Abstract

The Euler buckling theory states that the buckling critical strain is an inverse quadratic function of the length for a thin plate in the static compression process. However, the suitability of this theory in the dynamical process is unclear, so we perform molecular dynamics simulations to examine the applicability of the Euler buckling theory for the fast compression of the single-layer MoS2. We find that the Euler buckling theory is not applicable in such dynamical process, as the buckling critical strain becomes a length-independent constant in the buckled system with many ripples. However, the Euler buckling theory can be resumed in the dynamical process after restricting the theory to an individual ripple in the buckled structure.

Similar content being viewed by others

Introduction

The buckling critical strain of a thin plate can be described by the Euler buckling theory1, i.e.,  , where D is the bending modulus and C11 is the in-plane tension stiffness. L is the length of the plate. The Euler buckling theory was developed for static compression processes. The static compression process is equivalent to molecular dynamics (MD) simulations with extremely low strain rates. Although this theory has been widely used in static mechanical processes, it is still unclear whether the Euler buckling theory is applicable in dynamical compression processes, where the strain rate has important effect on the compression/tension behavior of the system2. For instance, it is crucial to apply mechanical strain at a very low strain rate for the study of structure transitions, so that the system has enough time to relax its structure. We thus examine in present work whether the Euler buckling theory is applicable in the dynamical compression process.

, where D is the bending modulus and C11 is the in-plane tension stiffness. L is the length of the plate. The Euler buckling theory was developed for static compression processes. The static compression process is equivalent to molecular dynamics (MD) simulations with extremely low strain rates. Although this theory has been widely used in static mechanical processes, it is still unclear whether the Euler buckling theory is applicable in dynamical compression processes, where the strain rate has important effect on the compression/tension behavior of the system2. For instance, it is crucial to apply mechanical strain at a very low strain rate for the study of structure transitions, so that the system has enough time to relax its structure. We thus examine in present work whether the Euler buckling theory is applicable in the dynamical compression process.

We investigate the applicability of the Euler buckling theory using the Molybdenum Disulphide (MoS2). MoS2 has attracted considerable attention in recent years on its electronic, thermal, or mechanical properties3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19. Different two-dimensional materials (eg. graphene and MoS2) have complementary physical properties. Therefore, experimentalists have combined graphene and MoS2 in specific ways to create heterostructures that mitigate the negative properties of each individual constituent20. However, the temperature change will lead to some mechanical compression/tension on the heterostructure, because of different thermal expansion coefficient of graphene and MoS221. This thermal-induced mechanical compression will trigger the buckling of some layers in the sandwich structure, as the buckling critical strain is usually very low for layered materials. Hence, it is important to investigate the buckling phenomenon for the single-layer MoS2 (SLMoS2), which was investigated by only limited works19.

In this paper, we perform MD simulations to examine the applicability of the Euler buckling theory in the dynamical compression of SLMoS2 at different strain rates. It turns out that the Euler buckling theory is not applicable for longer SLMoS2 at higher strain rates, in which the buckling critical strain becomes length independent. However, the Euler buckling theory will become applicable after restricting it to the individual ripple in the buckled SLMoS2.

Results

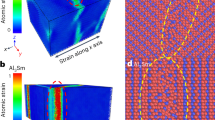

The SLMoS2 can be constructed by duplicating a rectangular unit cell of (5.40, 3.12) Å in the two-dimensional plane as shown in Fig. 1. The number of unit cell is nx and ny in the armchair and zigzag directions. The length of the SLMoS2 is 5.40 × nx and its width is 3.12 × ny. We fix ny = 10 for all simulations in present work. The free boundary condition is applied in the out-of-plane direction. We apply the fixed boundary condition in the armchair direction. The periodic boundary condition is applied in the zigzag direction. The SLMoS2 is compressed in the armchair direction. The zigzag direction is kept stress free during compression.

Fig. 2 shows the stress-strain relation for the SLMoS2 with nx = 100, which is compressed at strain rates of  , 108 s−1 and 107 s−1, respectively. A value for the thickness is required for the computation of the stress. However thickness is not a well-defined quantity in the quasi-two-dimensional layered materials such as SLMoS2. Hence, we have assumed the thickness of the SLMoS2 to be the space between two neighboring MoS2 layers in the three-dimensional bulk MoS2. That is the thickness is chosen as 6.09 Å for SLMoS2. The x-axis in Fig. 2 is the absolute value for the compression strain. The SLMoS2 buckles at the critical strain, at which the stress within the system starts to drop. The critical strain is sensitive to the strain rate and the buckling critical strain increases sharply with increasing strain rate. This phenomenon is not new and has been reported in our previous work19. It has also been observed in the compression of graphene22.

, 108 s−1 and 107 s−1, respectively. A value for the thickness is required for the computation of the stress. However thickness is not a well-defined quantity in the quasi-two-dimensional layered materials such as SLMoS2. Hence, we have assumed the thickness of the SLMoS2 to be the space between two neighboring MoS2 layers in the three-dimensional bulk MoS2. That is the thickness is chosen as 6.09 Å for SLMoS2. The x-axis in Fig. 2 is the absolute value for the compression strain. The SLMoS2 buckles at the critical strain, at which the stress within the system starts to drop. The critical strain is sensitive to the strain rate and the buckling critical strain increases sharply with increasing strain rate. This phenomenon is not new and has been reported in our previous work19. It has also been observed in the compression of graphene22.

Insets (from top to bottom) of Fig. 2 illustrate the buckling mode of the SLMoS2, which is compressed with strain rates of  , 108 s−1 and 107 s−1, respectively. An individual ripple in the buckling mode is enclosed by the rectangular. The length of the ripple decreases quickly with increasing strain rate. Normally, the buckling mode follows the shape of the first bending phonon mode in the system, in which only one ripple occurs after buckling. However, if the system is compressed very fast (i.e. with high strain rate), the buckling mode does not follow the shape of the first bending mode of the SLMoS2 and there will be more ripples in the buckling SLMoS2. In other words, higher-energy bending modes are actuated by the fast compression.

, 108 s−1 and 107 s−1, respectively. An individual ripple in the buckling mode is enclosed by the rectangular. The length of the ripple decreases quickly with increasing strain rate. Normally, the buckling mode follows the shape of the first bending phonon mode in the system, in which only one ripple occurs after buckling. However, if the system is compressed very fast (i.e. with high strain rate), the buckling mode does not follow the shape of the first bending mode of the SLMoS2 and there will be more ripples in the buckling SLMoS2. In other words, higher-energy bending modes are actuated by the fast compression.

This strain rate effect can be interpreted in terms of the relaxation time for each bending mode. The first bending mode has the longest relaxation time (or oscillation period), τ = 2π/ω, due to its lowest angular frequency ω. It means that the longest response time is needed for the appearance of the first bending mode during the compression of the SLMoS2. When the system is compressed very fast, the response time is too short for the appearance of the first bending mode. Instead, higher-energy bending modes have shorter relaxation time and are able to be actuated by buckling when the SLMoS2 is subjected to a fast compression.

Fig. 3 shows the buckling critical strain for SLMoS2 of different length. The system is compressed at three different strain rates. The simulation data are fitted to the function  . The second term

. The second term  obeys the Euler buckling theory, which says that the critical strain is an inverse quadratic function of the system length1. It means that the Euler buckling theory is valid for short systems. However, in the limit of nx → + ∞, the critical strain becomes a length-independent constant a = 0.0198, 0.0060 and 0.0015 for strain rates of 109 s−1, 108 s−1 and 107 s−1, respectively. This saturating phenomenon clearly demonstrates that the Euler buckling theory is not applicable in such dynamical process. For

obeys the Euler buckling theory, which says that the critical strain is an inverse quadratic function of the system length1. It means that the Euler buckling theory is valid for short systems. However, in the limit of nx → + ∞, the critical strain becomes a length-independent constant a = 0.0198, 0.0060 and 0.0015 for strain rates of 109 s−1, 108 s−1 and 107 s−1, respectively. This saturating phenomenon clearly demonstrates that the Euler buckling theory is not applicable in such dynamical process. For  , the critical strain is almost saturate when nx > 100. For higher strain rates, the saturation of the critical strain happens at shorter length. More specifically, the critical strain becomes a constant when nx > 50 for

, the critical strain is almost saturate when nx > 100. For higher strain rates, the saturation of the critical strain happens at shorter length. More specifically, the critical strain becomes a constant when nx > 50 for  and nx > 15 for

and nx > 15 for  . The fitting parameter a becomes closer to zero for lower strain rate, as the dynamical process is more similar as a static process when the strain rate is lower.

. The fitting parameter a becomes closer to zero for lower strain rate, as the dynamical process is more similar as a static process when the strain rate is lower.

To explore the origin for the inapplicability of the Euler buckling theory, we examine the ripples in the buckling mode. We first count the number of ripples in the buckling mode. For  , there is only one ripple in the buckled SLMoS2 with nx < 100. For

, there is only one ripple in the buckled SLMoS2 with nx < 100. For  , the buckled SLMoS2 has only one ripple if nx < 50.

, the buckled SLMoS2 has only one ripple if nx < 50.  , there is only one ripple in the buckled SLMoS2 with nx < 15 and more ripples are observed for longer systems with nx > 15. For instance, the insets of Fig. 2 show that there are many ripples in the buckled SLMoS2 with nx = 100, when this system is compressed at a strain rate of 109 s−1. These ripples are utilized to get the averaged ripple size. It should be noted that, for short systems with only one ripple in the buckling mode, the length of the SLMoS2 will be regarded as the averaged ripple size and the error is simply chosen as 10% of the length in this situation.

, there is only one ripple in the buckled SLMoS2 with nx < 15 and more ripples are observed for longer systems with nx > 15. For instance, the insets of Fig. 2 show that there are many ripples in the buckled SLMoS2 with nx = 100, when this system is compressed at a strain rate of 109 s−1. These ripples are utilized to get the averaged ripple size. It should be noted that, for short systems with only one ripple in the buckling mode, the length of the SLMoS2 will be regarded as the averaged ripple size and the error is simply chosen as 10% of the length in this situation.

Fig. 4 shows the length dependence of the averaged ripple size for SLMoS2, which is compressed at different strain rates. The inset of Fig. 4 shows the distribution of the ripple size for a buckling SLMoS2 with nx = 600, which is compressed at  . Twenty good ripple samples have been picked out from the buckled SLMoS2 for the production of this histogram plot. The averaged ripple size from the histogram figure is λ = 90.7 ± 3.3 Å. Fig. 4 shows an interesting phenomenon that the averaged ripple size is almost saturated for longer systems with larger nx, where more ripples appear. For higher strain rate, the averaged ripple size becomes saturated at smaller length. This saturation phenomenon is similar as the length dependence of the buckling critical strain shown in Fig. 3, which has demonstrated the inapplicability of the Euler buckling theory.

. Twenty good ripple samples have been picked out from the buckled SLMoS2 for the production of this histogram plot. The averaged ripple size from the histogram figure is λ = 90.7 ± 3.3 Å. Fig. 4 shows an interesting phenomenon that the averaged ripple size is almost saturated for longer systems with larger nx, where more ripples appear. For higher strain rate, the averaged ripple size becomes saturated at smaller length. This saturation phenomenon is similar as the length dependence of the buckling critical strain shown in Fig. 3, which has demonstrated the inapplicability of the Euler buckling theory.

The log-log plot for the length dependence of the average ripple size (λ) for SLMoS2 compressed by strain rates of 109 s−1, 108 s−1 and 107 s−1, respectively.

Inset shows the distribution of the ripple size for a buckling SLMoS2 with nx = 600, which is compressed at  . Twenty good ripple samples have been picked out from the buckled SLMoS2 for the production of this histogram plot. The averaged ripple size from the histogram figure is λ = 90.7 ± 3.3 Å. Lines are guide to the eye.

. Twenty good ripple samples have been picked out from the buckled SLMoS2 for the production of this histogram plot. The averaged ripple size from the histogram figure is λ = 90.7 ± 3.3 Å. Lines are guide to the eye.

To further understand the saturation phenomenon shown in Fig. 4, we compute the frequency dispersion for the bending wave using the same Stillinger-Weber potential. The obtained relation between the frequency (f) and the wave vector along the armchair direction (k) is f = 8.6 × 1012k2 s−1. The bending wave is a exural mode for the quasi-two-dimensional SLMoS2 system, so its frequency is a quadratic function of the wave vector k. The wave vector is an inverse proportional function of the length, i.e., k ∝ L−1, with L = nx × 5.40 Å as the length in the armchair direction. As a result, we have f = 8.6 × 1012L−2 s−1.

We take the strain rate  as an example. For this strain rate, there are two major findings in Fig. 4. First, the lowest-frequency bending motion is excited for short system with nx = 10; while this lowest-frequency bending motion is not excited for long system with nx = 100. This can be explained by the interplay between the strain rate and the bending frequency. A compression can only excite the bending motion with frequency higher than the strain rate for this compression. For nx = 10, the frequency of the bending wave is around f ≈ 2.9 × 109 s−1 according to the above formula. This frequency is larger than the strain rate. It means that a strain rate of

as an example. For this strain rate, there are two major findings in Fig. 4. First, the lowest-frequency bending motion is excited for short system with nx = 10; while this lowest-frequency bending motion is not excited for long system with nx = 100. This can be explained by the interplay between the strain rate and the bending frequency. A compression can only excite the bending motion with frequency higher than the strain rate for this compression. For nx = 10, the frequency of the bending wave is around f ≈ 2.9 × 109 s−1 according to the above formula. This frequency is larger than the strain rate. It means that a strain rate of  is slow enough to excite the lowest-frequency bending motion in this system. However, for nx = 100, the frequency of the bending wave is around f ≈ 2.9 × 107 s−1, which is about two orders smaller than the strain rate. As a result, a strain rate of

is slow enough to excite the lowest-frequency bending motion in this system. However, for nx = 100, the frequency of the bending wave is around f ≈ 2.9 × 107 s−1, which is about two orders smaller than the strain rate. As a result, a strain rate of  is too fast to allow the the appearance of the lowest-frequency bending motion. Second, it can be seen in Fig. 4 that the saturated value for the ripple size is about λ = 50 Å. The frequency for the bending wave according to this length is about f ≈ 3.4 × 109 s−1, which is on the same order as the strain rate. As a result, the saturated ripple size can be excited by a strain rate of

is too fast to allow the the appearance of the lowest-frequency bending motion. Second, it can be seen in Fig. 4 that the saturated value for the ripple size is about λ = 50 Å. The frequency for the bending wave according to this length is about f ≈ 3.4 × 109 s−1, which is on the same order as the strain rate. As a result, the saturated ripple size can be excited by a strain rate of  .

.

Inspired by the saturation phenomena in both Figs. 3 and 4, we find that the Euler buckling theory is closely related to the number of ripples in the buckling mode. It is valid only if one ripple is actuated in the buckling mode. However, the Euler buckling theory becomes invalid when more ripples appear. The Euler buckling theory says1,

where L is the length of the system. We have used the Stillinger-Weber potential to extract the bending modulus17 D = 9.61 eV and the in-plane tension stiffness16 C11 = 139.5 Nm−1 for the SLMoS2. We note an important fact that only one ripple is assumed in the buckling mode during the derivation of Eq. (1). However, Fig. 4 discussed the suitability of the Euler buckling theory with L as the total length of the system. It seems that a more proper way is to treat L in Eq. (1) as the size of an individual ripple in the buckling mode with many ripples. We thus show the relation between the buckling critical strain and the averaged ripple size in Fig. 5. The prediction of the Euler buckling theory is also plotted in the figure (black solid line) for comparison. We find that all simulation data (calculated with different strain rates) are closely distributed around the line for the Euler buckling theory. In other words, the Euler buckling theory is applicable and is independent of the strain rate, after we treat L in Eq. (1) as the averaged ripple size. The merit of using lower strain rate (107 s−1) is to extend the examination of the Euler buckling theory to larger ripple size.

The log-log plot for the buckling critical strain versus the averaged buckling ripple size for SLMoS2 compressed by strain rates of 109 s−1 s−1, 108 s−1 s−1 and 107 s−1, respectively.

The solid line is the prediction of the Euler buckling theory. All simulation data are close to the solid line, which validates the Euler buckling theory after using the averaged ripple size.

Discussions

We have performed MD simulations to investigate whether the Euler buckling theory is applicable for dynamical processes, in which the SLMoS2 is compressed at high strain rates. We found that the theory is not applicable in the presence of many ripples in the buckling mode, where the buckling critical strain becomes a length-independent constant. However, we have also showed that the Euler buckling theory becomes applicable if this theory is applied to a single ripple in the buckled SLMoS2.

Methods

MD simulation details

All MD simulations in this work are performed using the publicly available simulation code LAMMPS23, while the OVITO package was used for visualization24. The standard Newton equations of motion are integrated in time using the velocity Verlet algorithm with a time step of 1 fs. The interaction within MoS2 is described by the Stillinger-Weber potential16. All simulations are performed at 1.0 K low temperature, so that our MD simulations are more comparable with the Euler buckling theory, which does not consider the temperature effect. The SLMoS2 is thermalized using the Nosé-Hoover25,26 thermostat for 100 ps within the NPT (i.e. the number of particles N, the pressure P and the temperature T of the system are constant) ensemble. After thermalization, the SLMoS2 is compressed along the armchair direction, while the system is allowed to be fully optimized in the zigzag direction. The NPT ensemble is also applied in the compression step.

References

Timoshenko, S. & Woinowsky-Krieger, S. Theory of Plates and Shells, 2nd ed (McGraw-Hill, New York, 1987).

Jiang, J.-W., Leach, A. M., Gall, K., Park, H. S. & Rabczuk, T. A surface stacking fault energy approach to predicting defect nucleation in surface-dominated nanostructures. J. Mech. Phys. Solids 61, 1915–1934 (2013).

Kam, K. K. & Parkinson, B. A. Detailed photocurrent spectroscopy of the semiconducting group vi transition metal dichalcogenides. J. Phys. Chem. 86, 463–467 (1982).

Wang, Q. H., Kalantar-Zadeh, K., Kis, A., Coleman, J. N. & Strano, M. S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 7, 699–712 (2012).

Chhowalla, M. et al. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 5, 263–275 (2013).

Castellanos-Gomez, A. et al. Elastic properties of freely suspended mos2 nano sheets. Adv. Mater. 24, 772–775 (2012).

Castellanos-Gomez, A. et al. Mechanical properties of freely suspended semiconducting graphene-like layers based on mos2. Nanoscale Res. Lett. 7, 1–7 (2012).

Huang, W., Da, H. & Liang, G. Thermoelectric performance of mx2 (m = mo, w; x = s, se) monolayers. J. Appl. Phys. 113, 104304 (2013).

Bertolazzi, S., Brivio, J. & Kis, A. Stretching and breaking of ultrathin mos2 . ACS Nano 5, 9703–9709 (2011).

Cooper, R. C. et al. Nonlinear elastic behavior of two-dimensional molybdenum disulfide. Phys. Rev. B 87, 035423 (2013).

Cooper, R. C. et al. Erratum: Nonlinear elastic behavior of two-dimensional molybdenum disulfide (physical review b - condensed matter and materials physics(2013) 87 (035423)). Phys. Rev. B 87, 079901 (2013).

Varshney, V. et al. Md simulations of molybdenum disulphide (mos2): Force-field parameterization and thermal transport behavior. Comp. Mater. Sci. 48, 101–108 (2010).

Liu, X., Zhang, G., Pei, Q.-X. & Zhang, Y.-W. Phonon thermal conductivity of monolayer mos2 sheet and nanoribbons. Appl. Phys. Lett. 103, 133113 (2013).

Castellanos-Gomez, A. et al. Local strain engineering in atomically thin mos2 . Nano Lett. 13, 5361–5366 (2013).

Jiang, J.-W., Zhuang, X.-Y. & Rabczuk, T. Orientation dependent thermal conductance in single-layer mos2 . Sci. Rep. 3, 2209 (2013).

Jiang, J.-W., Park, H. S. & Rabczuk, T. Molecular dynamics simulations of single-layer molyb-denum disulphide (mos2): Stillinger-weber parametrization, mechanical properties and thermal conductivity. J. Appl. Phys. 114, 064307 (2013).

Jiang, J.-W., Qi, Z., Park, H. S. & Rabczuk, T. Elastic bending modulus of single-layer molybdenum disulphide (mos2): Finite thickness effect. Nanotechnology 24, 435705 (2013).

Jiang, J.-W., Park, H. S. & Rabczuk, T. Mos2 nanoresonators: Intrinsically better than graphene? Nanoscale 6, 3618 (2013).

Jiang, J.-W. The buckling of single-layer mos2 under uniaxial compression. Nanotechnology 25, 355402 (2014).

Britnell, L. et al. Strong light-matter interactions in heterostructures of atomically thin films. Science 340, 1311–1314 (2013).

Bao, W. et al. Controlled ripple texturing of suspended graphene and ultrathin graphite membranes. Nat. Nanotechnol. 4, 562–566 (2009).

Neek-Amal, M. & Peeters, F. M. Graphene nanoribbons subjected to axial stress. Phys. Rev. B 82, 085432 (2010).

Plimpton, S. J. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Stukowski, A. Visualization and analysis of atomistic simulation data with ovito - the open visualization tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010).

Nose, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 81, 511 (1984).

Hoover, W. G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 31, 1695 (1985).

Acknowledgements

The author thanks T.-Z. Zhang and X.-M. Guo at Shanghai Institute of Applied Mathematics and Mechanics for insightful discussions. The work is supported by the Recruitment Program of Global Youth Experts of China and the start-up funding from Shanghai University.

Author information

Authors and Affiliations

Contributions

J.W.J. designed the project, performed the calculations and wrote the paper.

Ethics declarations

Competing interests

The author declares no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/4.0/

About this article

Cite this article

Jiang, JW. The Strain Rate Effect on the Buckling of Single-Layer MoS2. Sci Rep 5, 7814 (2015). https://doi.org/10.1038/srep07814

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep07814

This article is cited by

-

Origins of Ripples in CVD-Grown Few-layered MoS2 Structures under Applied Strain at Atomic Scales

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

, which becomes a length-independent constant a in the limit of nx → + ∞.

, which becomes a length-independent constant a in the limit of nx → + ∞.