Abstract

The efficient electrocatalysts for many heterogeneous catalytic processes in energy conversion and storage systems must possess necessary surface active sites. Here we identify, from X-ray photoelectron spectroscopy and density functional theory calculations, that controlling charge density redistribution via the atomic-scale incorporation of heteroatoms is paramount to import surface active sites. We engineer the deterministic nitrogen atoms inserting the bulk material to preferentially expose active sites to turn the inactive material into a sufficient electrocatalyst. The excellent electrocatalytic activity of N-In2O3 nanocrystals leads to higher performance of dye-sensitized solar cells (DSCs) than the DSCs fabricated with Pt. The successful strategy provides the rational design of transforming abundant materials into high-efficient electrocatalysts. More importantly, the exciting discovery of turning the commonly used transparent conductive oxide (TCO) in DSCs into counter electrode material means that except for decreasing the cost, the device structure and processing techniques of DSCs can be simplified in future.

Similar content being viewed by others

Introduction

Increasing energy demands have stimulated intense research on electrocatalysts for oxygen reduction reaction, water reduction reaction and triiodide (I3−) reduction reaction etc, which are at the heart of the typical key renewable-energy technologies such as fuel cells1,2, water splitting3,4, dye-sensitized solar cells (DSCs)5,6 and so on. Platinum (Pt) is always the suitable electrocatalyst for these reduction reactions due to its high conductivity, good catalytic activity and chemical stability, but its low abundance ratio and high costs precluded the large-scale utilizations of these renewable-energy technologies. These considerations have led to ongoing efforts to design molecular catalysts that employ earth-abundant materials, to match up to or surpass the catalytic activity of Pt. Because high electric conductivity and good catalytic activity are the two main requirements for an efficient electrocatalyst, screening the alternatives among the abundant conductive materials like conductive oxides is a reasonable way. However, according to our previous theoretical research7, some conductive oxides such as indium oxide (In2O3), stannic oxide (SnO2) and zinc oxide (ZnO) are unfortunately proven to be electrocatalytically inactive, due to their low adsorption energies of reactant molecules and scarce active sites which are necessary for adsorption of the reactants, bond-breaking and bond-formation and desorption of the products in the heterogeneous catalytic process8. To deliver these intrinsically inactive but abundant materials into active catalysts, one needs to control the atomic-scale surface structure to preferentially expose a greater fraction of the active sites9 or exhibit a higher adsorption energy, which is highly challenging but desirable.

Along the way, recent studies have shown that doping the carbon nanotubes and graphene with heteroatoms or defects sites can introduce electrocatalytic active sites for oxygen reduction in fuel cells1,10,11 and for I3− reduction in DSCs6,12. Similarly, nitrogen-doped indium oxide (N-In2O3) can be photocatalytically active for water splitting13,14. More remarkably, the nitrate-type species in interstitial sites have been identified as an important role in the photoelectrochemical improvement of N-In2O314. However, such design strategies have rarely been based on molecular-level understanding of the reaction mechanism. In addition, how the heteroatoms transform the metal oxide with scarce active sites into high-efficiency catalysts with sufficient active sites has been unexplored. Within the density functional theory (DFT) framework, the adsorption energy of I atom (EadI) on the common (110) surface of In2O3 is found to be increased significantly when the interstitial N atoms are imported, which predicts that interstitial N-In2O3 could be catalytically active.

Herein, directed by this prediction, we describe our efforts to turn abundant In2O3 into a superior electrocatalyst by atomic-scale doping. We accomplish this through a facile one-step solution strategy to introduce trace amount of interstitial N atoms to In2O3 nanocrystals via decompostition of indium nitrate, which serves as both reactant and dopant source. To the best of our knowledge, this is the first report of interstitial N-In2O3 nanocrystals synthesized by a wet chemical technique. Further, the resultant N-In2O3 nanocrystals supported by fluorine-doped tin oxide (FTO) glass substrates were applied as counter electrode (CE) in DSCs for the first time. Amazingly, the DSCs with N-In2O3 CE achieved a power conversion efficiency (η) of 7.78% versus 7.17% for Pt under the same conditions, whereas the undoped In2O3 shows a η of only 0.96%. Furthermore, in order to understand how the trace nitrogen atoms turn the inactive In2O3 into a superior catalyst over Pt for I3− reduction, the catalytic activity of interstitial N-In2O3 towards I3− reduction was investigated by means of DFT calculations in detail.

Results

To explore the effect of interstitial N-doping on the catalytic activity of In2O3 toward I3− reduction reaction, we firstly performed DFT calculation to investigate the doping configuration in In2O3 and its adsorption toward I atom, aiming at providing a preliminary understanding for experimental synthesis. In pure In2O3 bulk, there exist two kinds of six-coordinated In atoms, forming a relatively regular and distorted octahedron structure, in which almost all the (at least seven kinds) possible initial structures for interstitial N-doping were optimized to identify the most stable one. The most stable configuration achieved is shown in Figure 1a. One can see that the inserted N atom prefers to bond with two lattice O atoms and an In atom, forming a local NO2δ− configuration with a bond length of N-O of ~ 1.36 Å, in which the two oxygen atoms deviate evidently from their original lattice site in In2O3 and the number of O-In bond is reduced from 4 to 2. Bader charge analysis indicates that these two O atoms are charged with ~ −0.77 e that is evidently less than the other O atoms (~−1.26 e) and N exhibits an oxidized state (denoted as Nδ+ with δ = 0.14 e). Based on this stable configuration, In2O3(110), one of the most exposed surfaces of In2O3, was modelled with interstitial N dopant at the near-surface (see Figure 1b and c). It shows that the doped N atom tends to be located at the subsurface and bind with the surface five-coordinated In atom at a distance of 2.30 Å, thus it can be expected that the binding ability of this kind of surface In atom toward I or I2 could be tuned due to the change of coordination environment. We calculated the adsorption of I atom at this five-coordinated surface In atom at the gas/solid interface and the adsorption energy (relative to half an I2 molecule) was calculated to be −0.54 eV for N doped In2O3(110), which is much enhanced compared to that (0.45 eV) of the pure In2O3(110) (see Figure 1b). The adsorption of I atom at the interfaces of CH3CN/In2O3(110) with or without N doping was also calculated, which increase to −0.94 and 0.16 eV, respectively, but give the same trend. Based on the thermodynamics model verified previously7,15, demonstrating that the EadI at the CH3CN/electrode interface can serve as a descriptor for the iodine reduction activity and it should usually range from around −0.33 to −1.20 eV for good catalysts. Thermodynamically, when EadI is evidently weak, the dissociation of I2 molecule would hardly proceed; while EadI is too strong, the overall activity can be limited by I* removal into I−(sol) owing to the large energy requirement. It is clear that the adsorption energy of I atom on In2O3 resulting from the interstitial N doping is well within required thermodynamic range for a good catalyst to catalyze triiodide reduction, suggesting the potentially enhanced catalytic activity of N-In2O3.

Structures of interstitial N doping and I atom adsorption.

(a) The most stable bulk structure of interstitial N-doped In2O3 (N-In2O3); (b) top view of the optimized surface structure of N-In2O3 (110); (c) side view of the optimized I adsorption structure on N-In2O3 (110). Red, brown, blue and purple balls represent O, In, N and I, respectively. Marked in circle shows the local configuration of NO2δ− resulting from the interstitial N doping and dark brown balls indicate the distorted lattice O accompanying the N doping.

Directed by the theoretical estimation, N-In2O3 nanocrystals were synthesized by a smart and facile one-pot solution process (see the Methods). The scanning electron microscopic energy-dispersive x-ray (SEM-EDX) analysis in Figure S1 (shown in SI) indicates that trace amount of N atoms of about 5.46 at.% were doped. In order to examine chemical changes caused by the doping with N atoms and the doping position of N atoms in In2O3 nanocrystals, the X-ray photoelectron spectroscopic (XPS) measurements were carried out. The XPS spectra of N-In2O3 sample recorded is shown in Figure 2a–b for N 1 s and O 1 s core levels and the survey spectrum and high-resolution In 3d XPS are shown in Figure S2–S3 in SI. Nitrogen 1 s core level shows a single peak at 399.3 eV, which appears at higher binding energy (BEs) than the typical energy for InN (397 eV16, or 396.5 eV17) and at lower BEs than free or adsorbed N species on metal oxides. According to the literature about N-doped In2O313,14,18 or N-doped TiO219, nitrogen atoms substitutionally doped into the In2O3 lattice (In-N-In linkages) own the characteristic peak at approximate 397 eV, which does not appear in the XPS of our sample and on the contrary, the peak at 399.3 eV in our sample can be attributed to a characteristic peak of interstitial N, being NOx located in an interstitial position. The N-In2O3 sample shows a single peak at 444.0 eV for In 3d 5/2, which is attributed to In2O3 according to the NIST XPS database (444.30 to 446.7 eV). This small lower BE shift may be due to a interstitial doping13. Gaussian fitting of the O 1 s region shows two peaks at 529.4 and 531.0 eV. The former peak can be attributed to the In-O bond in In2O313,18 and the peak at 531.0 eV is the characteristic of a non-stoichiometric oxide, oxynitride, or adsorbed water17,18. It is worth noting that the peak at 531.0 eV overwhelms the peak at 529.4 eV of pristine In2O3. This result indicate that the interstitial N enables the sample adsorb the foreign hydroxyls more easily18, which is consistent with our theory prediction of the increasing EadI at the acetonitrile/electrode interface. The morphology and crystallinity of as-prepared N-In2O3 nanocrystals were analyzed using transmission electron microscopy (TEM) and high-resolution TEM (HRTEM). Figure 2c shows the TEM image of quasi-monodisperse N-In2O3 nanocrystals and the nanocrystal diameter was approximately (9 ± 2) nm. From Figure 2d, it can be seen that the N-In2O3 nanocrystal is mainly bounded by {440} facets. As shown in Figure S4 in SI, all X-ray diffraction (XRD) peaks of the synthesized N-In2O3 can be indexed to the lattice planes of body-centered cubic In2O3 (JPCDs no. 71-2194), which is consistent with the TEM result. It is worth noting that compared to conventional costly preparation of irregular N-In2O3 powders via high-temperature calcinating, the way to produce N-In2O3 nanocrystals with small grain size and faceted morphology via a solution-base approach would lower the manufacturing cost and increase the catalytic activity of the material.

Atoms distribution and morphological analysis of N-In2O3 nanocrystals.

(a) high-resolution N 1 s XPS; (b) high-resolution O 1 s XPS; The open circles are the raw data of the X-ray photoelectron spectra and the blue and red/purple/green lines represent the base line and fitted lines, respectively. (c) representative morphologies and structures of the N-In2O3 nanocrystals in TEM; (d) HRTEM images.

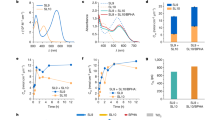

The performances of N-In2O3 on I3− reduction and further on photovoltaic conversion efficiency of DSCs were characterized in the following parts. For comparison, platinum and undoped In2O3 nanooctahedron synthesized according to the literature (see SI in details, SEM shown in Figure S5)20, were also used as CEs in DSCs constructed under the same condition in control experiments. Figure 3a shows the photocurrent-voltage (J-V) curves of three DSCs fabricated with N-In2O3, Pt and undoped In2O3 nanooctahedron electrodes as CEs. The detailed photovoltaic parameters from the J-V curves are summarized in Table 1. As shown in Table 1, the device equipped with N-In2O3 yields a remarkable η of 7.78%, which is superior to that of the device with a Pt CE, far better than that of undoped In2O3 nanooctahedron and Jsc increased in the same order. These interesting results demonstrate that the interstitial N atoms surely turn In2O3 into a superior catalyst surpassing Pt for I3− reduction, which is in accordance with our prediction results. To better understand the improved DSC performance for N-In2O3 CE, electrochemical impedance spectra (EIS) experiments of the symmetrical cells fabricated with two identical N-In2O3 and Pt CEs were carried out at 20°C and the results are shown in Figure 3b, while the EIS of undoped In2O3 nanooctahedron was given in SI (Figure S6). The EIS parameters were determined by fitting the impedance spectra using the ZSimpWin software via the circuit model inserted in Figure 3b and were summarized in Table 1. The high-frequency intercept on the real axis represents the series resistance (Rs), which is mainly composed of the bulk resistance of CEs materials, resistance of FTO glass substrate and contact resistance, etc. It can be seen that Rs of N-In2O3 (7.03 Ω) is smaller than that of Pt (9.64 Ω), which should be benefit to the increase of the Jsc of N-In2O3. While the lower Rs of N-In2O3 than that of undoped In2O3 (9.52 Ω) indicates that the introduction of the interstitial N atoms increases the electric conductivity of In2O3. The low-frequency region (the right semicircle) reflects the diffusion in the electrolyte, which is not closely related to catalysis and hence is not the focus of attention in this paper. The semicircle in the high frequency region (the left one) arises from the parallel connection of coupling between the constant phase angle element (CPE) at the CE/electrolyte interface and the charge-transfer resistance (Rct) of CE, which is directly proportional to the diameter of the left semicircle. Rct is a measure of the ease of electron exchange between the electrode and the electrolyte and thus varies inversely with the I3− reduction activity of the CEs21. As shown in Table 1, the Rct of N-In2O3 is 5.51 Ω, significantly smaller than that of Pt (8.65 Ω) and much smaller than that of undoped In2O3 nanooctahedron (379.4 Ω), which means that the N-In2O3 has a higher catalytic activity for I3− reduction than that of Pt. While the so high Rct of undoped In2O3 nanooctahedron indicates that it nearly has no catalytic activity for I3− reduction. It also can be seen that the CPE of N-In2O3 is lower than that of Pt, which means that N-In2O3 has a smaller active surface area22,23,24. But, it can be obtained that the low Rs and high catalytic activity (Rct) of N-In2O3 make up its small active surface area, resulting in the high Jsc and η of DSCs with N-In2O3. In order to further elucidate the catalytic activities of different CEs, we also performed the cyclic voltammograms (CVs) of the  redox couple on both the N-In2O3 and Pt electrodes. For the both electrodes, two pairs of oxidation and reduction peaks are well resolved, as shown in Figure S7. The left and right pairs are described by equations (1) and (2), respectively.

redox couple on both the N-In2O3 and Pt electrodes. For the both electrodes, two pairs of oxidation and reduction peaks are well resolved, as shown in Figure S7. The left and right pairs are described by equations (1) and (2), respectively.

Since the CE of a DSC is responsible for I3− reduction, we only focus on the left cathodic peak corresponding to I3− reduction. The high peak current and large peak area of the left cathodic peak reveal that N-In2O3 is a significant efficient electrochemical catalyst for I3− reduction, even better than Pt electrode6,25,26. To further examine the interfacial charge-transfer properties of the I3−/I− couple on the electrode surface, Tafel polarization measurements were carried out with dummy cells, similar to the one used in EIS measurements and the results are shown in Figure S8 in SI. From the Tafel zone at middle overpotential (with a sharp slope), we can obtain the exchange current density (J0), which can also be obtained from EIS parameters via equation (3).

where Rct is determined by EIS data and R, T, n and F have their usual significance, which means that high J0 means low Rct and high catalytic activity. The anodic and cathodic branches of the J-U plot (Figure S8 in SI) show a largest slop for the N-In2O3, indicating a highest J0 on this electrode in terms of the Tafel equation27,28, which means that N-In2O3 has a higher catalytic activity. These experimental results consistently show that the interstitial N atoms surely turn the intrinsically inactive In2O3 into an efficient electrocatalyst.

DSCs performances and electrochemical analysis.

(a) Photocurrent-voltage (I-V) curves of DSCs fabricated with Pt, N-In2O3 and In2O3 as counter electrodes and (b) electrochemical impedance spectra of the symmetrical cells fabricated with two identical counter electrodes and the insert gives the equivalent circuit where W(sol) represents Warburg parameter.

Further, to elucidate the origin of high catalytic activity of N-In2O3 and understand the role of the interstitial N in the performance of catalyst, a molecular level investigation into I3− reduction reaction at the CH3CN/N-In2O3(110) interface was conducted by virtue of DFT calculations. Herein, a full reaction energetic involving thermodynamics and kinetic are considered to demonstrate the catalytic activity of N-In2O3 toward I3− reduction. With respect to the I3− reduction reaction (I3−(sol) + 2 e− → 3I−(sol)) occurring on the CE, the general consensus of the reaction mechanism can be described in the reference7,29(see details in SI), which shows that the I2 reduction reaction (IRR) occurring at the liquid-solid interface, can determine the overall electrocatalytic activity owing the fast solution reaction (I3−(sol) ↔ I2(sol) + I−(sol)). Hence we focused our studies on the two elementary reaction steps involved in I2 reduction reaction at the CH3CN/electrode interface, containing I2(sol) + 2* → 2I*; I* + e− → I−(sol), to explore the activity of In2O3 with or without N doping. It is found that on N-In2O3(110) surface I2 molecule can readily dissociate into two I* atoms without an obvious dissociation barrier (Eadis), resulting in I* sitting preferably on the top of In atom at a distance (d(In-I)) of ~ 2.93 Å, while it is hard on pure In2O3(110). The adsorbed iodine atom (I*) can receive one electron and then desorb into solution in form of I− with a much elongated d(In-I) of 4.20 Å at the transition state (TS) structure, being surrounded by CH3CN molecules with H atoms in methyl pointing to it. The charge density differences show (Figure 4c) that the electrons accumulate at I atom in TS (Bader: 0.69 e), resulting from the electron depletion at the surface In atom and the surface adsorbed CH3CN molecules and there is no orbital overlap between the p-orbital of ion-like I and p-orbital of surface In atom, indicating a typical ionic bond of In-I. Figure 4a shows the reaction standard Gibbs free energy profile of IRR at the CH3CN/N-In2O3(110) interface, in which the energy profiles on two typical surfaces of Pt electrode, i.e. flat Pt(111) and stepped Pt(411), were also given as the references7,29. From the profile of N-In2O3, one can see that the Gibbs free energies of all elemental reactions at CH3CN/N-In2O3(110) interface decrease step by step from the initial state to final state, indicating a considerable catalytic activity. Quantitatively, the adsorption energy of I atom at CH3CN/N-In2O3(110) interface is between Pt(411) and Pt(111), giving a −0.94 eV, while the corresponding desorption barrier of I* is only 0.28 eV, lower than those at the CH3CN/Pt(111) and CH3CN/Pt(411) interfaces (0.39 eV and 0.63 eV, respectively). Considering that I2 molecule can readily dissociate on all these three surfaces, the dissociation of I2 molecule could be expected to be fast and may be in equilibrium approximately and one can therefore speculate that N-In2O3 can exhibit a good catalytic activity toward IRR owing to the lower Eades, even better than Pt(111). Furthermore, we estimated the equilibrium exchange current (i0) of IRR using the micro-kinetic analysis to compare their activity trend. For these three surfaces, the i0 of the IRR can be determined from equation (10) in SI, which quantitatively indicates the key role of the desorption barrier of I* (Eades); the smaller the Eades, the higher the catalytic activity. Accordingly, it can be concluded that their catalytic activities toward IRR follow in the order of N-In2O3(110) > Pt(111) > Pt(411), being consistent with the experimental Rct values, CV and Tafel measurements.

Electronic structures of intermediates and energy profiles.

(a) The standard Gibbs free energy profile of IRR at various systems of Pt(111), Pt(411) and N-In2O3(110); (b) and (c) indicate the structure of I adsorption and desorption transition state at the CH3CN/N-In2O3(110) interface, respectively, in which 3D isosurfaces of charge density difference before and after I atomic interacting with the electrode are also illustrated (yellow indicates the electronic accumulation and light blue for electronic depletion).

At this point, one question arises: why does interstitial N doping give rise to the enhancement of I* adsorption on In2O3(110) surface? Geometrically, the surface five-coordinated In atom on In2O3(110) surface strongly bonds with four surface lattice O (Os) and one subsurface O (Oss). After interstitial N doping at the subsurface, this surface In atom would form a relatively weak In-N bond compared to In-O bond, reflected in a longer In-N bond length (2.37 Å vs. 2.16 Å for In-Oss bond). On account of the bond conversation, the enhanced binding ability of the surface In atom resulting from N doping is reasonable. Electronically, as shown in Figure 4b, the I-In bond at the I* adsorption state exhibits evident characteristic of ionic bond and thus Bader charge analysis is conducted to understand the N doping effect (see details in Table S2 in SI). It shows that the electrons of the In2O3 system owing to N doping would be redistributed, probably rationalized by the obvious structural distortion in forming a local NO2δ− doping configuration. Compared with the pure In2O3, the total electron of all the O atoms would decrease by 1.04 e and the two O atoms binding directly with N atom decrease most, each giving ~ 0.49 e; while the total electron number of all the In atoms increases by 1.14 e and the increased electrons were delocalized at all of In atoms with a little more distributing at the surface In atoms. Upon adsorption on N-In2O3(110), I atom can gain 0.47 e, which mainly results from the In atoms (0.28 e) and the interstitial N dopant (0.10 e), giving rising to a relatively strong adsorption energy toward I atom (−0.54 eV). By contrast, as In3+ in pure In2O3 hardly further provide electron and there are no extra electrons on them, I* can only gain few electrons (0.29 e) from the O atoms (0.28 e) upon adsorption on pure In2O3(110) surface, resulting in a weak ionic bond and low adsorption energy (0.45 eV). In general, the enhancement of adsorption ability of In2O3 due to interstitial N doping could mainly be ascribed to the electron redistribution of In2O3, in which more extra electrons can distribute on In atom to facilitate I* adsorption, as well as the N atom itself would provide a small number of electrons in forming a local NO2δ− doping configuration.

As a whole, both experimental measurements and first-principles calculations demonstrate that the performance of In2O3 catalyst in catalyzing I3− reduction can be optimized by doping N atom and the catalytic activity of N-In2O3 can be even better than Pt(111) owing to its increased I* adsorption energy and lower desorption barrier.

Discussion

In summary, for the first time, we have prepared interstitial nitrogen-doped In2O3 nanocrystals via a low cost and facile one-step solution strategy and demonstrated that the small amounts of interstitial nitrogen can transform the intrinsically inactive In2O3 into a high-efficiency catalyst in DSCs, leading to a high η of 7.78%. Beyond this application, this work demonstrates that a cheap and abundant semiconductor with high electric conductivity such as In2O3 can be turned into an active catalyst by controlled interstitial doping of N atoms via a novel nanotechnology of a simple solution-based strategy and opens a new pathway to prepare effective Pt-free electrocatalysts. More importantly, the exciting discovery of turning the commonly used TCO in DSCs into a difunctional electrode material with both transparent conductive function and catalytic activity means that except for decreasing the cost, the device structure and processing techniques of DSCs can be simplified in future.

Methods

Synthesis of N-In2O3 nanocrystals

In a typical synthesis of interstitial N-In2O3 nanocrystals, 0.18 g In(NO3)3·4.5H2O was dissolved in the mixture of 5 mL 1-octadecylamine and 5 mL 1-octadecene (at 65°C). The solution was degaseed for at least 2 hours and heated at 150°C for 1 h under magnetic stirring. Then the solution temperature was raised to 280°C in 10 min and kept for 30 min. The product was collected by centrifugation, washed with chloroform and alcohol several times.

Materials characterizations

The morphology and structure of the samples were characterized by high-resolution transmission electron microscopy (TEM; Tecnai 30, 300 kV). XRD patterns were recorded on the dry membrane of aqueous dispersions of the N-In2O3 nanocrystals on a glass wafer by a Bruker D8 Advanced Diffractometer (Japan) using Cu Kα radiation (λ = 1.5406 Å) at 40 kV. Binding elements were analyzed with X-ray photoelectron spectroscopy (XPS, Kratos Axis Ultra DLD) and CASAXPS software was used to analyze the XPS data. All binding energies were referenced to the C1s peak (284.8 eV) arising from surface hydrocarbons (or possible adventitious hydrocarbon). The photocurrent–voltage performance of the DSCs was measured with a Keithley digital source meter (Keithley 2400, USA) and simulated under AM 1.5 illumination. The power of the simulated light was calibrated to 100 mW·cm−2 using a Newport Oriel PV reference cell system (model 91150 V). All the electrochemical experiments were conducted by using a computer-controlled electrochemical workstation (Parstat 2273, Princeton) in the dark. The measured frequency of EIS experiments ranged from 100 mHz to 1 MHz with an AC modulation signal of 10 mV and bias DC voltage of 0.60 V. The spectra were fitted by the ZSimpWin software. Tafel polarization measurements were carried out in a dummy cell with a scanning rate at 50 mV s−1. Cyclic voltammetry (CV) was conducted in a three-electrode system in an acetonitrile solution of 0.1 M LiClO4, 10 mM LiI and 1 mM I2 at a scanning rate of 20 mV s−1. The working electrodes were N-In2O3 nanocrystals and Pt loaded FTO, exposing an area of about 0.25 cm2. The Ag/Ag+ couple was employed as reference electrode and the CE was a platinum foil.

Theoretical calculation

All the spin-polarized calculations were performed with Perdew-Burke-Ernzerhof (PBE) functional30 within the generalized gradient approximation using the VASP code31,32. The project-augmented wave (PAW) method was used to represent the core-valence electron interaction33,34. To model the In2O3(110) surface, a seven-layer p(1 × 1) slab (14.406 × 10.187 Å2)35,36,37,38,39,40 corresponding to 28 In2O3 units cell (140 atoms) was used, in which a vacuum layer of 15 Å was applied. Because of the large size of the supercell, k-point sampling was restricted to the Γ point only. For total energy calculations, the valence electronic states were expanded in plane wave basis sets with an energy cutoff of 450 eV and the force convergence criterion in structural is set to be 0.05 eV/Å. The transition states were searched using a constrained optimization scheme41 and were verified when (i) all forces on atoms vanish; and (ii) the total energy is a maximum along the reaction coordination but a minimum with respect to the rest of the degrees of freedom. The force threshold for the transition state search was 0.05 eV/Å. To simulate the interface solution environment, several acetonitrile layers were introduced in the surface slab with a density of 0.79 g cm−3. The adsorption energy of I (EadI) is defined as: EadI = E(I/interface) − E(interface) + 1/2E(I2), where E(interface), E(I2) and E(I/interface) are the energies of the liquid/electrode interface, I2 in the gas phase and I adsorbed on the liquid/electrode interface, respectively. In addition, please see details for the relevant free energy calculation of each elementary reaction step.

References

Gong, K., Du, F., Xia, Z., Durstock, M. & Dai, L. Nitrogen-Doped Carbon Nanotube Arrays with High Electrocatalytic Activity for Oxygen Reduction. Science 323, 760–764 (2009).

Debe, M. K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 486, 43–51 (2012).

Kudo, A. & Miseki, Y. Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 38, 253–278 (2009).

Helm, M. L., Stewart, M. P., Bullock, R. M., DuBois, M. R. & DuBois, D. L. A Synthetic Nickel Electrocatalyst with a Turnover Frequency Above 100,000 s−1 for H2 Production. Science 333, 863–866 (2011).

O'Regan, B. & Grätzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991).

Xue, Y. et al. Nitrogen-Doped Graphene Foams as Metal-Free Counter Electrodes in High-Performance Dye-Sensitized Solar Cells. Angew. Chem. Int. Ed. 51, 12124–12127 (2012).

Hou, Y. et al. Rational Screening Low-Cost Counter Electrodes for Dye-Sensitized Solar Cells. Nat. Commun. 4, 1583 (2013).

Yu, D., Nagelli, E., Du, F. & Dai, L. Metal-Free Carbon Nanomaterials Become More Active than Metal Catalysts and Last Longer. J. Phys. Chem. Lett. 1, 2165–2173 (2010).

Kibsgaard, J., Chen, Z., Reinecke, B. N. & Jaramillo, T. F. Engineering the surface structure of MoS2 to preferentially expose active edge sites for electrocatalysis. Nat. Mater. 11, 963–969 (2012).

Wang, S. et al. BCN Graphene as Efficient Metal-Free Electrocatalyst for the Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 51, 4209–4212 (2012).

Yang, L. et al. Boron-Doped Carbon Nanotubes as Metal-Free Electrocatalysts for the Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 50, 7132–7135 (2011).

Roy-Mayhew, J. D., Bozym, D. J., Punckt, C. & Aksay, I. A. Functionalized Graphene as a Catalytic Counter Electrode in Dye-Sensitized Solar Cells. ACS Nano 4, 6203–6211 (2010).

Reyes-Gil, K. R., Reyes-García, E. A. & Raftery, D. Nitrogen-Doped In2O3 Thin Film Electrodes for Photocatalytic Water Splitting. J. Phys. Chem. C 111, 14579–14588 (2007).

Reyes-Gil, K. R., Sun, Y., Reyes-García, E. & Raftery, D. Characterization of Photoactive Centers in N-Doped In2O3 Visible Photocatalysts for Water Oxidation. J. Phys. Chem. C 113, 12558–12570 (2009).

Cheng, J. & Hu, P. Theory of the Kinetics of Chemical Potentials in Heterogeneous Catalysis. Angew. Chem. Int. Ed. 50, 7650–7654 (2011).

Lee, I. J., Kim, J.-Y., Shin, H.-J. & Kim, H.-K. Near-edge x-ray absorption fine structure and x-ray photoemission spectroscopy study of the InN epilayers on sapphire (0001) substrate. J. Appl. Phys. 95, 5540–5544 (2004).

Werner, F. et al. Electrical Conductivity of InN Nanowires and the Influence of the Native Indium Oxide Formed at Their Surface. Nano Lett. 9, 1567–1571 (2009).

Gai, L. et al. Nitrogen-doped In2O3 nanocrystals constituting hierarchical structures with enhanced gas-sensing properties. CrystEngComm 14, 7479–7486 (2012).

Di Valentin, C. et al. N-doped TiO2: Theory and experiment. Chem. Phys. 339, 44–56 (2007).

Ye, E., Zhang, S.-Y., Hon Lim, S., Liu, S. & Han, M.-Y. Morphological tuning, self-assembly and optical properties of indium oxide nanocrystals. PCCP 12, 11923–11929 (2010).

Wang, M. et al. CoS Supersedes Pt as Efficient Electrocatalyst for Triiodide Reduction in Dye-Sensitized Solar Cells. J. Am. Chem. Soc. 131, 15976–15977 (2009).

Wang, Y.-C. et al. FeS2 Nanocrystal Ink as a Catalytic Electrode for Dye-Sensitized Solar Cells. Angew. Chem. Int. Ed. 52, 6694–6698 (2013).

Xin, X., He, M., Han, W., Jung, J. & Lin, Z. Low-Cost Copper Zinc Tin Sulfide Counter Electrodes for High-Efficiency Dye-Sensitized Solar Cells. Angew. Chem. Int. Ed. 50, 11739–11742 (2011).

Wu, M., Lin, X., Wang, T., Qiu, J. & Ma, T. Low-cost dye-sensitized solar cell based on nine kinds of carbon counter electrodes. Energy Environ. Sci. 4, 2308–2315 (2011).

Huang, Z. et al. Application of carbon materials as counter electrodes of dye-sensitized solar cells. Electrochem. Commun. 9, 596–598 (2007).

Kung, C.-W. et al. CoS Acicular Nanorod Arrays for the Counter Electrode of an Efficient Dye-Sensitized Solar Cell. ACS Nano 6, 7016–7025 (2012).

Jiang, Q. W., Li, G. R. & Gao, X. P. Highly ordered TiN nanotube arrays as counter electrodes for dye-sensitized solar cells. Chem. Commun. 6720–6722 (2009).

Wu, M., Lin, X., Hagfeldt, A. & Ma, T. A novel catalyst of WO2 nanorod for the counter electrode of dye-sensitized solar cells. Chem. Commun. 47, 4535–4537 (2011).

Zhang, B. et al. Facet-Dependent Catalytic Activity of Platinum Nanocrystals for Triiodide Reduction in Dye-Sensitized Solar Cells. Sci. Rep. 3, 1836 (2013).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E., Jepsen, O. & Andersen, O. K. Improved tetrahedron method for Brillouin-zone integrations. Phys. Rev. B 49, 16223–16233 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Fuks, D., Shapiro, D., Kiv, A., Golovanov, V. & Liu, C.-C. Ab initio calculations of surface electronic states in indium oxide. Int. J. Quantum Chem. 111, 1902–1906 (2011).

Fuks, D. L. et al. Degradation Processes in Surface Layers of Indium Oxide. Device and Materials Reliability, IEEE Transactions on 12, 133–138 (2012).

Agoston, P. & Albe, K. Thermodynamic stability, stoichiometry and electronic structure of bcc-In2O3 surfaces. Phys. Rev. B 84, 045311 (2011).

Ye, J., Liu, C. & Ge, Q. DFT Study of CO2 Adsorption and Hydrogenation on the In2O3 Surface. J. Phys. Chem. C 116, 7817–7825 (2012).

Ye, J., Liu, C., Mei, D. & Ge, Q. Active Oxygen Vacancy Site for Methanol Synthesis from CO2 Hydrogenation on In2O3(110): A DFT Study. ACS Catalysis 3, 1296–1306 (2013).

Lin, S. & Xie, D. Initial Decomposition of Methanol and Water on In2O3(110): A Periodic DFT Study. Chin. J. Chem. 30, 2036–2040 (2012).

Alavi, A., Hu, P., Deutsch, T., Silvestrelli, P. L. & Hutter, J. CO Oxidation on Pt(111): An Ab Initio Density Functional Theory Study. Phys. Rev. Lett. 80, 3650–3653 (1998).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (91022023, 21076076, 21203061), SRF for ROCS, SEM, Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning, Major Basic Research Programme of Science and Technology Commission of Shanghai Municipality (10JC1403200), Australian Research Council's Future Fellowships (FT120100913), Fundamental Research Funds for the Central Universities (WM1314018) and Commission of Science and Technology of Shanghai Municipality (12ZR1442600). P. Hu thanks the Chinese Government for the “Thousands Talents” program.

Author information

Authors and Affiliations

Contributions

B.Z., N.N.Z., J.F.C., H.F.W. and H.G.Y. wrote the main manuscript. J.F.C., H.F.W. prepared Figure 1 and Figure 4. B.Z. and N.N.Z. prepared other Figures and Table 1. Y.H., S.Y., J.W.G., X.H.Y., J.H.Z. and H.J.Z. discussed the electrochemical section and P.H. provided several advices for theoretical calculation. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Revised Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Zhang, B., Zhang, N., Chen, J. et al. Turning Indium Oxide into a Superior Electrocatalyst: Deterministic Heteroatoms. Sci Rep 3, 3109 (2013). https://doi.org/10.1038/srep03109

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep03109

This article is cited by

-

TiO2 blocking layer incorporated TiO2/In2O3-based photoanode for DSSC application

Journal of Materials Science: Materials in Electronics (2023)

-

High-Efficiency (Over 10%) Parallel Tandem Dye-Sensitized Solar Cells Based on Tri-Carbon Electrodes

Transactions of Tianjin University (2022)

-

Carbon nanotubes influenced indium oxide as photoanode for dye-sensitized solar cell

Journal of Mechanical Science and Technology (2020)

-

Incident photon-to-current efficiency of thermally treated SWCNTs-based nanocomposite for dye-sensitized solar cell

Ionics (2019)

-

Theoretical study of triiodide reduction reaction on nitrogen-doped graphene for dye-sensitized solar cells

Theoretical Chemistry Accounts (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.