the TaOx film. Unfortunately, the RESET with the LRS samples prepared for the HR-TEM was extremely difficult and all the attempts ended up with failure. The conduction path in the TaOx matrix has the restricted oxygen interchange border only in the both sides because the HR-TEM samples were sliced into a form of thin flake and the HR-TEM chamber was kept at ultra-high vacuum12. Under these circumstances, the in-situ observation of the RESET process was impossible to work out as desired.

In conclusion, the stable and promising RS performance of the Ta/TaOx/Pt device was demonstrated in this research. From the experimental results, the main factor of the LRS in the TaOx based RS system turned out to be the Ta metal phases. The LRS of the tested Ta/TaOx/Pt device showed a typical temperature dependency characteristic of typical metals and device size independent nature. Moreover, thermodynamic equilibrium suggests that the only metallic phase in the Ta-O system is Ta metal. In addition, the electron DP of the device at the LRS indicated that two types of the Ta metal phases should exist in the TaOx matrix. It was the first direct observation on the origin of the conduction path formed in the TaOx film during the SET operation.

Methods

A TaOx thin film of approximately 30 nm thick was deposited on Pt/Ti/SiO2/Si substrates by reactive rf-sputtering technique at room temperature. During the TaOx thin film deposition, the rf-sputtering power and the deposition pressure were maintained at 100 W and 2 mTorr, respectively. A top electrode of 30 nm thick Ta layer was deposited on the TaOx film by dc-sputtering method at room temperature and patterned through photolithography and lift-off process, in order to measure the electrical properties of the TaOx thin film. The current-voltage (I–V) characteristics of the fabricated samples were examined using a Keithley4200 semiconductor characterization system at room temperature. The pulse endurance measurement was also performed using a HP81110A arbitrary function wave generator. The electrical pulses of 100 nsec/2 V and 500 nsec/−2.5 V were applied sequentially for writing and erasing operation of the device. The material composition of the fabricated device was analysed by Auger electron spectroscopy (AES) using a scanning Auger nano-probe (ULVAC PHI-700). The sample surface was sputtered off for 30 sec prior to the AES analysis to eliminate native oxides and the undesired on the top surface. During the AES analysis, the sputtering rate was maintained at 15 nm/min estimated from SiO2 case. The vertical structure of the Ta/TaOx/Pt device was characterized by HR-TEM (The FEI Titan™ 80–300, 200 kV, a lateral resolution of less than 0.1 nm). The cross-sectional sample for the HR-TEM analysis was prepared by focused ion beam (FIB) technique. Firstly, the sample was milled into an approximately 30 μm thick slice by mechanical polishing. Secondly, the polished sample was bonded onto a one-sided Mo grid and fabricated to thinner area of about 30 nm thick by FIB (Analytical) technique.

Additional Information

How to cite this article: Yang, M.K. et al. Direct evidence on Ta-Metal Phases Igniting Resistive Switching in TaOx Thin Film. Sci. Rep. 5, 14053; doi: 10.1038/srep14053 (2015).

References

Waser, R. & Aono, M. Nanoionics-based resistive switching memories. Nat. Mater. 6, 833–840 (2007).

Strukov, D. B., Snider, G. S., Stewart, D. R. & Williams, R. S. The missing memristor found. Nature 453, 80–83 (2008).

Waser, R., Dittmann, R., Staikov, G. & Szot, K. Redox-based resistive switching memories – nanoionic mechanisms, prospects and challenges. Adv. Mater. 21, 2632–2663 (2009).

Borghetti, J. et al. ‘Memristive’ switches enable ‘stateful’ logic operations via material implication. Nature 464, 873–876 (2010).

Sawa, A. Resistive switching in transition metal oxides. Mater. Today 11, 28–36 (2008).

Lee, M. J. et al. A fast, high-endurance and scalable non-volatile memory device made from asymmetric Ta2O5−x/TaO2−x bilayer structures. Nat. Mater. 10, 625–630 (2011).

Yang, J. J. et al. High switching endurance in TaOx memristive devices. Appl. Phys. Lett. 97, 232102 (2010).

Gonon, P. et al. Resistance switching in HfO2 metal-insulator-metal devices. J. Appl. Phys., 107, 074507 (2010).

Govoreanu, B. et al. 10×10nm2 Hf/HfOx crossbar resistive RAM with excellent performance, reliability and low-energy operation IEDMTech. Dig. 729 (2010).

Yang, J. J. et al. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotech. 3, 429–433 (2008).

Choi, B. J. et al. Resistive switching mechanism of TiO2 thin films grown by atomic-layer deposition. J. Appl. Phys. 98, 033715 (2005).

Kwon, D. et al. Atomic structure of conducting nanofilaments in TiO2 resistive switching memory. Nat. Nanotechnol. 5, 148 (2010).

Kim, G. H. et al. 32× 32 crossbar array resistive memory composed of a stacked Schottky diode and unipolar resistive memory. Adv. Funct. Mater. 23, 1440 (2012).

Miao, F. et al. Anatomy of a Nanoscale Conduction Channel Reveals the Mechanism of a High‐Performance Memristor. Adv. Mater. 23(47), 5633 (2011).

Mickel, P. R. et al. A physical model of switching dynamics in tantalum oxide memristive devices. Appl. Phys. Lett., 102, 223502 (2013).

Yang, J. J. et al. The mechanism of electroforming of metal oxide memristive switches. Nanotechnology 20, 215201 (2009).

International Technology Roadmap for Semiconductors: 2013 Edition - Emerging Research Devices. (2013) Available at: http://www.itrs.net/home.html. (Accessed: 23th July 2015).

Kim, G. H. et al. Improved endurance of resistive switching TiO2 thin film by hourglass shaped Magnéli filaments. Appl. Phys. Lett. 98, 262901 (2011).

Garg, S. P. et al. The O-Ta (Oxygen-Tantalum) system. J. Phase Equilib., 17, 63 (1996).

Chandrasekharan, R., Park, I., Masel, R. I. & Shannon, M. A. Thermal. Oxidation of Ta-Films at Various Oxidation States from 300 to 7001C. J. Appl. Phys. 98, 114908 (2005).

Moseley,P.T. & Seabrook. C. J. The crystal structure of β-tantalum ActaCrystallographica Section B Structural Crystallography and Crystal Chemistry, 29, 1170 (1973).

Swanson, H. E . & Tatge, E . Standard X-Ray Diffraction Powder Patterns. Natl. Bur. Stand. (U.S.), Circ. 539, 359 (1953).

Rittle, D. et al. Thermomechanical characterization of pure polycrystalline tantalum. Material Science and Engineering A. 447, 65 (2007).

Lee, D. et al. Texture, structure and phase transformation in sputter beta tantalum coating. Surface and Coatings Technology. 44, 177 (2004).

Acknowledgements

Dr. M.K. Yang and Dr. H. Ju contributed equally to this work. Dr. J.K. Lee and Dr. H.C. Ryu are designated conjointly as corresponding authors. This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (grant no. NRF-2013R1A1A1076113).

Author information

Authors and Affiliations

Contributions

M.K.Y., H.J. and G.H.K. planned the project and wrote the manuscript. J.K.L. and H.C.R. contributed to the conception of the experiment. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kyu Yang, M., Ju, H., Hwan Kim, G. et al. Direct evidence on Ta-Metal Phases Igniting Resistive Switching in TaOx Thin Film. Sci Rep 5, 14053 (2015). https://doi.org/10.1038/srep14053

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep14053

This article is cited by

-

Oxidation of Fine Tantalum Particles: Metastable Intermediates and Multistep Kinetics

Oxidation of Metals (2020)

-

Novel Vertical 3D Structure of TaOx-based RRAM with Self-localized Switching Region by Sidewall Electrode Oxidation

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.