Abstract

Vertical interfaces in vertically aligned nanocomposite thin films have been approved to be an effective method to manipulate functionalities. However, several challenges with regard to the understanding on the physical process underlying the manipulation still remain. In this work, because of the ordered interfaces and large interfacial area, heteroepitaxial (BaTiO3)1-x:(Sm2O3)x thin films have been fabricated and used as a model system to investigate the relationship between vertical interfaces and dielectric properties. Due to a relatively large strain generated at the interfaces, vertical interfaces between BaTiO3 and Sm2O3 are revealed to become the sinks to attract oxygen vacancies. The movement of oxygen vacancies is confined at the interfaces and hampered by the misfit dislocations, which contributed to a relaxation behavior in (BaTiO3)1-x:(Sm2O3)x thin films. This work represents an approach to further understand that how interfaces influence on dielectric properties in oxide thin films.

Similar content being viewed by others

Introduction

The emergence of novel phenomena and functionalities at artificially constructed oxide heterostructures has stimulated intense research activities over the past decade1,2. Among these studies, oxide interfaces are very attractive because the coexistence and interplay between different degrees of freedom (charge, orbit, spin and lattice) at interfaces can lead to rich physical phenomena, including two-dimensional electron gas (2DEG), superconductivity, colossal magnetoresistance and multiferroic behavior3,4,5,6,7,8,9,10. For instance, Liu et al. demonstrated that oxygen vacancies (VOs) are the dominant origin of the 2DEG at LaAlO3/SrTiO3 interfaces when the LaAlO3 overlayer is amorphous6. A novel ferromagnetic state was observed at the interface between antiferromagnet BiFeO3 and ferromagnet La0.7Sr0.3MnO3, which is directly attributed to an electronic orbital reconstruction at the interface11.

In addition to these conventional lateral interfaces (parallel to substrate surface), vertical interfaces (perpendicular to substrate surface) in vertically aligned nanocomposite thin films have been introduced and used to create or enhance functionalities of oxide thin films8,9. Compared to lateral interfaces, vertical interfaces possess impressive advantages, such as reduced clamping effect from substrates, larger interfacial area, strain tunability to larger thickness and easy interface probing etc12,13,14,15. Furthermore, such ordered structures allow for precise tuning of mechanical, electronic and magnetic properties through vertical strain control, as well as interfacial couplings. For example, Moshnyaga et al. showed colossal magnetoresistance effect has been enhanced in (La0.7Ca0.3MnO3)1-x:(MgO)x thin films through lattice strain8. Zheng et al. reported that magnetoelectric coupling has been realized in (BaTiO3)0.65:(CoFe2O4)0.35 thin films by vertical interfaces coulpings9. Besides, vertical interfaces induced strain state reversion and leakage current reduction have been achieved in (BiFeO3)0.5:(Sm2O3)0.5 thin films12,16. And enhanced low field magnetoresistance has been reported in heteroepitaxial (La0.7Sr0.3MnO3)0.5:(ZnO)0.5 via tuning the microstructure and vertical interface density17. It is clear that oxide interfaces are effective to control functionalities of oxide thin films. Most previous reports have focused on exploring magnetism, ferroelectricity, magnetoelectric coupling and electric transportation6,8,9,10,11. However, the question that arises naturally is whether dielectric properties can be manipulated by oxide interfaces. The work presented here suggests an answer in the affirmative.

Relaxation properties have been approved to be critical for the applications (such as transducers, actuators and sensors etc.) of dielectric materials18,19,20,21. It is highly attractive to manipulate relaxation properties through interfaces, which is also helpful to understand the relationship between oxide interfaces and physical properties. It has been showed that VOs is responsible for dielectric relaxations observed in epitaxial K0.5Na0.5NbO3/La0.67Sr0.33MnO3 and Ba0.7Sr0.3TiO3/Bi1.05La0.05FeO3 heterostructures22,23. As a typical dielectric oxide, BaTiO3 has attracted extensive studies because of excellent ferroelectric and dielectric properties. For instance, high Curie temperature, positive transverse piezoelectric coefficient and low leakage current have been obtained in (BaTiO3)0.5:(Sm2O3)0.5 thin films, which has been revealed to be originated from the strain at the vertical interfaces between BaTiO3 and Sm2O324,25,26. Considering the ordered interfaces and large interfacial area, (BaTiO3)1-x:(Sm2O3)x can be an unique system for investigating the relationship between the interfaces and dielectric properties. In this work, we present a comparative study on dielectric properties of (BaTiO3)1-x:(Sm2O3)x nanocomposite thin films with compositions of x = 0.5 and 0.62. Due to a relatively large strain generated at the interfaces, vertical interfaces between BaTiO3 (BTO) and Sm2O3 are revealed to become the sinks to attract VOs. The movement of VOs is confined at the interfaces and hampered by misfit dislocations along the interfaces, which results to a dielectric relaxation in the (BTO)1-x:(Sm2O3)x (BTO:Sm2O3) nanocomposite thin films.

Results

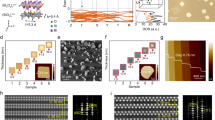

Typical x-ray diffraction (θ – 2θ) patterns for the composite thin films are shown in Fig. 1. Only (00l) diffraction peaks appear in the patterns for both thin films and substrates, suggesting that the BTO and Sm2O3 phases coexist in the composite thin films and are preferentially oriented along the c-axis. According to our previous works24,25,26,27, the orientation relationship between thin films and substrates is determined to be (002)BTO||(002)Sm2O3||(002)STO and [200]BTO||[220]Sm2O3||[200]STO. It should be noted that, due to the lattice mismatch between the BTO and Sm2O3 (the lattice constants of bulk BTO and Sm2O3 are 4.03 and 10.93 Å, respectively), misfit dislocations are thus generated for partial strain relaxation, which is confirmed by transmission electron microscopy (TEM) measurements and will be discussed later. Additionally, large residual strains of ~2.3% and ~3.4% have been found in the BTO phase in the composite thin films with compositions of x = 0.5 and 0.62 respectively, which is consistent with the reported results24,26.

In previous works, we have revealed that the BTO and Sm2O3 phases grow alternatively and spontaneously and form a vertically aligned columnar structure in the BTO:Sm2O3 thin films24,25,26. Fig. 2(a) show high resolution TEM images of the BTO:Sm2O3 thin films with compositions of x = 0.5 and 0.62 respectively, which demonstrate the excellent heteroepitaxial growth of the BTO and Sm2O3 on the STO substrates. Combined with previous results24,25,26, these images indicate that self-assembled Sm2O3 nanocolumns are evenly sized, distributed and embedded in a BTO matrix. And the diameter of single Sm2O3 nanocolumn is about 10 nm. So, the density of interfaces is estimated to be about 108/m. More than this, a periodic arrangement of misfit dislocations is found along the vertical interfaces, as shown in the corresponding Fourier-filtered images in Fig. 2(b). The density of misfit dislocations along the interfaces is estimated to be about 4.0 × 108/m for x = 0.5 and about 5.0 × 108/m for x = 0.62. Considering the density of interfaces, the areal density of misfit dislocations is estimated to be about 4.0 × 1016/m2 for x = 0.5 and about 5.0 × 1016/m2 for x = 0.62. In other words, the density of misfit dislocations is very high in the BTO:Sm2O3 thin films, which may originate from the large lattice mismatch between the BTO and Sm2O3. Besides, the density of misfit dislocations for x = 0.5 is lower than that for x = 0.62. All these results suggest that self-assembled vertical heteroepitaxial nanostructures of BTO:Sm2O3 are synthesized as expected and can be used as model system to explore the relationship between the vertical interfaces and dielectric properties in oxide thin films.

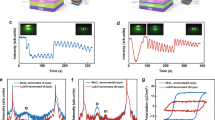

To investigate the vertical interface effects on dielectric behavior, the temperature dependence of the real part of dielectric constant (ε‘) and dielectric loss (tanδ) are measured at the frequency ranging from 1 kHz to 1 MHz by using a structure of Pt/BTO:Sm2O3/Nb-STO (shown as Fig. 3). In general, as the frequency increases, the tanδ ~T curve shifts towards a higher temperature region, indicating a typical characteristic of dielectric relaxation phenomenon. Furthermore, it is obvious that ε‘ gradually increases with increasing temperature (shown as insets of Fig. 3). It should be pointed that, because of a relatively large vertical strain observed in the BTO phase in the composite films (~2.3% and 3.4% for x = 0.5 and 0.62, respectively), the ferroelectric Curie temperature of the composite films may be over 833 K, which is comparable to the previous results24,28,29.

Figure 4 shows the frequency dependent tanδ for the BTO:Sm2O3 thin films measured at different temperatures. The peaks of tanδ shift towards a higher frequency region with increasing temperature, further approving the existence of dielectric relaxation in the composite thin films. In order to explore the physical mechanism of the relaxation process, we calculated the relaxation parameters for BTO:Sm2O3 thin films in terms of the Arrhenius Law

where  is the pre-exponential factor,

is the pre-exponential factor,  is activation energy required for relaxation process,

is activation energy required for relaxation process,  is the Boltzmann constant and

is the Boltzmann constant and  is the temperature where the maximum loss tangent occurs. The Arrhenius plots were shown as insets of Fig. 4(a). The values of

is the temperature where the maximum loss tangent occurs. The Arrhenius plots were shown as insets of Fig. 4(a). The values of  and

and  were found to be 0.53 eV and 2.17 × 107 Hz for x = 0.5 and 0.61 eV and 2.19 × 108 Hz for x = 0.62, respectively.

were found to be 0.53 eV and 2.17 × 107 Hz for x = 0.5 and 0.61 eV and 2.19 × 108 Hz for x = 0.62, respectively.

To further understand the physical process of the observed dielectric relaxation in the BTO:Sm2O3 thin films, the imaginary ( ) part of electric modulus (

) part of electric modulus ( ) given by M "=

) given by M "= as a function of temperature at a series of frequencies were illustrated in Fig. 5(a). As we expected, well-defined M "(T )

as a function of temperature at a series of frequencies were illustrated in Fig. 5(a). As we expected, well-defined M "(T )  peaks have been found in the whole temperature range. The

peaks have been found in the whole temperature range. The  ~ T curve shifts towards higher temperature with increasing frequency, indicating a typical relaxation nature. The Arrhenius plots for Ln (fmax) vs 103/T were also shown in Fig. 5(b). Accordingly, the relaxation parameters of

~ T curve shifts towards higher temperature with increasing frequency, indicating a typical relaxation nature. The Arrhenius plots for Ln (fmax) vs 103/T were also shown in Fig. 5(b). Accordingly, the relaxation parameters of  and

and  were deduced to be 0.54 eV and 4.85 × 108 Hz for x = 0.5 and 0.59 eV and 1.72 × 109 Hz for x = 0.62, respectively. The activation energy obtained from

were deduced to be 0.54 eV and 4.85 × 108 Hz for x = 0.5 and 0.59 eV and 1.72 × 109 Hz for x = 0.62, respectively. The activation energy obtained from  is almost the same as the calculated values from tanδ(T) (see insets of Fig. 4(a)), which further confirms that the fitting results are reasonable. It should be pointed out that, because the relaxation time (τ = 1/f) for

is almost the same as the calculated values from tanδ(T) (see insets of Fig. 4(a)), which further confirms that the fitting results are reasonable. It should be pointed out that, because the relaxation time (τ = 1/f) for  and tanδ (T) follow the general rule of τtanδ > τM”30,31, the pre-exponential factor deduced for

and tanδ (T) follow the general rule of τtanδ > τM”30,31, the pre-exponential factor deduced for  is always one order of magnitude larger than that estimated from tanδ (T).

is always one order of magnitude larger than that estimated from tanδ (T).

Variation of  as a function of temperature for BTO:Sm2O3 thin films with (a) x = 0.5 and (c) x = 0.62 measured at different frequencies. The corresponding Arrhenius plots of the frequency against temperature were shown in (b) and (d), respectively. The solid curves are the best fits to the Arrhenius law.

as a function of temperature for BTO:Sm2O3 thin films with (a) x = 0.5 and (c) x = 0.62 measured at different frequencies. The corresponding Arrhenius plots of the frequency against temperature were shown in (b) and (d), respectively. The solid curves are the best fits to the Arrhenius law.

Now it is important to investigate the origin of the dielectric relaxation in the BTO:Sm2O3 thin films. As a Pt/BTO:Sm2O3/Nb-STO vertical capacitor has been used in the dielectric measurements, the composite thin film can be reviewed as three parts connected in parallel: the BTO phase, the Sm2O3 phase and the vertical interfaces. Up to now, as far as we know, there are no reports on dielectric relaxation in the Sm2O3. And the activation energy of BTO-based perovskite oxides is 0.88 ~ 1.56 eV32,33,34,35, which is obviously higher than those in the present work. To further exclude the influence of the BTO and Sm2O3 phases on dielectric relaxation, the dielectric properties of pure BTO and Sm2O3 thin films were measured (not shown). There is no obvious dielectric relaxation in the pure Sm2O3 thin film. And, dielectric relaxation was observed in the pure BTO film with an Ea value of 1.08 eV, which is in consistent with the previous results. Therefore, neither the BTO nor the Sm2O3 phase is responsible for the dielectric relaxation observed in the composite films. In other words, the vertical interfaces dominate the relaxation behavior. On the other hand, it is well known that the dielectric loss is closely correlated with the leakage current in oxide thin films. And we have demonstrated that the leakage behavior is dominated by the vertical interfaces in (BTO)0.5:(Sm2O3)0.5 thin films, which further approves that the vertical interfaces are those who resulted to the dielectric relaxation26. It has also been reported that the electrode interfaces related to VOs gradients affect fatigue and dielectric loss in ferroelectric oxides36. However, the vertical interfacial area is about twenty ~ forty times of the electrode interfacial area in the BTO:Sm2O3 thin films. Though the contribution of the electrode interfaces may dominate the dielectric behavior in the pure BTO and Sm2O3 thin films, the dielectric behavior of the BTO:Sm2O3 composite films is totally different from those of the pure thin films. And, as we discussed earlier, the density of misfit dislocations is very high in the composite thin films. Considering all these factors, the contribution of the electrode interfaces to the dielectric relaxation in the BTO:Sm2O3 thin films should be neglected in the present work.

It is well known that VOs have been demonstrated to be intrinsic defects and are often unavoidable in oxide thin films. The relaxation occurring at high temperatures are exclusively related to the VOs. And an activation energy of 0.3 ~ 1.0 eV is the typical value for relaxation behavior caused by VOs, which is verified by many previous reports32,37,38,39. According to the values obtained in the BTO:Sm2O3 thin films, the dielectric relaxation in the measured temperature region was proposed to associate with VOs. On the other hand, because of the structural discontinuity as well as the strain, the interfaces have been approved to attract and gather the VOs6,40,41,42,43,44. For example, strain-driven accumulation of VOs along the vertical interfaces has been observed in (REBa2Cu3O7-δ)1-x:(BaZrO3)x composite thin films45. More than this, in our previous work, electron energy loss spectroscopy (EELS) measurements revealed that a large concentration of VOs forms at the vertical interfaces in (SrTiO3)0.5:(Sm2O3)0.5 composite thin films due to a large lattice misfit46. Considering a large vertical strain generated at the interfaces in the present work, the vertical interfaces are believed to become the sinks to attract VOs, which is the origin of the dielectric relaxation in the composite thin films26,47,48,49.

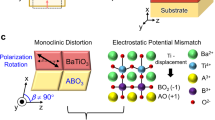

To understand the mechanism of the observed relaxation behavior, a model has been proposed and shown in Fig. 6. In this system, as shown in Fig. 6(a), Sm2O3 are nanocolumns embedded in a BTO matrix and vertical sandwich capacitors with a configuration of Pt/BTO:Sm2O3/Nb-STO have been used to investigate the dielectric properties. Electric field is applied parallel to the interfaces between Sm2O3 and BTO (shown as Fig. 6(b)). On the other hand, VOs have been attracted at the interfaces and can be viewed as ions with positive charges50,51. With the assistance of an electric field, VOs can move along the vertical interfaces in the direction of electric field. However, the long range movement of VOs will be hampered by the misfit dislocations observed in the vertical interfaces, which results to the dielectric relaxation of the BTO:Sm2O3 thin films. In addition, with the increasing density of misfit dislocations, the values of the activation energy varied from 0.53 to 0.61 eV, further confirming the above mechanism.

(a) Schematic diagram of Pt/BTO:Sm2O3/Nb-STO vertical sandwich capacitors. (b) The expanded view of the dashed part in the schematic diagram to show the interfaces between Sm2O3 nanocolumns and BTO matrix. E and blue lines represent the electric field and the pathway of movement of VOs, respectively.

The outcome of our above analysis shows that self-assembled vertically aligned nanocomposite thin films have three unique features: ordered vertical interfaces, large interfacial area and VOs gathered at the vertical interfaces26,45,46,47,48,49. With the assistance of an electric field, VOs can only move up and down along the vertical interfaces, which means that the transportation of VOs has been effectively confined. Meanwhile, misfit dislocations formed along the vertical interfaces can be used to manipulate the dynamics of VOs. These unique features are very helpful to investigate the transportation mechanism of VOs and to enhance ion conductivity in oxides, which play a key role in determining the performance of energy conversion and storage devices, such as thin films solid oxide fuel cells, photocatalysts and batteries52,53,54.

Discussion

In summary, epitaxial (BTO)1-x:(Sm2O3)x vertically aligned nanocomposite thin films with compositions of x = 0.5 and 0.62 have been fabricated by pulsed laser deposition, which were used as model system to investigate the relationship between the microstructure, the interfaces and the dielectric behavior. The structural discontinuity and a relatively large residual strain attract the accumulation of VOs at the vertical interfaces between the BTO and Sm2O3. With the assistance of an electric field, the movement of VOs has been confined along the interfaces and been hampered by the misfit dislocations, which results to an interface-induced relaxation behavior. The present work has broad implications for the understanding of the correlation between the interfaces and physical properties, for the manipulating or optimizing of functionalities in the nanocomposite oxide thin films and for the utilization of dielectric materials in high-temperature applications. More than this, the unique characteristics of vertically aligned nanocompsite thin films present potential applications in energy conversion and storage devices.

Methods

Epitaxial (BTO)1-x:(Sm2O3)x thin films with compositions of x = 0.5 and 0.62 were deposited on (001) oriented SrTiO3 (STO) and Nb-doped SrTiO3 (Nb-STO) substrates by pulsed laser deposition (PLD) with a KrF excimer laser (Lambda Physik, λ = 248 nm). A laser fluence of ~2 J/cm2 with a repetition rate of 3 Hz were focused onto composite targets with different molar ratios. An optimized substrate temperature of 720 oC and oxygen pressure of 25 Pa were used during depositions. Immediately following depositions, films were annealed in situ for one hour at a temperature of 450 oC and an oxygen pressure of 0.8 atm. X-ray diffraction (XRD, Rigaku K/Max) and transmission electron microscopy (TEM, FEI Tecnai F20 analytical microscope) were used to investigate the microstructure of thin films. The thickness of thin films was measured by cross-sectional TEM.

For electrical measurements, vertical sandwich capacitors with a configuration of Pt/BTO:Sm2O3/Nb-STO were fabricated, where thin films with a thickness of ~200 nm were used and Pt top electrodes with an area of 8 × 10−4 cm2 were deposited by sputtering. The dielectric properties were investigated using an Agilent 4294 A Impedance Analyzer. The measurements were performed at selected temperatures in a Linkam Scientific Instruments HFS600E-PB4 system.

Additional Information

How to cite this article: Li, W. et al. Vertical Interface Induced Dielectric Relaxation in Nanocomposite (BaTiO3)1-x:(Sm2O3)x Thin Films. Sci. Rep. 5, 11335; doi: 10.1038/srep11335 (2015).

References

Heber, J. Materials science: Enter the oxides. Nature 459, 28–30 (2009).

Ngai, J. H., Walker, F. J. & Ahn, C. H. Correlated Oxide Physics and Electronics. Annu. Rev. Condens. Matter Phys. 44, 1–17 (2014).

Hwang, H. Y. et al. Emergent phenomena at oxide interfaces. Nat. Mater. 11, 103–113 (2012).

Chakhalian, J., Millis, A. J. & Rondinelli, J. Whither the oxide interface. Nat. Mater. 11, 92–94 (2012).

Moetakef, P. et al. Carrier-Controlled Ferromagnetism in SrTiO3 . Phys. Rev. X 2, 021014 (2012).

Liu, Z. Q. et al. Origin of the Two-Dimensional Electron Gas at LaAlO3 /SrTiO3 Interfaces: The Role of Oxygen Vacancies and Electronic Reconstruction. Phys. Rev. X 3, 021010 (2013).

Reyren, N. et al. Superconducting Interfaces Between Insulating Oxides. Science 317, 1196–1199 (2007).

Moshnyaga, V. et al. Structural phase transition at the percolation threshold in epitaxial (La0.7Ca0.3MnO3)1–x:(MgO)x nanocomposite films. Nat. Mater. 2, 247–252 (2003).

Zheng, H. et al. Multiferroic BaTiO3-CoFe2O4 Nanostructures. Science 303, 661–663 (2004).

Chen, A. P. et al. A New Class of Room-Temperature Multiferroic Thin Films with Bismuth-Based Supercell Structure. Adv. Mater. 25, 1028–1032 (2013).

Yu, P. et al. Interface Ferromagnetism and Orbital Reconstruction in BiFeO3-La0.7Sr0.3MnO3 Heterostructures. Phys. Rev. Lett. 105, 027201 (2010).

MacManus-Driscoll, J. L. et al. Strain control and spontaneous phase ordering in vertical nanocomposite heteroepitaxial thin films. Nat. Mater. 7, 314–320 (2008).

MacManus-Driscoll, J. L. Self-Assembled Heteroepitaxial Oxide Nanocomposite Thin Film Structures: Designing Interface-Induced Functionality in Electronic Materials. Adv. Funct. Mater. 20, 2035–2045 (2010).

Chen, A. P., Bi, Z. X., Jia, Q. X., MacManus-Driscoll, J. L. & Wang, H. Microstructure, vertical strain control and tunable functionalities in self-assembled, vertically aligned nanocomposite thin films. Acta Mater. 61, 2783–2792 (2013).

Zhang, W. R. et al. Interfacial coupling in heteroepitaxial vertically aligned nanocomposite thin films: From lateral to vertical control. Curr. Opin. Solid State Mater. Sci. 18, 6–18 (2014).

Yang, H. et al. Vertical Interface Effect on the Physical Properties of Self-Assembled Nanocomposite Epitaxial Films. Adv. Mater. 21, 3794–3798 (2009).

Chen, A. P. et al. Tunable Low-Field Magnetoresistance in (La0.7Sr0.3MnO3)0.5:(ZnO)0.5 Self-Assembled Vertically Aligned Nanocomposite Thin Films. Adv. Funct. Mater. 21, 2423–2429 (2011).

Cross, L. E. Relaxor ferroelectrics. Ferroelectrics 76, 214–267 (1987).

Uchino, K. Relaxor ferroelectric devices. Ferroelectrics 151, 321-267 (1994).

Bokov, A. A. & Ye, Z.-G. Recent progress in relaxor ferroelectrics with perovskite structure. J. Mater. Sci. 41, 31–52 (2006).

Bokov, A. A. & Ye, Z.-G. DIELECTRIC RELAXATION IN RELAXOR FERROEL ECTRICS. J. Adv. Dielectr. 2, 1241010 (2012).

Miao, J., Xu, X. G., Jiang, Y., Cao, L. X. & Zhao, B. R. Ionized-oxygen vacancies related dielectric relaxation in heteroepitaxial K0.5Na0.5NbO3/La0.67Sr0.33MnO3 structure at elevated temperature. Appl. Phys. Lett. 95, 132905 (2009).

Miao, J. et al. Enhanced fatigue and ferroelectric properties in multiferroic (Ba0.7Sr0.3)TiO3/(Bi1.05La0.05)FeO3 epitaxial heterostructures. Appl. Phys. Lett. 102, 232902 (2013).

Harrington, S. A. et al. Thick lead-free ferroelectric films with high Curie temperatures through nanocomposite-induced strain. Nat. Nanotechnol. 6, 491–494 (2011).

Kursumovic, A. et al. A New Material for High-Temperature Lead-Free Actuators. Adv. Funct. Mater. 23, 5881–5886 (2013).

Li, W. W. et al. Vertical-Interface-Manipulated Conduction Behavior in Nanocomposite Oxide Thin Films. ACS Appl. Mater. Interfaces 6, 5356–5361 (2014).

Yang, H. et al. Structural and dielectric properties of epitaxial Sm2O3 thin films. Appl. Phys. Lett. 92, 062905 (2008).

Choi, K. J. et al. Enhancement of ferroelectricity in strained BaTiO3 thin films. Science 306, 1005–1009 (2004).

Damodaran, A. P., Breckenfeld, E., Chen, Z. H., Lee, S. K. & Martin, L. W. Enhancement of Ferroelectric Curie Temperature in BaTiO3 Films via Strain-Induced Defect Dipole Alignment. Adv. Mater. 26, 6341–6347 (2014).

Gerhardt, R. Impedance and dielectric spectroscopy revisited: Distinguishing localized relaxation from long-range conductivity. J. Phys. Chem. Solids 55, 1491–1506 (1994).

Cao, W. Q. & Gerhardt, R. Calculation of various relaxation times and conductivity for a single dielectric relaxation process. Solid State Ionics 42, 213–221 (1990).

Kang, B. S., Choi, S. K. & Park, C. H. Diffuse dielectric anomaly in perovskite-type ferroelectric oxides in the temperature range of 400–700 °C. J. Appl. Phys. 94, 1904 (2003).

Bidault, O., Goux, P., Kchikech, M., Belkaoumi, M. & Maglione, M. Space-charge relaxation in perovskites. Phys. Rev. B 49, 7868 (1994).

Warren, W. L., Vanheusden, K., Dimos, D., Pike, G. E. & Tuttle, B. A. Oxygen Vacancy Motion in Perovskite Oxides. J. Am. Ceram. Soc. 79, 536–538 (1996).

Li, Z. & Fan, H. Q. Relaxation behaviour induced by oxygen vacancies of barium strontium titanate at high temperatures. J. Phys. D: Appl. Phys. 42, 075415 (2009).

Verdier, C., Morrison, F. D., Lupascu, D. C. & Sccot, J. F. Fatigue studies in compensated bulk lead zirconate titanate. J. Appl. Phys. 97, 024107 (2005).

Wang, C. C. et al. Oxygen-vacancy-related dielectric relaxations in SrTiO3 at high temperatures. J. Appl. Phys. 113, 094103 (2013).

Liu, L. N. et al. Relaxor- and phase-transition-like behaviors in ZnO single crystals at high temperatures. Appl. Phys. Lett. 102, 112907 (2013).

Miao, J., Tian, H. Y., Zhou, X. Y., Pang, K. H. & Wang, H. Microstructure and dielectric relaxor properties for Ba0.5Sr0.5TiO3/La0.67Sr0.33MnO3 heterostructure. J. Appl. Phys. 101, 084101 (2007).

Cuong, D. D. et al. Oxygen Vacancy Clustering and Electron Localization in Oxygen-Deficient SrTiO3: LDA + U Study. Phys. Rev. Lett. 98, 115503 (2007).

Wimbush, S. C. et al. Interfacial Strain-Induced Oxygen Disorder as the Cause of Enhanced Critical Current Density in Superconducting Thin Films. Adv. Funct. Mater. 19, 835–841 (2009).

Donner, W. et al. Epitaxial Strain-Induced Chemical Ordering in La0.5Sr0.5CoO3-δ Films on SrTiO3 . Chem. Mater. 23, 984–988 (2011).

Gazquez, J. et al. Lattice mismatch accommodation via oxygen vacancy ordering in epitaxial La0.5Sr0.5CoO3-δ thin films . APL Mater. 1, 012105 (2013).

Pennycook, S. J. et al. Misfit accommodation in oxide thin film heterostructures. Acta Mater. 61, 2725–2733 (2013).

Cantoni, C. et al. Strain-Driven Oxygen Deficiency in Self-Assembled, Nanostructured, Composite Oxide Films. ACS Nano 5, 4783–4789 (2011).

Lee, S. et al. Novel Electroforming-Free Nanoscaffold Memristor with Very High Uniformity, Tunability and Density. Adv. Mater. 26, 6284–6289 (2014).

Hsieh, Y. H. et al. Local Conduction at the BiFeO3-CoFe2O4 Tubular Oxide Interface. Adv. Mater. 24, 4564–4568 (2012).

Fix, T. et al. Electric-Field Control of Ferromagnetism in a Nanocomposite via a ZnO Phase. Nano Lett. 13, 5886–5890 (2013).

Zhao, R. et al. Manipulating leakage behavior via distribution of interfaces in oxide thin films. Appl. Phys. Lett. 105, 072907 (2014).

Muller, D. A., Nakagawa, N., Ohtomo, A., Grazul, J. L. & Hwang, H. Y. Atomic-scale imaging of nanoengineered oxygen vacancy profiles in SrTiO3 . Nature 430, 657–661 (2004).

Mizokawa, T. et al. Role of Oxygen Holes in LixCoO2 Revealed by Soft X-Ray Spectroscopy. Phys. Rev. Lett. 111, 056404 (2013).

Yoon, J. S. et al. Vertically Aligned Nanocomposite Thin Films as a Cathode/Electrolyte Interface Layer for Thin-Film Solid Oxide Fuel Cells. Adv. Funct. Mater. 19, 3868–3873 (2009).

Su, Q. et al. Vertically aligned nanocomposite electrolytes with superior out-of-plane ionic conductivity for solid oxide fuel cells. J. Power Sources 242, 455–463 (2013).

Yildiz, B. “Stretching” the energy landscape of oxides-Effects on electrocatalysis and diffusion. MRS Bull. 39, 147–156 (2014).

Acknowledgements

The authors acknowledge the support of the National Natural Science Foundation of China (Grant No. 11274237, 51228201, 11004238, 11004145 and 51202153) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD). The effort at Texas A&M University is supported by the U.S. National Science Foundation (DMR-1401266, 1007969 and 0846504). C. Wang thanks financial support from National Natural Science Foundation of China (Grant No. 11404002, 11404003 and 51402001) and Co-operative Innovation Research Center for Weak Signal-Detecting Materials and Devices Integration of Anhui University (Grant No. 01001795). K.J. Jin also thanks the financial support from National Natural Science Foundation of China (No. 11134012) and the “Strategic Priority Research Program (B)” of the Chinese Academy of Sciences (No. XDB07030200).

Author information

Authors and Affiliations

Contributions

W.L. and W.Z. contributed equally to this work. H.Y. supervised the project. W.L., W. Z., R.Z., Y.L. and R.T. conducted the thin films fabrication and data analysis. W.L., L.W., J.G., H.G. and K.J. did the electrical properties measurements. A.C. and H.W. helped to collect and analyze the TEM results. C.W. helped to analyze the dielectric data. W.L., W.Z. and H.Y. co-wrote the manuscript. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Li, W., Zhang, W., Wang, L. et al. Vertical Interface Induced Dielectric Relaxation in Nanocomposite (BaTiO3)1-x:(Sm2O3)x Thin Films. Sci Rep 5, 11335 (2015). https://doi.org/10.1038/srep11335

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep11335

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.