Abstract

Silver is one of the most important materials in plasmonics. Tuning the size of various silver nanostructures has been actively pursued in the last decade. However, silver nanobelt, a typical one-dimensional silver nanostructure, has not been systematically studied as to tuning its size for controllable plasmonic response. Here we show that silver nanobelts, with mean width ranging from 45 to 105 nm and thickness at ca. 13 nm, can grow abundantly on monolithic activated carbon (MAC) through a galvanic-cell reaction mechanism. The widths of silver nanobelts are positively correlated to the growth temperatures. The width/thickness ratio of the silver nanobelts can be adjusted so that their transversal plasmonic absorption peaks can nearly span the whole visible light band, which endows them with different colours. This work demonstrates the great versatility of a simple, green and conceptually novel approach in controlled synthesis of noble metal nanostructures.

Similar content being viewed by others

Introduction

The advancement of nanoscience and technology has enabled its wide applications in catalysis, biomedicine and plasmonics etc1. Over the past two decades, a wealth of methods has been developed to preparing nanostructures with controlled size and shape2,3,4,5. Among them, wet chemical synthesis of nanostructured noble metals or alloys2,6,7,8 consisting of Au, Ag, Pd and Pt has shown great capability and flexibility. Particular attention has been paid to Ag, since in the visible (vis) and near-infrared (NIR) bands, it can support surface plasmon polaritons with the highest plasmonic ability9. Surface plasma not only give rise to vivid colours characteristic of specific types of Ag nanostructures, but also drive increasing applications such as biological labelling, imaging, sensing, photothermal therapy and plasmonic circuitry etc. Various Ag plasmonic nanostructures in such forms as cubes10, octahedra11, plates12, rods and wires13,14 have been created and sometimes their size can also be tuned to exhibit controllable plasmonic response. For example, by reducing the seed concentration in a seed-mediated micelle-directed synthesis, Ag nanorods with length/diameter aspect ratio ranging from 4.6 to 18 were prepared, which resulted in red-shift of the longitudinal plasmon mode from 885 nm to a wavelength longer than 1800 nm13. In addition, by collecting samples at different stages in a seed-mediated polyol synthesis, Ag nanocubes with different edge lengths ranging from 36 to 172 nm were obtained, which showed a gradual red-shift from 430 to 537 nm for the major dipole localized surface plasmon resonance (LSPR) peak10. The extinction spectra of Ag nanowires also demonstrated diameter-dependent red-shift from 391 to 547 nm for the transverse plasmon resonance, when the mean diameter was increased from 70 to 450 nm15. Notably, one-dimensional nanomaterial is of particular interest in that it supports propagating surface plasmon (PSP) and can be utilized as waveguides16. Beside nanowire, Ag nanobelt is another single-crystalline one-dimensional nanomaterial with a rectangular cross-section. Several methods (see Table 1) have been developed for the preparation of Ag nanobelts, such as reflux-induced nanoplates assembly17, polymer-controlled ascorbic acid reduction18, electrochemical method19,20, galvanic displacement21 and hydrothermal22 method etc. However, to our knowledge, there has been no report on the synthesis of Ag nanobelts with both tunable size and controlled plasmonic response. The scarcity in bulk production of Ag nanobelts with specified physical properties will certainly limit their application as nanoscale device components.

In our previous work23,24,25, a new method was developed to growing Ag micro/nano structures on monolithic activated carbon (MAC). Briefly, the functional groups on the interior surfaces, i.e., in the micropores of MAC (with sufficiently high BET area) caused the reduction of Ag+ ions on the exterior surface of MAC through a galvanic-cell mechanism. Abundant fluffy Ag products, like plant in a field, grew on the exterior surface of MAC and could be easily collected. This method differs from all other methods in that MAC acts as both solid substrate and reducing agent. The micropores of MAC do not confine the shape and size of Ag products, in contrast to commonly used substrates such as anodic aluminum oxide (AAO) containing cylindrical channels20,26. Rather, various structures such as dendrites23, belts, plates, flowers25 and cages24 can be selectively prepared by changing the identity and concentration of Ag precursors and modifying the MAC pretreatment. In particular, Ag belts can be routinely prepared in a large scale. However, the Ag belts obtained in our previous work actually had width of ca. 1 μm and thickness of ca. 300 nm. This size is too large to have interesting optical and electronic effects27. In the current work, by forming metallic particles on MAC surfaces in prior as the growth initiator and choosing sparingly soluble Ag2O as the Ag precursor to control Ag+ release and create a stable reaction environment, we prepared Ag nanobelts with width down to tens of nanometers and thickness of ca. 13 nm in a high yield. All the Ag nanobelts have characteristic colours dependent on their cross sectional aspect ratio. Moreover, it was found that the temperature of the reaction media inherently affected the size of the Ag nanobelts, which in turn determined the optical absorption properties of the Ag nanobelts. In principle, we have been able to tune the size of Ag nanobelts for controllable plasmonic response.

Results

Figure 1 displays typical electron microscopic (EM) images of Ag nanobelts grown on MAC. The SEM image (Fig. 1a) shows that abundant wire-like products were obtained, with very few quasi-spherical particle impurities. Figure 1b is a typical TEM image of the Ag nanobelts. The mean width of the nanobelts shown in this image is ca. 45 nm. The thickness, as measured from a twisted nanobelt near the left side, is ca. 9 nm. This flat and smooth nanostructure lying on TEM grid is also confirmed by a Moire pattern at the right side, originated from the stacking of two or three nanobelts with different crystal orientation17. Figure 1c presents the TEM image of an individual nanobelt. Its selected area electron diffraction (SAED) pattern, as inserted in the upper right corner, has a six-fold symmetry. The d spacing of the planes corresponding to the brightest set of spots (squared) is calculated to be 0.144 nm and the inner, weaker spots (circled) give a d spacing of 0.25 nm. This SAED pattern is identical to those reported previously18 and can be readily indexed to a single crystal fcc Ag in its  zone axis. The two diffraction spots, squared and circled, can be attributed to {220} and 1/3{422} reflections, respectively. The appearance of the formally forbidden 1/3{422} reflection spots also indicates that the nanobelts have flat top and bottom {111} facets17. In Fig. 1d, the HRTEM image of a Ag nanobelt exhibits clear fringes parallel to the edge with a spacing of 0.25 nm, which is due to the 1/3{422} reflection. A spacing of 0.29 nm for the planes perpendicular to the edge can be associated with {110} reflection, indicating that the Ag nanobelt is oriented along [110] direction. This [110] primary growth direction is also in accordance with most previous studies17,18,22. Occasionally, Ag nanobelt branches off into two stems at 60° (see Fig. 1b) and both are still along the <110> growth direction.

zone axis. The two diffraction spots, squared and circled, can be attributed to {220} and 1/3{422} reflections, respectively. The appearance of the formally forbidden 1/3{422} reflection spots also indicates that the nanobelts have flat top and bottom {111} facets17. In Fig. 1d, the HRTEM image of a Ag nanobelt exhibits clear fringes parallel to the edge with a spacing of 0.25 nm, which is due to the 1/3{422} reflection. A spacing of 0.29 nm for the planes perpendicular to the edge can be associated with {110} reflection, indicating that the Ag nanobelt is oriented along [110] direction. This [110] primary growth direction is also in accordance with most previous studies17,18,22. Occasionally, Ag nanobelt branches off into two stems at 60° (see Fig. 1b) and both are still along the <110> growth direction.

Figure 2 depicts the TEM images of five samples #1, #2, #3, #4 and #5, prepared at 30, 24, 24, 20 and 19 °C respectively, along with their width histogram. The mean widths of these nanobelts are listed in Table 2. They are 105.4 nm (#1), 67.5 nm (#2), 62.4 nm (#3), 61.8 nm (#4) and 45.3 nm (#5). These results suggest that the width of Ag nanobelts decreases at lower growth temperature. However, beside temperature, other experimental parameters such as MAC structure and properties and Ag seeds loading condition etc. may have a profound effect on the size of Ag nanobelts. These experimental conditions had not been able to strictly controlled and they often smeared the width-temperature relationship. Upon hundreds of experimental tests, it turned out to be a general trend that the width of Ag nanobelts positively correlated to the reaction temperature.

Due to the scarcity of nanobelts with their side edge parallel to the electron beam, it is difficult to get mean thickness of Ag nanobelts using TEM. Atomic force microscope (AFM) was employed to measure the thickness for the five samples mentioned above. A typical AFM image of an individual nanobelt is shown in Supplementary Fig. S1 and the section analysis yielded thickness of 13.607 nm (shown as “vertical distance” in the image). For the five samples mentioned above, the thicknesses of ca. 10 nanobelts per sample were measured and their mean thicknesses are also listed in Table 2. These nanobelts have mean thickness between 11 and 16 nm. Apparently, there is no simple relationship between the reaction temperature and mean thickness, suggesting that other parameters may affect the thickness no less than reaction temperature.

Importantly, these Ag nanobelts prepared on MAC showed different colours under common daylight illumination. For the five Ag nanobelt samples mentioned above, digital photographs were taken and displayed in Fig. 3. Nanobelts #1, #2, #3, #4 and #5 appear light-blue, blue-purple, red, blue and purple respectively. These as-grown colourful nanobelts resting on the MAC substrate (as most clearly seen in #2 of Fig. 3), looking like colourful seaweeds, can be easily detached by plastic tweezers and dispersed in suitable solvents. Notably, although there have been a variety of methods to preparing noble metal nanobelts28 and some methods seem to have some tunability on their size20,22, to our knowledge, there has been no report on the synthesis of noble metal nanobelts with different colours. Therefore, our simple synthetic method could provide a competitive alternative to tune the size and physical properties of noble metal nanobelts.

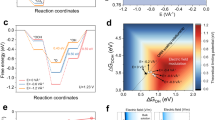

It is well known that the brilliant colour of noble metal nanoparticles is resulted from absorption and scattering of light associated with surface plasmon resonance (SPR)9, i.e. the collective oscillation of free electrons in phase with the alternating electric field of the incident light. Using UV-Vis-NIR to measure the extinction spectra is a traditional and most prevalent way to characterize the plasmonic response of noble metal nanoparticles. The extinction spectra of the five nanobelt samples mentioned above are illustrated in Fig. 4a. Each happens to exhibit three distinctive peaks at the UV, visible and IR band respectively. While the wavelength of the UV (335 nm) and IR (1459 nm) peaks are relatively invariant, that of the visible peak shifts significantly from 514 nm to 714 nm. (Yellow Ag nanobelts with their visible peak wavelength at 474 nm were also obtained in our experiments at reaction temperature 13 °C. However, due to the lack of structural characterization they are not included here. see Supplementary Fig. S2). Notably, though there have been many experimental and theoretical studies concerning UV-Vis-NIR extinction spectra of other nanostructures, those for Au and Ag nanobelts are quite scarce17,22,29. Here, the UV peak at 335 nm may be tentatively attributed to the out-of-plane quadrupole plasmon resonance mode, based on discrete dipole approximation (DDA) calculations by Schatz et al.17,30. The invariance of this peak is similar to the quadrupole resonance of Ag nanowires, whose wavelength is also independent on their diameter15. The NIR peak at 1459 nm should be ascribed to the first overtone of O-H stretch of the ethanol solvent31,32.

The change of visible peak wavelength in the extinction spectra (Fig. 4a) corresponds directly to the colour of these Ag nanobelts (Fig. 3), i.e., samples that appear blue have longer extinction wavelengths, while those showing red tint display shorter ones. Recently, J. H. Hafner et al.29 used dark field polarized light microscope to collect the extinction spectrum of individual Au nanobelt. By correlating the peak wavelength to the width/thickness ratio, assisted by finite-difference time domain (FDTD) calculations, they were able to establish positive relationship between a transversal antisymmetric plasmon peak wavelength and the width/thickness ratio. Inspired by their work, we also included in Table 2 the size (mean width as measured by TEM and mean thickness as measured by AFM) and visible peak wavelength for the five nanobelt samples. The relationship between the visible peak wavelength and the width/thickness ratio was plotted in Fig. 4b. Clearly, our results agree well with the positive correlation as found by Hafner et al.29. Notably, both their single and our collective spectral peak wavelenths somewhat deviate from the approximately linear relationship with width/thickness ratio proposed theoretically29. Therefore, the visible peaks observed in our extinction spectra can be assuredly attributed to the transversal plasmon mode. The blue- or red-shift of this peak as resulted from the variation of the width/thickness ratio, which is in turn tunable by experimental condition such as the reaction temperature, accounts for the different colours of Ag nanobelts prepared on MAC. This size-colour relationship was also confirmed by our XRD results, as presented in Supplementary Fig. S3.

Discussion

In this work, for the first time, we provide a method to growing Ag nanobelts with size-dependent plasmonic response in the visible wavelengths. Among all the available approaches for the synthesis of Ag nanobelts (Table 1), the hydrothermal22 and electrochemical20 methods also showed some tunability on the size, including the width and thickness. However, the reported data showed that the nanobelt sizes were a bit too large to give characteristic plasmonic absorption in the visible light region. Both reports20,22 gave nanobelts’ dimension somewhat larger than the electron mean free path (EMFP) of 52 nm for Ag33. In fact, only a broad peak centred at 392 nm was observed in the extinction spectrum by Yang22, which was attributed to the transverse plasmon absorbance and no extinction spectra were given by Liu20. On the other hand, in our current work, we prepared Ag nanobelts with their mean thickness and width at 11 ~ 16 and 45 ~ 105 nm respectively. According to Murphy et al.14, interesting optical and electronic effects are expected on the 10 ~ 100 nm scale for metallic nanoparticles. Therefore, the sizes of Ag nanobelt prepared in this work fall within the active scale for plasmon excitation, which explains why they exhibit excellent plasmonic response.

It is imperative to understand why the nanobelt size can be greatly reduced from micrometer25 to nanometer scale. Figure 5 displays the synthestic procedure of Ag nanobelts on MAC (see Methods for more detail) in this work. Briefly speaking, colourful Ag nanobelts (in Fig. 5d) were prepared by immersing MAC preloaded with metal particles (MAC@Ag as shown in Fig. 5c) in water, where sparingly soluble Ag2O powders had been placed at the bottom of the beaker. Fluffy Ag nanobelts grew on the exterior surface of MAC@Ag as resulted from continuous reduction of Ag+ (dissolved from Ag2O) by reductive functional groups (such as –OH or –CH=O) on the interior surface of MAC@Ag through a galvanic cell reaction mechanism (Fig. 6)23,24,25. There are mainly two differences from our previous work25, where Ag belts only at the micrometer scale were produced. Firstly, MAC should be preloaded with tightly bound metal particles. Beside Ag, we have found that preloaded Au, Pt or Pd particles can also be used to initiate the growth of nanometer-scaled Ag belts. There is no specific requirement for the size and shape of the preloaded metal particles. In our experiments, the MAC that had been used to grow Ag micro-belts or plates in [Ag(NH3)2]NO3 aqueous solution25 has proven to be excellent candidates only if the loosely-attached micro-belts or plates were removed and the MAC ultrasonicated and dried (see Fig. 5a–c). Secondly, instead of [Ag(NH3)2]NO3, Ag2O was used as the Ag precursor in our current work. We have found that, at appropriate concentrations, say, 10−4 M, [Ag(NH3)2]NO3 can also be occasionally used to grow nanometer-scaled Ag belts, but the reproducibility cannot stand test. On the other hand, Ag2O is a robust precursor for growing Ag nanobelts.

A schematic illustrating the synthetic procedure of silver nanobelts on MAC.

(a) Firstly, an MAC was immersed into a freshly prepared [Ag(NH3)2NO3] solution. (b) Secondly, after 24 hr, silver micro- belts/plates were prepared on the surface of MAC. (c) Thirdly, the MAC in (b) was stripped of loosely attached silver, ultrasonicated in ethanol and dried in air. It was labelled as MAC@Ag after the treatment. (d) Lastly, after immersing MAC@Ag in DI water containing Ag2O powder for 48 hr, fluffy silver nanobelts grew on MAC@Ag substrates. The insets show SEM images of (a) untreated MAC, (b) silver micro belts/plates grown on MAC, (c) the exterior surface of MAC@Ag and (d) silver nanobelts.

The metal particles preloaded on MAC may act as both electron conductors and heterogeneous nucleation sites. Since Ag+ ions were reduced by functional groups inside MAC micropores through a galvanic-cell mechanism, i.e., electrons transfer from inside MAC to the exterior surface during nanobelt growth, the tightly bound metal particles should be better electron conductors. Thus Ag+ ions should be preferentially reduced to Ag0 on these preloaded metal particles rather than on the carbon substrate. In addition, it may be due to the catalytic properties of metal particle surfaces34 that Ag+ ions, at so low concentrations as provided by Ag2O dissolution in DI water, could be reduced, overcome the nucleation barrier and grow into nanobelts. Without preloaded noble metal particles, we have found that no Ag product would appear after a prolonged immersion of MAC into a beaker containing Ag2O and DI water. This observation further implies the prerequisite of metal particles as the growth initiator of Ag nanobelts. These metal particles also provide substrates, breaking the symmetry of the reaction environment and imposing a geometric constraint appropriate for anisotropic growth of silver nanobelts35,36. Further, we have found that Ag nanobelts at thickness of ca. 13 nm could abundantly grow on MAC preloaded with micrometer-scaled metal particles (see the inset of Fig. 5c for a typical SEM image of MAC@Ag surface). To explain this phenomenon, it is suggested that these Ag nanobelts probably grow out from sharp edges or vertices of the metal particles21. Since the growth of Ag nanobelts is a diffusion limited kinetically controlled process2, the corners of the metal particles may have much more opportunity to interact with Ag+ ions and become sites of rapid growth37, ensuring the small size of the nanobelts irrespective of the initiating metal particles.

Choosing Ag2O as Ag precursor is another important measure toward successful synthesis of Ag belts at the nanometer scale. The solubility of Ag2O in water at 20 °C is 0.0013 g/100 mL38, which is equivalent to 0.112 mM Ag+. This concentration is lower than typical experimental conditions for wet chemical synthesis of Ag nanoparticles. For example, Bai et al.18 synthesized Ag nanobelts by reducing 0.5 mM AgNO3 with ascorbic acid. Cao et al.39, though also used saturated Ag2O supernatant solution (ca. 0.2 mM Ag+) as Ag precursor, applied a strong reducing agent, hydrazine hydrate and produced triangular and hexagonal nanoplates, with edge length varying from 40 to 145 nm and thickness at ca. 10 nm. In fact, in our previous work25, when 0.1 mM [Ag(NH3)2]NO3 was used as the precursor, the main product was also hexagonal plates (but having much larger sizes, with edge length at several μm and thickness at ca. 200 nm). In our current work, at first glance, the low Ag+ concentration, coupled to only modest reductive functional groups (such as –OH and –CH=O covalently bound to MAC)25, may not be a favourable condition for crystal nucleation, according to LaMer’s nucleation mechanism40. However, it may be due to the large BET area and high ion absorption properties of MAC, that Ag+ can be enriched near the exterior surface of MAC and reduced to Ag0 on the catalytic metal particles, creating a local layer where heterogeneous nucleation may occur. At the growth stage, the solid Ag2O may serve as a non-exhaustible reservoir for continuous supply of Ag+ onto the nanobelts growth frontier, creating a stable reaction environment. Notably, a scrutinized comparison of the nanobelts prepared in this work and the nanoplates synthesized by Cao et al.39 revealed a hidden similarity. Both use Ag2O as Ag precursor and both have thickness at 5 ~ 20 nm and edge length (or width) varying from 40 nm to over 100 nm. This similarity suggested that the low solubility of Ag2O played a key role in reducing the size of Ag particles down to nanometer scale.

Although size control of many nanostructures such as nanowires15, nanorods13, nanocubes10, nanoprisms12,39 has been reported by many researchers, surprisingly, there have been very few papers dealing with cross-sectional size control of wet-chemically synthesized nanobelts. In hydrothermal synthesis of Ag nanobelts, Yang et al.22 increased the [citrate3−]/[Ag+] ratio from 1:1 to 20:1, while keeping [Ag+] constant and found that the nanobelt width decreased gradually from 212 nm to 70 nm. Here the citrate served both as reducing and capping agent. They attributed the size-reduction to the improved protecting ability exerted by citrate3−. Liu et al.20, in their electrochemical growth of Ag nanobelts, found that by improving [NH3·H2O] in the electrolyte solution, the nanobelt thickness increased from 7 to 98 nm. The increase of the thickness of Ag nanobelts was ascribed to the reduction of the thickness of double layer on the surface of alumina nanochannels, associated with higher electrolyte (NH4+) concentration. In our current work, the reaction beaker contained only MAC@Ag and saturated Ag2O in DI water. It was quite “clean”41 without any water soluble organic or inorganic reagent. Therefore, reaction temperature was the only adjustable parameter during the growth of Ag nanobelts. Our results indicated that the reaction temperature positively correlated with nanobelt width (Fig. 2). To our knowledge, there has been no study describing the effect of reaction temperature on the size of wet chemically synthesized nanobelts. In their vapour-solid (VS) deposition for the growth of α-Al2O3 nanobelts, Fang et al. also found a positive correlation between temperature and nanobelt width within four deposition zones from 1100 to 1300 °C42. Higher partial pressure and higher flow rate of the reactant associated with higher temperature were credited to the larger cross-section. In the gallium-catalysed thermal oxidation of iron substrate for the growth of α-Fe2O3 nanostructure, Yang et al.43 found the width of α-Fe2O3 nanobelt increased with temperature at 600 ~ 750 °C. The increase of width was attributed to higher supersaturation and higher diffusion rate of Fe and O in Fe-Ga nanoscale droplet, which favoured the two-dimensional nucleation with larger width. In our current work, firstly, the solubility of Ag2O increases from 0.0013 to 0.0053 g/100 ml if the water temperature is elevated from 20 to 80 °C38. Secondly, the calculated mobility of Ag+ in aqueous solution can increase from 5.15 × 10−4 to 7.04 × 10−4 cm/s as the temperature is elevated from 15 to 30 °C44. As the solution was kept stationary during our experiment, both these factors mean that at higher temperatures, more Ag+ can be supplied to nanobelt growth frontier. Therefore, in principle, the width of Ag nanobelts can be increased with the enhanced supply of Ag+ at higher temperatures, similar to α-Al2O3 nanobelts prepared by vapour-solid deposition42.

As to the thickness of Ag nanobelts, although some data in Table 2 (such as nanobelts #2, #3, #4 and #5) suggest that it also has positive correlation with the growth temperature, this trend cannot be verified as the thickness of nanobelt #1 deviates significantly. We presume that the thickness of Ag nanobelt was more dictated by the metal particles preloaded on MAC, which, however, had not been controlled in this work. In their catalyst-assisted vapour-liquid-solid (VLS) growth of Ga2O3 nanobelts45, Zhang et al. also found that the thickness of Ga2O3 nanobelt was similar to the size of Sn catalyst, while the width had no relationship with the Sn particle size. Notably, as typified by some “zigzag” nanobelts shown for sample #2 (Fig. 2), the width of many Ag nanobelts prepared in our work often changes along the growth direction. In fact, previous reports frequently show images of individual nanobelt with constant thickness and varying width along the growth direction46,47,48. It is implied that for most single-crystalline nanobelts, the thickness can be determined in the early nucleation stage and keeps constant, while the width is more susceptible to the environment such as the fluctuation of the precursor concentration and the diffusivity etc. during crystal growth. However, this rule remains to be tested. Additionally, the roughness of silver nanobelts prepared in this work may induce scattering loss and affect the propagation of surface plasmon resonance (SPR) along the belts. Possible solution to reduce the roughness may include a special experimental design to reduce the fluctuation of [Ag+], which would be investigated in future work.

Conclusion

In summary, a method was developed to growing Ag nanobelts on monolithic activated carbon (MAC) with tunable size and size-dependent plasmonic response. Ag nanobelts were synthesized by reducing Ag+ with surface functional groups on MAC through a galvanic-cell mechanism. Loading metal particles on MAC as heterogeneous nucleation sites and choosing sparingly soluble Ag2O as Ag precursor to control the release of Ag+ cooperatively facilitated stable growth of fluffy Ag nanobelts with width at tens of nanometers and thickness down to ca. 13 nm. The width of Ag nanobelts was found positively correlated to the reaction temperature, while the thickness may be more dictated by the metal particles preloaded on MAC. The width/thickness ratio also positively correlated to the transversal plasmonic absorption peak wavelength, which was located at the visible light region and endowed nanobelts with tunable colours. This work represents the first attempt in chemically producing Ag nanobelts with tunable size and size-dependant plasmonic response. The controllable plasmonic response is very promising for novel applications such as nanomedicine, sensing, high confinement plasmonic waveguides and three-dimensional plasmonic nanocomposites49 etc.

Methods

Materials

Monolithic activated carbon (MAC) samples, derived from corn straw, were provided by Qufu Tembton Carbon Technology LLC. Shandong, China. Their compositional and structural information was similar to that described in our previous work25. In brief, they had a BET surface area of ca. 500 m2/g and apparent density of ca. 0.8 g/cm3. As measured by X-ray photoelectron spectrometer, they had 85 atom% of C, ~10 atom% of O and minor impurities such as Zn, Si and S etc. Ag2O, AgNO3, ammonia water (25 ~ 28 wt%) and anhydrous ethanol were purchased from Shanghai Chemical Reagent Co. Ltd. Deionized (DI) water was generated from a TTL-30C Ultrapure Water Generator with electrical resistivity of 18.2 MΩ·cm. All chemicals were of analytical grade and used without further purification.

Synthesis of silver nanobelts

Preparation of [Ag(NH3)2]NO3 solution

[Ag(NH3)2]NO3 solution was prepared by continuously dropping ammonia water into 1 M AgNO3 solution until the dissolution of brown Ag2O precipitate. Then the 1 M [Ag(NH3)2]NO3 solution was diluted to 10−4 M with deionized (DI) water, which was immediately used for the preparation of MAC loaded with Ag seeds (MAC@Ag).

Preparation of MAC with silver seeds (MAC@Ag)

MAC@Ag was prepared according to a procedure to preparing Ag hexagonal plates on MAC as described previously25. Firstly, the as-received MAC samples were cut into small pieces (ca. 0.2 g) and ultrasonicated in DI water to eliminate impurities. Then they were immersed into freshly prepared [Ag(NH3)2]NO3 solution (10−4 M) for 24 hr to grow Ag plates. Consequently, MAC was taken out and ultrasonicated in anhydrous ethanol for 1 hr to remove loosely attached Ag product and finally dried at 60 °C for 12 hr. The obtained MAC loaded with tightly bound Ag particles was labelled as MAC@Ag.

Synthesis of silver nanobelts

Firstly, ca. 0.2 g Ag2O powder was added into a glass beaker containing 250 ml DI water to prepare saturated AgOH solution (with most Ag2O stay in the bottom of the beaker since Ag2O is only sparingly soluble in water). Then, MAC@Ag was immersed into AgOH solution for 48 hr to synthesize Ag nanobelts. Temperature of the reaction medium was controlled by placing the glass beakers in a water bath. All experiments were carried out in the dark to avoid Ag photoreduction. The colourful Ag nanobelt products, as shown in Fig. 3, were detached from MAC@Ag substrate with tweezers, purified with cycles of cleansing and centrifuging by DI water or ethanol and finally dispersed in anhydrous ethanol for sample characterization.

Characterization

Photograph

All photographs in this work were taken with a digital camera (OLYMPUS SZ-10).

SEM

Scanning electron microscopic (SEM) images were collected on an FEI NOVA NanoSEM 230 instrument with a TLD detector. The accelerating voltage, working distance was set at 10 kV, 5 mm, respectively. SEM specimen was prepared by drying droplets of Ag nanobelts suspension in ethanol on silicon wafers.

TEM

Transmission electron microscopy (TEM) and selected-area electron diffraction (SAED) experiments were performed on a Philips CM10 instrument at an accelerating voltage of 160 kV. TEM specimen was prepared by drying droplets of Ag nanobelts suspension in ethanol on a carbon-film coated copper grid. TEM was mainly used to statistically measure the width of Ag nanobelts. High resolution electron microscopy (HREM) experiments were performed on a JEM 2100F at an accelerating voltage of 200 kV.

AFM

The thickness of ca. 10 nanobelts was measured for each sample by atomic force microscopy (AFM). A multimode Nanoscope IIIa scanning probe microscope (Digital Instruments) mounted with Si tips with tip radius less than 10 nm and force constant at ca. 40 N/m was operated in a tapping mode. The resonant frequency and scanning rate were set at ca. 300 kHz and 1 Hz respectively. AFM specimen was the same as that used for TEM experiments, i.e. droplets of Ag nanobelts suspended in ethanol were dried on the carbon-coated copper grid.

Extinction spectra

Extinction spectra of Ag nanobelts suspended in ethanol were recorded at 25 °C using a PerkinElmer Lambda 750S UV-Vis-NIR spectrophotometer with a 1-cm quartz cuvette.

XRD

The powder X-ray diffraction (XRD) pattern of Ag nanobelts (and other Ag products) was obtained by using a Bruker AXS D8 X-ray diffractometer with Cu Kα radiation (λ = 1.5418 Å). The 2θ was scanned from 10° to 90° at 2°/min with 0.02° sampling frequency. The tube voltage, current was set at 30 kV, 40 mA respectively. XRD samples were prepared by covering one side of a 3 × 2 × 0.2 cm3 silicon chip with Ag nanobelt powders.

Additional Information

How to cite this article: Zhao, H. et al. Tunable growth of silver nanobelts on monolithic activated carbon with size-dependent plasmonic response. Sci. Rep. 5, 13587; doi: 10.1038/srep13587 (2015).

References

Cao, G. & Wang, Y. Nanostructures and Nanomaterials: Synthesis, Properties and Applications (2nd Edition). (World Scientific Publishing, Singapore, 2011).

Xia, Y. N., Xiong, Y. J., Lim, B. & Skrabalak, S. E. Shape-Controlled Synthesis of Metal Nanocrystals: Simple Chemistry Meets Complex Physics? Angew. Chem. Int. Ed. 48, 60–103 (2009).

Kamat, P. V. Quantum Dot Solar Cells. Semiconductor Nanocrystals as Light Harvesters. J. Phys. Chem. C 112, 18737–18753 (2008).

Kim, H. C., Park, S. M. & Hinsberg, W. D. Block Copolymer Based Nanostructures: Materials, Processes and Applications to Electronics. Chem. Rev. 110, 146–177 (2010).

Pileni, M. P. Control of the size and shape of inorganic nanocrystals at various scales from nano to macrodomains. J. Phys. Chem. C 111, 9019–9038 (2007).

Tao, A. R., Habas, S. & Yang, P. D. Shape control of colloidal metal nanocrystals. Small 4, 310–325 (2008).

Murphy, C. J. et al. Anisotropic metal nanoparticles: Synthesis, assembly and optical applications. J. Phys. Chem. B 109, 13857–13870 (2005).

He, R. et al. Facile synthesis of pentacle gold-copper alloy nanocrystals and their plasmonic and catalytic properties. Nat. Commun. 5, 4237 (2014).

Rycenga, M. et al. Controlling the Synthesis and Assembly of Silver Nanostructures for Plasmonic Applications. Chem. Rev. 111, 3669–3712 (2011).

Zhang, Q. A. et al. Seed-Mediated Synthesis of Ag Nanocubes with Controllable Edge Lengths in the Range of 30-200 nm and Comparison of Their Optical Properties. J. Am. Chem. Soc. 132, 11372–11378 (2010).

Wang, Y. et al. Synthesis of Silver Octahedra with Controlled Sizes and Optical Properties via Seed-Mediated Growth. Acs Nano 7, 4586–4594 (2013).

Zhang, Q., Hu, Y. X., Guo, S. R., Goebl, J. & Yin, Y. D. Seeded Growth of Uniform Ag Nanoplates with High Aspect Ratio and Widely Tunable Surface Plasmon Bands. Nano Lett. 10, 5037–5042 (2010).

Jana, N. R., Gearheart, L. & Murphy, C. J. Wet Chemical Synthesis of High Aspect Ratio Cylindrical Gold Nanorods. J. Phys. Chem. B 105, 4065–4067 (2001).

Murphy, C. J. & Jana, N. R. Controlling the aspect ratio of inorganic nanorods and nanowires. Adv. Mater. 14, 80–82 (2002).

Chen, C. et al. Study on the synthesis of silver nanowires with adjustable diameters through the polyol process. Nanotechnology 17, 3933–3938 (2006).

Sanders, A. W. et al. Observation of plasmon propagation, redirection and fan-out in silver nanowires. Nano Lett. 6, 1822–1826 (2006).

Sun, Y. G., Mayers, B. & Xia, Y. N. Transformation of silver nanospheres into nanobelts and triangular nanoplates through a thermal process. Nano Lett. 3, 675–679 (2003).

Bai, J. W., Qin, Y., Jiang, C. Y. & Qi, L. M. Polymer-controlled synthesis of silver nanobelts and hierarchical nanocolumns. Chem. Mater. 19, 3367–3369 (2007).

Liu, B. Q., Luo, W. & Zhao, X. P. A facile synthesis of ordered ultralong silver nanobelts. Mater. Res. Bull. 44, 682–687 (2009).

Liu, L., Yoo, S. H., Lee, S. A. & Park, S. Electrochemical Growth of Silver Nanobelts in Cylindrical Alumina Nanochannels. Cryst. Growth Des. 11, 3731–3734 (2011).

Liu, R. & Sen, A. Unified Synthetic Approach to Silver Nanostructures by Galvanic Displacement Reaction on Copper: From Nanobelts to Nanoshells. Chem. Mater. 24, 48–54 (2012).

Yang, Z. Q. et al. Plasmonic Silver Nanobelts via Citrate Reduction in the Presence of HCl and their Orientation-Dependent Scattering Properties. J. Phys. Chem. Lett. 2, 1742–1746 (2011).

Wang, F. et al. Tunable growth of nanodendritic silver by galvanic-cell mechanism on formed activated carbon. Chem. Commun. 46, 3782–3784 (2010).

Wang, F. et al. Morphosynthesis of cubic silver cages on monolithic activated carbon. Phys. Chem. Chem. Phys. 15, 18367–18370 (2013).

Zhao, H. et al. Green “planting” nanostructured single crystal silver. Sci. Rep. 3, 1511 (2013).

Jones, M. R., Osberg, K. D., Macfarlane, R. J., Langille, M. R. & Mirkin, C. A. Templated Techniques for the Synthesis and Assembly of Plasmonic Nanostructures. Chem. Rev. 111, 3736–3827 (2011).

El-Sayed, M. A. Some interesting properties of metals confined in time and nanometer space of different shapes. Acc. Chem. Res. 34, 257–264 (2001).

Yu, S.-H. & Yao, W.-T. Inorganic Nanobelt Materials, in Encyclopedia of Inorganic and Bioinorganic Chemistry, (John Wiley & Sons, 2011).

Anderson, L. J. E., Payne, C. M., Zhen, Y. R., Nordlander, P. & Hafner, J. H. A Tunable Plasmon Resonance in Gold Nanobelts. Nano Lett. 11, 5034–5037 (2011).

Jin, R. C. et al. Photoinduced conversion of silver nanospheres to nanoprisms. Science 294, 1901–1903 (2001).

Liu, L. et al. Preliminary study on the application of visible-near infrared spectroscopy and chemometrics to classify Riesling wines from different countries. Food Chem. 106, 781–786 (2008).

Martelo-Vidal, M. J. & Vazquez, M. Evaluation of Ultraviolet, Visible and Near Infrared Spectroscopy for the Analysis of Wine Compounds. Czech J. Food. Sci. 32, 37–47 (2014).

Zhang, W. et al. Influence of the electron mean free path on the resistivity of thin metal films. Microelectronic Engineering 76, 146–152 (2004).

Niu, W. X., Zhang, L. & Xu, G. B. Seed-mediated growth method for high-quality noble metal nanocrystals. Sci. China Chem. 55, 2311–2317 (2012).

Xia, Y. N. et al. One-dimensional nanostructures: Synthesis, characterization and applications. Adv. Mater. 15, 353–389 (2003).

Zhang, Q. & Yin, Y. D. Beyond spheres: Murphy’s silver nanorods and nanowires. Chem. Commun. 49, 215–217 (2013).

Payne, C. M. et al. Synthesis and Crystal Structure of Gold Nanobelts. Chem. Mater. 26, 1999–2004 (2014).

CRC Handbook of Chemistry and Physics, 63rd ed. (ed. Weast, R. C. ) (CRC Press, Boca Raton, FL 1982).

Cao, Z. W. et al. Rapid room-temperature synthesis of silver nanoplates with tunable in-plane surface plasmon resonance from visible to near-IR. J. Mater. Chem. 18, 2673–2678 (2008).

Lamer, V. K. & Dinegar, R. H. Theory, Production and Mechanism of Formation of Monodispersed Hydrosols. J. Am. Chem. Soc. 72, 4847–4854 (1950).

Evanoff, D. D. & Chumanov, G. Size-controlled synthesis of nanoparticles. 1. “Silver-only” aqueous suspensions via hydrogen reduction. J. Phys. Chem. B 108, 13948–13956 (2004).

Fang, X. S. et al. Temperature-controlled growth of alpha-Al2O3 nanobelts and nanosheets. J. Mater. Chem. 13, 3040–3043 (2003).

Yang, Q. Growth of nanowire and nanobelt based oxides by thermal oxidation with gallium, in Nanowires Science and Technology (ed. Nicoleta, Lupu ) (INTECH, Croatia, 2010).

Glasstone, S. An Introduction to Electrochemistry. (D. van Nostrand Co. Inc., New York, 1947).

Zhang, J., Jiang, F. H., Yang, Y. D. & Li, J. P. Catalyst-assisted vapor-liquid-solid growth of single-crystal Ga2O3 nanobelts. J. Phys. Chem. B 109, 13143–13147 (2005).

Wang, Y. L., Jiang, X. C., Herricks, T. & Xia, Y. N. Single crystalline nanowires of lead: Large-scale synthesis, mechanistic studies and transport measurements. J. Phys. Chem. B 108, 8631–8640 (2004).

Zhao, N. et al. Controlled synthesis of gold nanobelts and nanocombs in aqueous mixed surfactant solutions. Langmuir 24, 991–998 (2008).

Shen, X. S. et al. Anisotropic Growth of One-Dimensional Silver Rod-Needle and Plate-Belt Heteronanostructures Induced by Twins and hcp Phase. J. Am. Chem. Soc. 131, 10812–10813 (2009).

Gajc M. et al. Nanoparticle Direct Doping: Novel Method for Manufacturing Three-Dimensional Bulk Plasmonic Nanocomposites. Adv. Funct. Mater. 23, 3443–3451 (2013).

Acknowledgements

The SJTU group appreciates the sponsorship from Green Support Materials Technologies (Shanghai) Co. Ltd. The HHIT and SU groups acknowledge the financial support by the Science and Technology Department of Jiangsu Province (No. BY2014085), the Education Department of Jiangsu Province (No. 14 KJB430006), the State Oceanic Administration (No. 201305007) and the Environmental Protection Department of Jiangsu Province (No. 2012010). The assistance on TEM and AFM characterization provided by Instrumental Analysis Center of SJTU is gratefully acknowledged. We also thank Mr. Xiang Yu, CEO of Carbon Valley Aesthetic Technologies Co. Ltd. Shanghai, for drawing schematic diagrams.

Author information

Authors and Affiliations

Contributions

B.Z. developed and directed the project. H.Z. and F.Y. did all the synthetic experiments and performed SEM and XRD characterization. Y.N. and C.D. carried out TEM, AFM and extinction spectral analysis. Y.N., H.Z. and B.Z. analysed the data and wrote the paper. F.W., Y.L., J.Z., S.L. and L.C. contributed to interpretation of the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhao, H., Ning, Y., Zhao, B. et al. Tunable growth of silver nanobelts on monolithic activated carbon with size-dependent plasmonic response. Sci Rep 5, 13587 (2015). https://doi.org/10.1038/srep13587

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep13587

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.