Abstract

Na-ion batteries are gaining an increased recognition as the next generation low cost energy storage devices. Here, we present a characterization of Na3FePO4CO3 nanoplates as a novel cathode material for sodium ion batteries. First-principles calculations reveal that there are two paths for Na ion migration along b and c axis. In-situ and ex-situ Fe K-edge X-ray absorption near edge structure (XANES) point out that in Na3FePO4CO3 both Fe2+/Fe3+ and Fe3+/Fe4+ redox couples are electrochemically active, suggesting also the existence of a two-electron intercalation reaction. Ex-situ X-ray powder diffraction data demonstrates that the crystalline structure of Na3FePO4CO3 remains stable during the charging/discharging process within the range 2.0–4.55 V.

Similar content being viewed by others

Introduction

Lithium ion batteries (LIBs) represent a real technological advancement in energy storage systems (ESSs), with many applications in our daily life1,2,3: laptops, cameras, mobile phones, etc. However, due to the increasing demand of Li for applications in large facilities, the lack of Li resources is a serious drawback. Compared with LIBs, sodium ion batteries (SIBs) appear more appropriate for ESSs because of the abundance of sodium natural resources, its better economic efficiency and the lower cost of raw materials4,5,6. In addition, because of sodium's lower potential for intercalation materials, the electrolyte offers more choices. Compared to standard H electrode, they are −2.71 V for Na+/Na and −3.02 V for Li+/Li, respectively.

Among the investigated cathode materials for SIBs7,8,9,10,11,12,13,14, polyanionic materials attract a large attention7,9,14,15,16,17,18,19,20,21,22,23,24,25, because the main structure contains strong covalent bonds of polyanion characterized by a good thermal stability, which imply improved safety characteristics for these batteries18,26,27,28,29,30. Carbonophosphates (A3MPO4CO3) introduced by Ceder's team are a good reference for these systems22,31. Theoretical works30,32,33,34 suggested that the A3MPO4CO3 structure can be better deintercalated with more than one Na from crystalline structure, pointing out the existence of a two-electrons reaction. Chen et al. successfully synthesized Na3MnPO4CO3 and with ex-situ solid state NMR experiments, they showed that both Mn2+/Mn3+ and Mn3+/Mn4+ redox couples are electrochemically active35. Actually, the two electrons reaction mechanism implies that electrode materials may have a high specific capacity31. However, their effective specific capacity was not good enough, especially at high rates. There are still few reports discussing the factors limiting the capacity or the cycle life. As a consequence, it is still a great challenge enhancing both rate capability and cyclability of Na3MnPO4CO3 cathode materials.

In the present work, we used a modified hydrothermal method to synthesize Na3FePO4CO3 nanoplates. The structural evolution of this compound was carried out by combining a DFT computation with in-situ and ex-situ XAS as well as XRD experiments. When used as cathode materials in Na ion batteries, both Fe2+/Fe3+ and Fe3+/Fe4+ redox are electrochemically active and the crystalline structure remains stable during charging/discharging process. However, when compared with previous works, the as-prepared Na3FePO4CO3 system shows better electrochemical properties in terms of both high-rate charge/discharge performance and cyclability31,35.

Results

Geometrical structure and possible Na+ transfer paths

Figure 1a displays the XRD pattern of the synthesized sample. Diffraction peaks are in good agreement with the standard p21/m space group Na3FePO4CO3 (PDF#35-0678). Diffraction features due to impurity were not detected, meanwhile, the strong intensity also suggests a high crystallinity of the as-prepared sample. The Rietveld refinement result points out that the accurate molecular formula is Na3-xFePO4CO3 with a = 8.948334 Å, b = 5.167109 Å, c = 6.593195 Å, β = 90.16091 and V = 304.8485 Å3, as listed in table S1.

Characterization of the geometrical structure.

(a) The XRD Rietveld refinement of the as-prepared Na3FePO4CO3 nanoplates; (b–d) geometrical model of the Na3FePO4CO3 along the a, b, c axis, respectively. In the model, Na, Fe, P, O and C are yellow, dark brown, purple, red and light brown spheres, respectively. The distorted Fe-O octahedra (dark brown), the P-O tetrahedra (purple) and the C-O plane triangles (light brown) are also shown.

Comparison of the white line energy at the Fe K edge among as-prepared Na3FePO4CO3, FeO and Fe2O3 standards supports the existence of a mixed valence between Fe2+ and Fe3+ configurations (see figure S1). The Mössbauer spectroscopy experiment performed on as-prepared products suggests rewriting the exact formula as Na2.24FePO4CO3, (see figure S8). However, as proposed in a previous work31, the crystal structure of the Na3FePO4CO3 is isostructural to Na3MnPO4CO3 (see figure 1b–d) with a main framework composed of distorted FeO6 octahedra, PO4 tetrahedra and CO3 plane triangles. These groups are connected with each other, forming a two dimensional chain in the (010) plane (see figure 1c). Two different sites (4f and 2e) are present in the crystal for the sodium atoms, named Na1 and Na2 and surrounded by 7 and 6 O atoms, respectively. A first-principles calculation showed that the band gap of the as-prepared Na3FePO4CO3 is 3.4 eV, smaller than the value of 3.7 eV of the LiFePO436. The electron density around the Fermi level demonstrates also that Na3FePO4CO3 compounds may have a good electronic conductivity (see figure 2a). From figure 2b and 2c, we show also that there are two-dimensional channels along b and c axis to insert Na atoms (Na1-Na2-Na1, Na1-Na1-Na2-Na1), in agreement with a previous report30. The energy barriers of two most ideal Na diffusion paths are 0.6 and 0.7 eV (see in table S2), respectively. Both are much higher than the energy barrier of LiFePO4 (0.3 eV)37, pointing out the low ionic conductivity of the Na3FePO4CO3. As a consequence, it is mandatory synthesizing highly oriented nanomaterials along b or c axis to obtain excellent electrochemical performances.

The calculated density of state (DOS) and the Na+ transfer paths in the Na3FePO4CO3.

(a) The DOS of pure Na3FePO4CO3 with GGA + U. The Fermi level is set as a reference; (b) one of the most probable Na diffusion pathways for the Na3FePO4CO3 is along the b axis. Its calculated energy barrier is just 0.642 eV; (c) another possible Na diffusion pathway is along the c axis with an energy barrier of 0.716 eV. Dark yellow spheres are 4f Na atoms, light yellow the 2a Na, while solid and dot black lines are the outwards and the inwards diffusion pathways among Na atoms.

Morphology and thermostability characterization of Na3FePO4CO3

The morphology and size of as-prepared Na3FePO4CO3 products were characterized by transmission electron microscopy (TEM). As shown in figure 3a, TEM images display a plate-like morphology with a width in the range of 100–200 nm and a thickness of ~50 nm. The Brunauer-Emmet-Teller (BET) characterization (see figure S3) demonstrates that the surface area is as high as 46 m2/g and the selected area electron diffraction (SAED) pattern reveals that the exposed planes of Na3FePO4CO3 nanoplates have the (001) orientation. As mentioned above, the [001] direction is also one of the Na ion diffusion paths, so that this preferred orientation enhances the Na ion transfer capabilities that results also in a better rate capability.

TEM, SEAD images and thermostability performance.

(a) A typical TEM image of as-prepared Na3FePO4CO3 nanoplates showing the rough plate-like nature; (b) TEM image of a relative smooth nanoplate required for the SEAD analysis, (c) SEAD image of the sample in (b), showing the c axis. (d) Both thermal gravimetric characterization (TG) and differential thermal analysis (DTA) of Na3FePO4CO3 nanoplates showing their stability until 550°C.

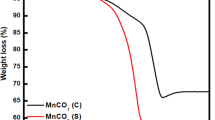

Figure 3d shows the thermal gravimetric (TG) and differential thermal analysis (DTA) of Na3FePO4CO3 nanoplates. Data points out that the material did not experience any thermal decomposition up to 550°C. Moreover, CO2, rather than other flammable gases, would be released even at the decomposition temperature of 550°C. This behavior ensures the safety of SIBs and guarantees the high thermal stability of this cathode candidate, an additional important feature that makes it a suitable cathode material for ESSs.

Electrochemical characterization of the Na3FePO4CO3

The electrochemical behaviour of the Na3FePO4CO3 has been tested with the galvanostatic discharge-charge technique. Figure 4a showed a discharge profile with different cycles at the current density of 10 mAg−1 at 20°C (100 mA/g was defined as 1 C). The long plateau at ~2.7 V in the first discharge curve is attributed to the reduction of Fe3+ to Fe2+. The first discharge capacity can deliver 121 mAh/g. After 50 cycles of test, the capacity still shows a reversible capacity of 96 mAh/g with a columbic efficiency >99%, that represents a really good stability.

Electrochemical performance of the Na3FePO4CO3 at RT.

(a) Galvanostatic charge/discharge profiles of Na3FePO4CO3 nanoplates at 10 mA/g for different cycles; (b) cycle performance of NIBs at 10 mA/g. (c) Coulombic efficiency of the sample in (b); (d) the rate capability of Na3FePO4CO3 nanoplates for different current rates.

Figure 5 shows the first three cyclic voltammogram (CV) curves of the electrodes recorded for the Na3FePO4CO3 at the scan rate of 0.1 mVs−1 at 20°C. The sample shows a strong peak at around 2.7 V in the first anodic scan that corresponds to a reduction from Fe2+ to Fe3+ while the broad peaks at ~4.2 V could be associated to the transition from Fe3+ to Fe4+. In the cathodic scan, two oxidation peaks also occur, accordingly. The two couples of redox features are similar to those of the Li2FeSiO4 data39,40, which have been recognized as electrochemically active Fe2+/Fe3+ and Fe3+/Fe4+ redox. The latter also implies the existence of a possible two electrons reaction path in the Na3FePO4CO3.

Regarding Na3FePO4CO3 nanoplates, another fundamental improvement is its rate capability. As shown in Figure 4d, the as-prepared Na3FePO4CO3 nanoplates showed the highest rate capability among the samples previously reported35. Even at the current density of 200 mA/g, Na3FePO4CO3 nanoplates still exhibit a favourable specific capacity of 58 mAh/g. Moreover, the Na3FePO4CO3 at 10 mAg−1 can recover the initial reversible specific capacity after the high rate measurements, implying their good reversibility.

Discussion

In order to get a deeper understanding of the charge/discharge mechanism and of the structural evolution of the two electrons process, electrochemical tests at different cutoff voltages, in-situ XANES, ex-situ XRD and XANES measurements were carried out. As shown in figure 6, two charge potentials around 2.7 and 4.2 V appear when it is charged to 4.55 V, while we observed only one charge potential for the other charged to 3.8 V. On the other hand, the discharge capacity delivered with 3.8 V cutoff potential was obvious lower than the one charged to 4.55 V. All the different electrochemical performances suggest that further Na+ can be extracted working with a higher voltage. In other words, the Fe3+/Fe4+ redox can only be active in a higher potential. A similar situation is found in another polyanionic Li2FeSiO4 system reported by Yang's team39.

In-situ XANES spectroscopy and ex-situ XRD were applied to further confirm the occurrence of the two electrons process. The K edge XANES spectroscopy of 3d transition metals originates from an electron excitation from a core level 1s to 4p unoccupied states41. Since it is driven by high order correlation functions beyond the pair correlation one, it can be considered a fingerprint of the local geometry around the absorption atoms42,43. Moreover, the absorption energy is related to the effective electrons of absorption atoms, so that assuming the same coordination, the energy position shifts to higher level for an increased oxidation state of the absorption atoms. We may then use the shift of the energy position of a XANES spectrum to establish and monitor the change of the valence state. From in-situ XANES spectroscopy showed in figure 7a, we found that both the edge shape and position of the pre-edge do not change, while the energy position shifts to higher energy when charged to 4.55 V. Compared with the reference samples FeO and Fe2O3, we may claim that the Fe valence state can be increased to a valence higher then 3+ (see figure 7a). On the contrary, for ex-situ experiments, after increasing to 3+, figure 7b showed that the Fe valence state remains constant. Because of the instability of the Fe4+ it is easy to understand that the Fe4+ configuration obtained by the electrochemical reaction can be reduced to Fe3+ in air. Therefore, the edge energy position does not shift. Regarding the pre-edge position, we are still unable to fully explain its behavior due to its complexity38. However, combined with data available in the literature13, it is reasonable to consider that the Fe3+/Fe4+ redox couple is active.

In-situ and ex-situ XANES spectroscopy characterization.

(a) in-situ Fe K edge XANES spectroscopy for different charging potentials showing the shift of the edge that probes the Fe valence change. Comparison with the reference samples FeO and Fe2O3 data point out that the valence may reach a value higher than 3+ in the charging process; (b) ex-situ Fe K edge XANES spectroscopy for samples exposed to air. No Fe4+ contributions is detected looking at the energy shift.

Ex-situ XRD patterns taken with a current of 10 mA/g at different charging/discharging potentials are shown in figure 8. No obvious changes are detectable in the diffraction features of XRD patterns during the Na ion insertion/de-insertion process, suggesting that the charging/discharging is a sing-phase process. The strong intensity of the diffraction peaks indicates also that the cathode material has a stable crystalline structure during the entire charging/discharging process.

XRD characteristics.

(a–b) Ex-situ XRD patterns analysis of Na3FePO4CO3 nanoplates during (a) charge and (b) discharge procedures. No structural transformations take place at different potentials during the first cycle. The strong intensity of the diffraction peaks indicates that the cathode material maintains a good crystalline structure during the entire charging/discharging process.

The good electrochemical performance of the Na3FePO4CO3 nanoplates can be due to: a) a preferred orientation that guarantees a high electrical conductivity of the overall electrode, an improved specific capacity, a good cycling performance and a high rate capability; b) an existing electrochemical active Fe3+/Fe4+ redox couple that offers the possibility to obtain a high capacity. As a consequence, the unique characterization of the as-prepared Na3FePO4CO3 nanoplates provides a good electrochemical performance when applied to SIBs.

In summary, a simple modified hydrothermal method has been setup to synthesize Na3FePO4CO3 nanoplates. A full characterization by SEM, TEM and SEAD revealed that the nanoplate size ranges from 100 to 200 nm with a thickness of about 50 nm. A preferred orientation on the (001) plane has been identified. Moreover, the capacity of Na3FePO4CO3 nanoplates stabilized at 96 mAh/g with a current density of 10 mA/g after 50 cycles. Finally, in-situ and ex-situ XANES spectroscopy at the Fe K edge provided a direct evidence of the existence of an electrochemical active Fe3+/Fe4+ redox. To our knowledge, this is the first systematic evidence of a clear capacity contribution due to Fe2+/Fe3+ and Fe3+/Fe4+ redox couples. The successful tests performed with the carbonophosphates suggested also that when optimized, polyanion materials could become reliable high-performance and low-cost electrode materials for the next generation of SIBs.

Methods

Computational method

Density functional theory (DFT) calculation was performed using the plane-wave based Vienna ab initio simulation package (VASP) with the generalized gradient approximation (GGA) and exchange correlation functional parametrized by Perdew-Burke-Eernzerhof (PBE). The U parameter for the transition metal Fe is 4.0 eV while the energy cutoff was set to 600 eV for all computations.

Synthesis of the Na3FePO4CO3

Na3FePO4CO3 nanoplates were prepared by a modified hydrothermal method. 4 mmol FeSO4.7H2O and 50 mg citric acid were dissolved in 10 ml water/ethylene glycol (EG) mixed solution (volume ratio: H2O/EG = 3/1) to form a clear solution A. After 4 mmol (NH4)2HPO4 and 4 g Na2CO3 were dissolved in 20 ml H2O/EG mixed solution (volume ratio: H2O/EG = 3/1) to form a clear solution B. After a vigorous stirring, the solution A was dropped wisely in the solution B and this mixture was kept stirring for half hour. After that, the mixture products were transferred inside a 40 ml stainless steel autoclave and heated at 180°C for 70 hours. The final products were washed five times by distilled water and dried at 80°C in a vacuum oven overnight.

Material characterization

XRD experiments were carried out using an X-ray diffractometer (Bruker D8-Advance) equipped with a Cu Kα radiation (λ = 1.5406 Å). For the Rietveld refinement analysis we scanned over a 2θ range from 8 to 120° at steps of 0.02° for 8 s and data were analyzed using the TOPAS software. Ex-situ XRD data at different voltages during the charging and discharging procedure were collected in a conventional way29. To get the desired electrodes, the coin cells, which were charged/discharged to the desired cutoff voltages, needs to be disassembled by an electric criming machine (MTI Co.). Finally, the disassembled electrodes were washed with dimethyl carbonate (DMC) and dried by a hair drier. SEM images recorded by a JEOL 4800 SEM show the sampl morphology. TEM images and SEAD were acquired with a JEM2100F HRTEM. The thermal stability of the samples was evaluated at a heating rate of 5°C/min from RT to 1000°C in air with a TG/DTA thermo-gravimetric analyzer. Fe K edge XANES spectra were recorded at the 1W2B beamline of the Beijing synchrotron radiation facility (BSRF) and at the 14W1B beamline of the Shanghai synchrotron radiation facility (SSRF). For in-situ XAS experiment, coin cells were disassembled in an Ar-filled glove box to take out at first the positive electrode material. To remove the influence of the electrolyte, we cleaned them by DMC solutions. After drying, the positive electrode materials were sealed by a 3 M sellotape in an atmosphere of Ar.

Electrochemical characterization

The Na3FePO4CO3 nanoplate samples were mixed with carbon (super P) and a Poly tetra fluoro ethylene (PTFE) binder to form a slurry at the weight ratio of 6:3:1. The mixture was rolled in a thin sheet of uniform thickness (about 40–60 um). After, it was cut in appropriate sections before drying them in a vacuum oven at 120°C for 12 h. The cells were then assembled in an Ar-filled glove box. Metallic Nawas were used as anode for NIBs tests. A high potential electrolyte (purchased from the Beijing Institute of Chemical reagents) with 1 M NaClO4 was used as the electrolyte for NIBs. A separator (whatman) was used for NIB and the charging-discharging performance under different current density was characterized with a cutoff potential in the range 2.0–4.55 V. The cyclic voltammogram was achieved at the scan rate of 0.1 mV/s.

References

Li, H., Wang, Z., Chen, L. & Huang, X. Research on Advanced Materials for Li-ion Batteries. Adv. Mater. 21, 4593–4607 (2009).

Goodenough, J. B. & Kim, Y. Challenges for Rechargeable Li Batteries. Chem. Mater. 22, 587–603 (2010).

Goodenough, J. B. & Park, K. S. The Li-Ion Rechargeable Battery: A Perspective. J. Am. Chem. Soc. 135, 1167–1176 (2013).

Ong, S. P. et al. Voltage, stability and diffusion barrier differences between sodium-ion and lithium-ion intercalation materials. Energ. Environ. Sci. 4, 3680–3688 (2011).

Palomares, V. et al. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energ. Environ. Sci. 5, 5884–5901 (2012).

Wang, L. et al. A Superior Low-cost Cathode for a Na-ion Battery. Angew. Chem. Int. Ed. 52, 1964–1967 (2013).

Ellis, B. L., Makahnouk, W. R., Makimura, Y., Toghill, K. & Nazar, L. F. A multifunctional 3.5 V iron-based phosphate cathode for rechargeable batteries. Nat. Mater. 6, 749–753 (2007).

Sauvage, F., Laffont, L., Tarascon, J. M. & Baudrin, E. Study of the insertion/deinsertion mechanism of sodium into Na0.44MnO2 . Inorg. Chem. 46, 3289–3294 (2007).

Abouimrane, A. et al. A new class of lithium and sodium rechargeable batteries based on selenium and selenium-sulfur as a positive electrode. J. Am. Chem. Soc. 134, 4505–4508 (2012).

D'Arienzo, M. et al. Layered Na0.71CoO2: a powerful candidate for viable and high performance Na-batteries. PCCP 14, 5945–5952 (2012).

Qian, J., Zhou, M., Cao, Y., Ai, X. & Yang, H. Nanosized Na4Fe(CN)6/C Composite as a Low-Cost and High-Rate Cathode Material for Sodium-Ion Batteries. Adv. Eng. Mater. 2, 410–414 (2012).

Tepavcevic, S. et al. Nanostructured Bilayered Vanadium Oxide Electrodes for Rechargeable Sodium-Ion Batteries. Acs Nano 6, 530–538 (2012).

Yabuuchi, N. et al. P2-type Na-x[Fe1/2Mn1/2]O−2 made from earth-abundant elements for rechargeable Na batteries. Nat. Mater. 11, 512–517 (2012).

Lu, Y., Wang, L., Cheng, J. & Goodenough, J. B. Prussian blue: a new framework of electrode materials for sodium batteries. Chem. Commun. 48, 6544–6546 (2012).

Barpanda, P. et al. Structural, Transport and Electrochemical Investigation of Novel AMSO(4)F (A = Na, Li; M = Fe, Co, Ni, Mn) Metal Fluorosulphates Prepared Using Low Temperature Synthesis Routes. Inorg. Chem. 49, 7401–7413 (2010).

Trad, K. et al. NaMnFe2(PO4)3Alluaudite Phase: Synthesis, Structure and Electrochemical Properties As Positive Electrode in Lithium and Sodium Batteries. Chem. Mater. 22, 5554–5562 (2010).

Trad, K., Carlier, D., Wattiaux, A., Ben Amara, M. & Delmas, C. Study of a Layered Iron(III) Phosphate Phase Na3Fe3(PO4)(4) Used as Positive Electrode in Lithium Batteries. J. Electrochem. Soc. 157, A947–A952 (2010).

Tripathi, R., Ramesh, T. N., Ellis, B. L. & Nazar, L. F. Scalable synthesis of tavorite LiFeSO4F and NaFeSO4F cathode materials. Angew. Chem. Int. Ed. 49, 8738–8742 (2010).

Zhao, J. et al. A novel sol-gel synthesis route to NaVPO4F as cathode material for hybrid lithium ion batteries. J. Power Sources 195, 6854–6859 (2010).

Lee, K. T., Ramesh, T. N., Nan, F., Botton, G. & Nazar, L. F. Topochemical Synthesis of Sodium Metal Phosphate Olivines for Sodium-Ion Batteries. Chem. Mater. 23, 3593–3600 (2011).

Barpanda, P. et al. Sodium iron pyrophosphate: A novel 3.0V iron-based cathode for sodium-ion batteries. Electrochem. Commun. 24, 116–119 (2012).

Chen, H., Hautier, G. & Ceder, G. Synthesis, computed stability and crystal structure of a new family of inorganic compounds: carbonophosphates. J. Am. Chem. Soc. 134, 19619–19627 (2012).

Jain, A. et al. A Computational Investigation of Li9M3(P2O7)3(PO4)2 (M = V, Mo) as Cathodes for Li Ion Batteries. J. Electrochem. Soc. 159, A622 (2012).

Kang, J. et al. High rate performance of a Na3V2(PO4)3/C cathode prepared by pyro-synthesis for sodium-ion batteries. J. Mater. Chem. 22, 20857 (2012).

Kim, H. et al. New iron-based mixed-polyanion cathodes for lithium and sodium rechargeable batteries: combined first principles calculations and experimental study. J. Am. Chem. Soc. 134, 10369–10372 (2012).

Ellis, B. L., Makahnouk, W. R. M., Rowan-Weetaluktuk, W. N., Ryan, D. H. & Nazar, L. F. Crystal Structure and Electrochemical Properties of A2MPO4F Fluorophosphates (A = Na, Li; M = Fe, Mn, Co, Ni)†. Chem. Mater. 22, 1059–1070 (2010).

Trad, K. et al. Structural study of the Li(0.5)Na(0.5)MnFe2(PO4)3 and Li(0.75)Na(0.25)MnFe2(PO4)3 alluaudite phases and their electrochemical properties as positive electrodes in lithium batteries. Inorg. Chem. 49, 10378–10389 (2010).

Liu, Y. et al. Porous amorphous FePO4 nanoparticles connected by single-wall carbon nanotubes for sodium ion battery cathodes. Nano Lett. 12, 5664–5668 (2012).

Shakoor, R. A. et al. A combined first principles and experimental study on Na3V2(PO4)2F3 for rechargeable Na batteries. J. Mater. Chem. 22, 20535 (2012).

Zelang, J. et al. Carbon coated Na3V2(PO4)3 as novel electrode material for sodium ion batteries. Electrochem. Commun. 14, 86–89 (2012).

Chen, H. et al. Carbonophosphates: A New Family of Cathode Materials for Li-Ion Batteries Identified Computationally. Chem. Mater. 24, 2009–2016 (2012).

Hautier, G., Fischer, C. C., Jain, A., Mueller, T. & Ceder, G. Finding Nature's Missing Ternary Oxide Compounds Using Machine Learning and Density Functional Theory. Chem. Mater. 22, 3762–3767 (2010).

Hautier, G. et al. Novel mixed polyanions lithium-ion battery cathode materials predicted by high-throughput ab initio computations. J. Mater. Chem. 21, 17147 (2011).

Hautier, G., Ong, S., Jain, A., Moore, C. & Ceder, G. Accuracy of density functional theory in predicting formation energies of ternary oxides from binary oxides and its implication on phase stability. Phys. Rev. B 85 (2012).

Chen, H. et al. Sidorenkite (Na3MnPO4CO3): A New Intercalation Cathode Material for Na-Ion Batteries. Chem. Mater. 25, 2777–2786 (2013).

Wang, Z. L. et al. Investigation of Electronic Conductivity and Occupancy Sites of Mo Doped into LiFePO4 by ab Initio Calculation and X-ray Absorption Spectroscopy. J Phys. Chem. C 112, 17450–17455 (2008).

Dathar, G. K. P., Sheppard, D., Stevenson, K. J. & Henkelman, G. Calculations of Li-Ion Diffusion in Olivine Phosphates. Chem. Mater. 23, 4032–4037 (2011).

Westre, T. E. et al. A multiplet analysis of Fe K-edge 1s->3d pre-edge features of iron complexes. J. Am. Chem. Soc. 119, 6297–6314 (1997).

Lv, D. et al. A novel Li2FeSiO4/C composite: Synthesis, characterization and high storage capacity. J. Mater. Chem. 21, 9506 (2011).

Lv, D. et al. Understanding the High Capacity of Li2FeSiO4: In Situ XRD/XANES Study Combined with First-Principles Calculations. Chem. Mater. 25, 2014–2020 (2013).

Huang, W.-F. et al. Investigation of Structural and Magnetic Properties of CoPt/CoAu Bimetallic Nanochains by X-ray Absorption Spectroscopy. J Phys. Chem. C 117, 6872–6879 (2013).

Zhang, L. et al. Regulation of Magnetic Behavior and Electronic Configuration in Mn-Doped ZnO Nanorods through Surface Modifications. Chem. Mater. 24, 1676–1681 (2012).

Zhang, L. J. et al. High-Tc ferromagnetism in a Co-doped ZnO system dominated by the formation of a zinc-blende type Co-rich ZnCoO phase. Chem. Commun. 48, 91–93 (2012).

Acknowledgements

Authors acknowledge Dr. Lin and Dr. Li of the Shanghai Institute of Applied Physics for their kind help on the Mossbauer experiment. This work was partly supported by the National Basic Research Program of the Ministry of Science & Technology of China (2012CB825800), the Science Fund for Creative Research Groups, NSFC (11321503), the Knowledge Innovation Program of the Chinese Academy of Sciences (KJCX2-YW-N42), the major program of the Beijing Municipal Natural Science Foundation (No.2110001) and the National Natural Science Foundation of China (NSFC 10805055, 11179023,11275227, U1232131 and No.11179001). We sincerely acknowledge the staff of the XAS beamlines of the Beijing Synchrotron Radiation Facility and of the Shanghai Synchrotron Radiation Facility for their support.

Author information

Authors and Affiliations

Contributions

D.X. and Z.W. designed the experiments. W.H., B.L., J.M. and S.T. performed experiments and data analysis. J.Z., W.H., W.C. and Z.W. pformed the calculations. D.X. and Z.W. led the whole work and the analysis. W.H., D.X. and Z.W. wrote the text.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

supporting information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Huang, W., Zhou, J., Li, B. et al. Detailed investigation of Na2.24FePO4CO3 as a cathode material for Na-ion batteries. Sci Rep 4, 4188 (2014). https://doi.org/10.1038/srep04188

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04188

This article is cited by

-

In situ IR spectroscopy during oxidation process of cobalt Prussian blue analogues

Scientific Reports (2021)

-

Cathode Properties of Na3FePO4CO3 Prepared by the Mechanical Ball Milling Method for Na-ion Batteries

Scientific Reports (2020)

-

Na3FePO4CO3 as a cathode for hybrid-ion batteries—study of Na+/Li+ electrochemical exchange

Ionics (2019)

-

Recent Advances in Sodium-Ion Battery Materials

Electrochemical Energy Reviews (2018)

-

Recent advances on Fe- and Mn-based cathode materials for lithium and sodium ion batteries

Journal of Nanoparticle Research (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.