Abstract

Surface potential measurement on atomically thin MoS2 flakes revealed the thickness dependence in Schottky barriers formed between high work function metal electrodes and MoS2 thin flakes. Schottky diode devices using mono- and multi- layer MoS2 channels were demonstrated by employing Ti and Pt contacts to form ohmic and Schottky junctions respectively. Characterization results indicated n-type behavior of the MoS2 thin flakes and the devices showed clear rectifying performance. We also observed the layer dependence in device characteristics and asymmetrically enhanced responses to NH3 and NO2 gases based on the metal work function and the Schottky barrier height change.

Similar content being viewed by others

Introduction

Two-dimensional (2D) nano-sheets that can be exfoliated from layered materials such as graphite, BN and MoS2 have been of intense interest because of their unique electrical, mechanical and chemical properties1,2,3,4,5,6,7. Since the field effect characteristic of single layer graphene was demonstrated with extremely high carrier mobility8,9, interest in such 2D nanomaterials dramatically increased because they are considered as promising materials for advanced nanoelectronic applications. For the last decade, numerous efforts have been made to implement such unique nano-sheets in practical electronic systems. Various techniques for large-scale synthesis and integration of 2D materials were discussed including solution-based deposition using chemical exfoliation10,11,12 and chemical vapor deposition (CVD)13,14,15. Recent investigations reported a layered heterostructure of various 2D materials by using a direct growth technique, which may enable practical and advanced nanoelectronic devices16,17. Unlike graphene, which has a zero or very small energy band gap, single layer MoS2 has a direct energy band gap very similar in size to silicon; thus, it has been used as an active layer with a high on/off ratio and high carrier mobility in field effect transistor devices4. Furthermore, recent studies of photo-excitation and chemical exfoliation of MoS2 layers showed tunability of the energy band structure with the layer thickness and metallic transition due to atomic structure deformation18,19. Also, unlike bulk MoS2, which shows clear n-type behavior, some MoS2 thin film based transistor devices showed ambipolar characteristics depending on the surrounding environments (e.g., ionic liquid and polymer gate dielectric) and its carrier mobility for holes was even higher than that for electrons20,21. A scanning tunneling microscope (STM) measurement on a MoS2 nanosheet22 also demonstrated p-type semiconducting behavior, which depended on the surface defect concentration. These previous results strongly support the possibility of energy band structure engineering and suggest a wide range of applications of MoS2 in the field of electronics and optoelectronics.

To realize a MoS2 thin film based CMOS device that may possibly replace silicon-based technology and overcome its fundamental limitations, understanding physical phenomena at the interface between MoS2 and a metal electrode is very important. Since the Schottky barrier height in the metal/semiconductor contact is closely related to the difference between the work function of the metal and the electron affinity of the semiconductor, it has been predicted that metal electrodes with a low work function such as Ti would show better contact properties with a MoS2 thin film than a high work function metal electrode like Pt or Au. Based on this prediction, a previous study revealed that a MoS2 field effect device using Sc source and drain electrodes (work function <4 eV) showed superior performance compared to that using high work function metal electrodes; further, the effect of Fermi level pinning close to the conduction band of MoS2 was also reported23. However, a clear and detailed explanation of the physical phenomena occurring at the interface between MoS2 and the metal contact has not yet been given. In particular, the layer dependence on a MoS2/metal Schottky contact has never been reported.

In this study, we designed and fabricated a MoS2 thin film diode device with an asymmetric metal contact to explore Schottky barrier formation with a high work function metal. Ti electrodes and Pt electrodes were applied to a MoS2 thin flake to form ohmic contacts and Schottky contacts, respectively. The surface potential difference profile of the MoS2 layers and visualization of charge depletion around Pt electrodes using electrostatic force microscopy (EFM) demonstrated the Schottky contact formation and the layer dependence. The device was operated and analyzed under n-type behavior of the MoS2 channel. The source-drain current showed highly rectifying behavior based on the high Schottky barrier between the Pt electrode and single layer MoS2. However, multi-layer MoS2 showed a higher reverse current because of the relatively small Schottky barrier height. This result indicates that a band structure engineering is potentially possible for the hetero-junction device using two different 2D materials.

To evaluate the layer dependent energy band structure of MoS2, we employed EFM, which can provide the contact potential difference between a probe tip and sample from surface band bending24. When the conducting tip and sample are brought close enough, there will be electrostatic force due to the work function difference of the two materials as

where dC/dz is the derivative of the sample-tip capacitance, qs is surface charge and qt is charge induced on the tip. A voltage consisting of an AC/DC bias is applied between the tip and sample. The tip has a specific resonance frequency, ω and the scanning VDC (DC bias) is used to minimize the electrostatic force and eliminate the ω term; this DC bias represents the measured surface potential, Vcontact.

Figure 1(a) shows the image of MoS2 flake measured by AFM. We can see that the flake is consists of 4 different regions and the thickness for each region is represented in Fig. 1(c). Since the thickness of single layer MoS2 was estimated less than 1 nm in a previous study4, our result indicates 1-, 2-, 3- and 4-layer of MoS2 respectively. Figure 1(b) represents the surface potential result of the same flake. The normal distribution based on the surface potential result shows the layer dependence as shown in Fig. 1(d). This result is corresponding to a previous study showed the same measurement with epitaxially grown graphene layers and supports the layer dependent energy band gap change of MoS218,25. According to the surface potential result, the thicker MoS2 layer seems to have the higher electron affinity and work function value since the potential value here represents the difference between the work function of the tip and the surface as below26,27,

where Фm is the metal work function of the tip, χs is the electron affinity of the surface, ΔEfn is the Fermi level position referenced to the bottom of the conduction band and ΔФ represents band bending caused by surface states. If the surface state distribution is locally negligible, Vcontact can represent the work function of target surface. A relatively larger difference in the potential value between 2 and 3 layers can be due to the band gap change or substrate effect since the single layer MoS2 can be more affected by surface charges on SiO2 substrate while the effect on 2 layers or thicker MoS2 can be screened by their bottom-most layer.

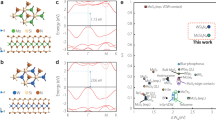

Figure 2(a) represents a schematic image of the energy band structure for the MoS2 layers and the Pt electrode based on the surface potential result and Fermi level shift. The strong interlayer coupling of electron orbitals on sulfur atoms and the quantum confinement effect of single layer MoS2 is the main reason for the transition of energy band structure when the thickness of MoS2 is reduced from bulk to single layer28,29,30. The result suggests a relatively lower Schottky barrier height at the interface between the thicker MoS2 and the high work function metal. In Fig. 2(b), we tested several devices with various flake thicknesses. The thinner MoS2 sample tends to have a lower current amplitude and relatively nonlinear I-VDS characteristic which suggests a high contact resistance and Schottky barrier. Figure 2(c,d) show a more clear comparison in the current flow. To eliminate unintended fluctuations among the samples, we tested the current flow over three different areas having thickness of 2 nm, 5 nm and 20 nm respectively in a single flake as shown in Fig. 2(c). Figure 2(d) shows I-VDS characteristics of the device. The current through the thickest layer (the current from electrode C1 to C2) showed a much higher amplitude compared to that through the thinnest layer (the current from electrode A1 to A2). Also, the thicker layer showed more symmetric and ohmic I-VDS characteristics while the thinnest layer showed clear asymmetric and Schottky characteristics. Since the device was designed carefully by the electron beam lithography to have identical channel lengths and contact areas, the differences can be understood by differences in electron concentrations and the Schottky barrier height with its thickness. According to the energy difference between the conduction band of MoS2 and the work function of Pt electrode, the thicker layer of MoS2 can have the relatively lower Schottky barrier height.

(a) Schematic image of the energy band alignment for MoS2 layers and Pt electrode according to the surface potential measurement. (b) I-VDS characteristics of several MoS2 layers with different thicknesses. (c) Optical image of the device with Pt electrodes. (d) I-VDS characteristics of the corresponding MoS2 flake. Thicker layer shows more ohmic characteristics.

For further analysis, we applied Ti/Pt asymmetric metal contacts on MoS2 device and made MoS2 Schottky diode devices. A schematic image of the device is illustrated in Fig. 3(a). Figure 3(b) shows an image of the device obtained by AFM. Thickness of the MoS2 flake was estimated as 5 nm and each metal electrode was designed to have the same distance from the adjacent electrodes to eliminate the effect of channel length. Figure 3(d) shows the device image measured by EFM, which provides the surface potential difference for Pt and Ti contacts, respectively. The relative difference in surface potential can be observed by the change in color and that for MoS2 is in between that of the Ti and Pt electrode. We can also confirm the layer-dependent change. The thicker part of the MoS2 flake showed a lower Vcontact.

(a) Schematic view of MoS2 schottky diode device. Two pairs Ti and Pt electrodes were used to form ohmic and Schottky contacts with MoS2, respectively. (b) AFM image of the device. (c) Normal distribution of the relative work function differences for Ti, Pt and MoS2. (d) Surface potential measurement result of the same device.

In the EFM result for the device, the potential difference between Ti and MoS2 was very small. On the other hand, the area that is covered by a Pt electrode shows a large potential difference compared to MoS2 and the Ti electrode as shown in Fig. 3(c), a normal distribution of the measured surface potential in each area. Based on the small difference in the potential between the Ti electrode and MoS2, we assumed that the effect of Schottky barrier height at the Ti/MoS2 interface on the device characteristics is small enough to be ignored and we considered Pt/MoS2 Schottky contact only23.

A schematic of the energy band structure of Schottky diode device is illustrated in Fig. 4(a) based on the surface potential measurement. The actual value by the EFM measurement was a little higher than the work function of Ti, which is around 4.2 eV. This value can be slightly varied due to the surface states of MoS2 and defects. Figure 4(b) shows corresponding Schottky diode characteristics in the proposed energy band structure. Since the Ti/MoS2 junction shows a very small Schottky barrier height and almost ohmic contact, the device with asymmetric contact will show rectifying operation based on the Schottky barrier at the MoS2/Pt junction. With these asymmetric metal contacts, the source-drain current showed a much higher level under the forward bias voltage (+ for Pt drain electrode and – for Ti drain electrode) than in the case of symmetric Pt contacts. Under the reverse bias voltage, the source-drain current is almost the same as that of the Pt symmetric contacts, which has a very high Schottky barrier. This result supports the assumption that MoS2 forms ohmic contact with Ti and the bottleneck of current flow in the device is the Schottky barrier with a Pt contact.

(a) Schematic image of the energy band alignment corresponding to the surface potential measurement. (b) I-VDS characteristics for the Pt - Ti asymmetric contacts and Pt - Pt symmetric contacts. The asymmetric contact device showed clear diode performance. (c) Transfer curves for the device. The current amplitude is higher under the forward bias condition. However on/off ratio is much higher under the reverse bias due to its low ‘off’ state current. (d) Field effect transistor performance of two different types of device. Filed effect mobility is about 6 cm2/Vs for Ti symmetric contact device and 2 cm2/Vs for Ti/Pt asymmetric contact device. The device with asymmetric contact showed a much lower ‘off’ current compared to symmetric contact device.

In Fig. 4(c), we observe that the source-drain current under reverse bias is almost the same as that under forward bias when a high positive back gate voltage is applied. This tendency can be explained by the Schottky barrier height modulation by the back gate bias and it also suggests a Schottky transistor behavior of MoS2 thin film channel. A majority charge carrier concentration change in MoS2 thin flake is the main reason for the current level change with the gate bias. However, with the high positive gate bias, the Schottky junction can allow the high reverse current flow since a charge carrier injection under the reverse bias can be increased substantially as the barrier height is lowered by the gate bias. On the other hand, under the negative gate bias, the current gap between the forward and reverse bias increases because the reverse current is easily blocked, while the current flow under the forward bias is difficult to be turned off. Therefore, under the reverse bias, contrary to the forward bias, we observe a very low ‘off’ state current and a higher on/off ratio. The on/off ratio of the device during transistor performance is relatively small for the forward bias (<102) compared to the reverse bias case (>104), as shown in Fig. 4(b). The effect of the Schottky barrier on transistor performance can be shown more clearly when we compare the device with Ti/MoS2/Ti junctions (ohmic) and Pt/MoS2/Ti junctions (Schottky) as shown in Fig. 4(d). Under the reverse bias between the source and drain electrode, the current can be turned off with a relatively higher gate voltage since the Schottky barrier at Pt/MoS2 junction can effectively block the charge carrier injection from MoS2 as compared to the ohmic device, where the charge carrier concentration change due to the electric field effect is fully responsible for the transistor operation.

Under the assumption that the device has a Schottky contact between the Pt electrode and MoS2 flake, we can draw an energy band diagram, as shown in Fig. 5(a), with a Schottky barrier for the majority charge carrier according to the Fermi level pinning of MoS2 close to its conduction band with the high work function metal. Here, Фm is the metal work function and ФB is the Schottky barrier height. Red lines indicate the energy band of multi-layer MoS2 based on the assumption that the thicker MoS2 layer has higher electron affinity. Figures 5(b) represents Schottky diode performance of mono-layer MoS2 under various back gate biases with Ti and Pt as the source and drain electrodes, respectively. Under forward bias (VSD > 0), the device exhibits a drastic current increase, which gradually increases with the back gate bias. With a +10 V back gate bias, the device showed the highest current amplitude. When a reverse bias (VSD < 0) is applied to the device, the current is blocked by the high Schottky barrier. The ratio of the current under the forward bias and reverse bias is almost 104 and it seems to be changed by back gate bias modulation. On the other hand, with ten layer MoS2 device, the current ratio between the forward and reverse bias is less than 10 as shown in Fig. 5(c). According to the previous results, the Schottky barrier between the high work function metal and multi-layer MoS2 may be smaller than that of mono-layer MoS2. Therefore, the current under reverse bias cannot completely be blocked by the Schottky barrier compared to the mono-layer deivce and the I-VDS characteristic shows less asymmetric feature. This layer dependent reverse current supports the surface potential difference of MoS2 layers and its effects on the device performance. Also, these two different device performances can provide significant advantage in gas molecule detection.

Absorption of gas molecules may also confirm the Schottky barrier effect on the device performance; in addition, we can be able to achieve much higher sensitivity for certain gases. In the device with mono-layer MoS2, the electrical resistance decreased when exposed to 10 ppm of NH3, as shown in Fig. 6(a). The device shows diode characteristics because of the Schottky barrier and an asymmetric current change between the forward and reverse bias. Under a forward bias, there is a slight change in the current during the gas reaction. Since NH3 is well known as an electron-donating molecule for 2D materials, the resistance decrease in the forward bias can be understood as the effect of charge carrier concentration change. However, under a reverse bias, the current, which is originally blocked by the Schottky barrier, showed a more drastic increase compared to the forward bias case. With the multi-layer MoS2 channel, there is a significant reverse current as shown in Fig. 5(c) and this relatively high reverse current, which is due to the smaller Schottky barrier, is drastically reduced when the device is exposure to 10 ppm of NO2 as shown in Fig. 6(b).

This behavior can be understood by the metal work function change as a result of gas molecule absorption. Previous studies showed the work function of Pt can be decreased by NH3 and increased by NO231. Therefore, in the mono-layer MoS2 device, the Schottky barrier height at the Pt/MoS2 junction can be reduced to allow more reverse current under NH3 exposure and the opposite reaction can be occurred in the multi-layer MoS2 device under NO2 exposure. The signal change in reverse current is much greater than that in forward current. This difference confirms that the Schottky barrier formation and its modulation under ambient gas condition. Also, we observe the clear layer dependence in the reverse current change. The distinct differences from the layer thickness and bias direction support the result of surface potential measurement and confirm its effect on diode device.

This result can be a great advantage for improving gas response when we compare the response to NH3 under reverse bias (Fig. 7(a)) and forward bias (Fig. 7(b)) since the current under reverse bias is much lower than that of a forward bias in the pristine state. The work function of Ti also can be changed by gas molecule absorption. However, this effect seems much smaller than that for Pt since it already forms an ohmic contact with the MoS2. The response of the device to NH3 confirms the previous device performance originates from Schottky barrier formation at the Pt/MoS2 junction and its modulation based on the electric field effect.

In this paper, we showed the layer dependence of Schottky barrier height at the MoS2 / Pt interface and demonstrated a MoS2 Schottky diode device. By applying the asymmetric metal contacts, we observed clear current rectification performance with a MoS2 thin flake channel. The surface potential difference profile measured from EFM indicated a high Schottky barrier formation with Pt and ohmic contact formation with Ti. The device performance also showed results consistent with the suggested energy band structure. The gate voltage dependence in the current rectification performance and transistor characteristic indicates Schottky barrier height modulation by the electric field effect and highlights the importance of proper selection of a metal contact for the high performance MoS2 electronic devices. In the future, a clear and detailed explanation of a wide range of energy band structure deformation of MoS2 nanosheets including p-type transitions or ambipolar characteristics should be made since these highly tunable electronic properties can encourage the realization of practical and diverse applications in nanoelectronics.

Method

Fabrication of MoS2 devices

MoS2 flakes were prepared on highly doped Si/SiO2 substrates by mechanical exfoliation of bulk MoS2 purchased from SPI Supplies. Thickness of MoS2 was estimated via optical color contrast and confirmed by atomic force microscopy (Nanoscope IV, Veeco). 100 nm of Ti electrodes were patterned by electron beam lithography and deposited by electron beam evaporation followed by lift-off in acetone. The same processes were applied for Pt electrodes after Ti electrodes formation. The device performance was characterized by typical source/drain and source/gate voltage modulation (Keithley 2400 source meter) with room temperature probe station.

Surface potential measurement

Interleave mode of electric force microscopy (Nanoscope IV, Veeco) with PtIr-coated n-doped silicon probe tip (SCM-PIT, Veeco) were used for surface potential measurements. Topological profile of the surface was provided by the first scan of the tip followed by its second scan to measure electrostatic force between the surface and tip. Vcontact can be obtained by this technique as a feedback potential that minimize the amplitude of oscillation.

Additional Information

How to cite this article: Yoon, H. S. et al. Layer dependence and gas molecule absorption property in MoS2 Schottky diode with asymmetric metal contacts. Sci. Rep. 5, 10440; doi: 10.1038/srep10440 (2015).

References

Novoselov, K. S. et al. Two-dimensional gas of massless Dirac fermions in graphene. Nature 438, 197–200 (2005).

Zhang, Y., Tan, Y. W., Stormer, H. L. & Kim, P. Experimental observation of the quantum Hall effect and Berry’s phase in graphene. Nature 438, 201–204 (2005).

Pacilé, D., Meyer, J. C., Girit, Ç. Ö. & Zettl, A. The two-dimensional phase of boron nitride: Few-atomic-layer sheets and suspended membranes. Appl. Phys. Lett. 92, 133107 (2008).

Radisavljevic, B., Radenovic, A., Brivio, J., Giacometti, V. & Kis, A. Single-layer MoS2 transistors. Nature Nanotech. 6, 147–150 (2011).

Lebègue, S. & Eriksson, O. Electronic structure of two-dimensional crystals from ab initio theory. Phys. Rev. B 79, 115409 (2009).

Ling, X. et al. Raman Enhancement Effect on Two-Dimensional Layered Materials: Graphene, h-BN and MoS2 . Nano lett. 14, 3033–3040 (2014).

Ataca, C., Topsakal, M., Aktürk, E. & Ciraci, S. A Comparative Study of Lattice Dynamics of Three- and Two-Dimensional MoS2 . J. Phys. Chem. C 115, 16354–16361 (2011).

Schwierz, F. Graphene transistors. Nature Nanotech. 5, 487–496 (2010).

Du, X., Skachko, I., Barker, A. & Andrei, E. Y. Approaching ballistic transport in suspended graphene. Nature Nanotech. 3, 491–495 (2008).

Han, W. Q., Wu L., Zhu, Y., Watanabe, K. & Taniguchi, T. Structure of chemically derived mono- and few-atomic-layer boron nitride sheets. Appl. Phys. Lett. 93, 223103 (2008).

Stankovich, S. et al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45, 1558–1565 (2007).

Eda, G. et al. Photoluminescence from Chemically Exfoliated MoS2 . Nano Lett. 11, 5111–5116 (2011).

Li, X. et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 5, 1312–1314 (2009).

Song, L. et al. Large Scale Growth and Characterization of Atomic Hexagonal Boron Nitride Layers. Nano Lett. 10, 3209–3215 (2010).

Lee, Y. H. et al. Synthesis of Large-Area MoS2 Atomic Layers with Chemical Vapor Deposition. Adv. Mater. 24, 2320–2325 (2012).

Liu, Z. et al. Direct Growth of Graphene/Hexagonal Boron Nitride Stacked Layers. Nano Lett. 11, 2032–2037 (2011).

Shi, Y. et al. van der Waals Epitaxy of MoS2 Layers Using Graphene As Growth Templates. Nano Lett. 12, 2784–2791 (2012).

Lee, H. S. et al. MoS2 Nanosheet Phototransistors with Thickness-Modulated Optical Energy Gap. Nano Lett. 12, 3695–3700 (2012).

Lin, Y. C., Dumcenco, D. O., Huang, Y. S. & Suenaga, K. Atomic mechanism of the semiconducting-to-metallic phase transition in single-layered MoS2 . Nature Nanotech. 9, 391–396 (2014).

Zhang, Y., Ye, J., Matsuhashi, Y. & Iwasa, Y. Ambipolar MoS2 Thin Flake Transistors. Nano Lett. 12, 1136–1140 (2012).

Bao, W., Cai, X., Kim, D., Sridhara, K. & Fuhrer, M. S. High mobility ambipolar MoS2 field-effect transistors: Substrate and dielectric effects. Appl. Phys. Lett. 102, 042104 (2013).

McDonnell, S., Addou, R., Buie, C., Wallace, R. M. & Hinkle, C. L. Defect-Dominated Doping and Contact Resistance in MoS2 . ACS Nano 8, 2880–2888 (2014).

Das, S., Chen, H. Y., Penumatcha, A. V. & Appenzeller, J. High Performance Multilayer MoS2 Transistors with Scandium Contacts. Nano Lett. 13, 100–105 (2013).

Meoded, T., Shikler, R., Fried, N. & Rosenwaks, Y. Direct measurement of minority carriers diffusion length using Kelvin probe force microscopy. Appl. Phys. Lett. 75, 2435 (1999).

Filleter, T., Emtsev, K. V., Seyller, T. & Bennewitz, R. Local work function measurements of epitaxial graphene. Appl. Phys. Lett. 93, 133117 (2008).

Bridger, P. M., Bandic´, Z. Z., Piquette, E. C. & McGill, T. C. Measurement of induced surface charges, contact potentials and surface states in GaN by electric force microscopy. Appl. Phys. Lett. 74, 3522 (1999).

Rodriguez, B. J., Yang, W. C., Gruverman, A. & Nemanich, R. J. Scanning probe investigation of surface charge and surface potential of GaN-based heterostructures. Appl. Phys. Lett. 86, 112115 (2005).

Chhowalla, M. et al. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nature Chem. 5, 263 (2013)

Kuc, A., Zibouche, N. & Heine, T. Influence of quantum confinement on the electronic structure of the transition metal sulfide TS2 . Phys. Rev. B 83, 245213 (2011)

Splendiani, A. et al. Emerging Photoluminescence in Monolayer MoS2 . Nano Lett. 10, 1271 (2010).

Zimmer, M. et al. Gold and platinum as ozone sensitive layer in work-function gas sensor. Sens. Act. B 80, 174–178 (2001).

Acknowledgements

This work was partially supported by the Priority Research Centers Program (2009-0093823), the Pioneer Research Center Program (2010-0019313), Korea Electric Power Corporation Research Institute though Korea Electrical Engineerung & Science Research Institute (R14XA02-2), Yonsei University Future-leading Research Initiative of 2014 (2014-22-0168) and the Basic Science Research Program (2013R1A1A2A10013147) through the National Research Foundation of Korea funded by the Ministry of Science, ICT & Future Planning. The authors also acknowledge the financial support from NRF (NRL program: Grant No. 2014R1A2A1A01004815).

Author information

Authors and Affiliations

Contributions

H.S.Y. wrote the manuscript and analyzed data. H.E.J. and B.K.L. performed surface potential measurement. S.J.K. prepared MoS2 samples. H.S.L. and S.I. provided useful advices and comments. S.C.J. supervised the work.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yoon, H., Joe, HE., Jun Kim, S. et al. Layer dependence and gas molecule absorption property in MoS2 Schottky diode with asymmetric metal contacts. Sci Rep 5, 10440 (2015). https://doi.org/10.1038/srep10440

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep10440

This article is cited by

-

Metal–semiconductor interface engineering in layered 2D materials for device applications

Bulletin of Materials Science (2021)

-

Tunable rectification in a molecular heterojunction with two-dimensional semiconductors

Nature Communications (2020)

-

All-inkjet-printed high-performance flexible MoS2 and MoS2-reduced graphene oxide field-effect transistors

Journal of Materials Science (2020)

-

Carrier Transport Properties of MoS2 Asymmetric Gas Sensor Under Charge Transfer-Based Barrier Modulation

Nanoscale Research Letters (2018)

-

Nanoscale enhancement of photoconductivity by localized charge traps in the grain structures of monolayer MoS2

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.