Abstract

To extend density limits in magnetic recording industry, two separate strategies were developed to build the storage bit in last decade, introduction of perpendicular magnetic anisotropy (PMA) and adoption of ferrimagnetism/antiferromagnetism. Meanwhile, these properties significantly improve device performance, such as reducing spin-transfer torque energy consumption and decreasing signal-amplitude-loss. However, materials combining PMA and antiferromagnetism rather than transition-metal/rare-earth system were rarely developed. Here, we develop a new type of ferrimagnetic superlattice exhibiting PMA based on abundant Heusler alloy families. The superlattice is formed by [MnGa/Co2FeAl] unit with their magnetizations antiparallel aligned. The effective anisotropy (Kueff) over 6 Merg/cm3 is obtained and the SL can be easily built on various substrates with flexible lattice constants. The coercive force, saturation magnetization and Kueff of SLs are highly controllable by varying the thickness of MnGa and Co2FeAl layers. The SLs will supply a new choice for magnetic recording and spintronics memory application such as magnetic random access memory.

Similar content being viewed by others

Introduction

Nanometer ferromagnets have been widely used in storage media1,2,3,4,5,6, non-volatile memory and logical devices based on spintronics, where the magnetization is manipulated by magnetic field7,8,9,10,11, spin-polarized current12,13 and electric field14,15. As demanded by cell minimization, ferromagnets employed for information storage experienced a transition from in-plane to perpendicular magnetization in last decades. Several types of ferromagnets with perpendicular magnetic anisotropy (PMA) were developed to fulfill this request, including tradition/noble metal alloys/multilayers (e.g, FePt, CoPt alloys), rare-earth/transition metal alloys16, newly developed CoFeB thin films17 and recent promising tetragonal Heusler alloys18,19,20. The high Kueff is necessary to overcome the thermal fluctuation as cell lateral size minimization. Additional advantages are the low energy consumption of the spintronics-devices manipulated by spin-transfer torque (STT) and the simplified head structure for Hard disk drive storage. Beyond the stability requested for individual cells, the long-range static magnetic interaction between neighboring magnetic units becomes critically important as the density increasing when facing the integration of devices. As the bit distance decreases, a collective behavior occurs as a result of the dipolar interaction21,22,23. Ferrimagnetic/antiferromagnetic materials were proposed as recording media, owing to the fact that the distance between ferrimagnetic especially antiferromagnetic islands can be drastically reduced without fearing of the information stored on one island affecting that of neighboring islands compared to ferromagnets. In addition, the antiferromagnetic bit has a low signal amplitude loss compared with usual ferromagnets6. Beyond being proposed for recording media, antiferromagnetic and ferrimagnetic composites have drawn intensive attention recently, owing to their abundant domain phase-diagram24,25, special dynamics process and unusual FMR model26,27,28,29,30. In addition, the double magnetic sub-lattice makes them one of the candidate for all optical switching media31,32,33,34,35. Nowadays, the perpendicular magnetized ferromagnetic composite were mainly based on transition-metal/rare-earth system, such as Dy-Co and Tb-Fe alloy/multilayers and ferromagnetic/nonmagnetic multilayers with interlayer antiferromagnetic coupling34,35,36,37. However, the fabrication and investigation on perpendicularly magnetized ferrimagnetic composites based on 3d metal without noble and rare-earth elements is rarely been reported, owing to the significant challenge of developing easily-to-built ferrimagnetic composites with systematically controllable parameters.

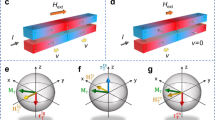

Here, using the Heusler alloys Mn62Ga38 (MnGa) and Co50Fe23.7Al26.3 (CFA), we design a new ferrimagnetic superlattices (SLs) exhibiting PMA for magnetic recording and spintronics devices application. The MnGa and CFA alloys used for SLs architecture are L10 ordered PMA ferromagnet and cubic soft ferromagnet, respectively18,38, ensuring that the magnetic parameters of SLs formed with [MnGa/CFA] are highly flexible. Both of the alloys belong to the Heusler family with small in-plan lattice mismatch, which makes the architecture of SLs available with tunable lattice constants. Ideal Co2FeAl, shown in Figure 1a, has an L21 structure, where Fe and Al atoms occupy two interpenetrating fcc lattices with an NaCl-type structure33. The Co atoms form a simple cubic lattice and they are tetrahedrally coordinated with both the Fe and Co atoms, at the corners of a cube. MnxGa100-x is a promising tetragonal Heusler alloy exhibiting PMA18,19,20. The L10 structure stable for x = 50–65, is a highly distorted tetragonal variant of the L21 Heusler unit cell, which is stretched by ~25% along the c axis. The structure of Mn50Ga50 can be regarded as periodic atomic planes of Mn and Ga along the c direction. As the Mn content increases, parts of the Ga atoms are replaced by Mn atoms and the moments of the substituted Mn atoms are antiparallel to those of the original Mn atoms along the c direction20.

Formation and structural information of SLs.

(a), Schematic picture of L21 Co2FeAl (up) and L10 MnGa (down) alloys. (b), Illustration of ferrimagnetic SLs, where the magnetizations of the CFA and MnGa layers are antiparallel aligned. (c), (d), Cross-sectional TEM image (c) and EDX spectrum (d) of [MnGa(1.5 nm)/CFA(3 nm)]5 SL on an MgO(001) substrate. The gray, red, green and purple lines in (d) correspond to the EDX intensity of the Mg, Mn, Co and Cr elements, which correspond to the MgO, MnGa, CFA and Cr layers, respectively.

Results

Ordered structure with flexible lattice constants of SLs

The periodic layered SLs illustrated in Figure 1b are formed by [MnGa/CFA] units with the magnetizations of the MnGa and CFA layers antiparallel to each other owing to the antiferromagnetic interfacial exchange coupling between them. Figure 1c shows the typical transmission electron microscope (TEM) cross-sectional image of [MnGa(3.0 nm)/CFA(1.5 nm)]5 SL deposited on an MgO(001) single-crystal substrate buffered with a 40-nm-Cr layer. Well crystallized structure is shown in the sample, where the MnGa and CFA layers have the same in-plane lattice constant, indicated by the continuous vertical lattice line. The clear alternative Energy Dispersive X-ray (EDX) spectroscopy peaks of Mn (MnGa) and Co (CFA) shown in Figure 1d indicate the periodic layered structure formed in the SL sample.

To study the structure and magnetic properties systematically, four series of SLs with different thickness of CFA (tCFA = 0.5, 1.0, 1.5 and 2.0 nm) were fabricated on MgO(001) substrate, which are denoted as CFA05, CFA10, CFA15 and CFA20, respectively. The thickness of the MnGa layer (tMnGa) in each series varies from 1.0 to 6.0 nm (see method). The lattice parameters of the SLs were determined by in-plane and out-of-plane X-ray diffraction (XRD) using a Cu Kα source with λ = 1.5418 Å. Figure 2a shows the in-plane 2θ patterns of the CFA05 samples. The single (200) peaks indicate the same in-plane lattice constant (a) for MnGa and CFA in each sample, which is consistent with the TEM result. As tMnGa increases, diffraction peaks of SLs shift to higher angle gradually, implying that the a value decreases as tMnGa increases. The out-of-plane 2θ patterns of CFA05 SLs are shown in Figure 2b. The (004) peaks of SLs marked in the square shift from 61.81° to 51.75° gradually, corresponding to the increase in lattice constant c of the SLs as tMnGa increases. The diffraction peaks of (200) and (004) of SLs shown in Figures (a) and (b) indicates well-ordered structure formed in SLs, where MnGa and CFA layers have L10 and B2 ordering20,38. Detailed XRD patterns of all SL samples are shown in supporting information (Figures S1 to S5).

XRD patterns and lattice constants of SLs on MgO(001) substrate.

(a),(b), In-plane (a) and out-of-plane (b) XRD patterns for [MnGa(tMnGa nm)/CFA(0.5 nm)]5, where tMnGa = 1, 2, 3, 4, 5 and 6 nm. The green dotted lines in (b) are typical 004 peak positions for MnGa and CFA bulk materials. The diffraction pattern of (200) and (004) peaks are marked in the dashed circles in (a) and (b), respectively. (c), (d), Lattice constant a (c) and c (d) as a function of tMnGa for four SL series, where tCFA = 0.5 (squares), 1 (circles), 1.5 (triangles) and 2.0 nm (diamonds). As tMnGa increases, the lattice constants change gradually from CFA-regime to MnGa-regime, which are marked with dashed lines.

Owing to the in-plane lattice mismatch between the MnGa and CFA materials, the lattice constants of SLs strongly depend on the thickness of the MnGa and CFA layers. The a and c values of SLs calculated from the XRD patterns are summarized in Figures 2c and d, respectively. Generally, the SLs lattice exhibits a transition from CFA-dominated to MnGa-dominated as tMnGa increase for each series. Here, the a values of SLs are calculated in the frame of tetragonal cell as a reference of MnGa cell, where a is  times of the cubic cell (a'). For each series, a decreases as tMnGa increases and exhibits a dramatic change at certain tMnGa, which possibly correspond to the transition of the SLs from cubic to tetragonal. The c values of SLs exhibit a monotonic increase with tMnGa in each series and SLs with thinner tCFA have larger c. As the MnGa layer is thick enough, such as 4 and 6 nm for the CFA05 and CFA15 series, the c of SLs are almost same as that of the MnGa alloys.

times of the cubic cell (a'). For each series, a decreases as tMnGa increases and exhibits a dramatic change at certain tMnGa, which possibly correspond to the transition of the SLs from cubic to tetragonal. The c values of SLs exhibit a monotonic increase with tMnGa in each series and SLs with thinner tCFA have larger c. As the MnGa layer is thick enough, such as 4 and 6 nm for the CFA05 and CFA15 series, the c of SLs are almost same as that of the MnGa alloys.

Ferrimagnetism and PMA nature of SLs with widely tunable parameters

Typical M(H) loops in the perpendicular direction for CFA15 SLs are plotted in Figure 3a. For tMnGa ≥ 2.0 nm, the SLs exhibits PMA indicated by square-shaped M(H) loops. It is noted that both the Hc and Ms of SLs strongly depend on tMnGa and exhibit a non-monotonic dependence. The perpendicular M(H) loops of the four series of SLs are shown in supporting information (Figures S6 to S9). Figure 3b shows the perpendicular and in-plane M(H) loops for the [MnGa(6 nm)/CFA(1.5 nm)]5 sample. A linear M(H) loop in the in-plane direction indicates a well PMA and the effective anisotropy (Kueff) calculated from HsMs/2 is 6.8 Merg/cm3, where Hs is the saturation field of the in-plane M(H) curve.

Magnetic properties of SLs on MgO(001) substrate.

(a), Out-of-plane Kerr loops of the CFA15 series. (b), Out-of-plane (⊥) and in-plane (//) M(H) loops of the [MnGa(6.0 nm)/CFA(1.5 nm)]5 SL. (c), (d), (e), Ms (c), Kueff (d) and Hc (e) of SLs as a function of t′MnGa for the CFA05, CFA10, CFA15 and CFA20 series, where tCFA = 0.5 (squares), 1.0 (circles), 1.5 (triangles) and 2.0 nm (diamonds). t′MnGa is effective MnGa thickness with consideration of addtional MnGa layer deposited on the top of SLs. The solid lines in c, d and e are fits based on formulas (1), (2) and (3), respectively.

The Ms of SLs as a function of t′MnGa (t′MnGa is effective thickness of MnGa layer with consideration of additional MnGa layer on the top of SLs, see method) for the four SL series are shown in Figure 3c. For each series, Ms firstly decreases in the CFA-dominated regime as tMnGa increases, owing to the fact that the increase in the antiparallel-aligned magnetization of MnGa decreases the net magnetization of SLs. As t′MnGa increases further in the MnGa-dominated regime, Ms increases as t′MnGa increases, owing to the magnetization of SLs being in the same direction as the MnGa layers. Based on the antiparallel alignment of magnetizations of MnGa and CFA layers, the Ms of SLs can be described by the following formula.

The fits are shown by the solid lines in Figure 3c; the fitted magnetizations of the MnGa and CFA layers are ~460 and ~1050 emu/cm3, respectively, which are comparable to the values of bulk MnGa and CFA materials18,38 (see supporting information Figure S10). It is noted that, the magnetization of SLs is zero for certain t′MnGa, so-called compensational points. At these points, the magnetizations of the CFA and MnGa layers have the same magnitude with antiparallel configuration, the SLs are antiferromagnetic composites.

Kueff of the SLs estimated from HsMs/2 are plotted in Figure 3d. Generally, SLs with small tCFA and large t′MnGa exhibit a high Kueff; the phase-diagram of Kueff as a function of tCFA and t′MnGa is shown in the supporting information (Figure S11). For a density of 1 Tbit/inch2, the smallest volume V for the stability condition KueffV/kBT ≥ 60 to be satisfied at room temperature is 800 nm3 if considering the distance between neighboring bits is the same as the bit diameter, for Kueff of 3 Merg/cm3. This volume corresponds to a nano-pillar with a height equal to its diameter with dimensions of 10.5 nm17. Assume the PMA of SLs originates from the MnGa layers, the Kueff the of SLs can be described by:

where Ku-MnGa denotes the effective uniaxial anisotropy of the MnGa layer in SLs. From the fits shown with the solid lines, the Ku-MnGa and MCFA are ~8 Merg/cm3 and ~1100 emu/cm3, respectively (see support information Fig. S12). It is reasonable to attribute the smaller Ku-MnGa compared with the bulk material to the structural change of the MnGa layer in SLs. In particular, the Ku-MnGa is 6 Merg/cm3 for the CFA20 series owing to the cubic-like lattice of the SLs.

In each series, Hc shows a maximum value near compensational points marked by the dotted line in Figure 3e. Hc decreases to zero as tMnGa decrease to zero, where the PMA of SLs disappears. On the other side, Hc saturates to that of single-MnGa-layer when t′MnGa is thick enough, where the property of SLs is dominated by the MnGa. Here, simply based on the Stoner-Wohlfarth description, the coercivity is proportional to the uniaxial anisotropy field39

Thus, Hc increases as the magnetization decreases for certain Kueff. In principle, Hc is infinite at the compensational points. The solid-lines in Figure 3e are the fitted values from 2C Kueff/Ms, with the scaling factor C is around 0.1. Ideally, the constant C is 1 for single domain particles. The small scaling factor in the fitting is because the Hc of continuous film depend on nucleation field, in addition to Kueff only. It shows that the non-monotonic t′MnGa dependent of Hc can be well described by the Stoner-Wohlfarth model39.

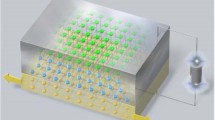

Formation of SLs on SiO2 amorphous substrate

For materials designed for application, fabrication on different substrates, especially on amorphous substrates, is essentially important. Here, we demonstrate the formation of textured SLs on an amorphous substrate. The SL stacks with periodic CFA/MnGa layers were deposited on Si/SiO2 substrate at room temperature, buffered with Ta(10 nm)/Cr(5 nm)/MgO(2 nm) and capped with 5-nm-Ta layer, as shown in Figure 4a. Post annealing at 400°C was performed for 10 min in vacuum to crystallize the SLs. Three series of SLs (cfa12, cfa15 and cfa20) were fabricated, where tCFA = 1.2, 1.5 and 2.0 nm, respectively. Square-shaped out-of-plane M(H) loops of cfa15 SLs are observed, as shown in Figure 4b. This indicates that the SLs exhibit PMA owing to the textured structure formed on SiO2 substrate. Up to now, tetragonal MnGa layers were only achieved on single crystal substrates such as GaAs(001) SiTiO3(001) and MgO(001) owing to the matastable nature of the tetragonal order40,41,42. The ordered structure of SLs well formed on the amorphous substrate is likely induced by the crystalline structure of the CFA layer. The tMnGa dependence of Ms, Kueff and Hc of the SLs for the three series are summarized in Figure 4c, where the solid lines are the fits based on formula (1), (2) and (3), respectively. The MMnGa and MCFA in these SLs from the fit of Ms(tMnGa) are ~460 and ~1100 emu/cm3, which is consistent with that for the SLs deposited on MgO(001) substrate.

Fabrication of SLs on SiO2 amorphous substrate.

(a), SL film stack structure deposited on the Si/SiO2 substrate. (b), Out-of-plane Kerr loops of the cfa15 series, where tCFA = 1.5 nm. The black, green, blue and cyan lines are the Kerr loops of SLs with tMnGa = 2, 4, 5 and 6 nm, respectively. (c), Ms, Hc and Kueff of SLs as a function of tMnGa for the cfa12, cfa15, cfa20 series, where tCFA = 0.5 (diamonds), 1.0 (circles) and 1.5 nm (squares). The solid lines in each panel are fits based on formula (1), (2) and (3), respectively.

Discussion

The magnetism of Mn-Ga alloys originates from the Mn atoms, which have a half-filled d shell. This makes the exchange interaction involving Mn-Ga thin film more sensitive to the interfacial environment and more flexible to being tuned. An antiferromagnetic exchange coupling at the MnGa/Co2FeAl interface was achieved when the structure was annealed at 400°C, owing to the Co atoms presented in the interface43. Since both the materials belong to the Heusler family, this supplies the structural basis for the architecture of the ferrimagnetic SL. The in-plane lattice mismatch and different magnetic properties of MnGa and CFA enable well control of the properties of SLs by simply changing the thickness of MnGa and CFA layers. The SLs depicted here, can be easily built on amophous substrates, exhibit flexible magnetic and structure properties, leading to a desirable combination for wide applictions in information storage.

In summary, based on antiferromagnetic exchange coupling at the MnGa/CFA interface, we developed ferrimagnetic SLs exhibiting high PMA with Kueff over 6 Merg/cm3. The SLs formed with [MnGa(tMnGa)/CFA(tCFA)] units exhibit widely tunable magnetic properties, with Ms and Hc varying from 0 to 400 emu/cm3 and from 30 mT to 1500 mT. At the compensation points, where the antiparallel aligned magnetizations of MnGa and CFA have same magnitude, the SLs are antiferromagnets exhibiting zero Ms with PMA, which is a potential candidate for antiferromagnetic electronics and all-optical switching media.

Experimental section

Sample preparation

The stoichiometric compositions of the Co2FeAl and Mn-Ga films were Co50Fe23.7Al26.3 (CFA) and Mn62Ga38 (MnGa), analyzed with inductively coupled plasma mass spectrometry. [MnGa(tMnGa)/CFA(tCFA)]5/MnGa(tMnGa) SL stacks were fabricated using an ultrahigh-vacuum sputtering system with a base pressure of less than 1 × 10−7 Pa on a MgO(001) single-crystal substrate, with a 40-nm-Cr as the buffer layer. Here, tMnGa = 1.0, 2.0, 3.0, 4.0, 5.0 and 6.0 nm, tCFA = 0.5, 1.0, 1.5 and 2.0 nm. Since there is an additional MnGa layer on the 5-periodic MnGa/CFA structure, the effective MnGa thickness (t′MnGa) is in the used in the discussion of magnetic properties, where t′MnGa = 6tMnGa/5. All of the layers were deposited at room temperature and in-situ annealing was carried out at 700°C after the deposition of Cr. Then, a capping layer of MgO(2.2 nm)/Ta(2.0 nm) was deposited on top to prevent contamination and oxidation of the SLs. The SLs deposited on the SiO2 substrate were fabricated under the same conditions with a buffer layer of Ta(5.0 nm)/Cr(5.0 nm)/MgO(2.0 nm). Three series of SLs were fabricated on the SiO2 substrate with structure of [MnGa(tMnGa)/CFA(tCFA)]5, where tCFA = 1.2, 1.5 and 2.0 nm. In each series, tMnGa varies from 2.0 to 6.0 nm. Before the measurement, the SLs stacks were annealed for 10 min at 400°C in vacuum.

Characterization

The crystal structure was characterized using XRD both in-plane and out-of-plane with a 9-kW rotating anode. The Cu Kα line (wave length λ = 1.5418 Å) was used in the experiment. Atomic structure was characterized using high-resolution TEM (HRTEM) with an accelerate voltage of 200 kV. The element distribution was examined using EDX spectroscopy. The magnetic properties were measured using a vibrating sample magnetometer and the polar magneto-optical Kerr effect at room temperature with a field range of 2 T.

References

Iwasaki, S. & Nakamura, Y. An analysis for the magnetization mode for high density magnetic recording. IEEE Trans. Magn. MAG-13, 1272–1277 (1977).

Park, B. G. et al. A spin-valve-like magnetoresistance of an antiferromagnet-based tunnel junction. Nat. Mater. 10, 347–351 (2011).

Loth, S. Bistability in Atomic-Scale Antiferromagnets. Science 335, 196–199 (2012).

Acharya, B. R., Abarra, E. N. & Okamoto, I. SNR Improvements for Advanced Longitudinal Recording Media. IEEE Trans. Magn. 37, 1475–1477 (2001).

Mangin, S. et al. Current-induced magnetization reversal in nanopillars with perpendicular anisotropy. Nat. Mater. 5, 210–215 (2006).

Fullerton,. Eric, E. et al. Antiferromagnetically coupled magnetic media layers for thermally stable high-density recording. Appl. Phys. Lett. 77, 3806–3808 (2000).

Chou, S. Y. et al. Single-domain magnetic pillar array of 35 nm diameter and 65 Gbits/in.2 density for ultrahigh density quantum magnetic storage. J. Appl. Phys. 76, 6673–6675 (1994).

Miyazaki, T. & Tezuka, N. Giant magnetic tunneling effect in Fe/Al2O3/Fe junction. J. Magn. Magn. Mater. 139, L231–L234 (1995).

Moodera, J. S. et al. Large Magnetoresistance at Room Temperature in Ferromagnetic Thin Film Tunnel Junctions. Phys. Rev. Lett. 74, 3273–3276 (1995).

Parkin, S. S. P. et al. Giant tunnelling magnetoresistance at room temperature with MgO (100) tunnel barriers. Nat. Mater. 3, 862–867 (2004).

Yuasa, S. et al. Giant room-temperature magnetoresistance in single-crystal Fe/MgO/Fe magnetic tunnel junctions. Nat. Mater. 3, 868–871 (2004).

Slonczewski, J. Current-driven excitation of magnetic multilayers. J. Magn. Magn. Mat. 159, L1–L7 (1996).

Krivorotov, I. V. et al. Time-Domain Measurements of Nanomagnet Dynamics Driven by Spin-Transfer Torques. Science 307, 228–231 (2005).

Weisheit, M. et al. Electric Field–Induced Modification of Magnetism in Thin-Film Ferromagnets. Science 315, 349 (2007).

Maruyama, T. et al. Large voltage-induced magnetic anisotropy change in a few atomic layers of iron. Nat. Nano. 4, 158 (2009).

Weller, D. et al. High Ku Materials Approach to 100 Gbits/in2. IEEE Trans. Magn. 36, 10–15 (2000).

Ikeda, S. et al. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 9, 721–724 (2010).

Winterlik, J. et al. Design Scheme of New Tetragonal Heusler Compounds for Spin-Transfer Torque Applications and its Experimental Realization. Adv. Mater. 24, 6283–6287 (2012).

Mizukami, S. et al. Long-Lived Ultrafast Spin Precession in Manganese Alloys Films with a Large Perpendicular Magnetic Anisotropy. Phys. Rev. Lett. 106, 117201 (2011).

Kurt, H. et al. High spin polarization in epitaxial films of ferrimagnetic Mn3Ga. Phys. Rev. B 83, 020405(R) (2011).

Puntes, V. F. et al. Collective behaviour in two-dimensional cobalt nanoparticle assemblies observed by magnetic force microscopy. Nat. Mater. 3, 263–268 (2004).

Albrecht, M. et al. Magnetic multilayers on nanospheres. Nat. Mater. 4, 203–206 (2005).

Galanakis, I. et al. Defects in CrAs and related compounds as a route to half-metallic ferrimagnetism. Phys. Rev. B 74, 140408(R) (2006).

Hellwig, O. et al. A new phase diagram for layered antiferromagnetic films. Nat. Mater. 2, 112–116 (2003).

Rößler, U. K. & Bogdanov, A. N. Synthetic metamagnetism – magnetic switching of perpendicular antiferromagnetic superlattices. J. Magn. Magn. Mater. 269, L287–L291 (2004).

LePage, J. G. & Camley, R. E. Spin-wave spectrum of a superlattice with antiferromagnetic interfacial coupling. Phys. Rev. B 8, 9113–9121 (1989).

Lauhoff, G. et al. Ferrimagnetic τ-MnAl/Co Superlattices on GaAs. Phys. Rev. Lett. 79, 5290–5293 (1997).

Qiu, R. et al. Magnon energy gap and the magnetically structural symmetry in a three-layer ferrimagnetic superlattice. phys. stat. sol. (b) 243, 1983–1995 (2006).

Velthuis, S. G. E. et al. Spin Flop Transition in a Finite Antiferromagnetic Superlattice: Evolution of the Magnetic Structure. Phys. Rev. Lett. 89, 127203 (2002).

Lauter-Pasyuk, V. et al. Transverse and Lateral Structure of the Spin-Flop Phase in Fe/Cr Antiferromagnetic Superlattices. Phys. Rev. Lett. 89, 167203 (2002).

Stanciu, C. D. et al. All-Optical Magnetic Recording with Circularly Polarized Light. Phys. Rev. Lett. 99, 047601 (2007).

Alebrand, S. et al. Light-induced magnetization reversal of high-anisotropy TbCo alloy films. Appl. Phys. Lett. 101, 162408 (2012).

Mangin, S. et al. Engineered materials for all-optical helicity-dependent magnetic switching. Nat. Mater. 13, 286–192 (2014).

Stanciu, C. D. et al. Subpicosecond Magnetization Reversal across Ferrimagnetic Compensation Points. Phys. Rev. Lett. 99, 217204 (2007).

Ostler, T. A. et al. Ultrafast heating as a sufficient stimulus for magnetization reversal in a ferrimagnet. Nat. Commun. 3, 666 (2012).

Piramanayagam, S. N. et al. Magnetic and First-Order Reversal Curve Investigations of Antiferromagnetically Coupled Nanostructures of Co/Pd Multilayers. IEEE Trans. Magn. 48, 3410–3413 (2012).

Deng, S. et al. Magnetostatic Interactions in Antiferromagnetically Coupled Patterned Media. J. Nano. Nano. 11, 2555–2559 (2011).

Galanakis, I., Dederichs, P. H. & Papanikolaou, N. Slater-Pauling behavior and origin of the half-metallicity of the full-Heusler alloys. Phys. Rev. B 66, 174429 (2002).

Coey, J. M. D. Magnetism and Magnetic Materials (Cambridge University Press, Cambridge, England, 2010).

Zhu, L. et al. Multifunctional L10-Mn1.5Ga Films with Ultrahigh Coercivity, Giant Perpendicular Magnetocrystalline Anisotropy and Large Magnetic Energy Product. Adv. Mater. 24, 4547–4551 (2012).

Li, M. et al. Strong dependence of the tetragonal Mn2.1Ga thin film crystallization temperature window on seed layer. Appl. Phys. Lett. 103, 032410 (2013).

Lu, E. et al. Reconstruction Control of Magnetic Properties during Epitaxial Growth of Ferromagnetic Mn3-δGa onWurtzite GaN(0001). Phys. Rev. Lett. 97, 146101 (2006).

Ma, Q. L. et al. Abrupt Transition from Ferromagnetic to Antiferromagnetic of Interfacial Exchange in Perpendicularly Magnetized L10-MnGa/FeCo Tuned by Fermi Level Position. Phys. Rev. Lett. 112, 157202 (2014).

Acknowledgements

This work was partially supported by the Strategic Japanese-German Cooperative Program ASPIMATT (JST), a Grant-in-Aid for Scientific Research (No. 24686001) and the Asahi Glass Foundation.

Author information

Authors and Affiliations

Contributions

Q.M. conceived the idea and designed the experiments. Q.M. fabricated and measured the samples with the help of S.M. Q.M., S.M., X.Z. and T.M. discussed the results. Q.M. anlysed the results and wroted the manuscript with the help of all authors. The study was performed under the supervision of S.M. and T.M.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Ma, Q., Zhang, X., Miyazaki, T. et al. Artificially engineered Heusler ferrimagnetic superlattice exhibiting perpendicular magnetic anisotropy. Sci Rep 5, 7863 (2015). https://doi.org/10.1038/srep07863

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep07863

This article is cited by

-

Material Study of Co2CrAl Heusler Alloy Magnetic Thin Film and Co2CrAl/n-Si Schottky Junction Device

Journal of Electronic Materials (2020)

-

Design and Synthesis of an Artificial Perpendicular Hard Ferrimagnet with High Thermal and Magnetic Field Stabilities

Scientific Reports (2017)

-

Magnetic properties of individual Co2FeGa Heusler nanoparticles studied at room temperature by a highly sensitive co-resonant cantilever sensor

Scientific Reports (2017)

-

Growth of Co2FeAl Heusler alloy thin films on Si(100) having very small Gilbert damping by Ion beam sputtering

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.