Abstract

Polymer brushes and hydrogels are sensitive to the environment, which can cause uncontrolled variations on their performance. Herein, for the first time, we report a non-swelling “PEG molecular net-cloth” on a solid surface, fabricated using a novel “visible light induced surface controlled graft cross-linking polymerization” (VSCGCP) technique. Via this method, we show that 1) the 3D-network structure of the net-cloth can be precisely modulated and its thickness controlled; 2) the PEG net-cloth has excellent resistance to non-specific protein adsorption and cell adhesion; 3) the mild polymerization conditions (i.e. visible light and room temperature) provided an ideal tool for in situ encapsulation of delicate biomolecules such as enzymes; 4) the successive grafting of reactive three-dimensional patterns on the PEG net-cloth enables the creation of protein microarrays with high signal to noise ratio. Importantly, this strategy is applicable to any C-H containing surface and can be easily tailored for a broad range of applications.

Similar content being viewed by others

Introduction

Tethering polymer brushes onto a substrate is an effective approach to tailor surface properties such as reactivity to biologically active molecules and adhesion1,2,3,4. In the past decade, the fabrication of grafted, cross-linked and hydrogel-like films has become increasingly popular due to its advantages such as more stable interface with substrates5,6, more uniform coverage, higher storage capacity to accommodate nanoparticles, enzymes, cells, drug molecules, etc7,8,9.

However, the surface properties and storage capacity of current surface attached hydrogel films are usually highly environmentally sensitive. Indeed, changes in a number of environmental parameters, such as solvent, temperature, pH, ionic strength or the presence of biomolecules, will induce considerable variations in the mesh-size of the polymer networks, thus affecting their encapsulating ability and surface properties. In addition, swelling-induced surface instabilities such as creases in the hydrogel layer can cause its delamination from the substrate10,11. In general, fabricating a network with hydrophobic macromolecules is a facile solution to prevent this swelling in water. However, the resulting hydrophobic network is not a friendly host for delicate biomolecules. Therefore, there is great demand for a non-swelling hydrophilic “molecular net-cloth” grafted on a substrate. To realize this aim, there are a number of chemistry issues that must be faced: 1) how to achieve perfect covalent attachment to the substrate, 2) how to form uniform and mesh size adjustable network, 3) and how to achieve the controllable thickness of the net-cloth.

Currently reported methods for fabricating cross-linked networks on various substrates mostly utilize conventional free radical polymerization which is characterized by two limitations due to their uncontrollable polymerization mechanism: one is the production of heterogeneous network structures, the second is defective polymer layers or layers with arbitrary thickness12,13,14,15,16. Controlled/living radical polymerization (CLRP) techniques have been demonstrated to be advantageous in developing homogeneous polymer networks with controlled microstructure17,18,19. However, since the CLRP methods generally require tedious pretreatment process prior to the immobilization of initiators on surface, it is difficult to directly apply them to inert polymeric substrates. What is worse, considering the restraints of bio-applications, i.e., the susceptibility of biomolecules to harsh environments, most of these systems have inherent adverse elements such as the copper used in atom transfer radical polymerization (ATRP)20, high temperatures in nitroxide-mediated polymerization (NMP)21 and UV irradiation in photoiniferter-controlled polymerization22. Therefore, the goal of developing a polymerization strategy capable of producing the desired molecular network but also compatible with biomolecules represents a great challenge.

Herein, with poly(ethylene glycol) diacrylate (PEGDA) as bifunctional monomer and LDPE as model of substrates at room temperature, we provide an ideal solution to fabricate a dense “PEG molecular net-cloth” on polymeric substrates without swelling. This is achieved using a novel bottom-up strategy of visible light induced surface controlled graft cross-linking polymerization (VSCGCP).Our work demonstrates that: 1) this molecular net-cloth is characterized by a uniform mesh size, non-swelling and even/controllable thickness and could be fabricated onto any substrate containing C-H groups; 2) this strategy is suitable for in situ encapsulation of active biomolecules like enzymes within the molecular net-cloth and 3) it displays excellent surface anti-fouling properties and retains dormant groups on its surface, making it facile to fabricate protein chips or microarrays with high immobilization density on this anti-fouling background. In particular, the simplicity of implementing this reaction makes its use in industry highly feasible.

Results

Synthesis and formation mechanism of PEG-based molecular net-cloth

The reaction mechanism and procedures are shown in (Supplementary Fig. S1). The pre-treatment step uses UV light to seed isopropyl thioxanthone (ITX) dormant groups onto the surface of a substrate (in this case, low-density polyethylene (LDPE) film was used as a model). Under UV irradiation, the excited ITX abstracted surface H atoms from the LDPE film to form ITX semipinacol (ITXSP) radicals and surface radicals, which sequentially coupled with each other, leading to a ITXSP terminated LDPE film (denoted as LDPE-ITXSP)23,24. Following this, with the LDPE-ITXSP film as a substrate and a sandwich-like reaction setup, we conducted surface graft polymerization of PEGDA 575 (i.e. PEGDA with molecular weight of 575 Da) under visible light (380–700 nm). Figure 1a and 1b show the kinetic character of the grafted system where the graft density Dg increased with irradiation time and was significantly influenced by irradiation intensity and PEGDA 575 concentration, which demonstrated that the values of Dg could precisely controlled by these parameters. Then, with scanning electron microscopy (SEM), we measured the cross section and surface of PEGDA grafted film and very surprisingly found that the grafted layer not only had an unusual uniform thickness (Fig. 1c) and a smooth top surface (Supplementary Fig. S5) but also had a dense inner-structure (Fig. 1d). By quantification of the average thickness of the grafted PEGDA layer, it was found that the PEGDA layer increased linearly with irradiation time (Fig.1e). An average growth rate of 33.2 nm/min was derived by linear regression from the range of the PEGDA thickness from 450 nm to 3.25 μm. This revealed the controlled grafting nature of the VSCGCP strategy. The growth rate for PEGDA is higher than that of GMA (12.6 nm/min) reported previously23. This may be attributed to the formation of a denser network structure with PEGDA rather than with GMA. Such a dense network could restrict diffusion of ITXSP. Thus radical deactivation within the local environment was significantly impeded, resulting in a higher radical concentration and subsequently a faster polymerization rate.

Synthesis of PEG molecular net-cloth covalently attached on LDPE with controllable thickness and its cross-sectional morphology.

(a) Effect of light intensity on the Dg of graft polymerization, reaction conditions: 20 wt% PEGDA 575 aqueous solution. (b) Effect of monomer concentration on the Dg of graft polymerization, reaction conditions: light intensity = 3900 μW/cm2 (λ = 420 nm). (c) SEM image of cross-section of PEG network grafted on LDPE (irradiation time = 90 min). (d) Typical SEM image of cross-section of PEG network grafted on LDPE at different irradiation times. (e) Relationship between thickness of PEG network layer and irradiation time ((20 wt% PEGDA, light intensity = 2900 μW/cm2 (λ = 420 nm)). All values were averaged of 3 repeats and error bars correspond to the standard deviation.

To investigate the stability and swelling properties of the PEGDA grafted layers, we fabricated arrays of PEGDA 575 micro-columns on LDPE film with a photomask. We put the patterned films in phosphate-buffered saline (PBS, pH 7.4) at 37°C for 4 weeks and found no detachment, indicating a stable interface between the PEGDA arrays and the base LDPE film. In contrast, micropatterns of PEGDA gel on glass as reported in the literature were delaminated from the surface upon hydration for 3 days25,26. The swelling properties of the PEGDA 575 micro-columns were investigated by measuring height and width changes before and after swelling. It was unexpectedly found that neither height nor diameter of the PEGDA 575 micro-columns showed detectable changes after immersion in deionized water for 24 hours (Supplementary Fig. S6). This is rather different from the swelling properties of the PEGDA 575 hydrogel reported previously, where more than 16% swelling was observed11,27. However, when higher molecular weight PEGDA, such as PEGDA 1000 and PEGDA 4000 were used, a detectable swelling was observed. For PEGDA 1000 and PEGDA 4000 arrays, the increases of micro-column height were 1.6 ± 0.4% and 7.1 ± 1.0% respectively. It is clear that the degree of swelling depends on the chain length of the PEGDA oligomer and consequently the mesh size of the cross-linked PEGDA network. Considering the results above, it can be concluded that with PEGDA 575 as bifunctional monomer and using the VSCGCP strategy, we have, for the first time fabricated a kind of grafted PEG network layer featuring dense/even controllable thickness, flat surface and non-swelling property onto surface of routine polymeric substrates. In order to differentiate it from the previous reported hydrogel films, we use the name “PEG molecular net-cloth” to designate this special 3D structure.

Formation of the PEG molecular net-cloth could be ascribed to a two-phase polymerization system consisting of a solid ITXSP-LDPE and an aqueous PEGDA solution, with the polymerization taking place at the interface of the two phases, as shown in Fig. 2a. Under visible light, ITXSP dormant groups on the LDPE film were photolyzed to produce surface carbon radicals and ITXSP radicals. Surface carbon radicals immediately initiate polymerization and cross-linking of PEGDA, forming a layer of PEG network grafted on the surface. However, the ITXSP radicals, due to very low initiating ability, would only couple to the chain radicals of the PEG network and terminate the polymerization. Consequently, a “controlled surface graft polymerization” featuring a reversible deactivation/activation equilibrium with ITXSP as dormant groups was formed (Fig. 2b). In the meantime, PEGDA monomers in solution gradually diffused and were deposited onto the surface and consequently were incorporated into the PEG network. This ensured continuous, even growth of the PEG network layer from the bottom up.

Many UV radiation systems reported previously showed fast layer growth rates in the range of tens to hundreds of micrometers within one minute28,29. In contrast, the growth rate of the PEG network layer in the present system is very low (i.e. 33.2 nm/min, Fig. 1e). Clearly, this low growth rate came from the controlled polymerization of the system defined by a reversible deactivation/activation equilibrium (Fig. 2b). Undoubtedly, this slow polymerization rate provides sufficient time for diffusion and incorporation of the PEGDA monomer onto the surface of the PEG networks30, which are highly relevant in achieving the even mesh size, even thickness and flat surface of the film. Therefore, it is believed that the non-swelling property of the PEGDA 575 network was partially due to the smaller mesh size defined by the short chain length of PEGDA 575 and partially due to the restriction of chemical binding of the network on the surface31.

Should the reaction follow the above mechanism, no double bonds or pendent free chains would exist during the VSCGCP process. To investigate this, we tracked the attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectra of the PEG network layer during its growth process. As shown in Fig. 2c, the characteristic peak of ester groups at 1729 cm−1 was observed, indicating the presence of PEG network layer on LDPE. We compared the ratios of integral peak area of C = O stretches at 1729 cm−1 over that of methylene deformation at 1460 cm−1 at different irradiation times. The ratios were 1.25, 1.86, 2.25 and 2.72 for 10, 20, 50, 70 minutes irradiation respectively. The results were in good agreement with the progress of the polymerization process. However, no characteristic peak for C = C groups, typically at 1636 cm−1, was observed during the whole polymerization process, suggesting no acrylic groups left in the grafted layer and thus providing convincing evidence to the above-mentioned mechanism32,33.

All the formed PEG molecular net-cloths are hydrophilic, having a similar water contact angle of 50° regardless of their irradiation time and consequently their thickness (Supplementary Fig. S7a). This again indicates a uniform coverage of the PEGDA layer on LDPE films. The anti-fouling property of the PEG molecular net-cloth was evaluated by the adsorption of a model protein, fluorescein isothiocynate labeled bovine serum albumin (FITC-BSA). As shown in Supplementary Fig. S7b, the unmodified LDPE region showed strong fluorescence (due to the absorbed FITC-BSA) whereas the PEG molecular net-cloth strips remain dark, indicating an excellent resistance to protein absorption on the PEG molecular net-cloth. Similarly, no cells adhered to the PEG molecular net-cloth patterns after 24 h in culture (Supplementary Fig.S7c), demonstrating its excellent resistance to cell adhesion.

Entrapment of enzyme in PEG molecular net-cloth

The unique formation of a dense, non-swelling PEG molecular net cloth under bio-friendly conditions offers an ideal “3D net” to accommodate delicate biomolecules, such as enzymes or antibodies34. However, to realize this, it is necessary to evaluate whether VSCGCP can smoothly proceed in the presence of these biomacromolecules and if they can be effectively encapsulated by the 3D PEG molecular net-cloth in situ. As a proof-of-concept, we evaluated this with a dual enzyme system of horseradish peroxidase (HRP) and glucose oxidase (GOD), which have been well established for the detection of glucose concentration (Fig. 3a and b). In a typical reaction, one molecule of glucose is oxidized to gluconic acid by oxygen in the presence of GOD and produces one molecule of H2O2, which react quantitatively with 4-aminoantipyrine and phenol to form red products in the catalysis of HRP. The absorption intensity of the red colored product at 505 nm is directly proportional to the glucose concentration in the sample and can be easily detected by a UV-vis spectrometer. The PEGDA 575 monomer solutions containing enzymes were used in the same VSCGCP procedure on a LDPE film, resulting in a PEG molecular net-cloth with trapped enzymes throughout the film (denoted as LDPE-ENZYME). By a dye-complexation method, we found that more than 58% of the enzymes were immobilized, which corresponded to an immobilization density of 8.2 ± 2.1 μg/cm2, indicating the VSCGCP occurred successfully and was able to entrap enzymes in situ.

In situ Entrapment of enzyme under visible light and its application in glucose detection.

(a) Scheme for preparation of enzyme entrapped composite films under visible light. (b) Scheme of the glucose detection reaction catalyzed by GOD and HRP. (c)The absorbance change at 505 nm after immersing LDPE-ENZYME film into glucose solution (Cglucose = 5 mmol/L). The first, second and third data in the figure represents the reuse number of same film. The data labelled UV represents a film with enzymes was entrapped in gel layer under UV irradiation for 3 minutes at intensity of 9000 μW/cm2 (λ = 254 nm). (d) Relationship of absorbance with glucose concentration after immersing an LDPE-ENZYME film into glucose solution for 10 minutes. All values were averaged of 3 repeats and error bars correspond to the standard deviation.

Next, we evaluated the activities of the entrapped enzymes and stability of the trapping. We immersed a LDPE-ENZYME film in a 5 mmol/L glucose solution and monitored its absorbance at 505 nm. As shown in Fig. 3c, a typical linear relationship between absorbance and time was observed, showing the activity of the entrapped enzymes. In a control experiment, HRP and GOD were entrapped under UV irradiation and completely lost their enzymic activity after 3 min exposure to UV light (Fig. 3c). Importantly, the plots from three repeated experiments on the same LDPE-ENZYME film (with washing in between) match each other (Fig. 3c). This shows an excellent retention of enzymes within the PEG molecular net-cloth, allowing reliable comparison of multiple measurements with the same film. As shown in Fig. 3d, a linear increase of absorbance with glucose concentration was obtained, showing the detection limit of 2 mmol/L for the film with the immobilization density of 8.2 ± 2.1 μg/cm2. It is anticipated that the detection limit could be greatly improved by further increasing the enzyme trapping density.

High density protein immobilization on anti-fouling background

In the development of high performance biochips, improving immobilization density of probe biomolecules and eliminating nonspecific adsorption are both critical35. Our VSCGCP strategy offers a most practical solution to these issues, as shown in Fig. 4a. Firstly, the layer of PEG molecular net-cloth provided an excellent anti-fouling background. Secondly, with a photomask, the PEG layer allows further grafting polymerization of monomers with reactive groups on top and at defined regions. The feature of controlled polymerization enables precise control of the thickness and mesh size of the second functional layer, so that small biomolecules (e.g proteins or DNA) can enter its whole network and be immobilized by chemical conjugating. Consequently, this can enable substantially higher immobilization density than can be commonly achieved.

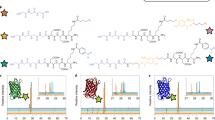

High-density immobilization of protein in 3D microarray with anti-fouling background prepared by VSCGCP.

(a) Scheme for preparing a reactive 3D microarray with anti-fouling background. (b) Fluorescence intensities of spots containing immobilized Rhodamine conjugated rabbit anti-goat IgG (Rh-IgG) as a function of the spot height. (c, d) Fluorescence image of the microarray with and without PEG molecular net-cloth. To prepare a protein conjugated microarray, the patterned film was immersed into a Rh-IgG solution with a concentration of 0.5 mg/mL for 2 hours at 30°C.

To evaluate this, we chose glycidyl methacrylate (GMA) as a co-monomer with PEGDA to conduct a secondary controlled grafting polymerization and obtained 40 μm micro-columns with their height varying from 187 nm to 1273 nm. In order to identify mesh sizes of the column-network that enable diffusion of proteins into the column and maintain column shape, we optimized grafting recipes and found that the 2:1 (weight ratio) of GMA to PEGDA was best. Rhodamine labeled rabbit anti-goat immunoglobulin G (Rh-IgG) was conjugated to the epoxy groups of the micro-columns. It was found that the fluorescence intensity of micro-columns increase with their height, suggesting the thicker the film of micro-columns, the more immobilized proteins (Fig. 4b). The background fluorescence signals are negligible for those with the PEG underlayer (Fig. 4c) but significantly higher for those without (Fig. 4d). These results make us believe that this 3D-microarray construction with antifouling background could markedly elevate array density and sensitivity of biochips. In addition, considering the excellent anti-absorption property of the PEG molecular net-cloth to enzymes and cell, it is feasible to prepare enzyme or cell microarrays using an approach similar to the in situ encapsulation protocol.

Discussion

As a three dimensional network, hydrogels can provide more capacity to accommodate biomolecules than linear polymer chains. Moreover, hydrogels can provide a quasi-liquid environment which is favorable for activity retention of native proteins. Therefore, surface attached hydrogel layers are more suited to immobilize biomolecules than polymer brushes. Using the VSCGCP technique, we successfully prepared a well-defined cross-linked layer grafted onto a LDPE surface. By adjusting the PEG chain length between crosslink points, it is facile to obtain either a non-swelling molecular net-cloth graft layer or a swellable hydrogel graft layer. The precise modulation of swelling behavior of the hydrogel was believed to be attributed to the slow growth of individual chains in the controlled graft cross-linking polymerization, which guaranteed enough time for chain relaxation and diffusion, leading to a homogeneous network.

The non-swelling property of the hydrogel layer is greatly desirable when it is used to encapsulate proteins, avoiding rapid release of the physically loaded biomolecules upon hydration. More importantly, reaction conditions of for VSCGCP are very mild and so are suitable for in situ encapsulation of delicate biomolecules. On the other hand, the biological inertness of the PEG-based net-cloth and its reactivation capability are favorable for it to serve as an anti-fouling substrate with stable bulk properties. After further decoration of the net-cloth layer and combing it with generally used protein immobilization technology, a three-dimensional protein microarray was fabricated. This creative design eliminates non-specific absorption of background and enhances protein immobilization density at the same time, offering a new way to fabricate high performance protein chips.

Conclusion

In summary, here we present the first report of a visible light induced surface controlled graft cross-linking polymerization. This strategy not only provide a new chemistry for preparing well-defined surfaces and interfaces, but also provides an ideal solution for immobilization of biomolecules that are easily damaged when exposed to UV light. Due to the universal applicability of this reaction to any surface containing C-H groups, this protocol could be readily adapted to other plastics or inorganic substrates without requiring complex pretreatment procedures.

Methods

ITXSP was firstly immobilized on LDPE surfaces by abstracting hydrogen-coupling reaction under UV irradiation and denoted as LDPE-ITXSP. For conducting a VSCGCP, PEGDA aqueous solution was coated on the LDPE-ITXSP with a quartz plate cover to form a sandwich structure. This setup was then irradiated using visible light (wavelengths of 380–700 nm) for a predetermined time. The surface morphology and thickness of the cross-linked layer were analyzed by SEM. Surface chemical compositions and physical properties were analyzed by XPS, ATR-FTIR and contact angle. To produce a patterned surface, a chrome photomask was placed on top of the surface of the sandwich structure, controlling the irradiated area. The height of the microarray was characterized by atomic force microscopy. For in situ enzyme encapsulation, enzymes were added into the monomer solution in a process similar to that of PEGDA graft polymerization. The effectiveness of entrapped enzymes in the detection of glucose was tested by spectrometry. A 3D pattern with anti-fouling background was fabricated by two step graft polymerization each similar to VSCGCP of PEGDA. That is, PEGDA was firstly grafted on LDPE as anti-fouling background and then co-monomer of PEGDA and GMA were grafted on first layer to form a reactive 3D layer. Through routine reaction of epoxy and protein, fluorescence-labeled IgG was conjugated on the surface and its quantity was analyzed by fluorescence microscopy.

References

Azzaroni, O., Brown, A. A. & Huck, W. T. S. Tunable wettability by clicking counterions into polyelectrolyte brushes. Adv. Mater. 19, 151–154 (2007).

Nie, Z. & Kumacheva, E. Patterning surfaces with functional polymers. Nature Mater. 7, 277–290 (2008).

Klein, J., Kumacheva, E., Mahalu, D., Perahia, D. & Fetters, L. J. Reduction of frictional forces between solid surfaces bearing polymer brushes. Nature 370, 634–636 (1994).

Barbey, R. et al. Polymer Brushes via Surface-initiated controlled radical polymerization: synthesis, characterization, properties and applications. Chem. Rev. 109, 5437–5527 (2009).

Kuroki, H., Tokarev, I., Nykypanchuk, D., Zhulina, E. & Minko, S. Stimuli-responsive materials with self-healing antifouling surface via 3D polymer grafting. Adv. Funct. Mater. 23, 4593–4600 (2013).

Li, A. et al. Surface-grafted, covalently cross-linked hydrogel brushes with tunable interfacial and bulk properties. Macromolecules 44, 5344–5351 (2011).

Bai, S., Nguyen, T. L., Mulvaney, P. & Wang, D. Using hydrogels to accommodate hydrophobic nanoparticles in aqueous media via solvent exchange. Adv. Mater. 22, 3247–3250 (2010).

Kiyonaka, S. et al. Semi-wet peptide/protein array using supramolecular hydrogel. Nature Mater. 3, 58–64 (2003).

Cushing, M. C. & Anseth, K. S. Hydrogel cell cultures. Science 316, 1133–1134 (2007).

Kim, J., Yoon, J. & Hayward, R. C. Dynamic display of biomolecular patterns through an elastic creasing instability of stimuli-responsive hydrogels. Nature Mater. 9, 159–164 (2009).

Revzin, A. et al. Fabrication of poly (ethylene glycol) hydrogel microstructures using photolithography. Langmuir 17, 5440–5447 (2001).

Junk, M. J. N., Berger, R. D. & Jonas, U. Atomic force spectroscopy of thermoresponsive photo-cross-linked hydrogel films. Langmuir 26, 7262–7269 (2010).

Kizilel, S., Pérez-Luna, V. H. & Teymour, F. Photopolymerization of poly (ethylene glycol) diacrylate on eosin-functionalized surfaces. Langmuir 20, 8652–8658 (2004).

Kızılel, S., Sawardecker, E., Teymour, F. & Pérez-Luna, V. H. Sequential formation of covalently bonded hydrogel multilayers through surface initiated photopolymerization. Biomaterials 27, 1209–1215 (2006).

Wang, L., Yu, Y., Liu, L. & Yang, W. Surface photografting polymerization of trimethylolpropane triacrylate onto LDPE substrate in tetrahydrofuran/water mixtures. J. Appl. Polym. Sci. 106, 621–629 (2007).

Avens, H. J., Randle, T. J. & Bowman, C. N. Polymerization behavior and polymer properties of eosin-mediated surface modification reactions. Polymer 49, 4762–4768 (2008).

Wang, R., Luo, Y., Li, B.-G. & Zhu, S. Modeling of branching and gelation in RAFT copolymerization of vinyl/divinyl systems. Macromolecules 42, 85–94 (2008).

Gao, H., Li, W. & Matyjaszewski, K. Synthesis of polyacrylate networks by ATRP: parameters influencing experimental gel points. Macromolecules 41, 2335–2340 (2008).

Ide, N. & Fukuda, T. Nitroxide-controlled free-radical copolymerization of vinyl and divinyl monomers. 2. Gelation. Macromolecules 32, 95–99 (1999).

Sigg, S. J. et al. Horseradish peroxidase as a catalyst for atom transfer radical polymerization. Macromol. Rapid Commun. 32, 1710–1715 (2011).

Nicolas, J. et al. Nitroxide-mediated polymerization. Prog. Polym. Sci. 38, 63–235 (2013).

Krause, J. E. et al. Photoiniferter-mediated polymerization of zwitterionic carboxybetaine monomers for low-fouling and functionalizable surface coatings. Macromolecules 44, 9213–9220 (2011).

Bai, H. D., Huang, Z. H. & Yang, W. T. Visible light-induced living surface grafting polymerization for the potential biological applications. J. Polym. Sci., Part A: Polym. Chem. 47, 6852–6862 (2009).

Li, C. Y. et al. Creating “living” polymer surfaces to pattern biomolecules and cells on common plastics. Biomacromolecules 14, 1278–1286 (2013).

Moeller, H.-C., Mian, M. K., Shrivastava, S., Chung, B. G. & Khademhosseini, A. A microwell array system for stem cell culture. Biomaterials 29, 752–763 (2008).

Lee, H. J., Kim, D. N., Park, S., Lee, Y. & Koh, W.-G. Micropatterning of a nanoporous alumina membrane with poly (ethylene glycol) hydrogel to create cellular micropatterns on nanotopographic substrates. Acta Biomater. 7, 1281–1289 (2011).

Russell, R. J., Axel, A. C., Shields, K. L. & Pishko, M. V. Mass transfer in rapidly photopolymerized poly (ethylene glycol) hydrogels used for chemical sensing. Polymer 42, 4893–4901 (2001).

Kızılel, S., Pérez-Luna, V. H. & Teymour, F. Mathematical Model for Surface-Initiated Photopolymerization of Poly (ethylene glycol) Diacrylate. Macromol. Theory Simul. 15, 686–700 (2006).

Luo, N., Metters, A. T., Hutchison, J. B., Bowman, C. N. & Anseth, K. S. A methacrylated photoiniferter as a chemical basis for microlithography: micropatterning based on photografting polymerization. Macromolecules 36, 6739–6745 (2003).

Gao, H., Li, W. & Matyjaszewski, K. Synthesis of polyacrylate networks by ATRP: Parameters influencing experimental gel points. Macromolecules 41, 2335–2340 (2008).

Tokarev, I. & Minko, S. Stimuli-responsive hydrogel thin films. Soft Matter 5, 511–524 (2009).

Suh, K. Y., Seong, J., Khademhosseini, A., Laibinis, P. E. & Langer, R. A simple soft lithographic route to fabrication of poly(ethylene glycol) microstructures for protein and cell patterning. Biomaterials 25, 557–563 (2004).

Huang, W., Baker, G. L. & Bruening, M. L. Controlled synthesis of cross-linked ultrathin polymer films by using surface-initiated atom transfer radical polymerization. Angew. Chem. Int. Ed. 40, 1510–1512 (2001).

Hanefeld, U., Gardossi, L. & Magner, E. Understanding enzyme immobilisation. Chem. Soc. Rev. 38, 453–468 (2009).

Angenendt, P. Progress in protein and antibody microarray technology. Drug Discov. Today 10, 503–511(2005).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51033001, 51221002, 51103009) and National High Technology Research and Development Program (863 Program 2009AA03Z325) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Contributions

W.T.Y. planned the project, designed the study, interpreted the results and wrote the manuscript. C.W.Z. designed and performed experiments, analyzed data and wrote the manuscript. Z.F.L. prepared reactive 3D microarray with anti-fouling background and conducted the fluorescence test. H.B.Y. contributed to the discussion of the results and writing of the manuscript. Y.H.M. and F.J.X. contributed to the discussion of results. All authors commented on the manuscript. We thank Dr. Phillip Dobson for proofreading the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

SUPPLEMENTARY INFO

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Zhao, C., Lin, Z., Yin, H. et al. PEG Molecular Net-Cloth Grafted on Polymeric Substrates and Its Bio-Merits. Sci Rep 4, 4982 (2014). https://doi.org/10.1038/srep04982

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04982

This article is cited by

-

A mild route to entrap papain into cross-linked PEG microparticles via visible light-induced inverse emulsion polymerization

Journal of Materials Science (2018)

-

Net-Immobilization of β-glucosidase on Nonwoven Fabrics to Lower the Cost of “Cellulosic Ethanol” and Increase Cellulose Conversions

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.